Pressure-control fracturing method for improving fracture complexity of deep shale gas well

A shale gas well, complex technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of difficult to increase the complexity of fractures, narrow construction pressure window, etc., to achieve enhanced long-term flow conductivity, Improve the complexity of cracks and the effect of efficient reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

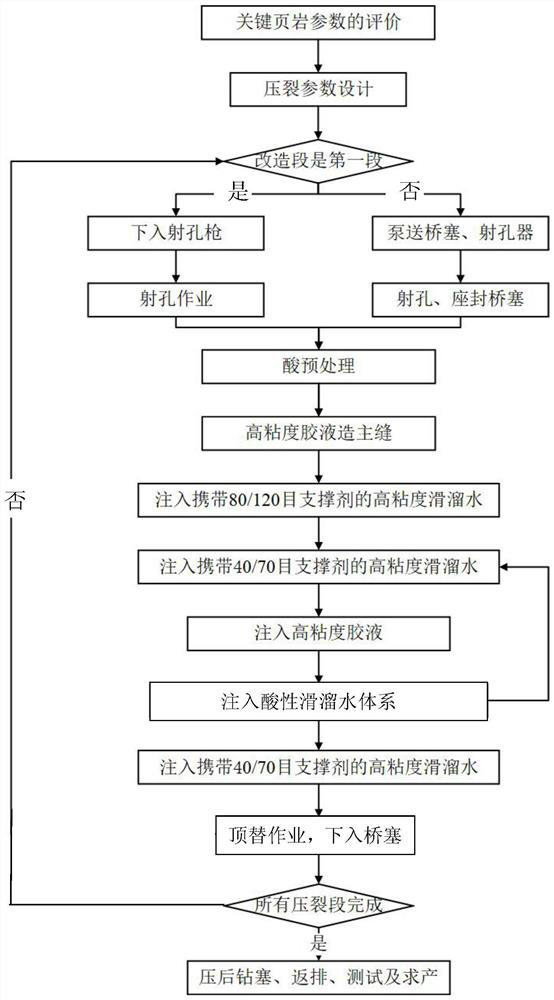

Method used

Image

Examples

Embodiment 1

[0078] The D1 shale gas well is located in the southwest of Sichuan, with a vertical depth of 4231m, a sounding depth of 6062m, and a horizontal section length of 1504m. The buried depth of this well is relatively large, and the construction pressure is high. The pressure-controlled fracturing method that increases the complexity of fracturing proposed by the present invention is used to carry out reservoir reconstruction, specifically:

[0079] (1) Evaluation of key shale parameters and optimization of fracturing parameters;

[0080] (2) The perforating operation is carried out by using the coiled tubing to enter the perforating gun;

[0081] (3) at 1.5m 3 A total of 20m of pretreatment acid (15% HCl + 2.0% corrosion inhibitor + 1.5% drainage aid + 2.0% clay stabilizer + 1.5% iron ion stabilizer) was injected per min 3 . then at 5m 3 / min displacement into high-viscosity glue 60m 3 For acid. Displacement down to 1m 3 / min, then continue to inject high-viscosity slipper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com