Shale gas well CO2 and slickwater mixing fracturing technology

A shale gas well, CO2 technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of low flowback speed and flowback efficiency, increased cost, and high difficulty, so as to reduce the reservoir Damage, increase flowback speed and flowback rate, and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

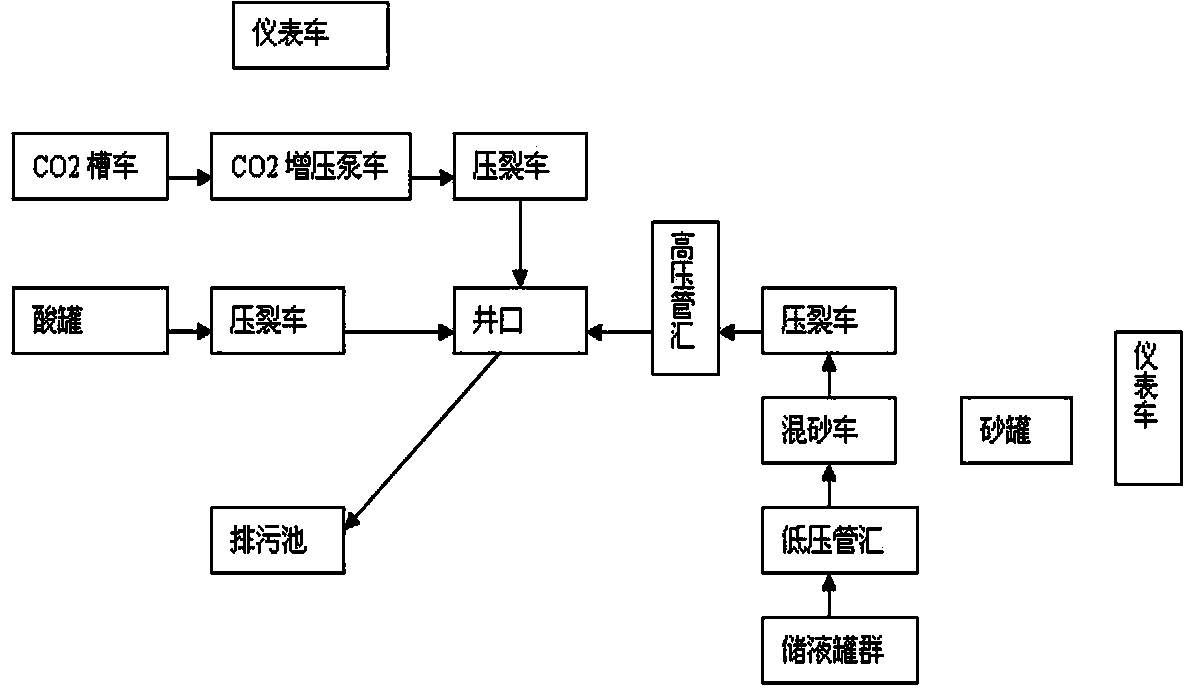

[0043] Shale gas well CO 2 and slick water mixed fracturing technology, the construction needs to be equipped with fracturing trucks, sand mixing trucks, CO 2 Tanker and CO 2 Pump trucks, instrument trucks, fracturing manifold trucks, acid tanks and liquid storage tank groups, the fracturing manifold trucks are equipped with low-pressure manifolds and high-pressure manifolds, and the instrument trucks are equipped with monitoring instruments, which are characterized in that: Follow the steps below:

[0044] Step 1: Prepare well site planning; place CO 2 Tank car and CO 2 The booster pump truck and the fracturing truck are connected in series to the wellhead, and the liquid storage tanks, low-pressure pipes, sand mixing truck, fracturing truck, and high-pressure manifold are connected in series to the wellhead; the acid tank and the fracturing truck are connected to the wellhead ;The wellhead is equipped with a blowout pipeline; the instrument vehicle is connected to the ab...

Embodiment 2

[0071] XX shale gas well, with a target interval of 2440.00-2490.00m, is black shale in the Shan 1 member of the Shanxi Formation. The logging gas log shows obvious results, which is comprehensively interpreted as a shale gas layer, and there is no productivity after perforation. The well uses CO 2 And slick water mixed fracturing process fracturing.

[0072] Step 1: If figure 1 Connect fracturing equipment and pipelines and prepare acid and fracturing fluid.

[0073] The fracturing method using bare casing injection, using P110 steel grade casing, the outer diameter of the casing is 51 / 2"; 10.0 m of acid liquid is prepared before fracturing 3 , the formula is 5.0% HCl + 8% high-efficiency pressure-reducing agent + 0.3% corrosion inhibitor + 0.2% iron ion stabilizer, equipped with slippery water fracturing fluid 2000 m 3 , the formula is clear water + 0.05% drag reducing agent + 1.5% clay stabilizer + 0.4% drainage aid + 0.3% gas well foaming agent + 0.05% fungicide. Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com