A flat die pellet machine

A granulator and flat die technology, applied in the field of agriculture and forestry, can solve the problems of large overall size of the granulator, many materials used in the chassis, and increased installation space, and achieve the effects of smooth work, saving installation space, and reducing the height of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

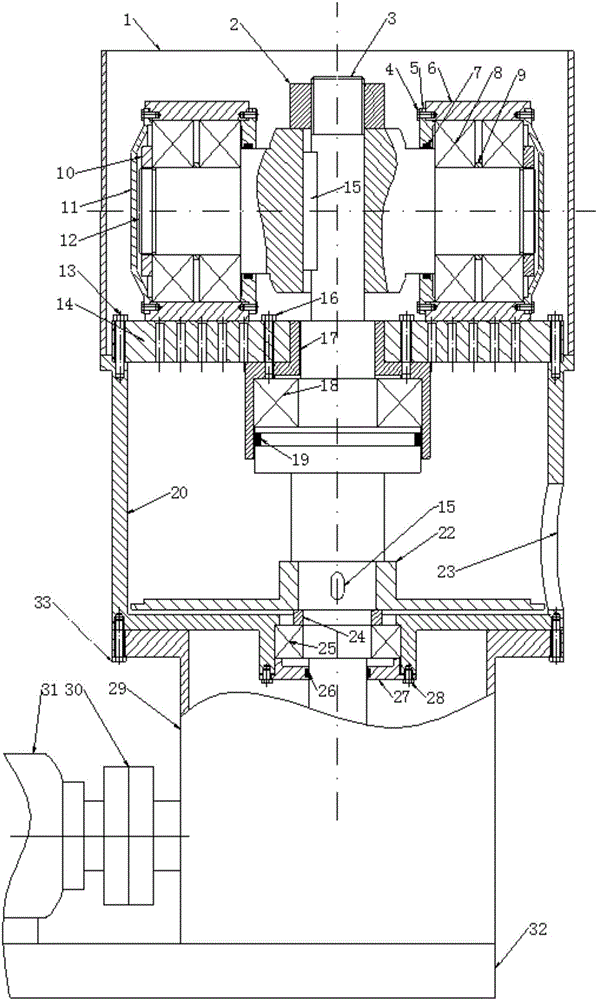

[0022] In order to illustrate the details of the implementation steps and devices of the present invention, a flat-die granulator of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] A flat-die granulator of the present invention includes a material barrel 1, a chassis 20, a working assembly, a main shaft assembly, and a transmission assembly. The transmission assembly is fixedly connected to the chassis 20, and the chassis 20 and the material barrel 1 are connected together through the main shaft assembly and the working assembly. , the main shaft 3 protrudes from the gearbox 29, passes through the casing 20 and reaches the material barrel 1, the output shaft of the gearbox 29 is the main shaft 3, the gearbox 29 is connected with the casing 20 through the casing screw 33, and the main shaft assembly is composed of the main shaft 3. The compression nut 2, the key 15, the centripetal thrust bearing assembly, the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com