Zinc liquid storage tank for hot galvanizing production line and method for storing zinc liquid by using same

A hot-dip galvanizing and storage tank technology, applied in hot-dip galvanizing process, coating, instruments, etc., can solve the problems of enterprise customer loss, enterprise loss, multi-energy and other problems, achieve energy saving, small footprint, reduce zinc the effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the protection scope of the present invention is not limited to the scope expressed in the embodiments.

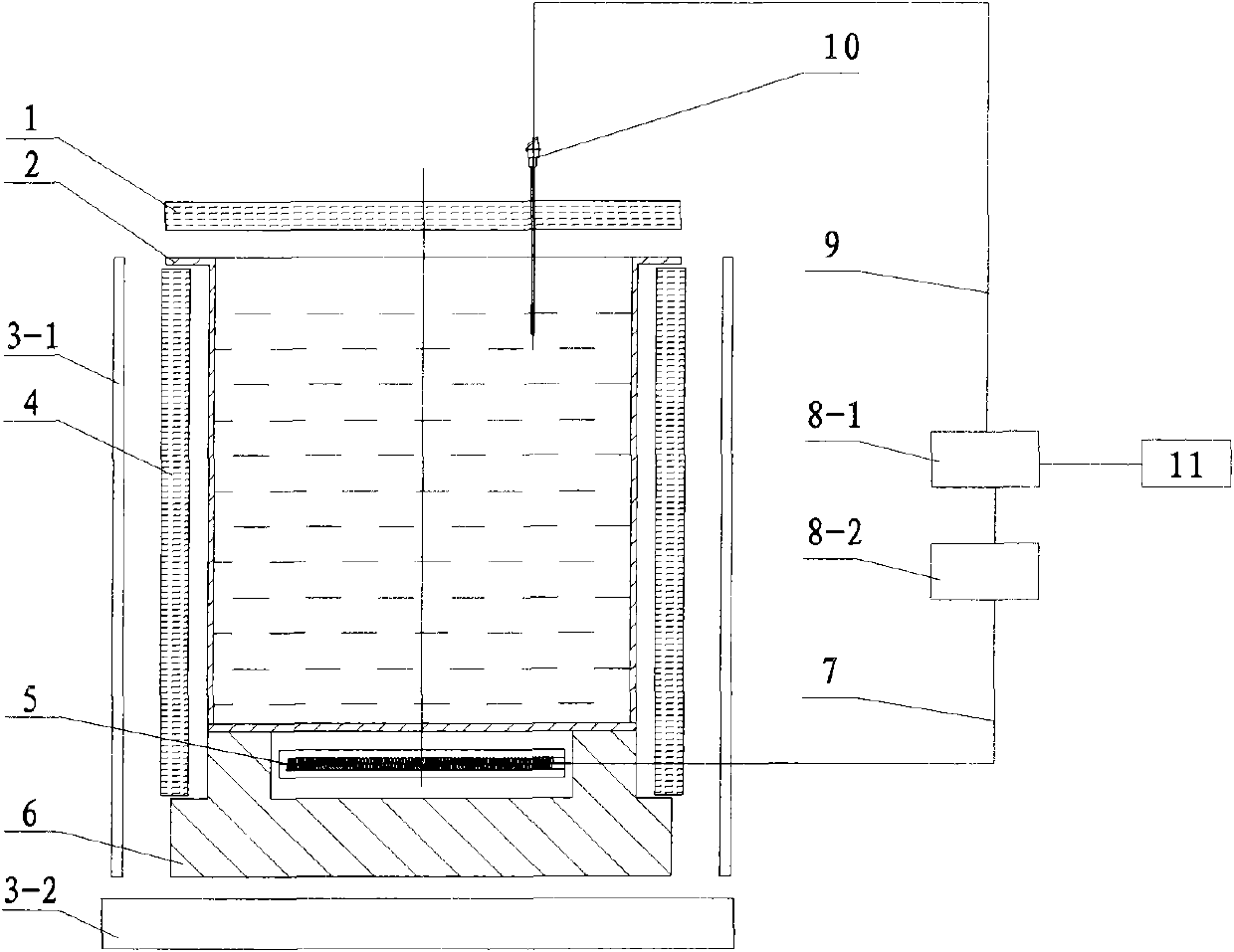

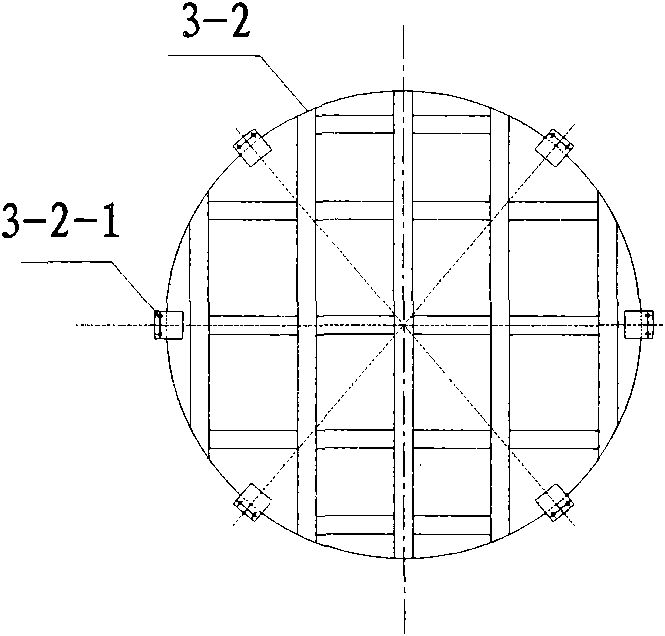

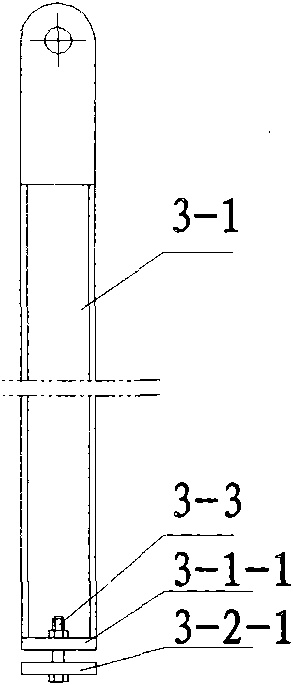

[0036] like figure 1As shown, a liquid zinc storage tank for a hot-dip galvanizing production line includes a zinc storage tank and a PLC temperature acquisition and control system; the zinc storage tank includes a zinc storage tank liner 2, a tank wall insulation lining 4, and a tank bottom Brickwork 6, tank body insulation cover 1, steel structure column 3-1 and chassis 3-2; the lower part of the tank inner liner 2 is provided with brickwork 6, the sides are provided with tank wall insulation lining 4, and the upper part is provided with tank The body insulation cover 1; the inner liner 2 of the tank is a special steel plate material for hot-dip galvanized zinc pots with a thickness of 20-50mm. The special steel plate material for hot-dip ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com