Pushing-sliding installation device and method for sail type box steel beam

A technology of installation device and installation method, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of poor positioning accuracy at high altitudes, poor economic benefits, and many welding nodes, so as to save welding and bearing capacity Large, metal-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

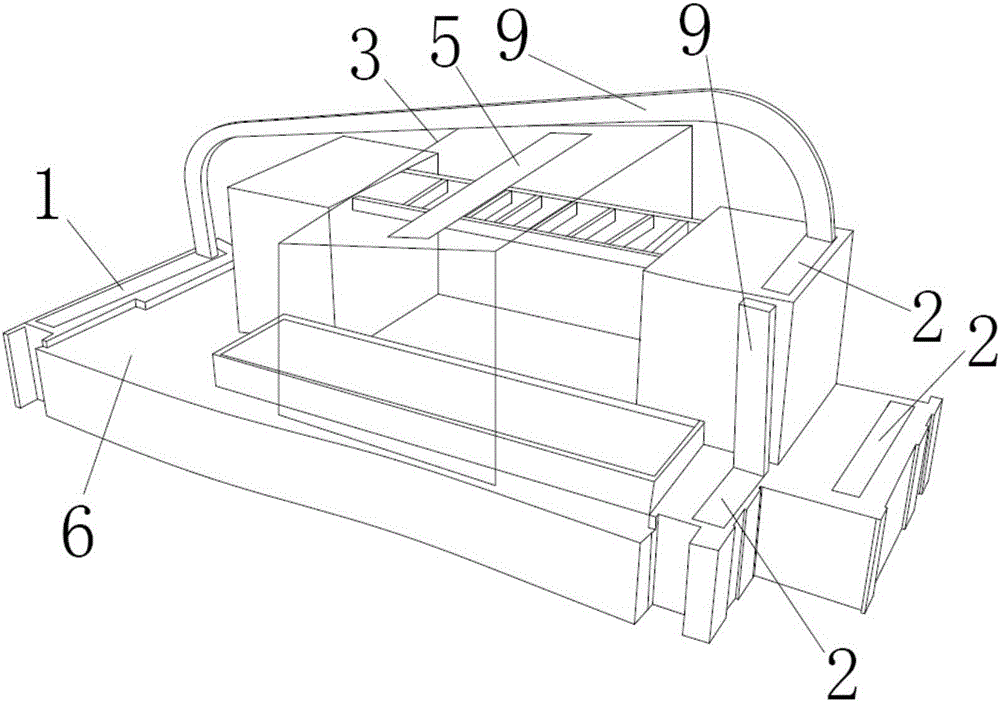

[0049] 1. The first steel girder 9 of the tower crane is erected on the first slideway 1, the second slideway 2 and the third slideway 5, using the first slideway 1, the second slideway 2 and the third slideway respectively A plurality of pushers 4 on the road 5 simultaneously pushes and slides the first steel girder 9, and fixes the first steel beam 9 to a set position.

[0050] 2. The second steel girder 9 of the tower crane is erected on the first slideway 1, the second slideway 2 and the third slideway 5, using the first slideway 1, the second slideway 2 and the third slideway respectively A plurality of pushers 4 on the road 5 simultaneously pushes and slides the second steel beam 9, and fixes the second steel beam 9 to a set position parallel to the first steel beam 9.

[0051] 3. Install the connecting beam 8 and the truss between the first steel beam 9 and the second steel beam 9, and fix it by welding.

[0052] 4. All the other steel beams 9 are welded and fixed in t...

Embodiment 2

[0055] 1. Decompose the first steel beam 9 into the upper half and the lower half, and decompose the second slideway 2 into the first section and the second section. Among them, it is erected on the first slideway 1, the second slideway 2 and the third slideway 5, wherein the second slideway 2 is divided into two sections, one section is used to support the upper half section of the first steel beam 9, and the other section Used to support the lower half of the first steel girder 9. A plurality of pushers 4 pushes and slides the upper half of the first steel beam 9 at the same time, and pushes the upper half of the first steel beam 9 to the bottom half connected with the first steel beam 9. position, and welded securely.

[0056] 2. The remaining second steel girders 9 are welded and fixed in the same manner as above.

[0057] 3. Install the connecting beam 8 and the truss between the first steel beam 9 and the second steel beam 9, and fix it by welding.

[0058] 4. All the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com