Drilling tool capable of replacing drill bit without lifting drill and with high expanding and converging success rate

A technology of success rate and drill bit replacement, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., to achieve the effect of flexible aiming and small fillet radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

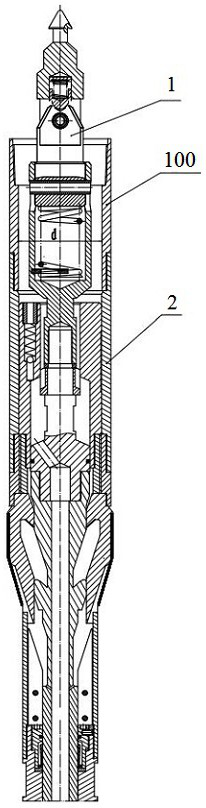

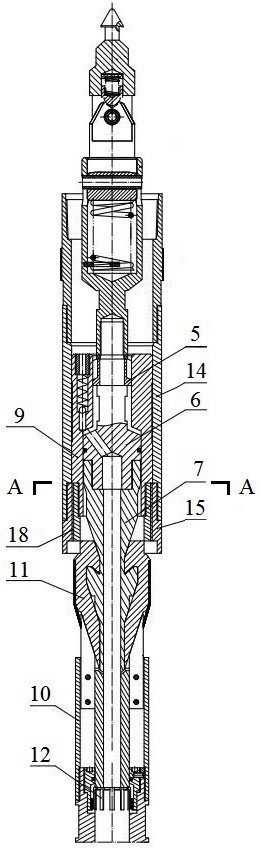

[0049] Prior art 1: The Chinese utility model of CN85200563U discloses the position tension type without lifting the drill to replace the drill bit. Both the aiming mechanism and the suspension mechanism of the tool are based on the arrow-shaped spline pair 18. On the one hand, when the main drilling tool 1 enters the auxiliary drilling tool 2, the outer arrow-shaped splines of the drill bit holder 10 and the inner arrow-shaped splines of the positioning end pipe 15 are automatically aligned so that the auxiliary drill bit 11 is aligned with the drill bit holder 10; on the other hand, during suspension, the suspension joint 9 is suspended on the arrow portion of the arrow-shaped spline in the positioning end pipe 15, which is a point suspension structure.

[0050] The drilling tool without changing the drill bit provided in this embodiment and the drilling tool without changing the drill bit in the prior art both include a main drilling tool 1 and an auxiliary drilling tool 2 ...

Embodiment 2

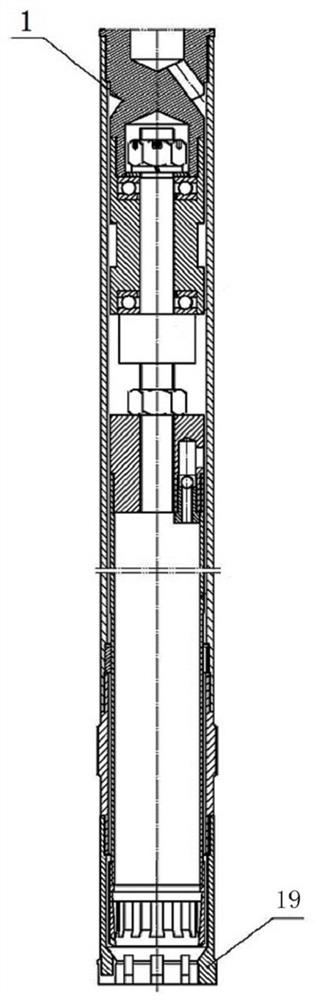

[0064] This embodiment is further optimized on the basis of the above embodiments, such as image 3 , Figure 12 As shown, a drain eye 8 is also arranged on the suspension joint 9 .

[0065] Generally, there is water in the drill pipe in the hole. When the main drilling tool 1 is put into operation, the gap between the outer diameter of the main drilling tool 1 and the inner diameter of the drill pipe is very small, usually 1mm~2mm. Down, similar to a piston movement. Therefore, in prior art 1 and prior art 2, the descending speed of the main drilling tool 1 is relatively slow, generally about 15 minutes is required for a hole depth of 800 m. If the water discharge eye is added on the suspension joint 9 of the main drilling tool 1, the water passing area will be increased by 47%, and the main drilling tool 1 of the depth of the hole of 800m only needs about 10 minutes to descend.

[0066] Therefore, adding the drain hole 8 on the suspension joint 9 can increase the deliver...

Embodiment 3

[0069] This embodiment is further optimized on the basis of the above embodiments, and a strip-shaped powder discharge channel 4 is added to the outer cylindrical surface of the positioning end pipe 15 .

[0070] In this embodiment, the drilling tool does not mention drilling and changing the drill bit. The same as the prior art 1 and the prior art 2, the main drill bit 19 and the secondary drill bit 11 are used to crush the rock. The sudden change in the cross section of the pipe 15 is likely to cause accumulation of rock powder, resulting in repeated crushing, which seriously affects the drilling efficiency and greatly reduces the life of the auxiliary drill bit 11. Therefore, in this embodiment, by adding a strip-shaped powder discharge channel 4 on the outer cylinder of the auxiliary drill bit 11, the powder discharge channel of the auxiliary drill bit 11 is increased to reduce repeated crushing, which can increase the life of the auxiliary drill bit 11 and improve the ROP....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com