Clamping and fixing method for part blank

A fixing method and a technology of parts, which are applied in the direction of clamping, metal processing machinery parts, positioning devices, etc., can solve problems such as surface chattering of parts, adverse effects of tools, etc., and achieve the goals of reducing overhang length, improving surface quality, and reducing production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

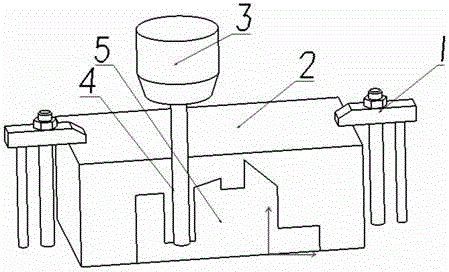

[0013] The installation and working methods of the present invention will be described below in conjunction with the accompanying drawings.

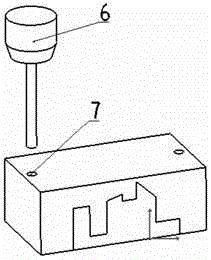

[0014] (1) Drill 1-2 bolt holes at the original pressure plate of the blank, such as figure 2 shown

[0015] Use the φ12 drill bit 6 to drill the bolt hole 7, the hole position is 15mm away from the edge of the blank, and 10-30mm away from the part.

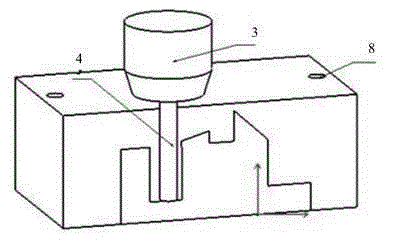

[0016] (2) Screw the bolts into the part blank, such as image 3 shown

[0017] Screw the inner hexagonal bolt 10 into the corresponding bolt hole of the part blank, the upper surface of the bolt should be lower than the upper surface of the part blank, so that the tool feeding of the part will not be affected during processing, and the overhang length 9 of the tool will also be reduced by 20-30mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com