Microwave combined heating method for improving surimi product gel strength

A technology for surimi products and gel strength, which is applied in food heat treatment, food ingredients as gelling agents, food preservation, etc. It can solve the problems of surimi products being hard and surimi structure damage, saving time and improving gel strength , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

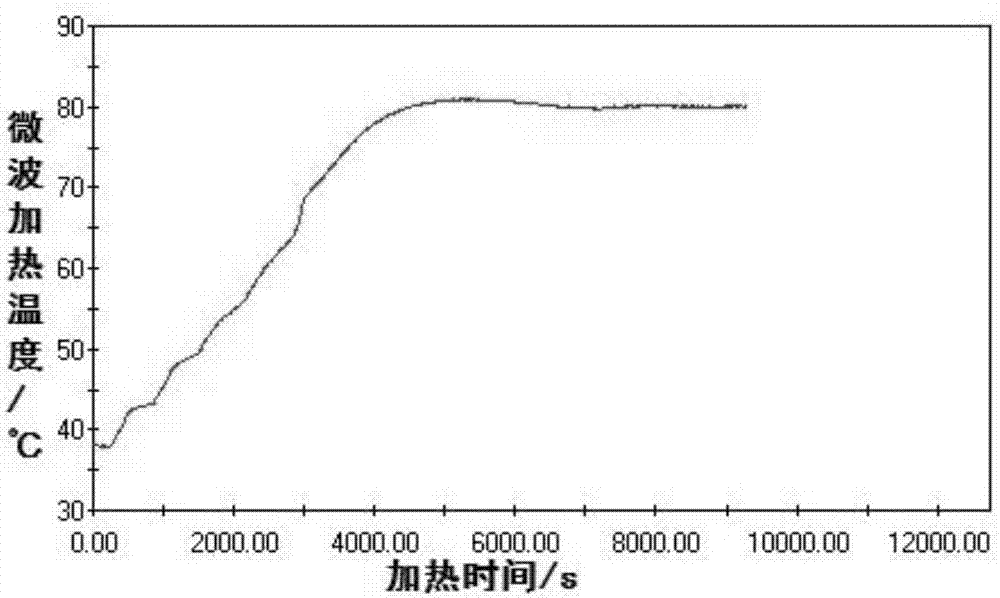

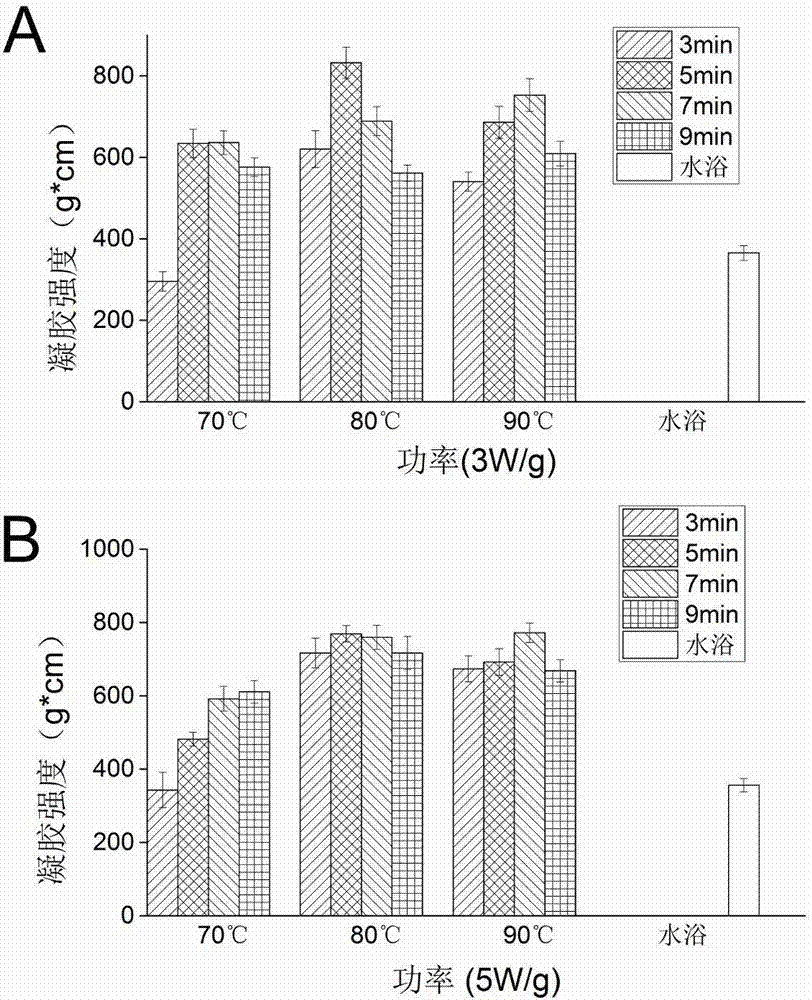

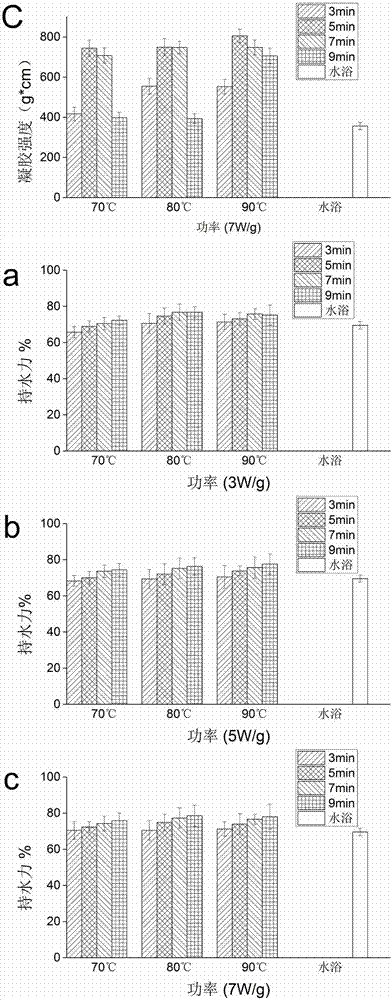

[0036] The present embodiment is the optimization of microwave combined heating method conditions, specific examples are as follows:

[0037] A. Thaw

[0038] Thaw surimi frozen in a copper pot under the trade name of Ningbo Jinhai Seawater Products stored at -20°C at a temperature of 4°C for 10-14 hours. Below -3°C.

[0039] B. Soybean emulsified pulp

[0040] Add soybean protein: chicken skin: ice water into the chopping pot according to the ratio of 1:1:5, and emulsify for 5-6 minutes until the material becomes a fine emulsified slurry.

[0041] C. Empty cut

[0042] Put the thawed minced surimi at a temperature ≤ 5°C into the chopping machine, and cut it for 2-3 minutes under the condition that the rotation speed of the knife shaft of the chopping machine is 2000-3000r / min, until the minced surimi appears "grouped". Adding 1±0.1% phosphate to the surimi finally reaches the state of the surimi without hard particles, and obtains the empty-cut surimi.

[0043] D. Salt c...

Embodiment 2

[0054] The difference between embodiment 2 and embodiment 1 is that in the microwave combined heating method, when the microwave heating reaches the set temperature, reduce the microwave power and continue heating with 1 / 8-1 / 4 of the original power to maintain The temperature at the center of the surimi fluctuates within 2°C above and below the set temperature. If the temperature of the surimi is higher than the set temperature, reduce the power at this time until the temperature returns to the set temperature and maintain it for a period of time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com