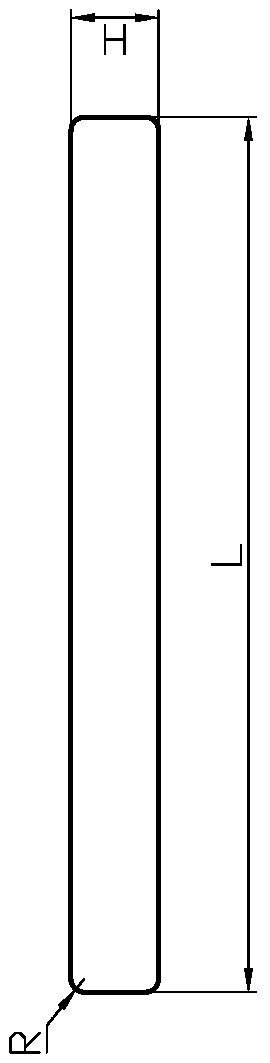

Production and processing technology of super wide-thickness ratio rectangular wire for automobile spring

A technology of automotive springs and processing technology, which is applied in the directions of vehicle parts, metal rolling, transportation and packaging, etc. It can solve the problems of uneven wear around the mold, insufficient filling of rounded corners around the mold, and low life of the mold, achieving good market prospects, Good flatness and excellent shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

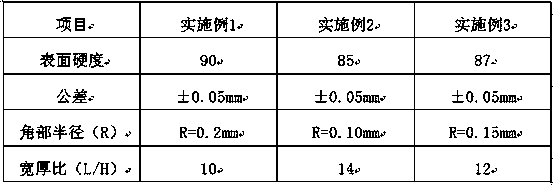

Embodiment 1

[0028] (1) Drawing: drawing the round wire into a square wire.

[0029] (2) Annealing: Using the isothermal recrystallization annealing process, place the square wire rod in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 690 ° C, and keep it for 3 hours; then, at 13 ° C / Cool down to 620°C at a cooling rate of h, and keep it warm for 1.6h, and then return to normal temperature at a cooling rate of 19°C / h; the inert gas is methanol, and the flow rate of methanol gas is 2L / min.

[0030] (3) Cold rolling: use a cold rolling mill to cold-roll square wires to form rectangular wires. Tension rolling is used in cold rolling. The cold rolling mill frame is a closed frame. The upper part of the frame is connected by an upper beam, and the lower part is The roll changing track is connected, the work roll and the back-up roll are in the frame window, the push-up cylinder is installed at the lower part of the frame w...

Embodiment 2

[0032] (1) Drawing: drawing the round wire into a square wire.

[0033] (2) Annealing: Using the isothermal recrystallization annealing process, place the square wire rod in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 700 ° C, and keep it for 2.5 hours; then, at 10 ° C Cool to 610°C at a cooling rate of 18°C / h and keep warm for 1.5h, then return to normal temperature at a cooling rate of 18°C / h; the inert gas is methanol, and the flow rate of methanol gas is 2L / min.

[0034] (3) Cold rolling: use a cold rolling mill to cold-roll square wires to form rectangular wires. Tension rolling is used in cold rolling. The cold rolling mill frame is a closed frame. The upper part of the frame is connected by an upper beam, and the lower part is The roll changing track is connected, the work roll and the back-up roll are in the frame window, the push-up cylinder is installed at the lower part of the frame window, t...

Embodiment 3

[0036] (1) Drawing: drawing the round wire into a square wire.

[0037] (2) Annealing: Using the isothermal recrystallization annealing process, place the square wire rod in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 710°C and keep it for 2.8h; then, heat it at 14°C Cool to 630°C at a cooling rate of 22°C / h and keep warm for 1.8h, then return to room temperature at a cooling rate of 22°C / h; the inert gas is methanol, and the flow rate of methanol gas is 2L / min.

[0038] (3) Cold rolling: use a cold rolling mill to cold-roll square wires to form rectangular wires. Tension rolling is used in cold rolling. The cold rolling mill frame is a closed frame. The upper part of the frame is connected by an upper beam, and the lower part is The roll changing track is connected, the work roll and the back-up roll are in the frame window, the push-up cylinder is installed at the lower part of the frame window, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com