Gob-side entry driving surrounding rock control method using remaining small pillars

A control method and small coal pillar technology, which is applied in the direction of earthwork drilling, mining equipment, blasting, etc., to achieve the effect of reducing labor intensity of workers, reducing the number of construction and the amount of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

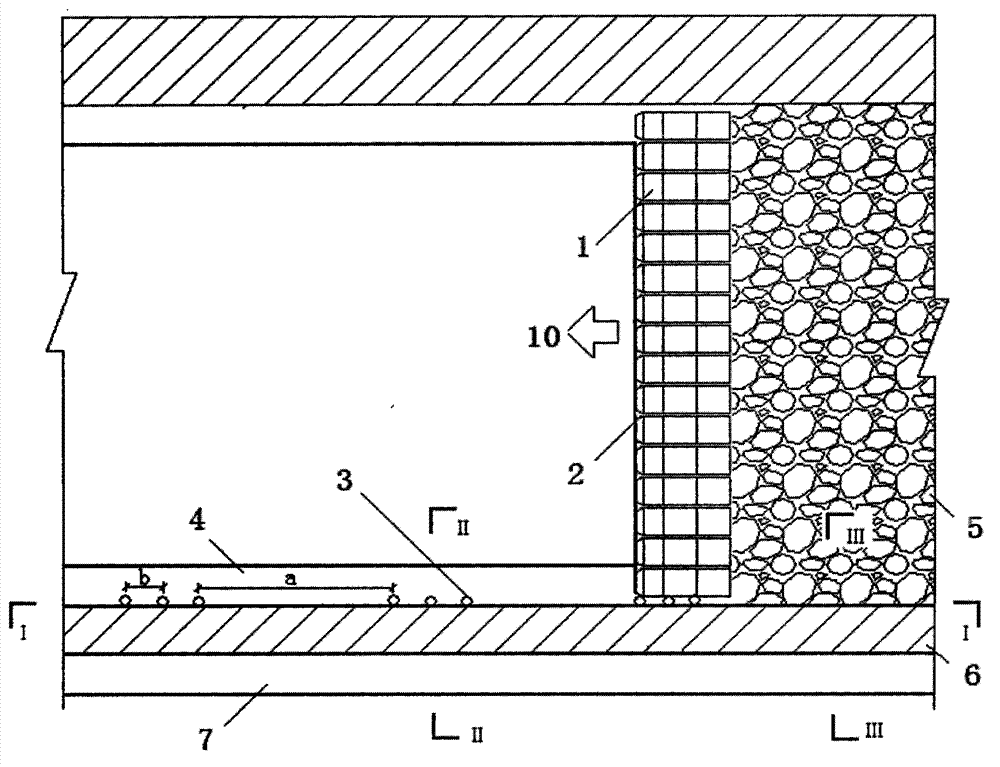

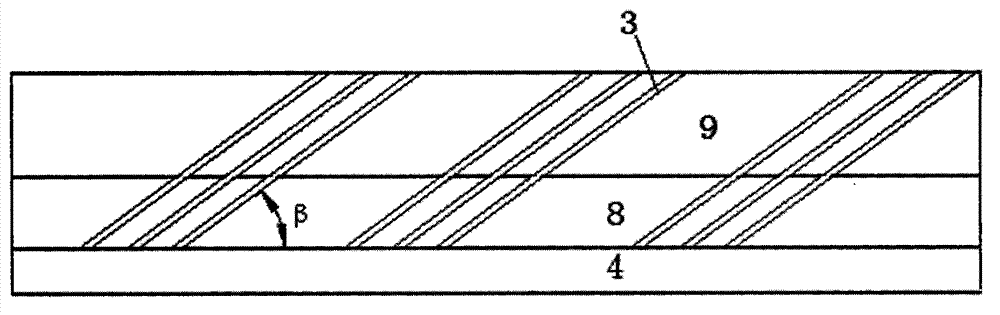

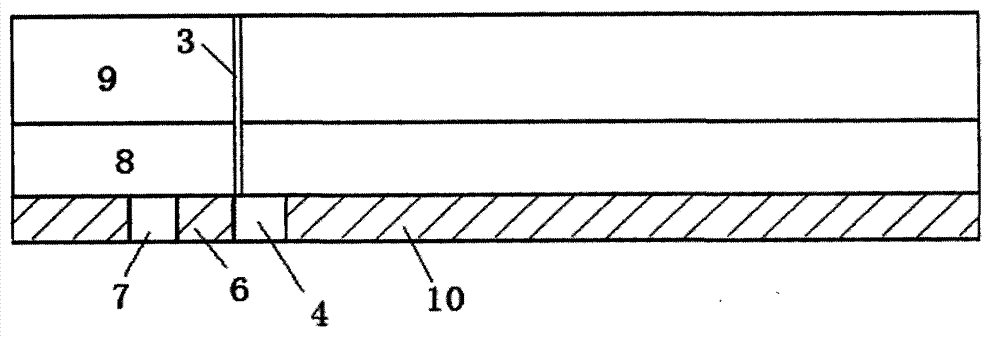

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] Such as Figure 1-Figure 5 As shown together, the No. 15 coal seam is mined in the fully mechanized mining face of a certain mine, and the coal seam mining height is 26m. The immediate roof is carbonaceous mudstone, with an average thickness of 4.5m; the basic roof is medium- and fine-grained sandstone, with an average thickness of 6.8m, the sandstone is dense and hard, with a tensile strength of 8.2MPa, and the load of the basic roof is 202.3kN / m 2 . The implementation steps are as follows:

[0036] (1) First calculate the hole group spacing a:

[0037] a = h σ t 3 · n · q = 6.8 × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com