Processing technique of liquid crystal television metal frame

A technology of LCD TV and processing technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of lower product quality, large impact of aluminum plate 2, easy breakage of rounded corners, etc., to prevent breakage and small rounded corner radius , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

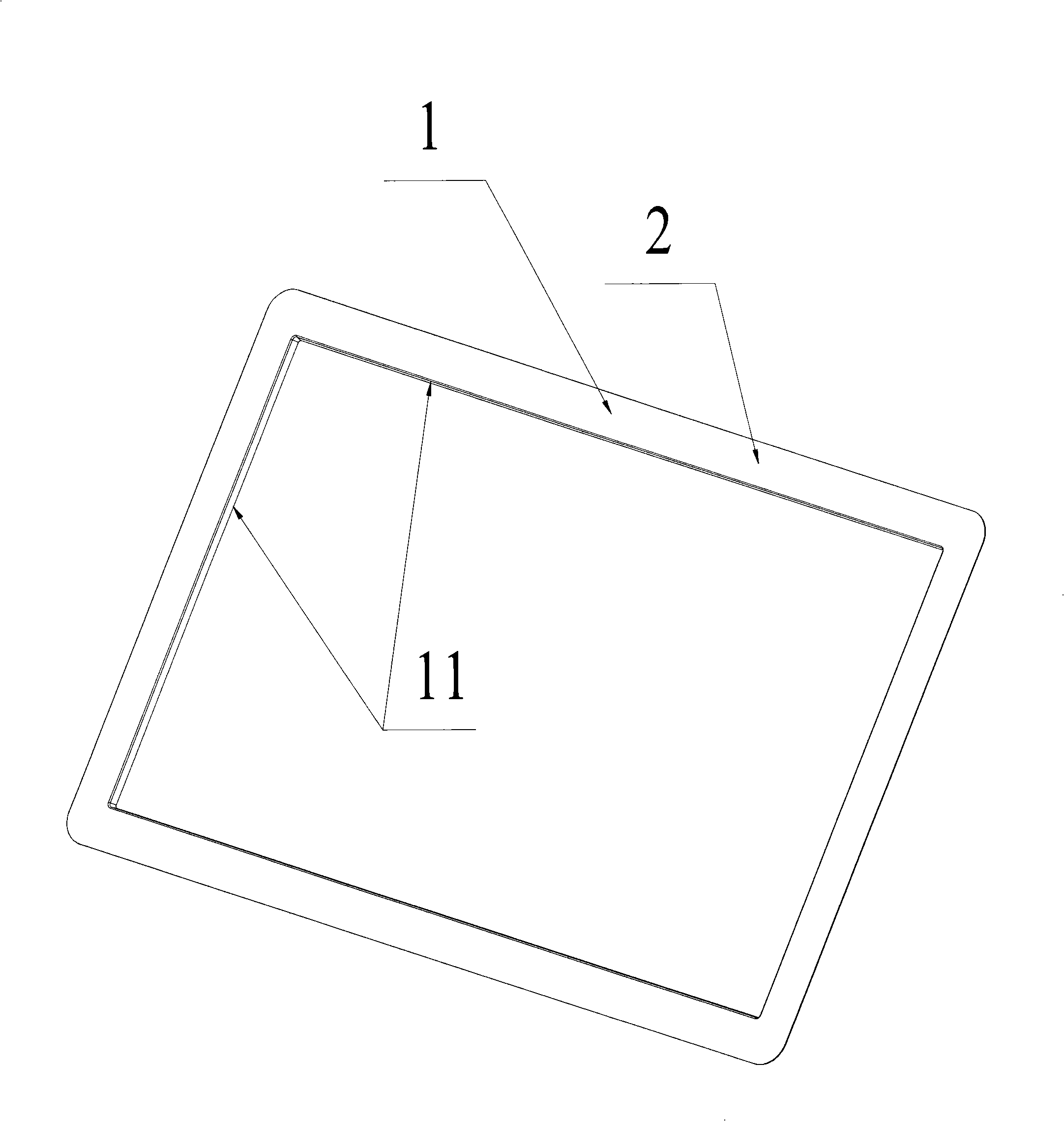

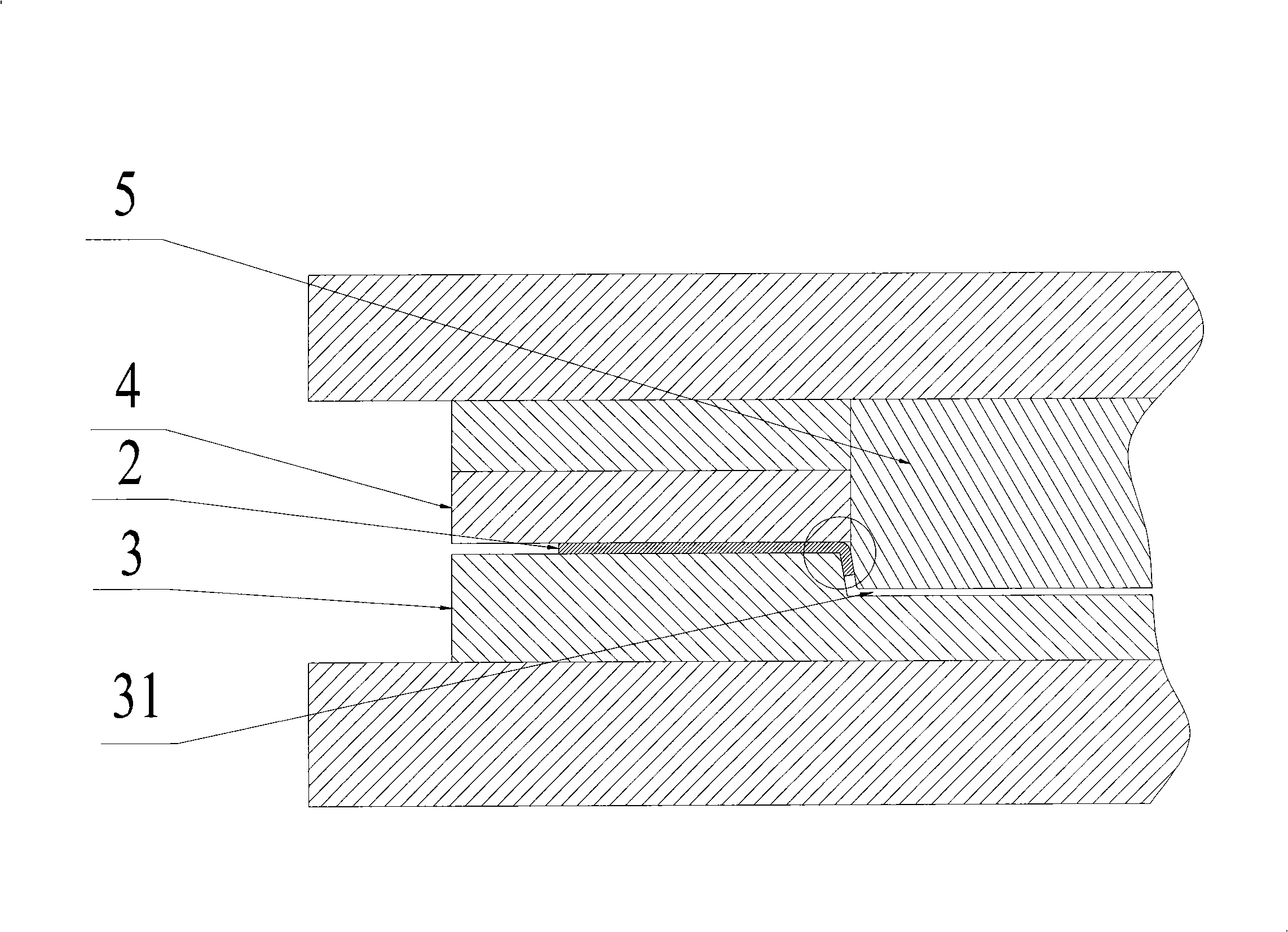

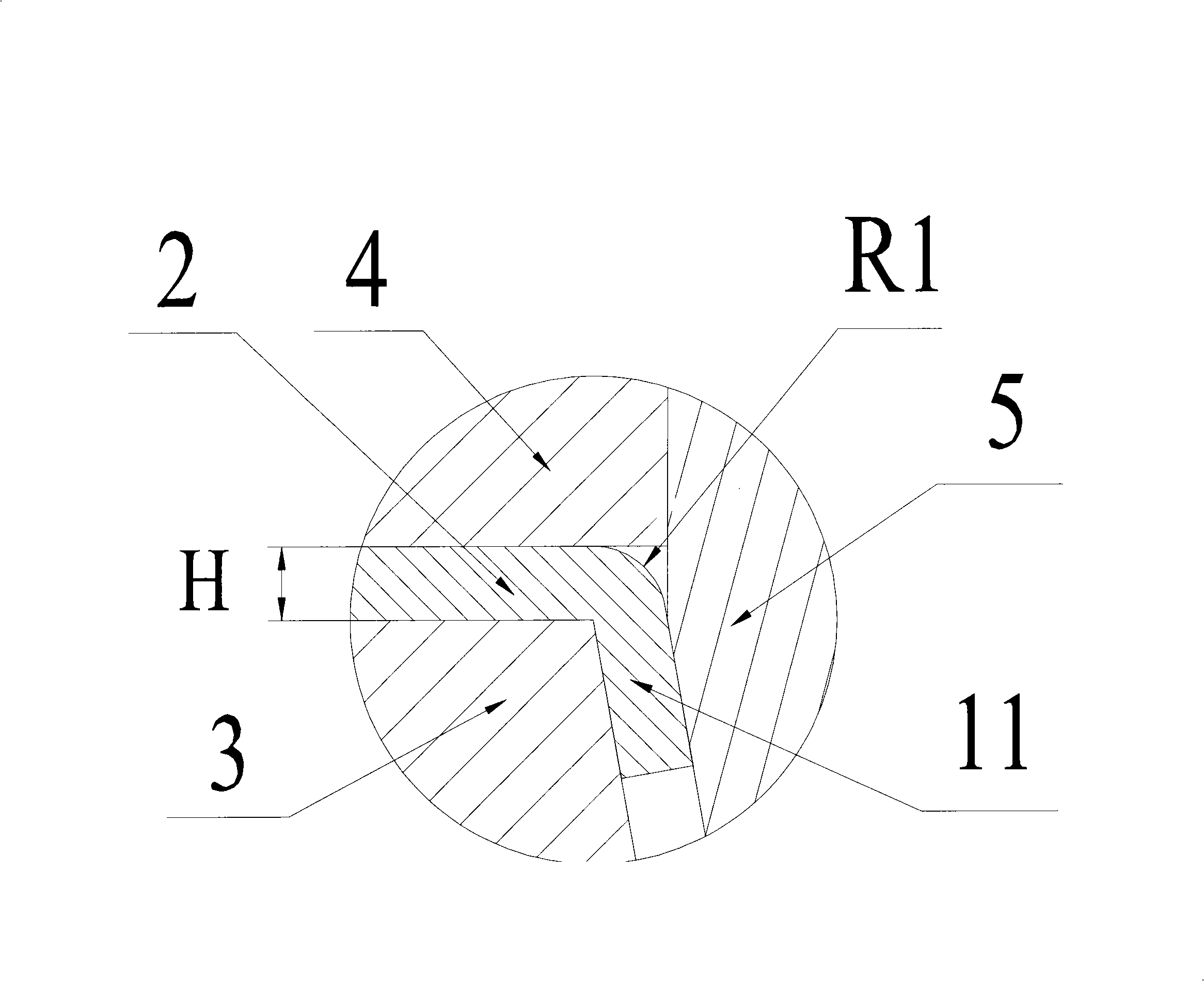

[0021] Example: Combine Figure 4 , Figure 5 , Image 6 and Figure 7 The specific embodiment of the processing technology of the liquid crystal TV metal frame of the present invention will be further described. In this embodiment, the thickness H of the processed aluminum plate 2 is 3 mm.

[0022] The processing technology of the metal surface frame of the liquid crystal television in this embodiment includes the bending edge processing process and the rounded corner processing process carried out in sequence:

[0023] like Figure 5 , Image 6 As shown, in the bending edge processing process, the aluminum plate 2 with the middle opening is fixed between the concave template 3 and the fixed plate 4, wherein the edge of the concave mold cavity 31 of the concave template 3 is added with a circle of ribs extruded into the aluminum plate 2 32, and then press the inner edge of the aluminum plate 2 through the convex plate 5 to form the bent edge 11. In this embodiment, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com