Numerical control machining clamping method for aircraft wing beam parts

A technology of parts and wings, which is applied in the field of high-efficiency CNC machining of aircraft wing beam parts, can solve the problems of no longer practical processing methods, difficult clamping and positioning, and long time required for clamping and positioning of parts, so as to save preparation time, avoid secondary correction errors, design and manufacture simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

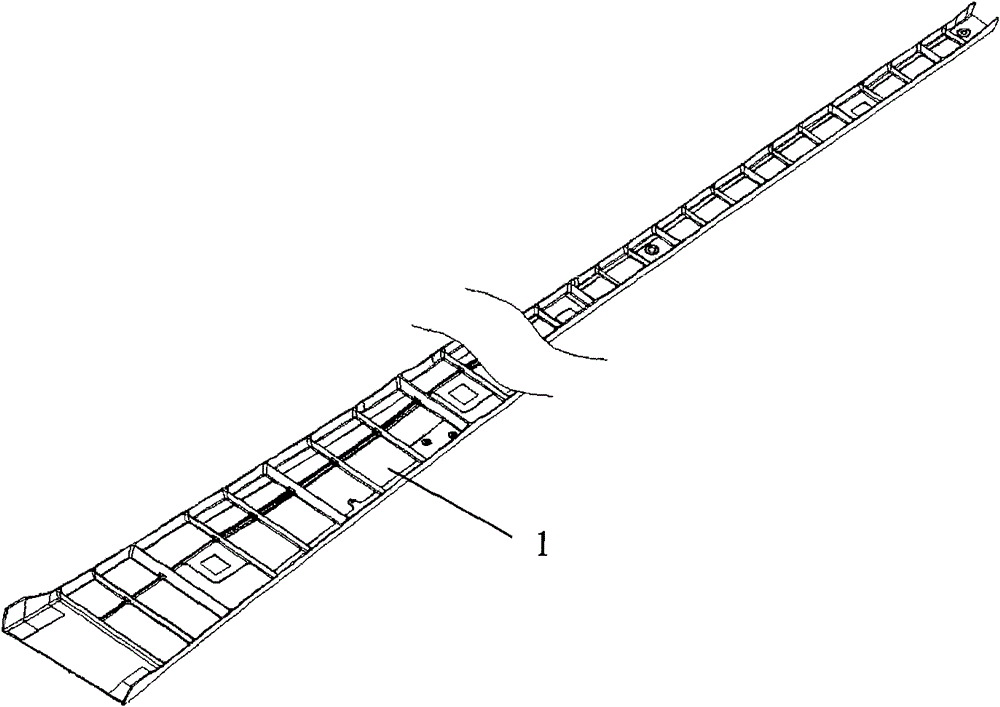

[0014] figure 1 The beam part 1 shown is a complex elongated structure, the bottom is flat, and the height of the rib top of the part varies unevenly.

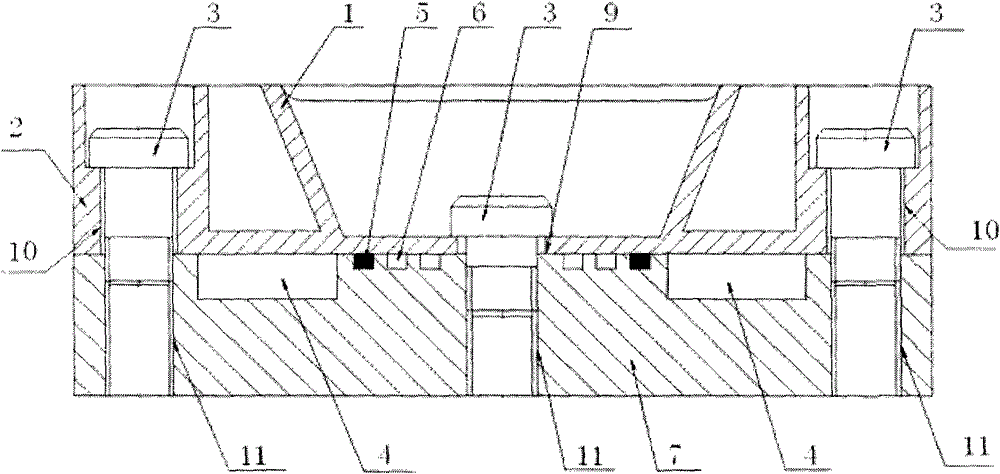

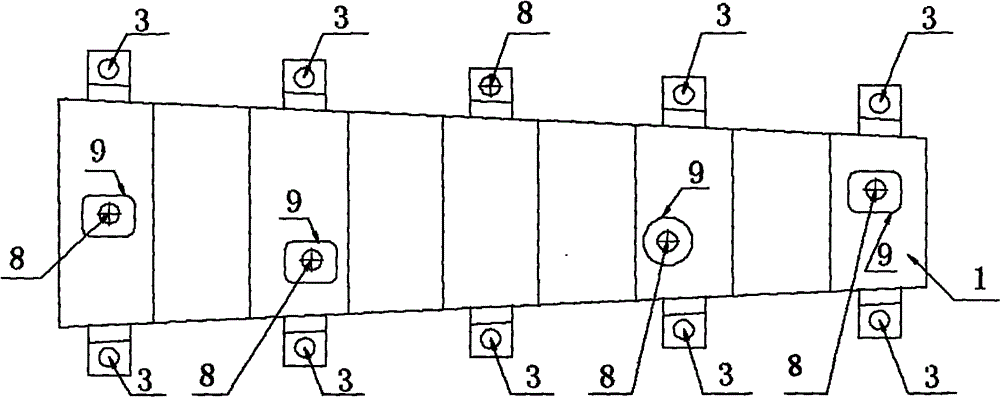

[0015] figure 2 The beam part 1 shown is clamped on the vacuum milling body 7, and the undercut 4 of the closed angle of the machining shape of the part on both sides of the tool is milled at the theoretical shape position of the part 1. The theoretical outline of the part is located in the undercut of the milling tool. The width of the undercut 4 is preferably 1.5-2 times the diameter of the tool used to process the shape of the part. The depth of the undercut should be based on the diameter of the tool used and the shape of the part. The size of the web angle is considered comprehensively. Take the tool whose diameter is D and the bottom angle is R0 as an example. If the closed angle of the part is α, then the depth H of the undercut should be greater than D*sinα / tgα. On both sides of the blank of the part 1, a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com