Rock drilling and explosion method for mining

An empty hole and charging technology, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of large charging volume, low efficiency and difficulty in blasting holes, and achieve the effect of high safety factor and low dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

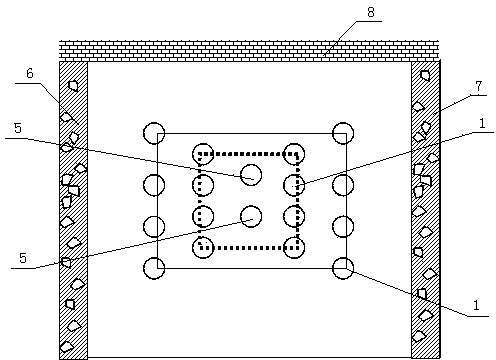

[0020] 1. Double cut hole ( image 3 )

[0021] For cutting holes in harder rock. The auxiliary density is increased, and the amount of charge is increased. The footage can be between 2.0 and 2.5 meters with this method of cutting. Requirements for internal cut holes: hole depth 1.2-1.5 meters, hole distance 1.2 meters; external cut hole requirements: hole depth 2.5-2.8 meters, hole distance 1.6 meters.

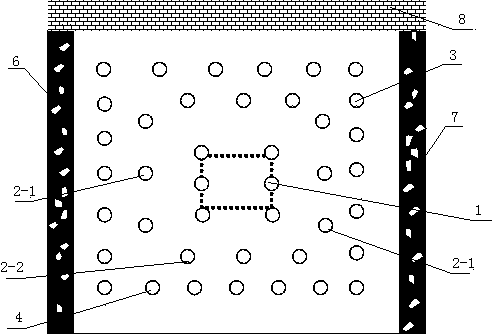

[0022] 2. Right cut ( Figure 4 )

[0023] For working surfaces. The rocks on the left are shallow, the right is deep, and the rocks on the left are hard, while the rocks on the right are soft and have broken zones and slippery rocks, which help to increase the footage of a single shot.

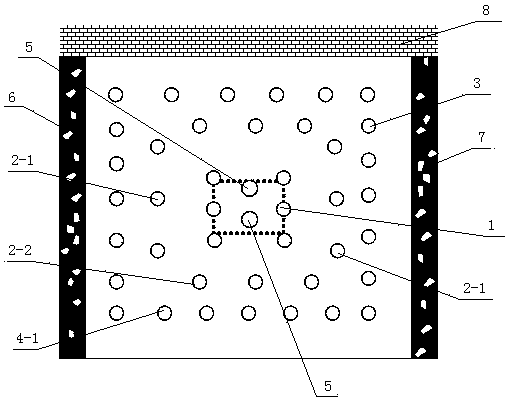

[0024] 3. Left cut ( Figure 5 )

[0025] For working surfaces. The rocks on the left are deep, the right is shallow, and the rocks on the left are soft, while the rocks on the right are hard and the rocks on the left have broken zones and rocks with free sliding surfaces, which hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com