Light guide lens and vehicle head lamp

A vehicle and lens technology, applied in the field of light guide elements, can solve the problems of unreduced manufacturing cost, light loss, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

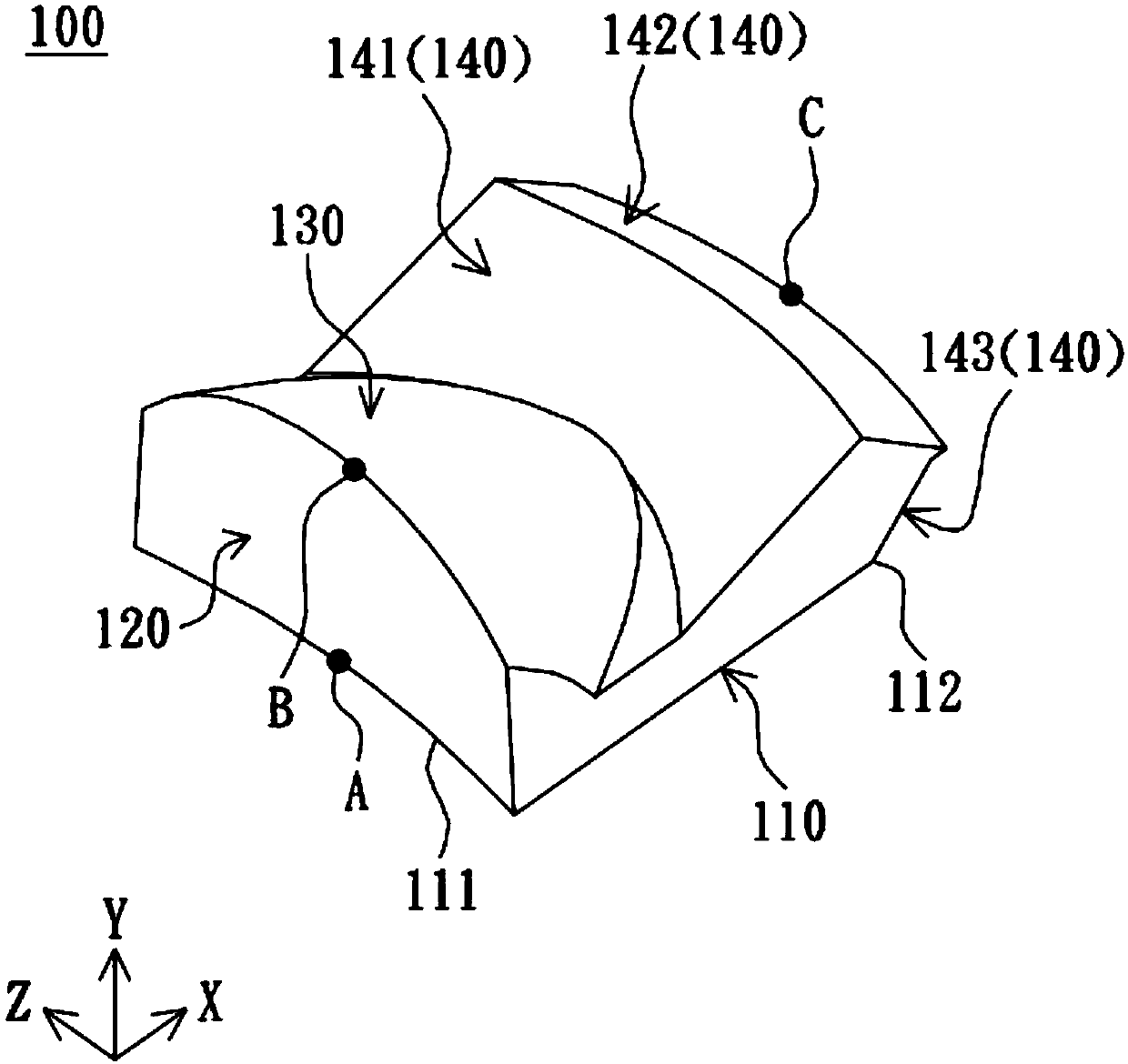

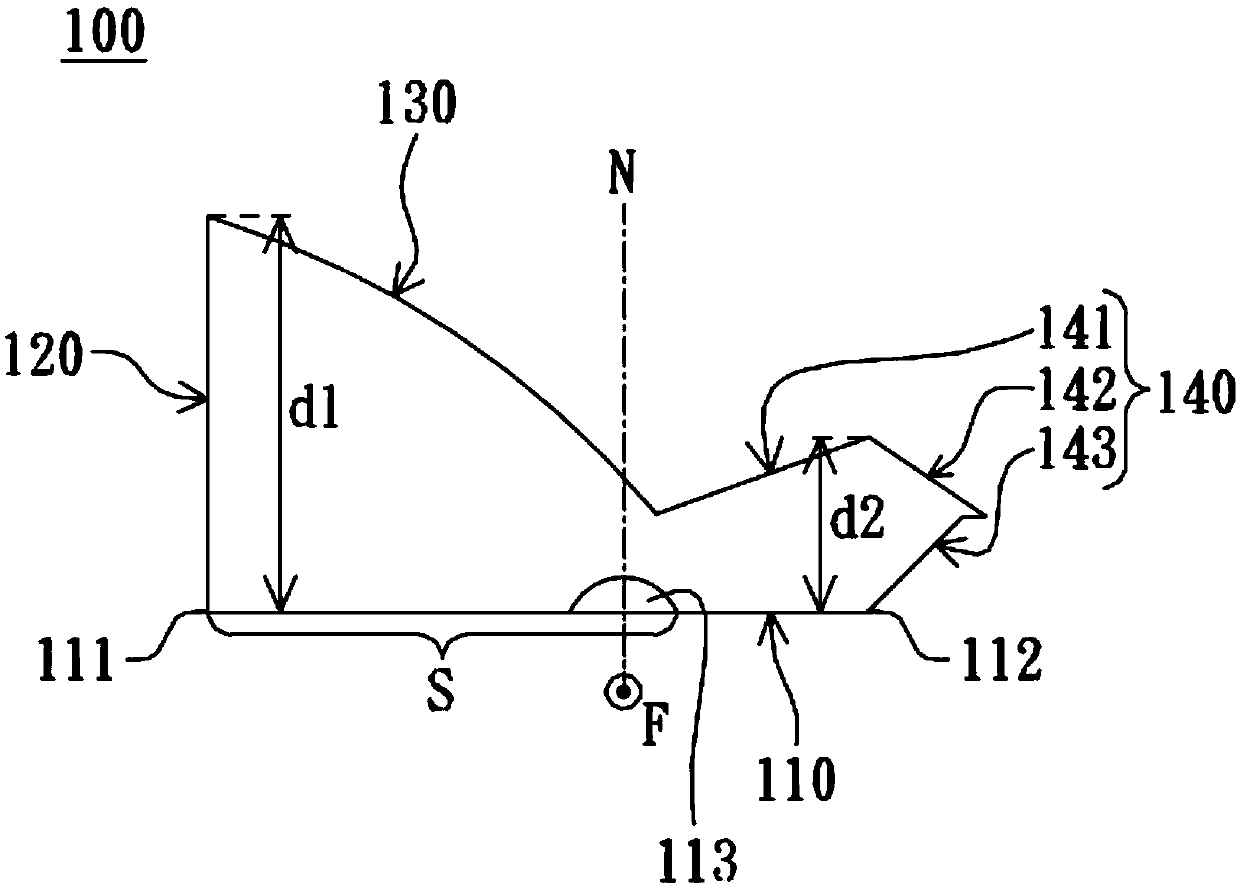

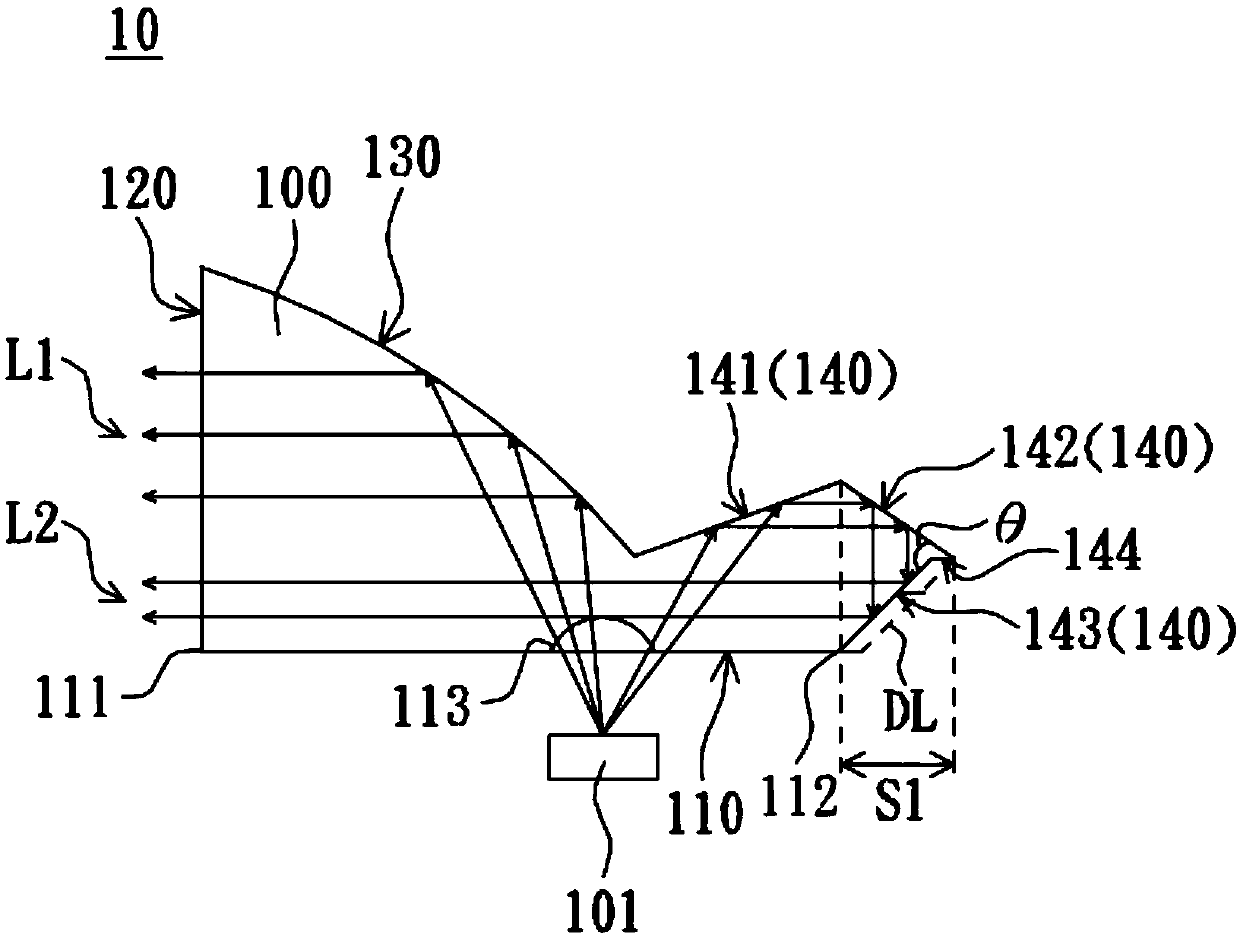

[0035] Figure 1A It is a schematic diagram of a light guide lens according to an embodiment of the present invention, Figure 1B for Figure 1A A schematic cross-sectional view through the first side and the second side parallel to the XY plane, for example through Figure 1A A schematic cross-sectional view of points A, B, and C in . Please refer to Figure 1A and Figure 1B , the light guide lens 100 of this embodiment is suitable for vehicle headlights (not shown) to guide the light provided by the light emitting element (not shown), the light guide lens 100 has a bottom surface 110, a light exit surface 120, a first reflective surface 130 and reflective structure 140. The bottom surface 110 has a first side 111 and a second side 112 opposite to each other, and a light incident portion 113 located between the first side 111 and the second side 112. The light emitting surface 120 is connected to the first side 111 . The first reflective surface 130 is part of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com