Fracturing method for staged supporting of proppants with different particle sizes in multi-scale cracks

A proppant and multi-scale technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of uneven laying of proppant with different particle sizes, increase the effective volume of reconstruction, etc., and achieve expansion pressure The effect of cracking the spread, increasing the volume of transformation, and avoiding doping and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

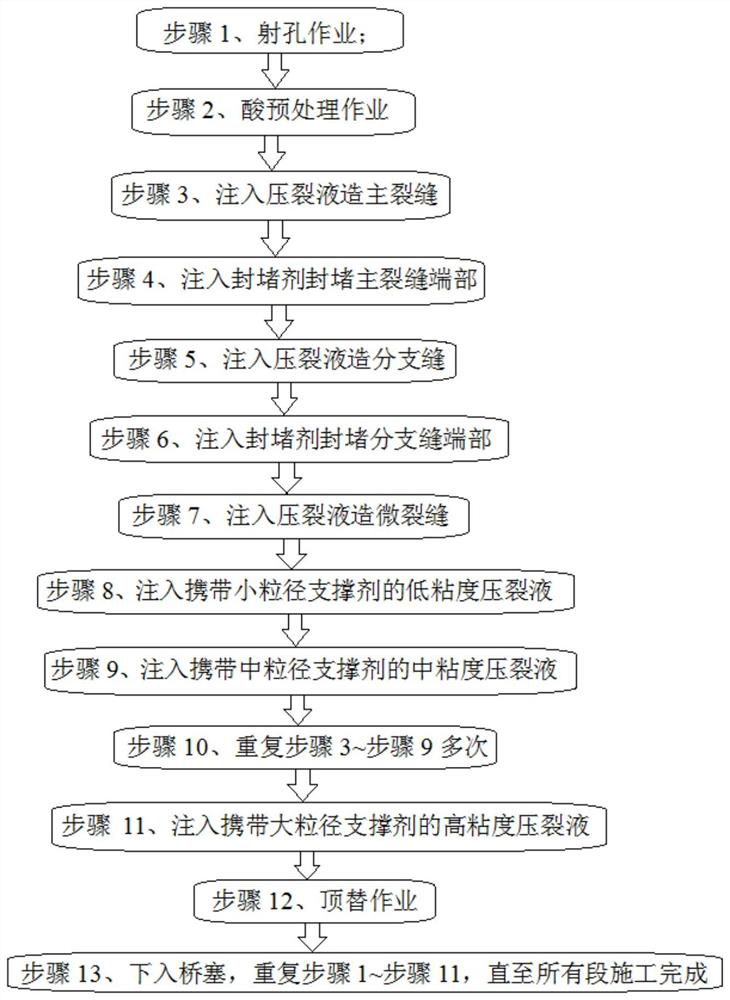

Method used

Image

Examples

Embodiment 1

[0093] A shale gas well in southwestern Sichuan has a vertical depth of 2180m, a sounding depth of 3970m, and a horizontal section length of 1200m. Follow the steps below to retrofit:

[0094] (1) Analyze the fracturability, mechanical properties and fracturing quality of shale, optimize the location of engineering sweet spots and segment clusters, based on the commonly used commercial simulation software ECLIPSE for fracturing production prediction and the commonly used commercial simulation software MEYEY for fracture propagation simulation, based on The simulation optimization of the conventional process determines that the optimal fracturing stage is 19 stages, the optimal fracture half-length is 300m, and the sand volume scale of a single stage is 100m 3 , a total of 2 clusters in a single section, the perforation length of each cluster is 1.5m, the perforation density is 16 holes / m, and the fracturing construction parameters are optimized.

[0095] (2) After the first s...

Embodiment 2

[0110] A shale gas well in southwestern Sichuan has a vertical depth of 2068m, a sounding depth of 4100m, and a horizontal section length of 1360m. Follow the steps below to retrofit:

[0111] (1) Analyze the fracturability, mechanical properties and fracturing quality of shale, optimize the location of engineering sweet spots and segment clusters, based on the commonly used commercial simulation software ECLIPSE for fracturing production prediction and the commonly used commercial simulation software MEYEY for fracture propagation simulation, based on The simulation optimization of the conventional process determines that the optimal fracturing stage is 19 stages, the optimal fracture half-length is 300m, and the sand volume scale of a single stage is 100m 3 , a total of 2 clusters in a single section, the perforation length of each cluster is 1.5m, the perforation density is 16 holes / m, and the fracturing construction parameters are optimized.

[0112] (2) After the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com