Patents

Literature

45 results about "Waste compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste compaction is the process of compacting waste, reducing it in size. Garbage compactors and waste collection vehicles compress waste so that more of it can be stored in the same space. Waste is compacted again, more thoroughly, at the landfill to conserve valuable airspace and to extend the landfill's life span.

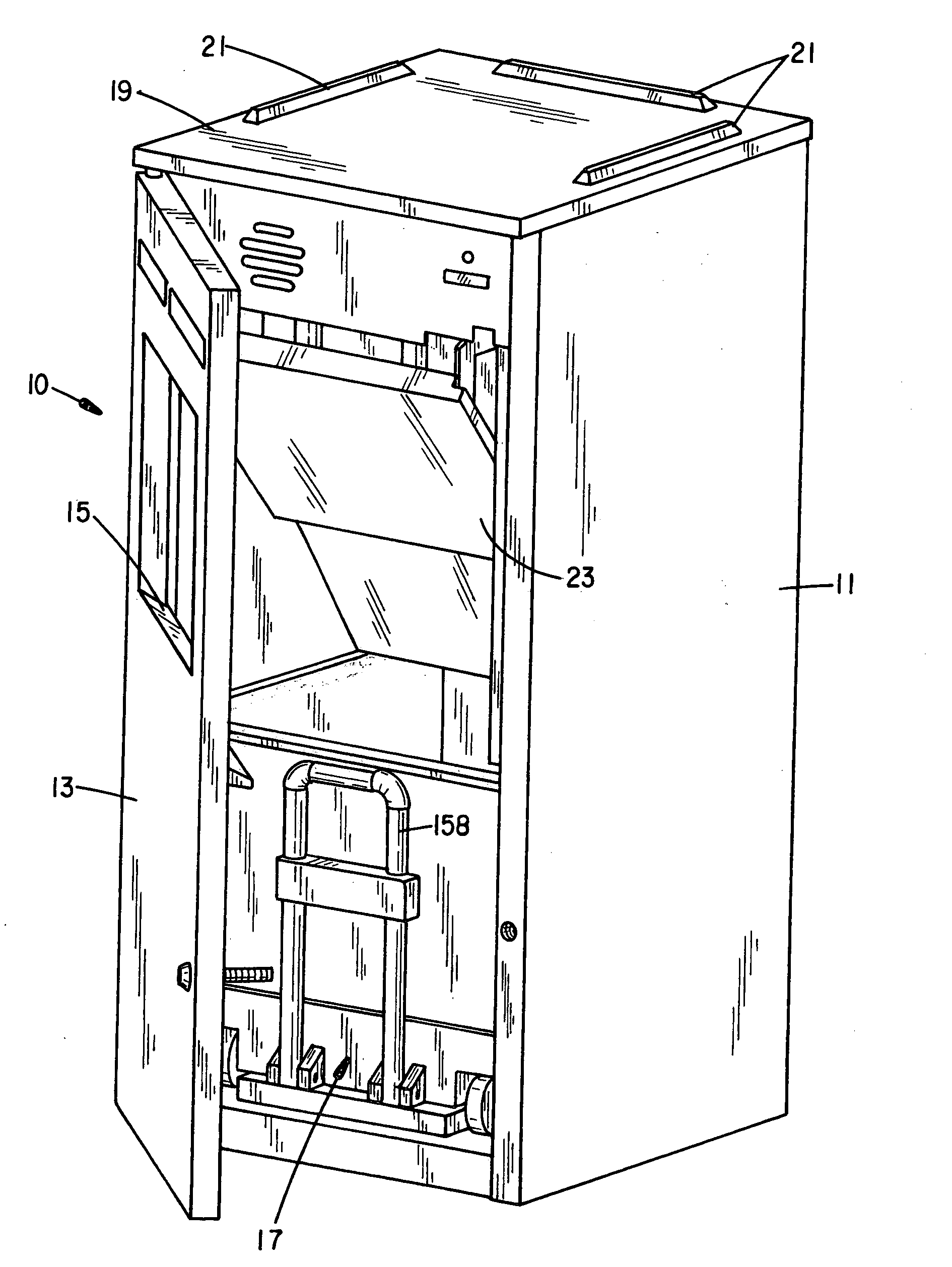

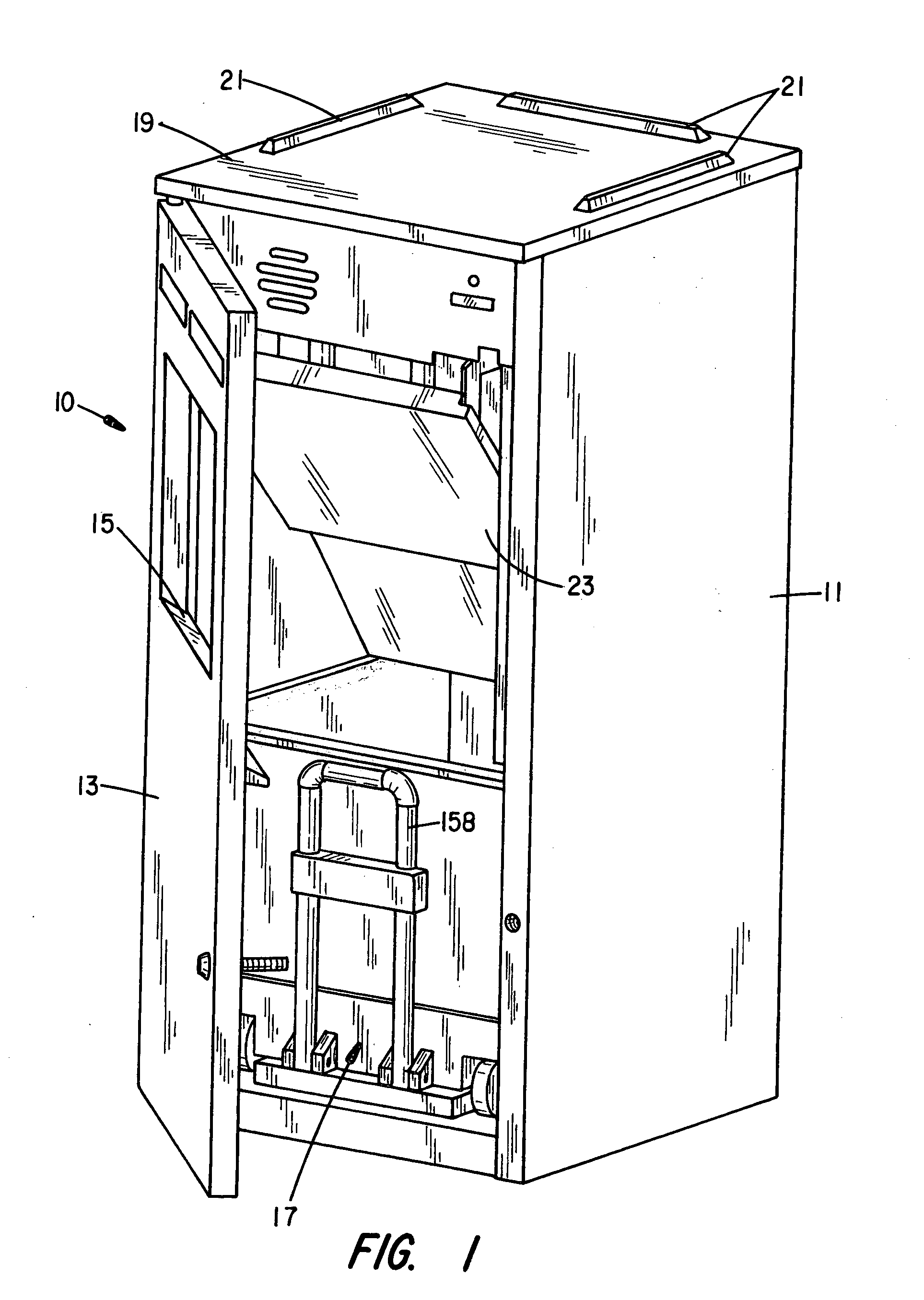

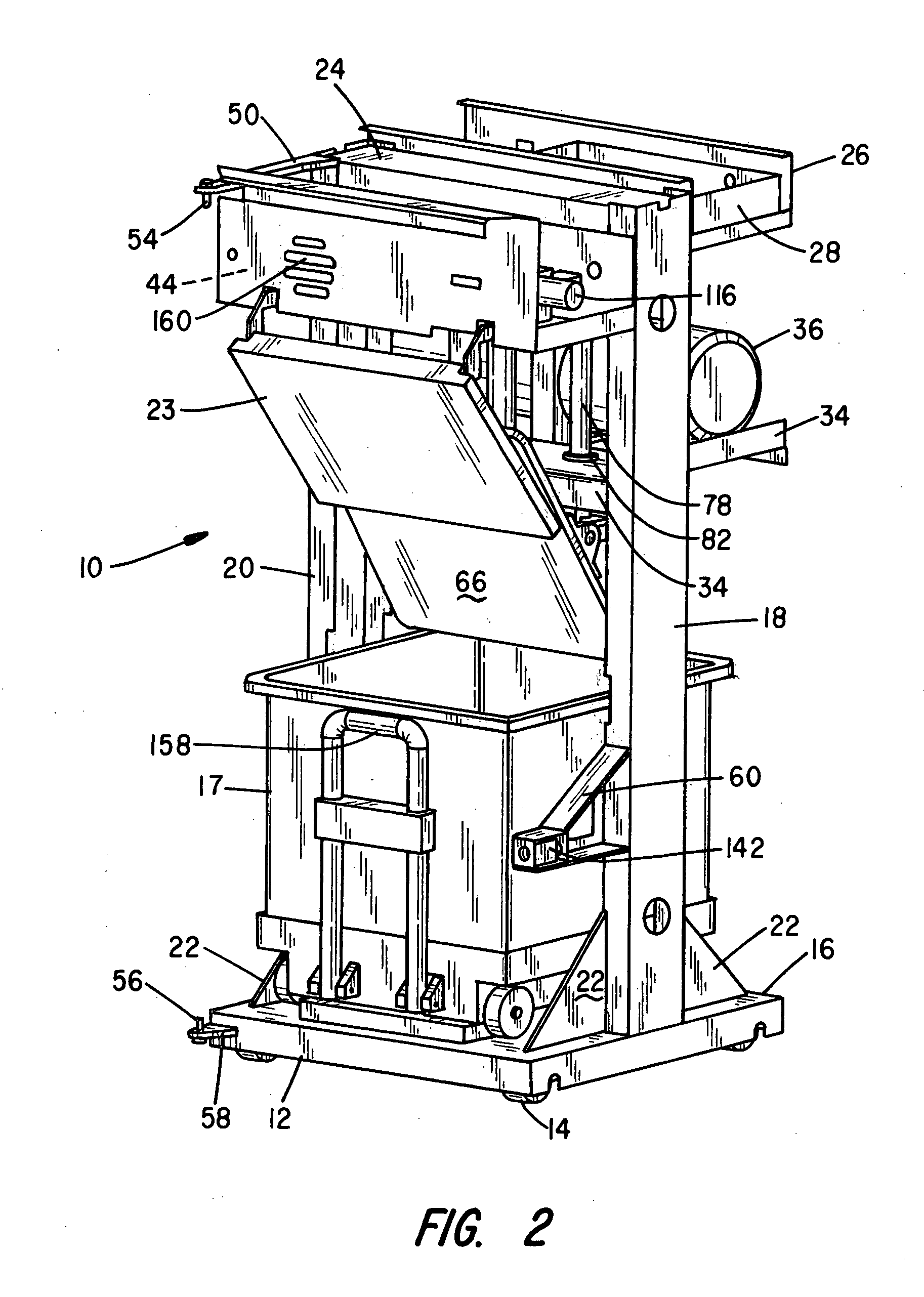

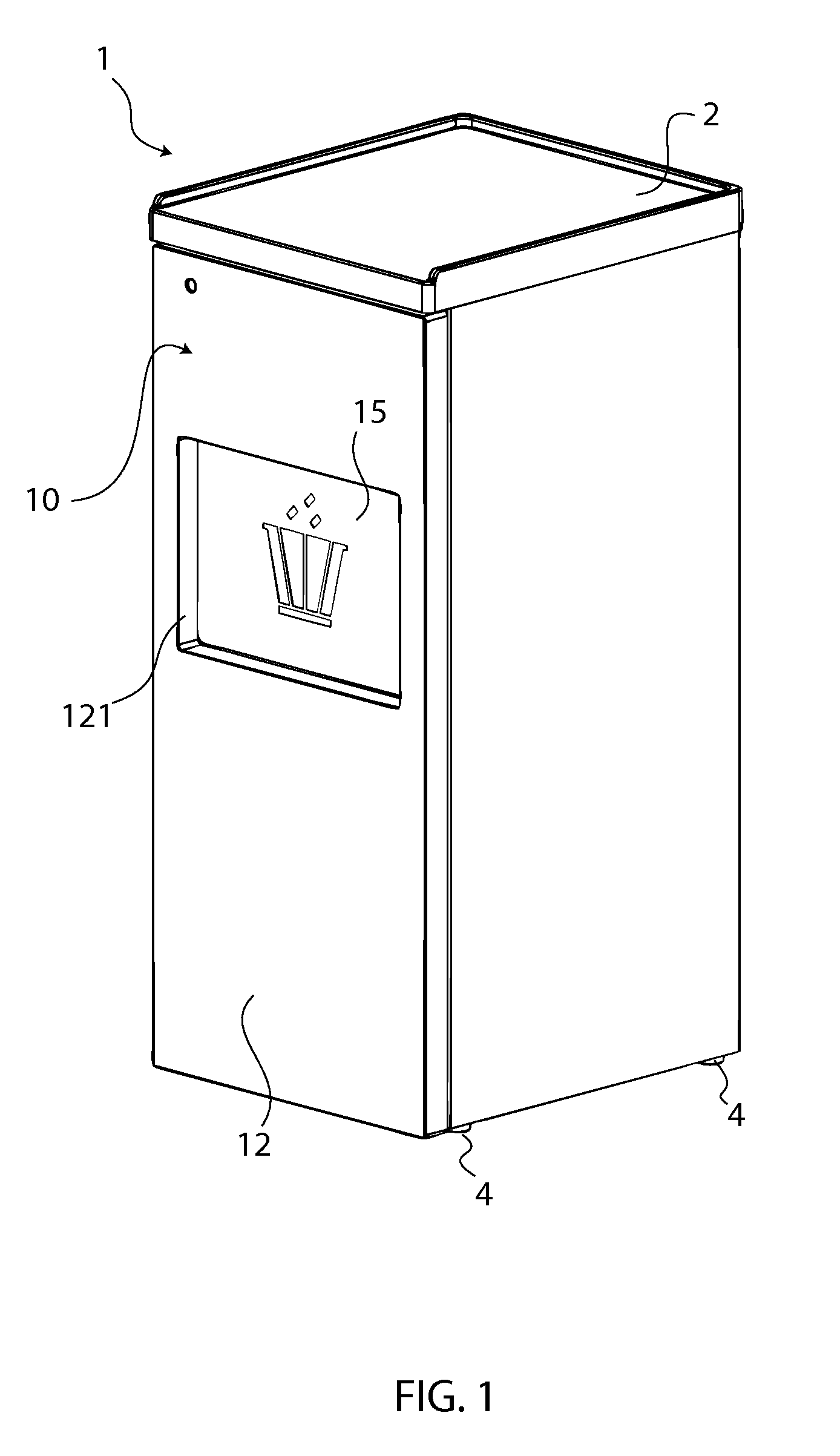

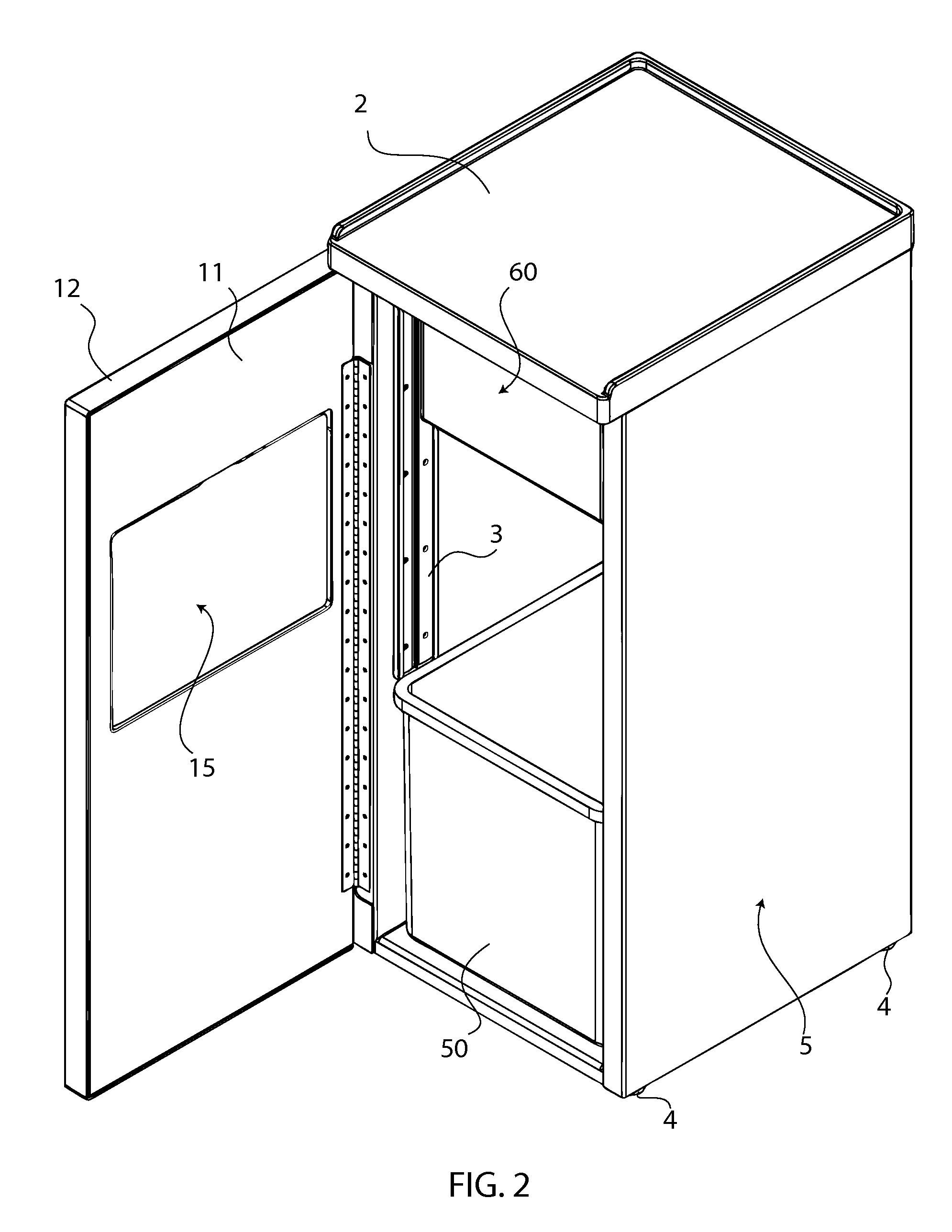

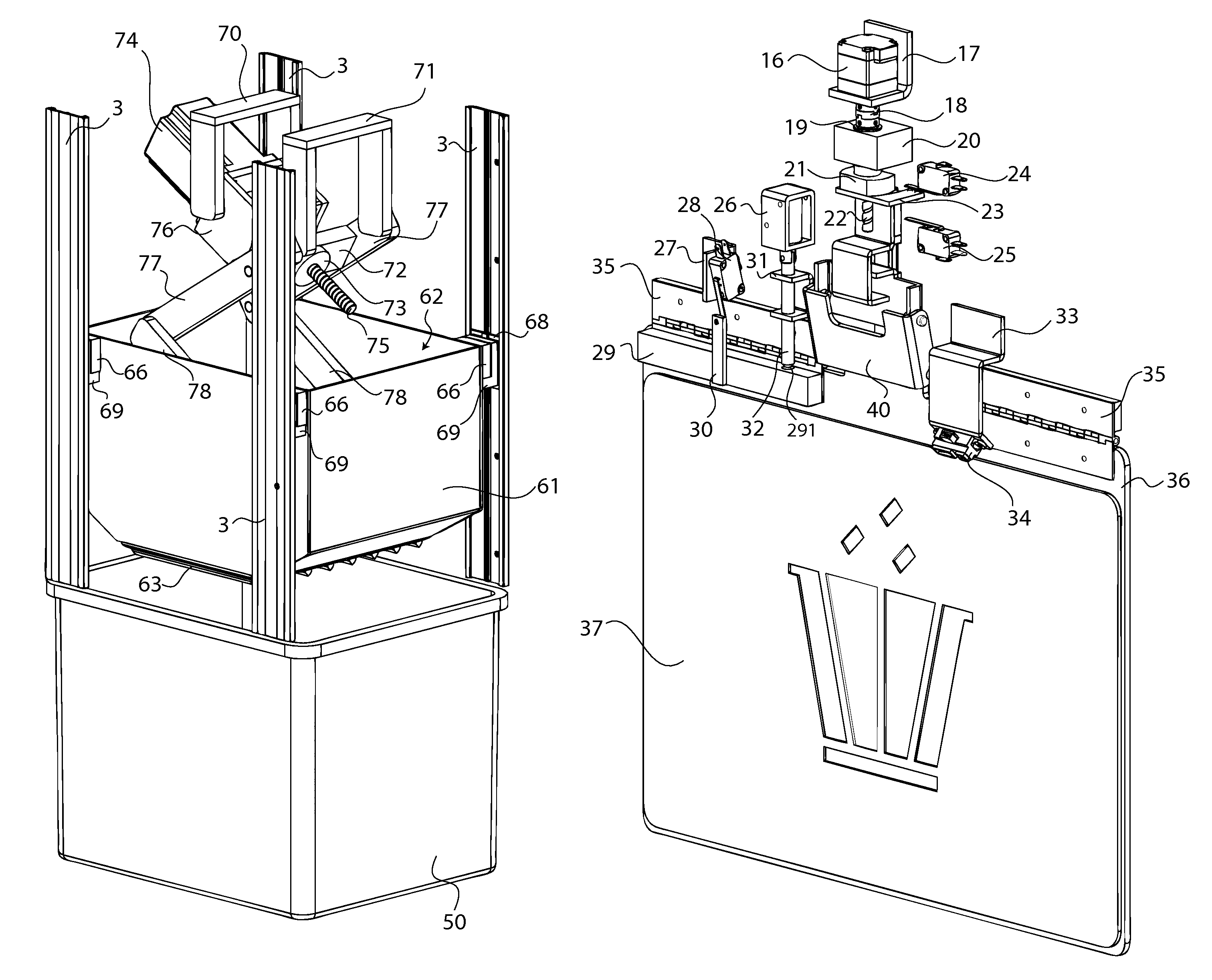

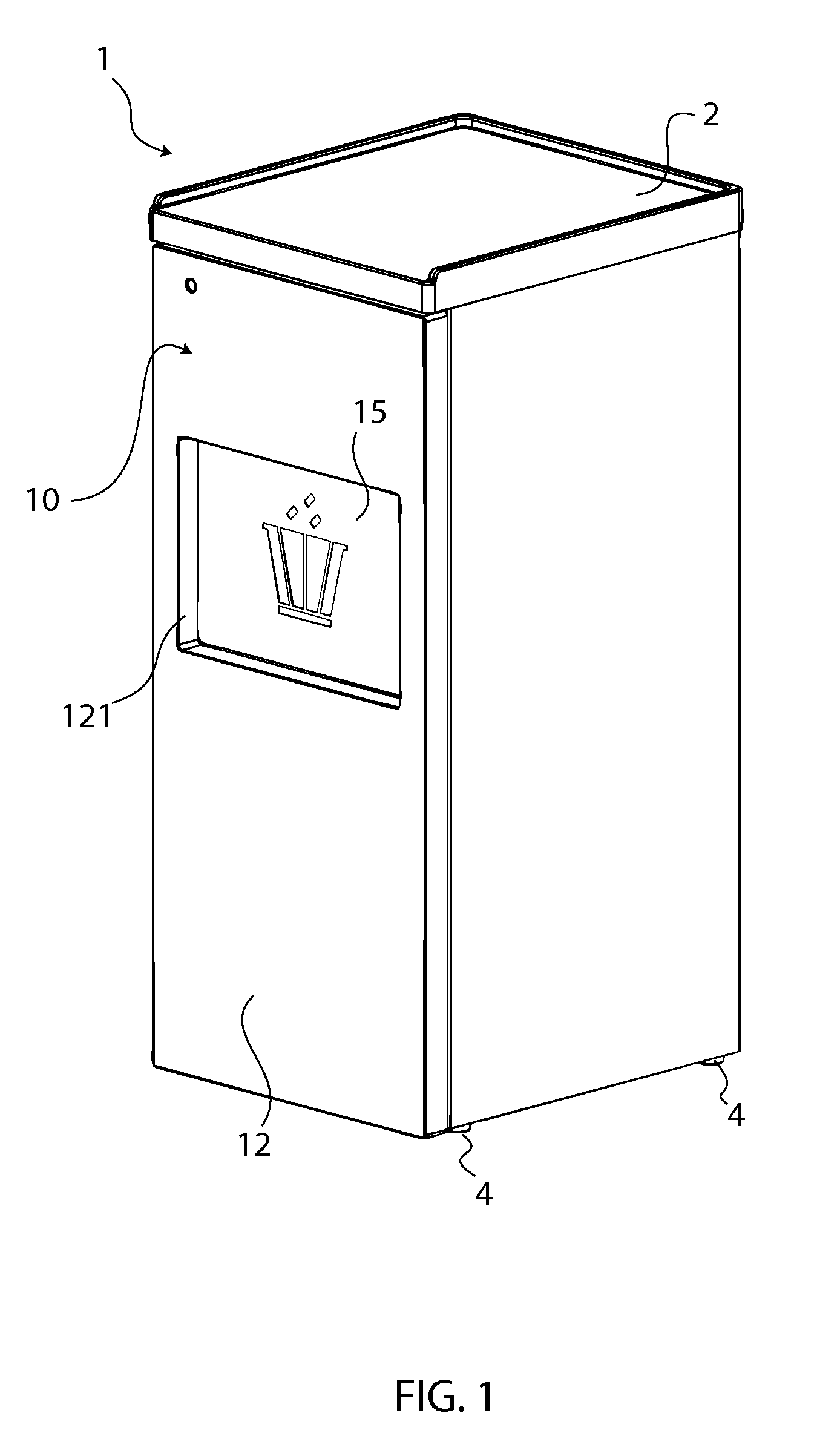

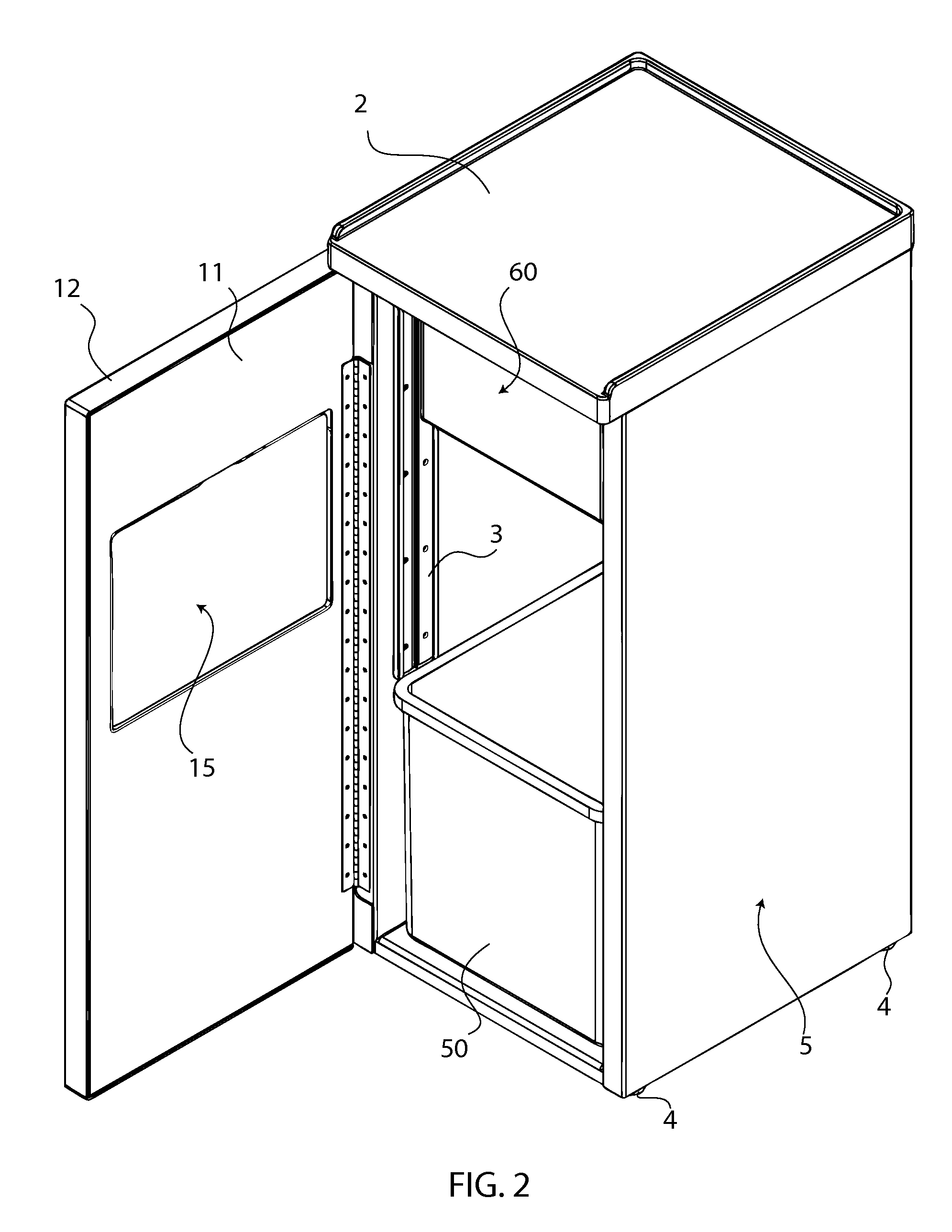

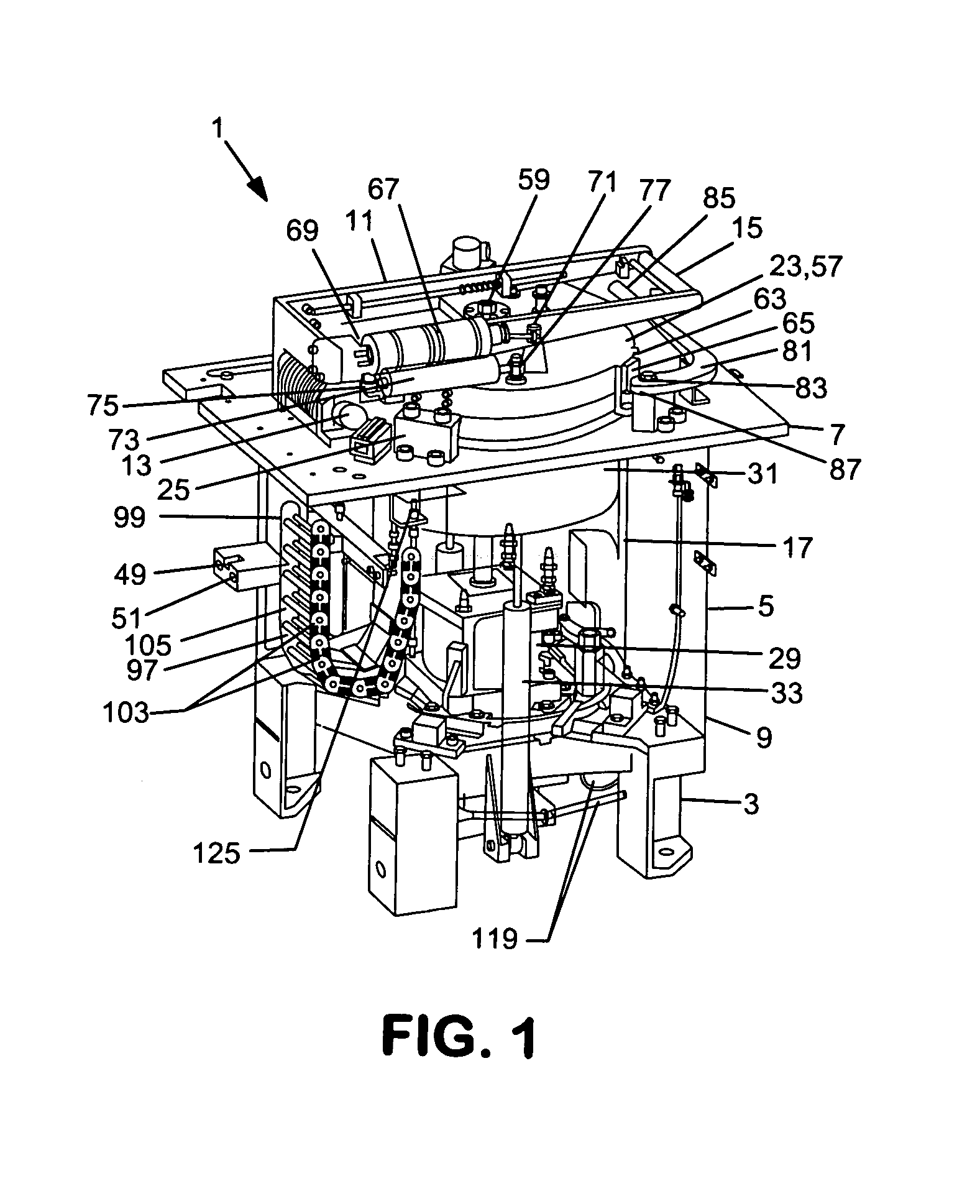

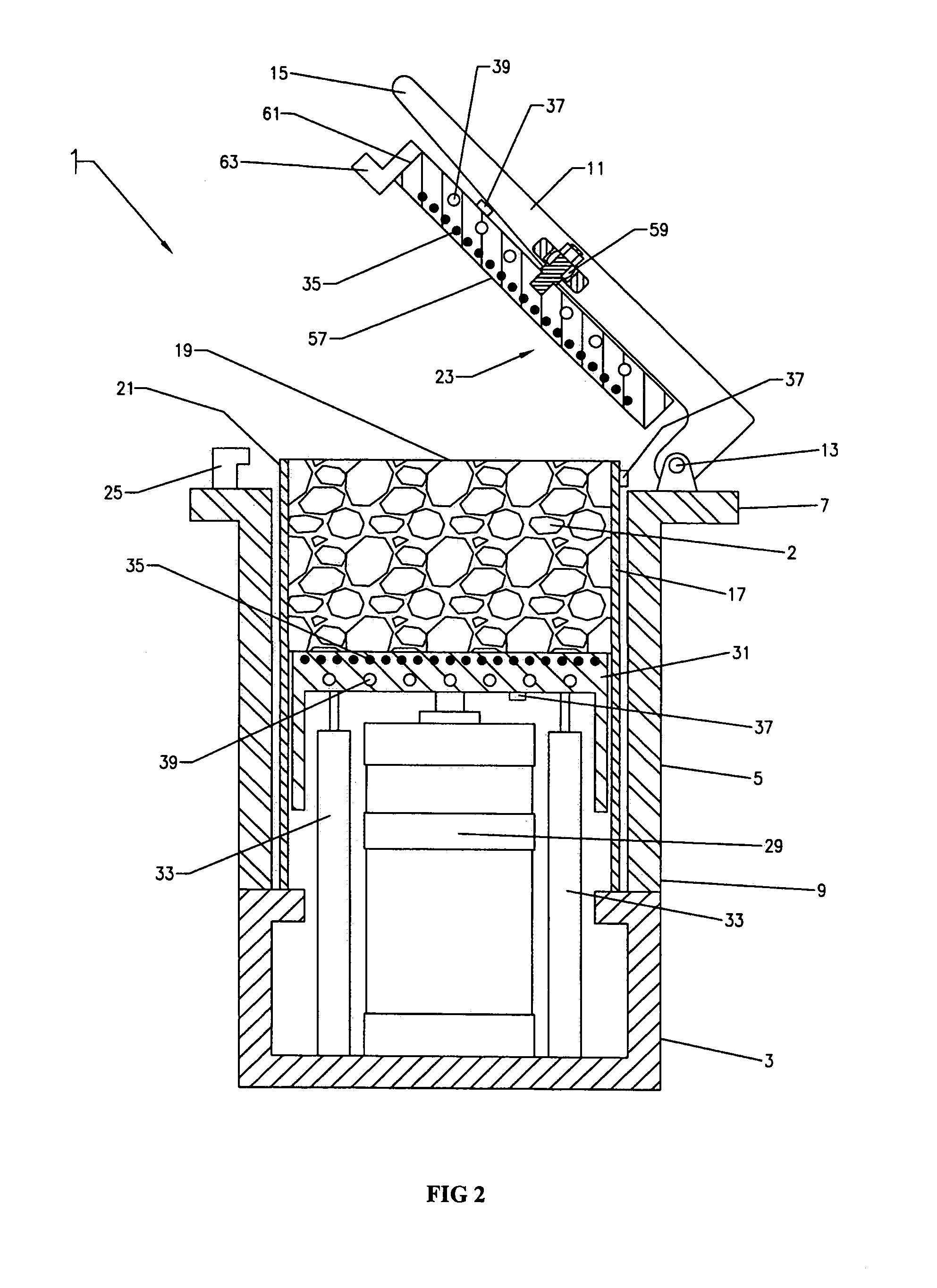

Trash compactor for fast food restaurant waste

InactiveUS20050061167A1Maintain alignmentEngineering safety devicesPress ramMotion detectorHydraulic ram

A refuse compactor especially designed for use in fast-food restaurant environments includes a hydraulic pump driven by an electric motor for actuating a hydraulic ram to compress restaurant waste materials. The compactor includes a unique compaction plate assembly that maintains the platen inclined at a predetermined angle to the vertical when the platen is elevated and which forces the platen to a horizontal disposition during a downward compaction stroke. A motor operated closure member selectively blocks and unblocks a refuse-receiving opening formed in a front door of the compactor unit and with a motion detector controlling the opening and closing of the refuse entry door panel.

Owner:BUHL HARDWICK

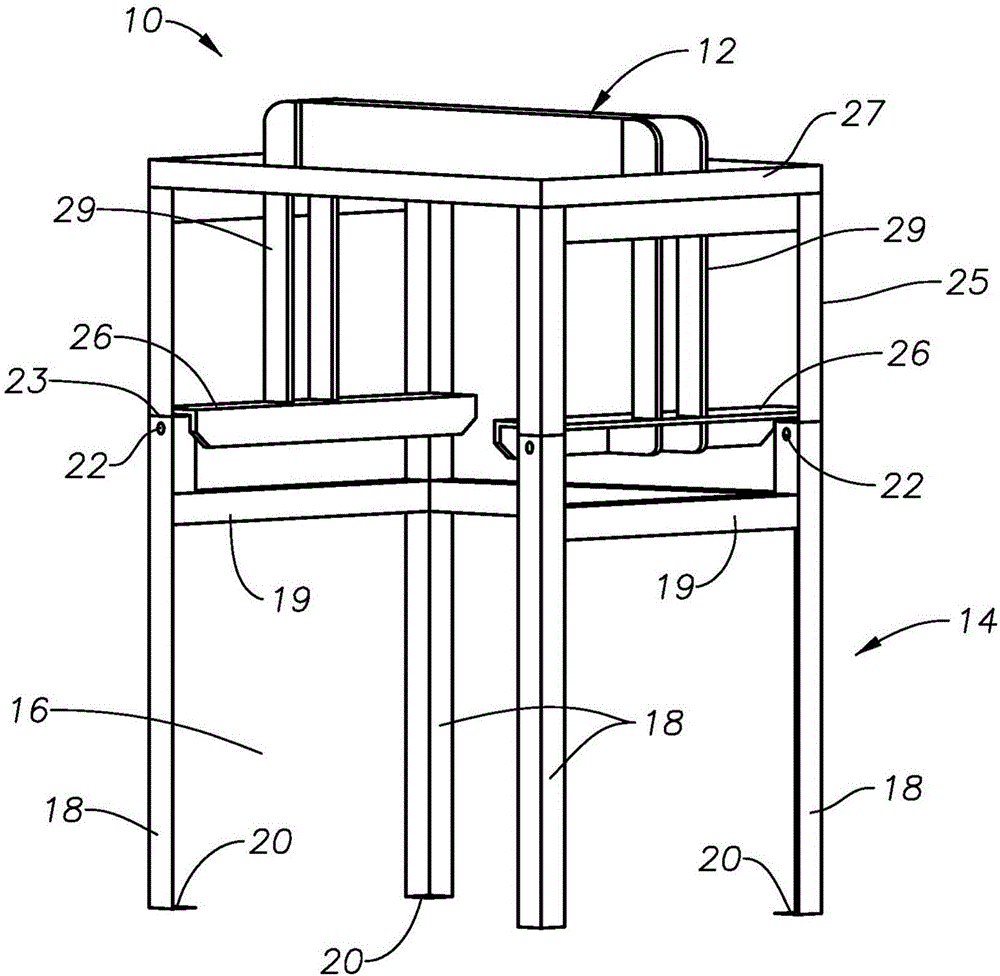

Waste Compaction and Lift Gate Mechanism

A waste bin with an automated waste compaction mechanism and a automated gate lifting mechanism for convenience usage. The present invention makes use of sensors and switches to allow the compaction and gate mechanism to operate automatically. The unique combination of components also ensures the reliability of the mechanism.

Owner:KACHKOVSKY OLIVER

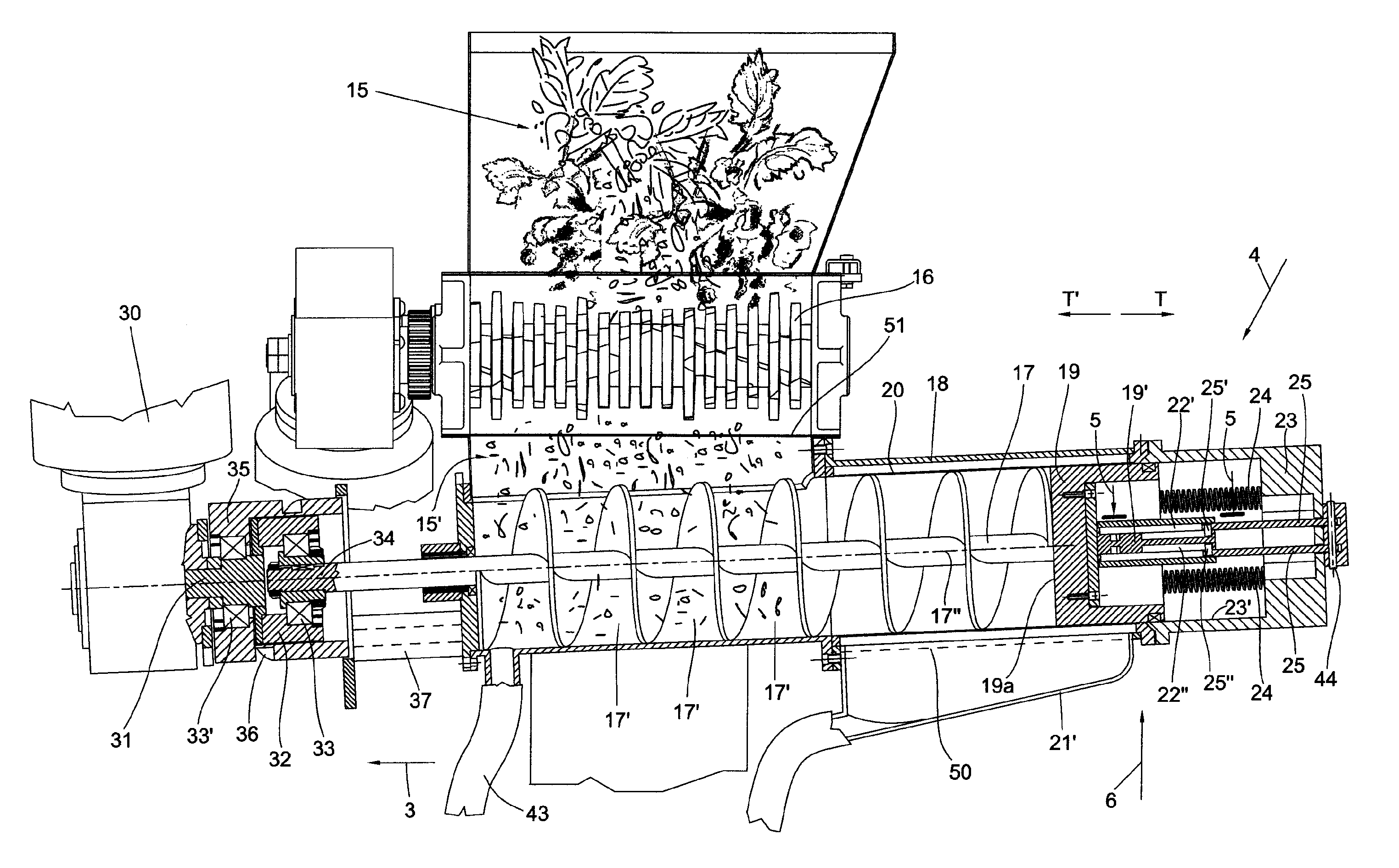

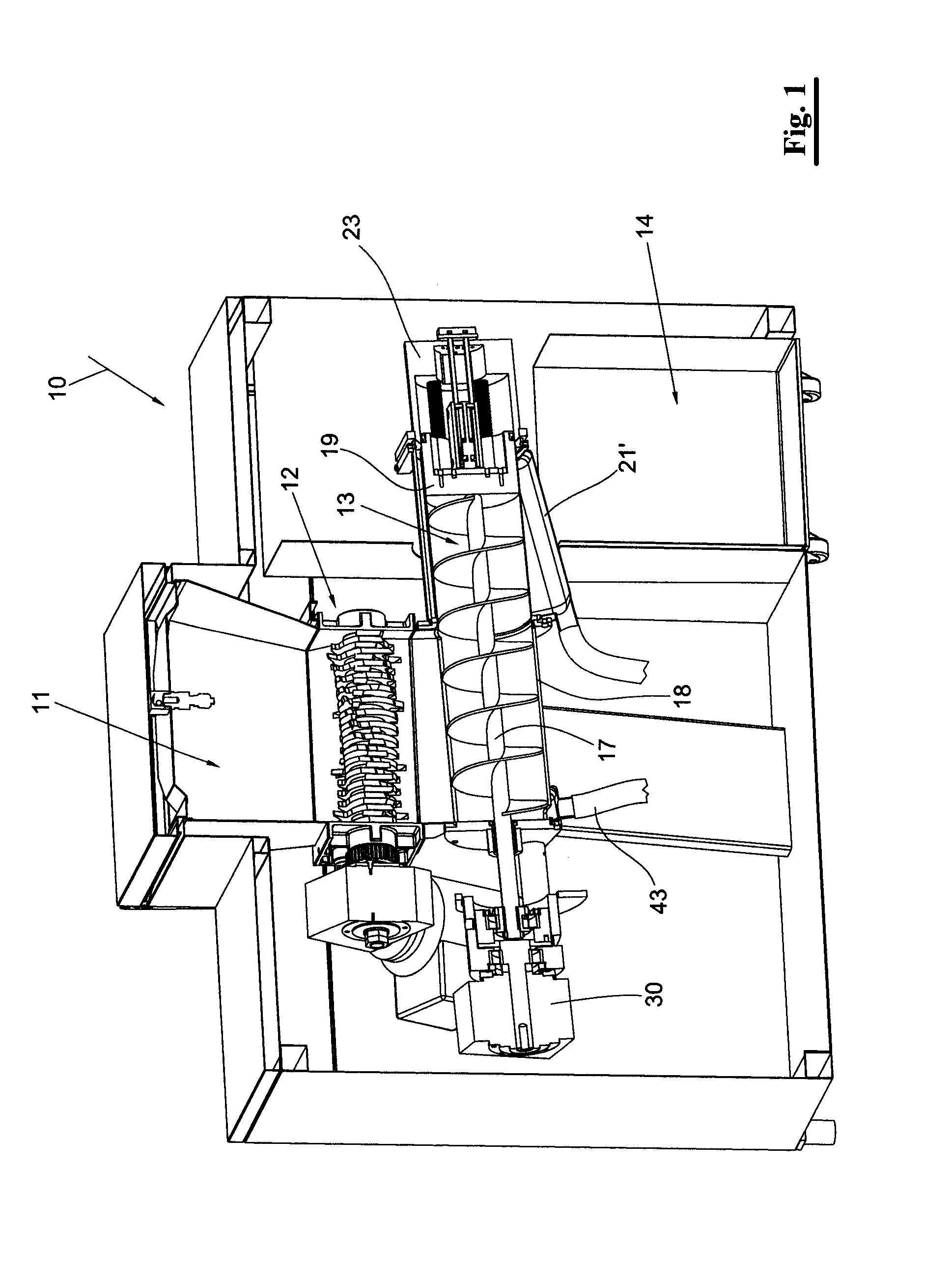

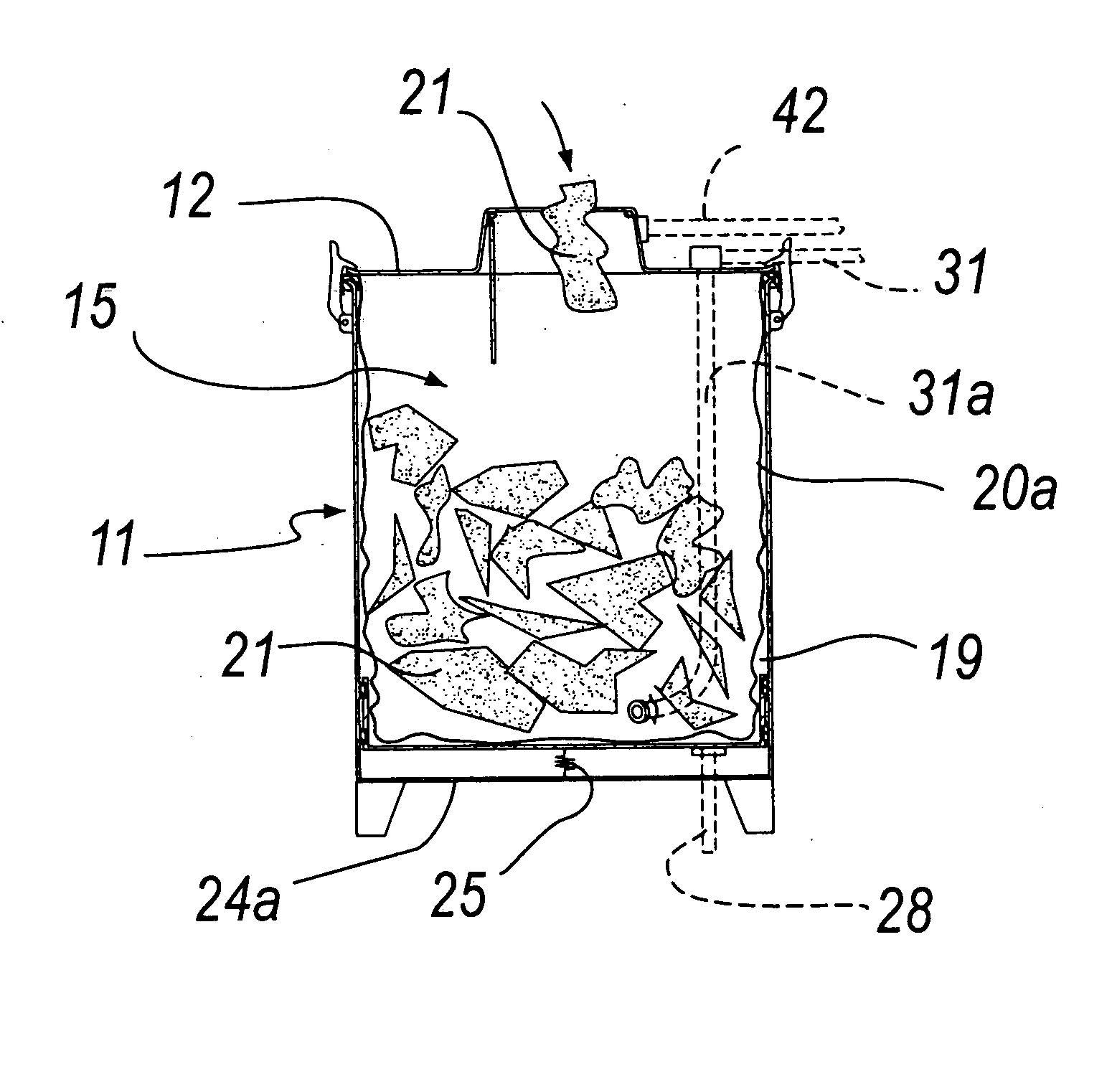

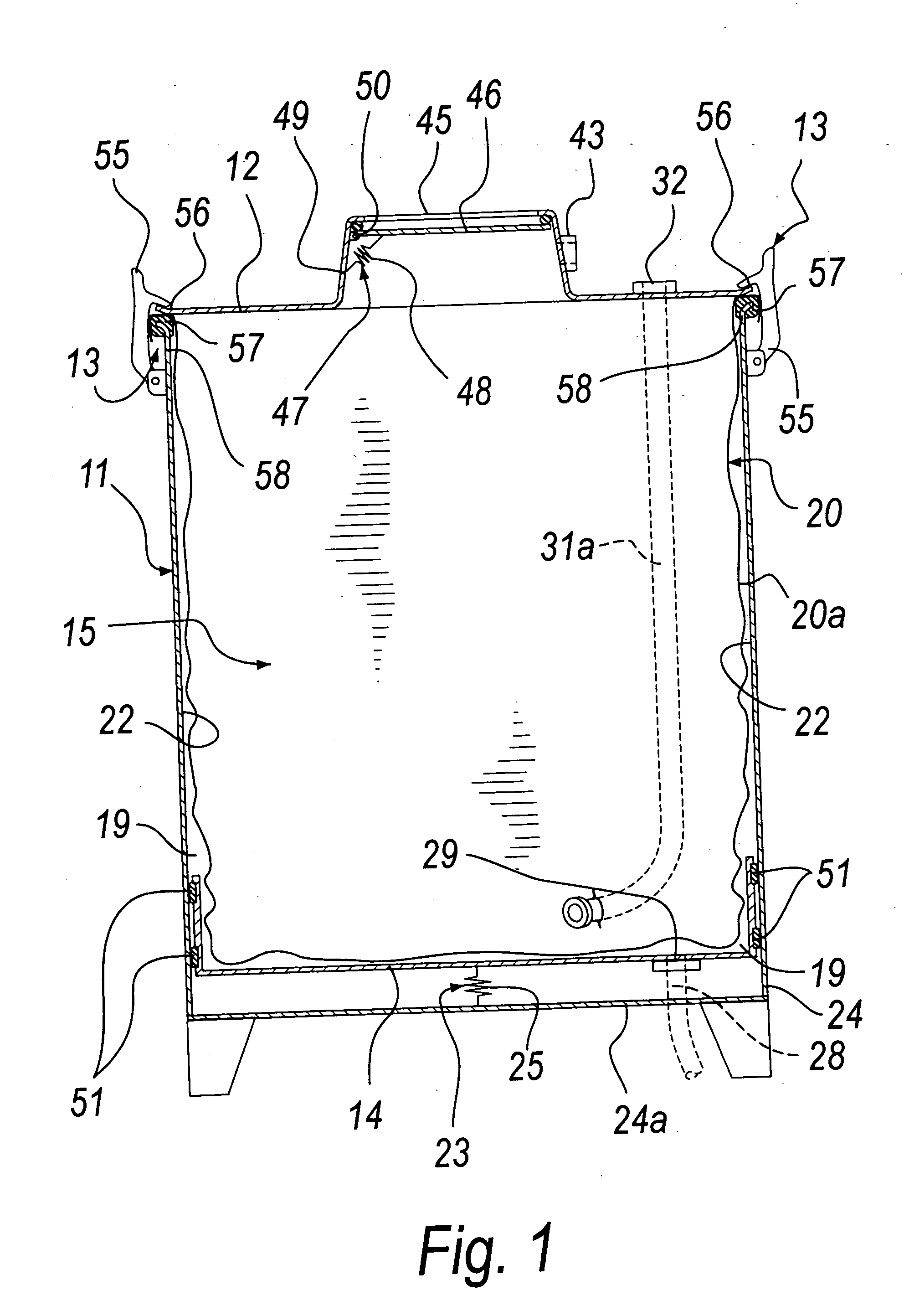

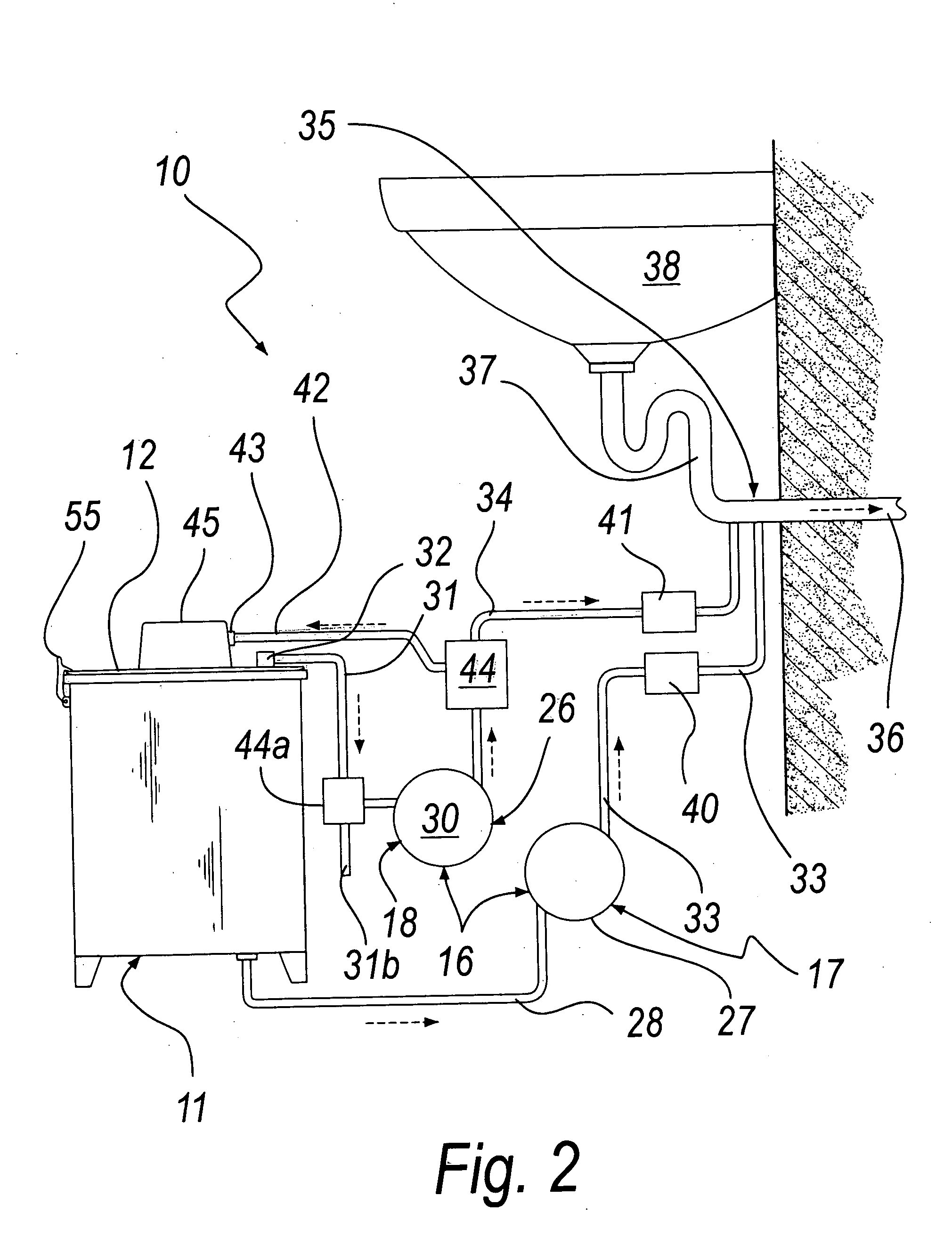

Apparatuses and methods for compacting waste

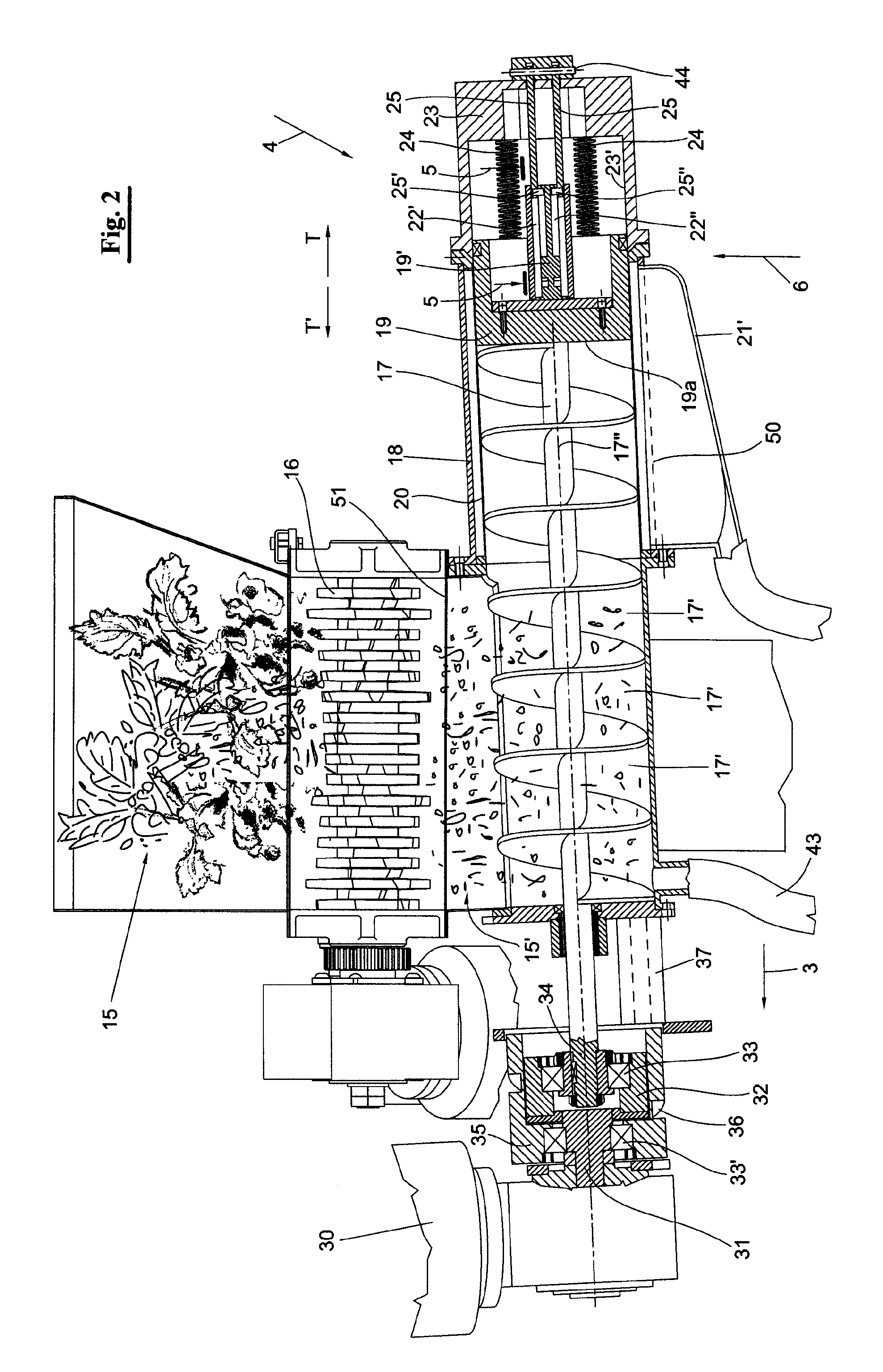

ActiveUS20130118363A1Improving compacting step and dehumidificationEasy to separateGrain treatmentsStrainersEnvironmental engineeringWaste compaction

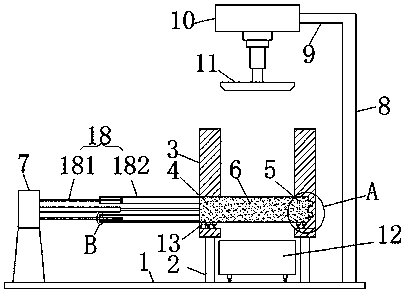

An apparatus and a method for treating organic waste, like the waste that is eliminated in kitchens, foresee containing the waste (15) to be treated, grinding the waste, compacting the ground waste and exerting a squeezing action to remove residual liquids. A screw device (17) is foreseen which rotates inside a casing (18) around a longitudinal axis to convey and compact the ground waste against a closure (19) which moves during compacting. A solution for cleaning the apparatus is also foreseen to remove remaining any waste, when the apparatus needs to stay empty for longer periods of inactivity.

Owner:ATOP SPA

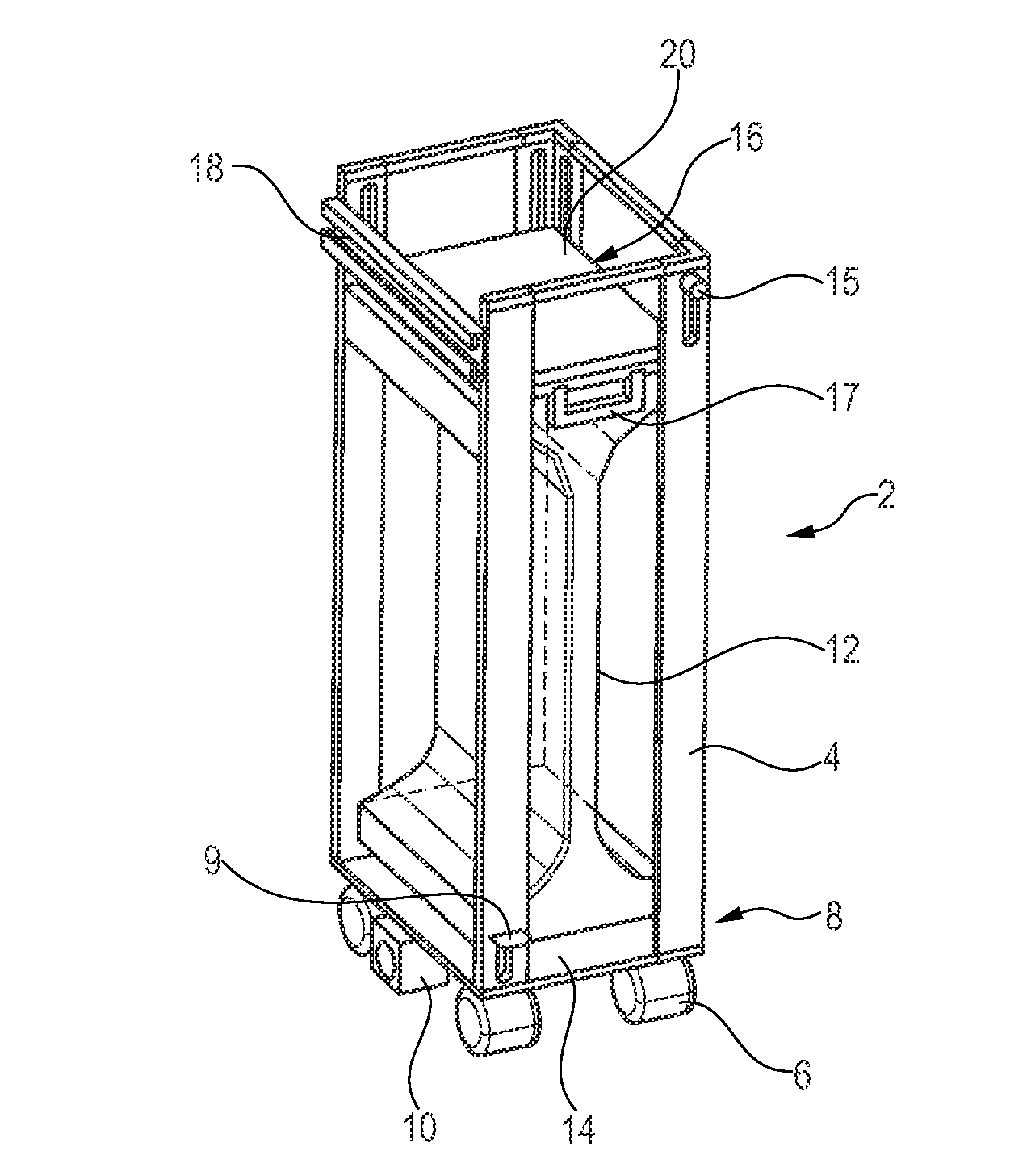

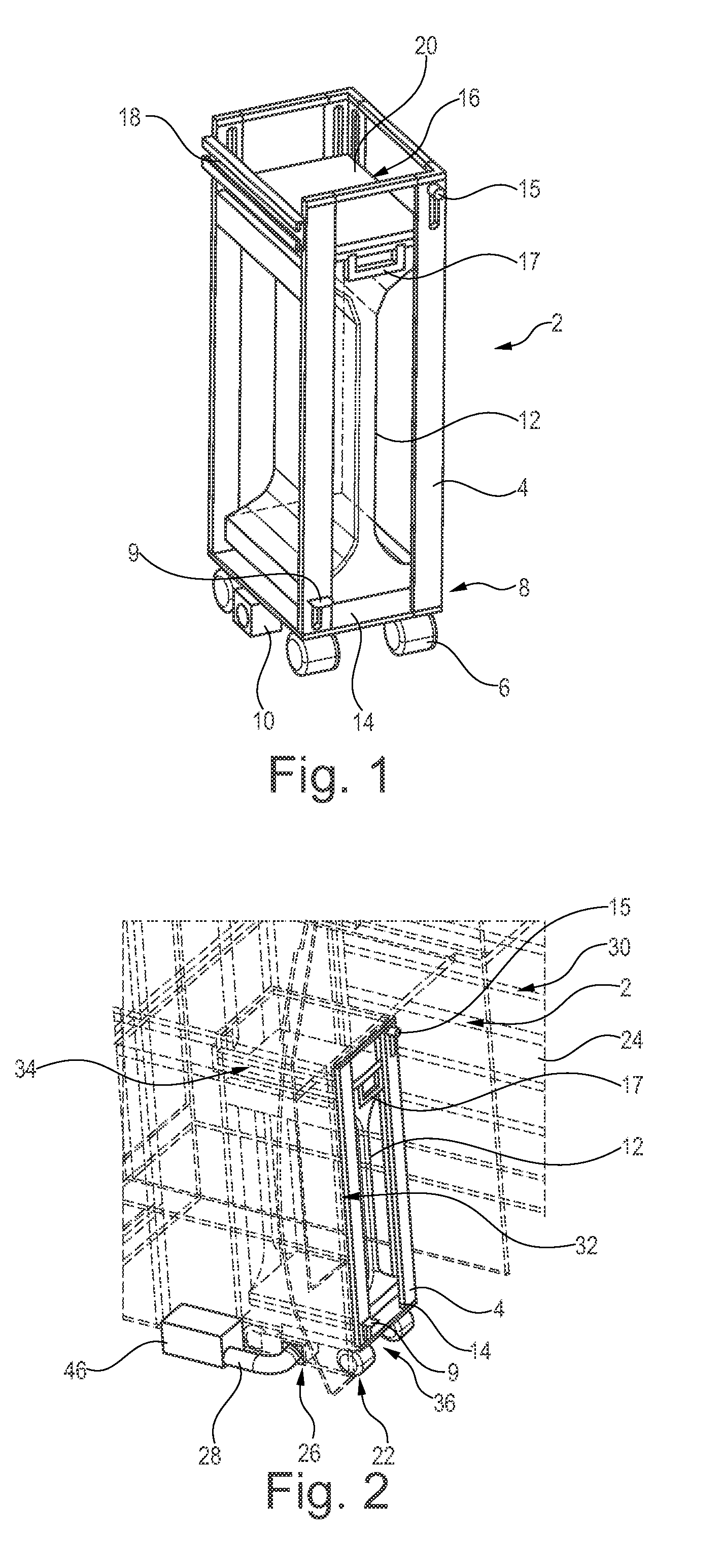

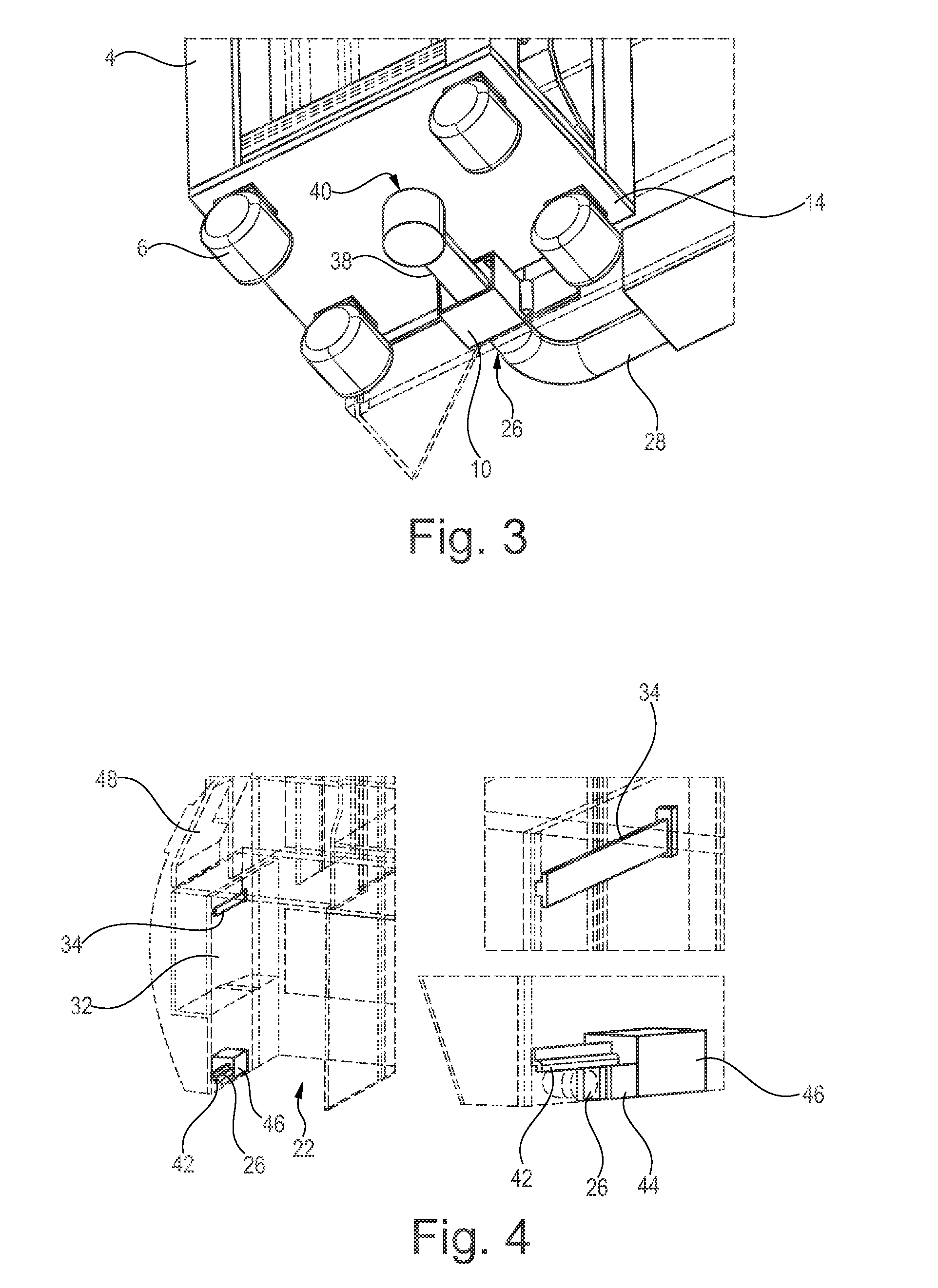

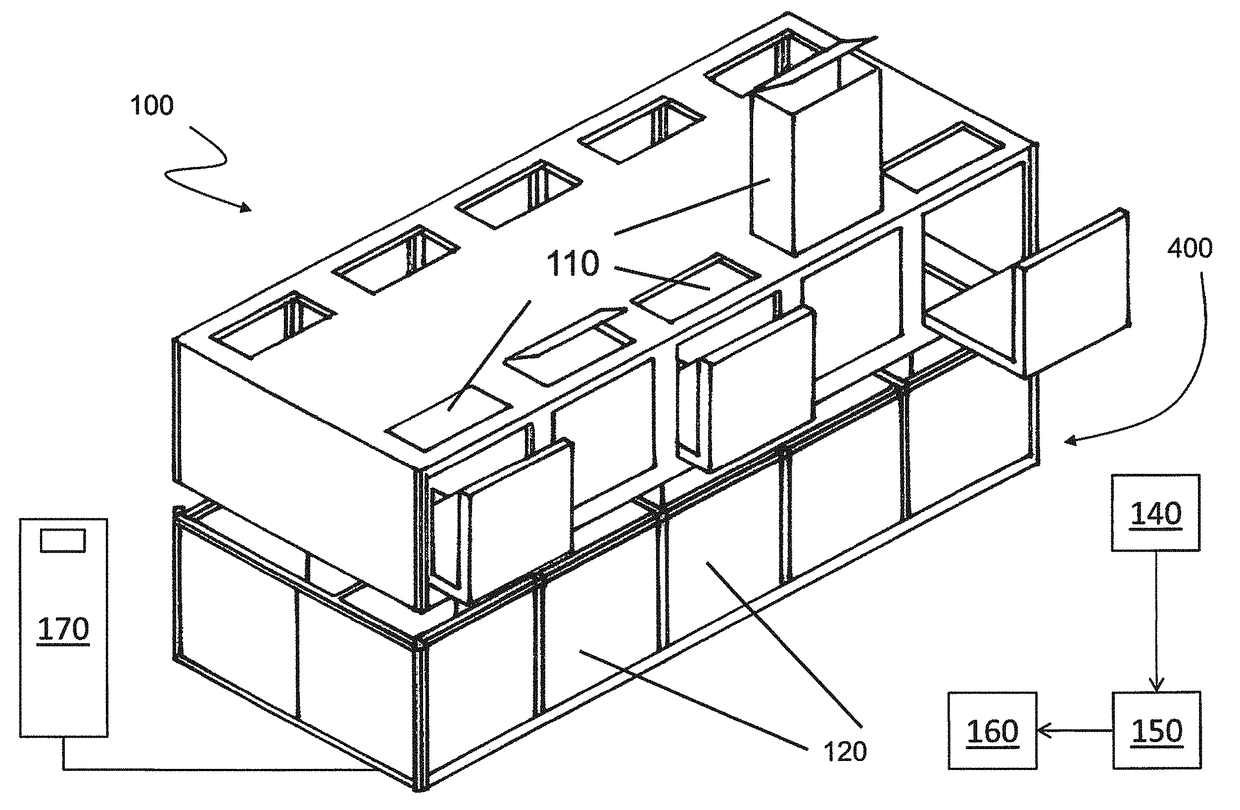

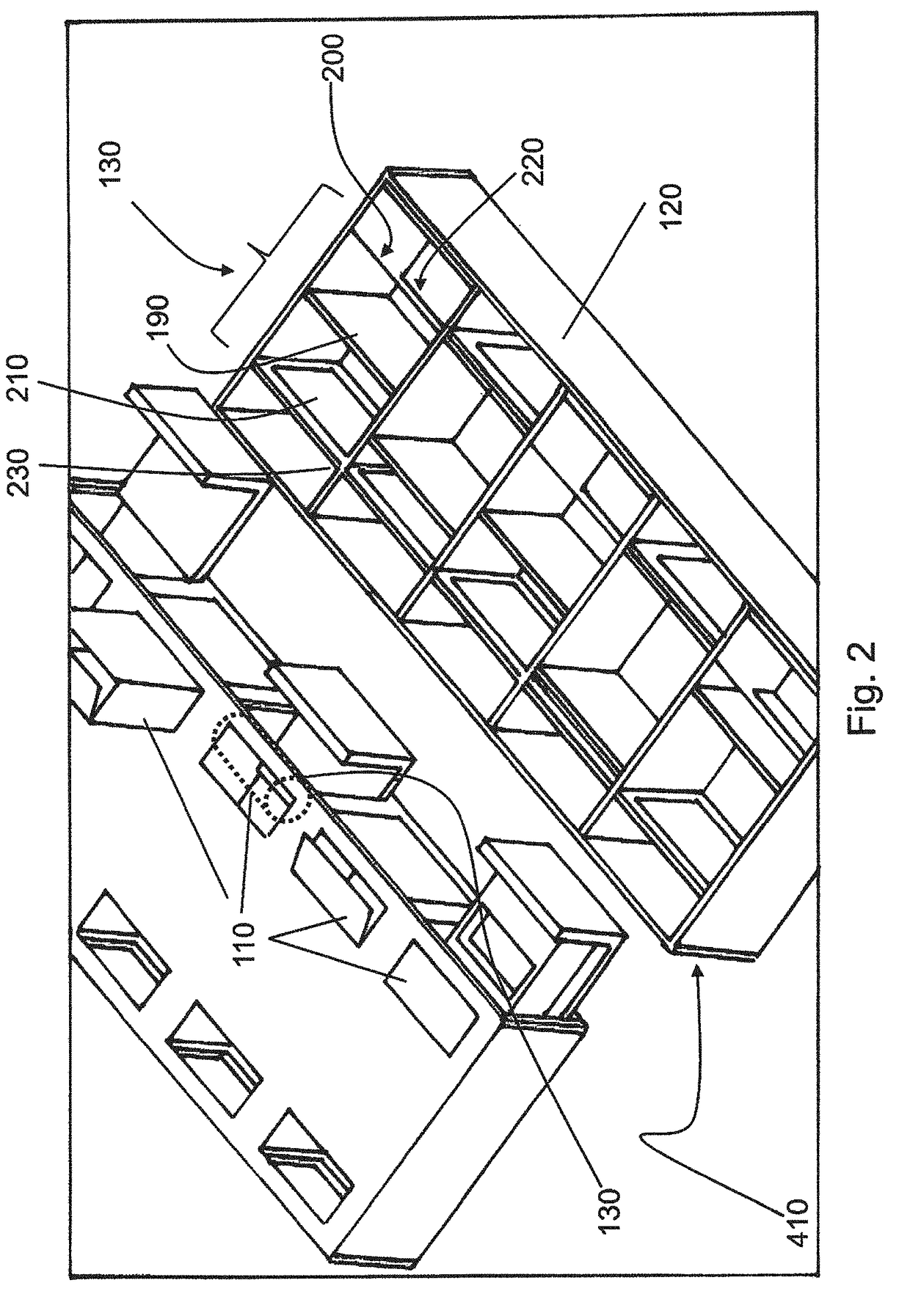

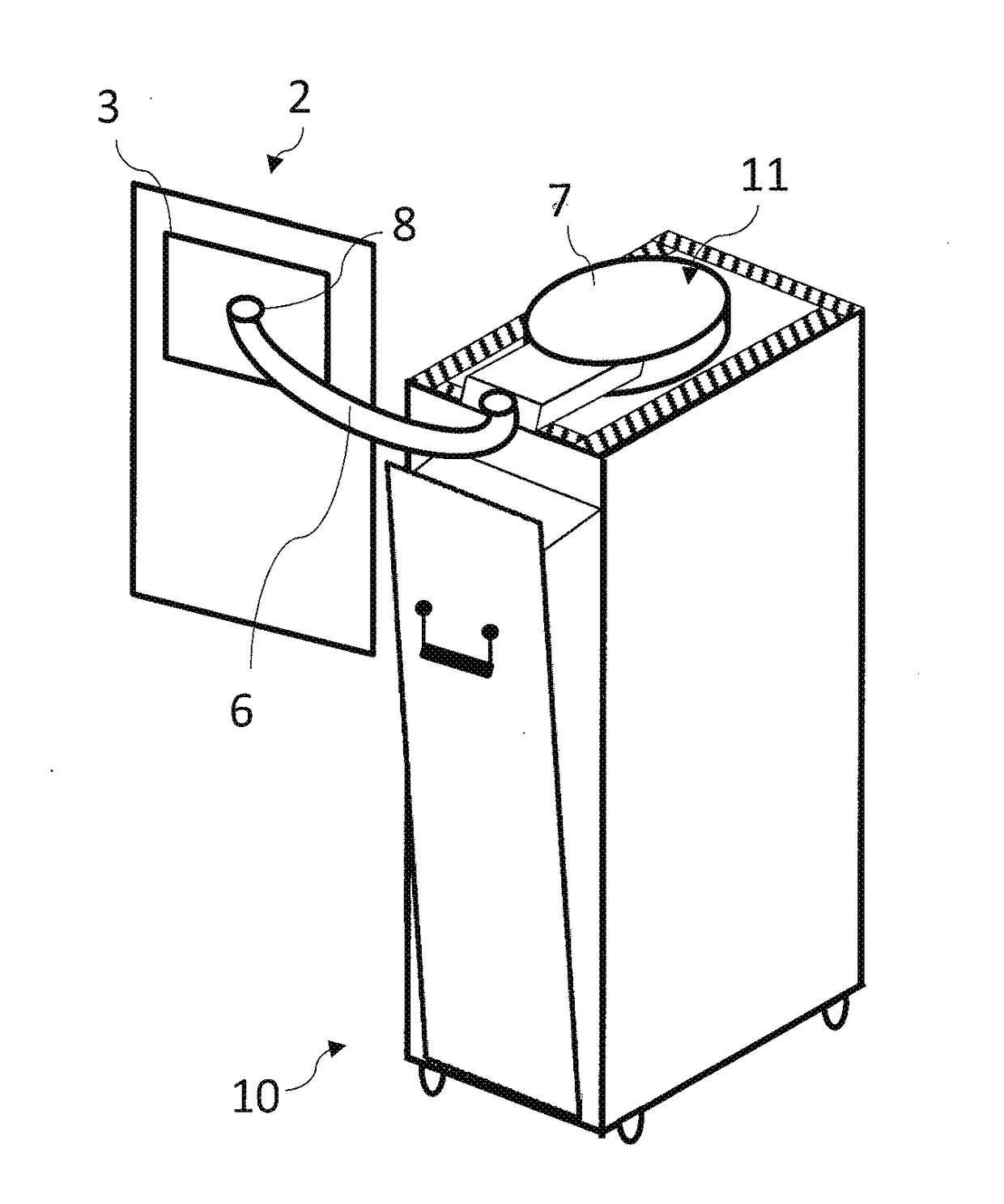

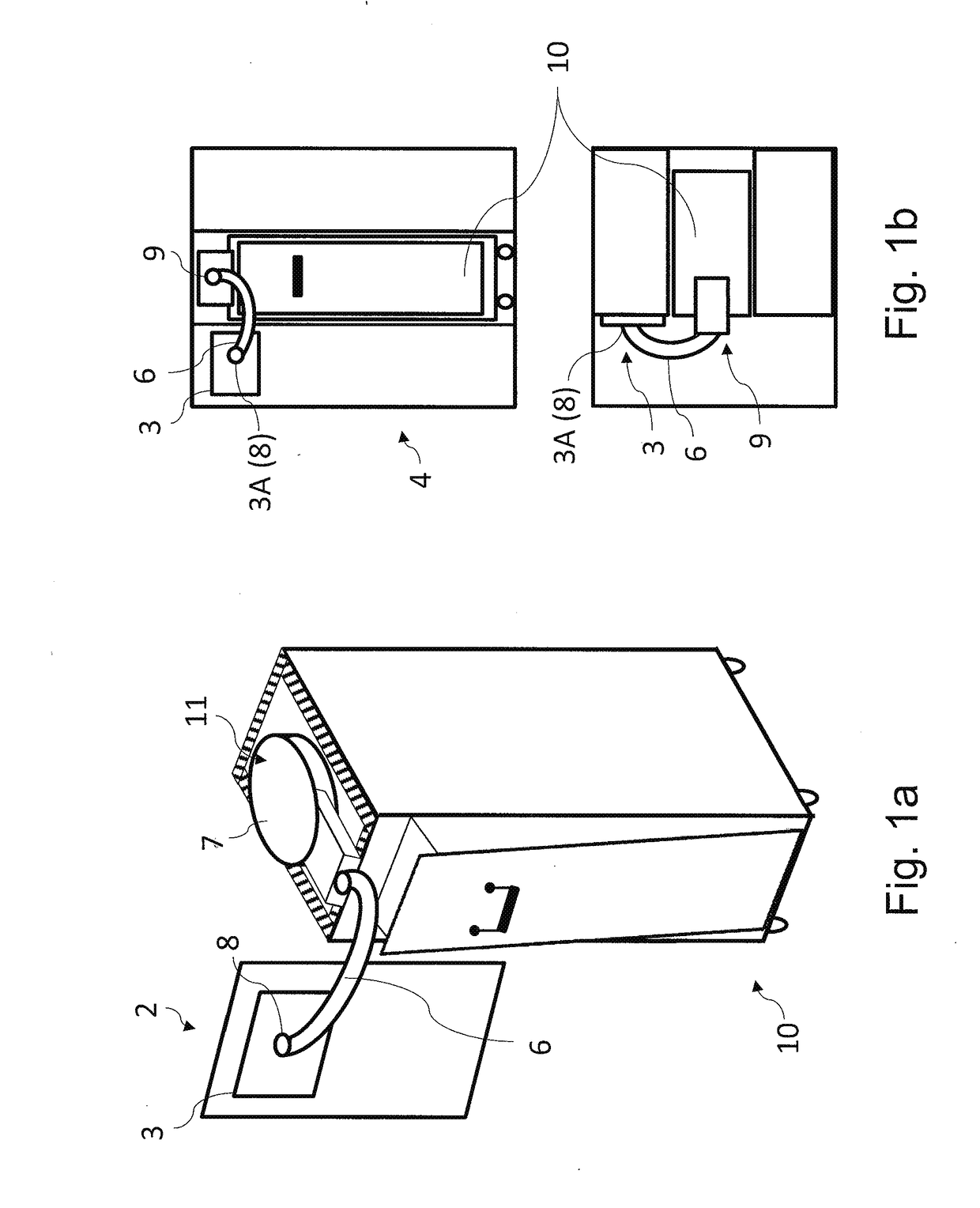

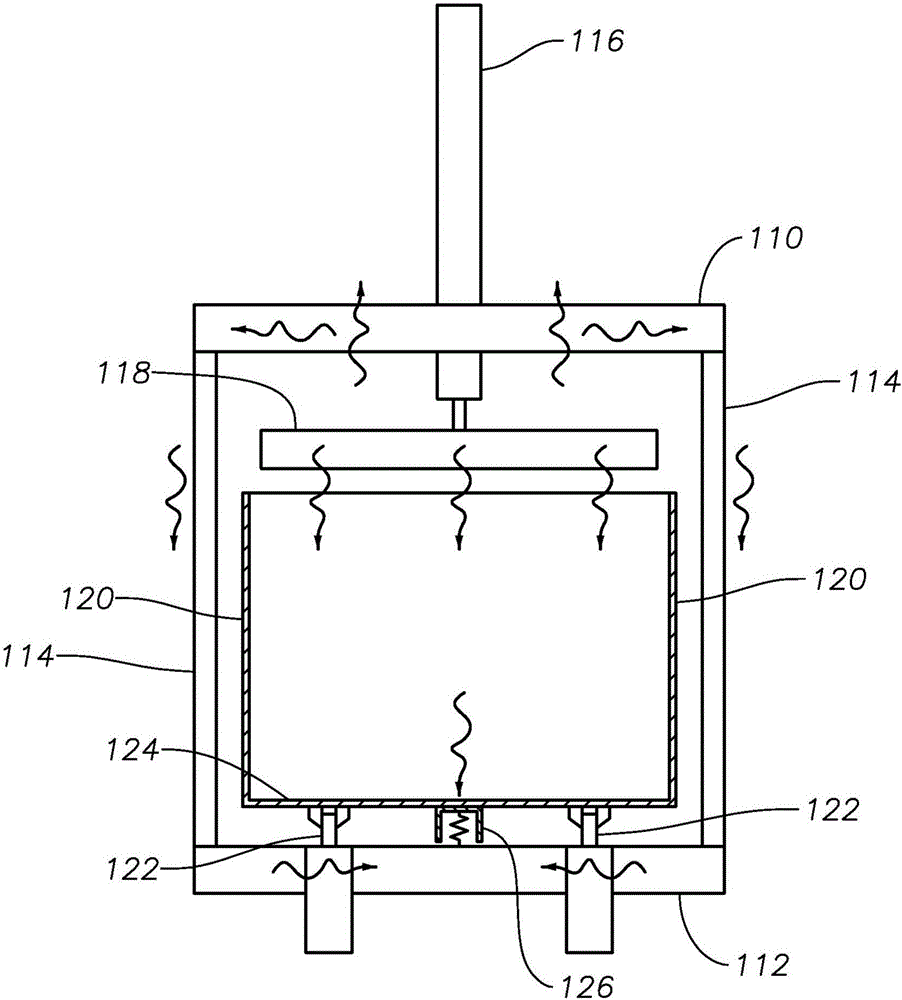

Waste Compaction System For A Vehicle, Cabin Monument For A Vehicle Having Such A Waste Compaction System And Vehicle Having At Least One Waste Compaction System

ActiveUS20150343732A1Waste collection capacityLarge capacityGalleysRefuse receptaclesDocking stationLine tubing

A waste compaction system for a vehicle includes a moveable trolley for storing waste, and a docking station integratable into a cabin monument for inserting the trolley. The trolley includes a housing having an opening for inserting waste, a vacuum waste compacting mechanism inside the housing and a first suction port accessible from outside the housing, the first suction port being couplable with the vacuum waste compacting mechanism. The docking station and the trolley are adapted to each other such that the trolley is engageable with the docking station, and wherein the docking station includes a second suction port couplable with a suction line in the vehicle and the first suction port. Resultantly, a lightweight and efficient waste compaction system is provided, which allows moving the trolley for collecting waste inside a cabin of the vehicle.

Owner:AIRBUS OPERATIONS GMBH

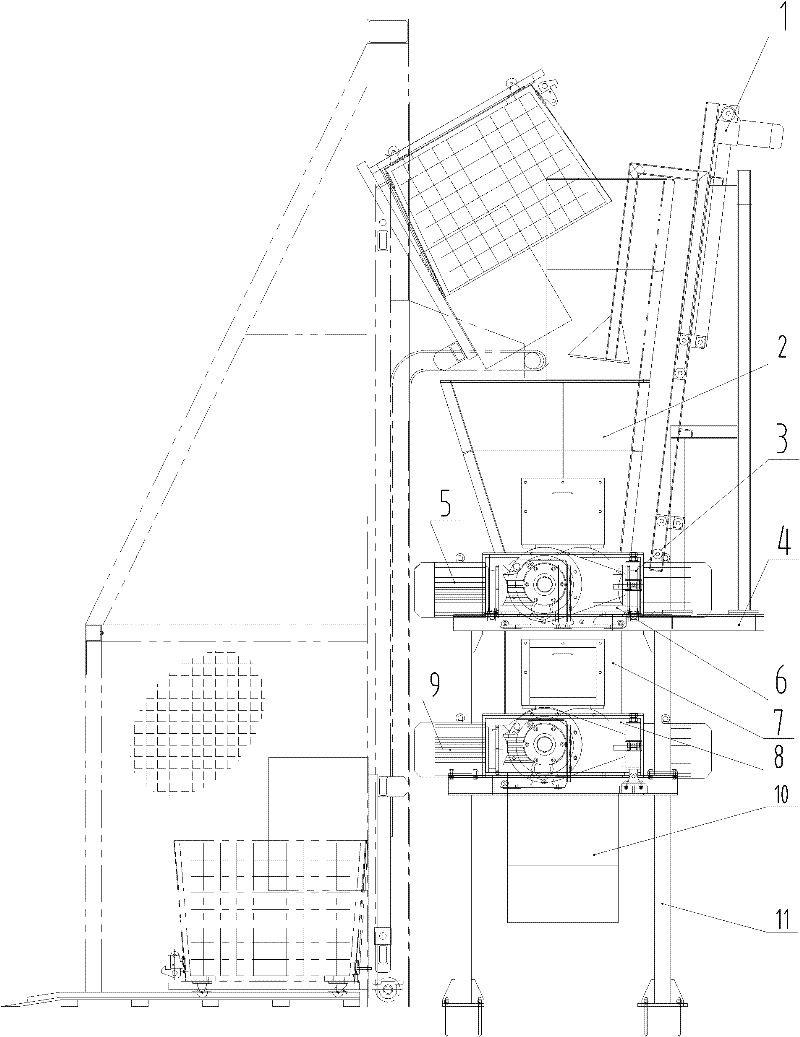

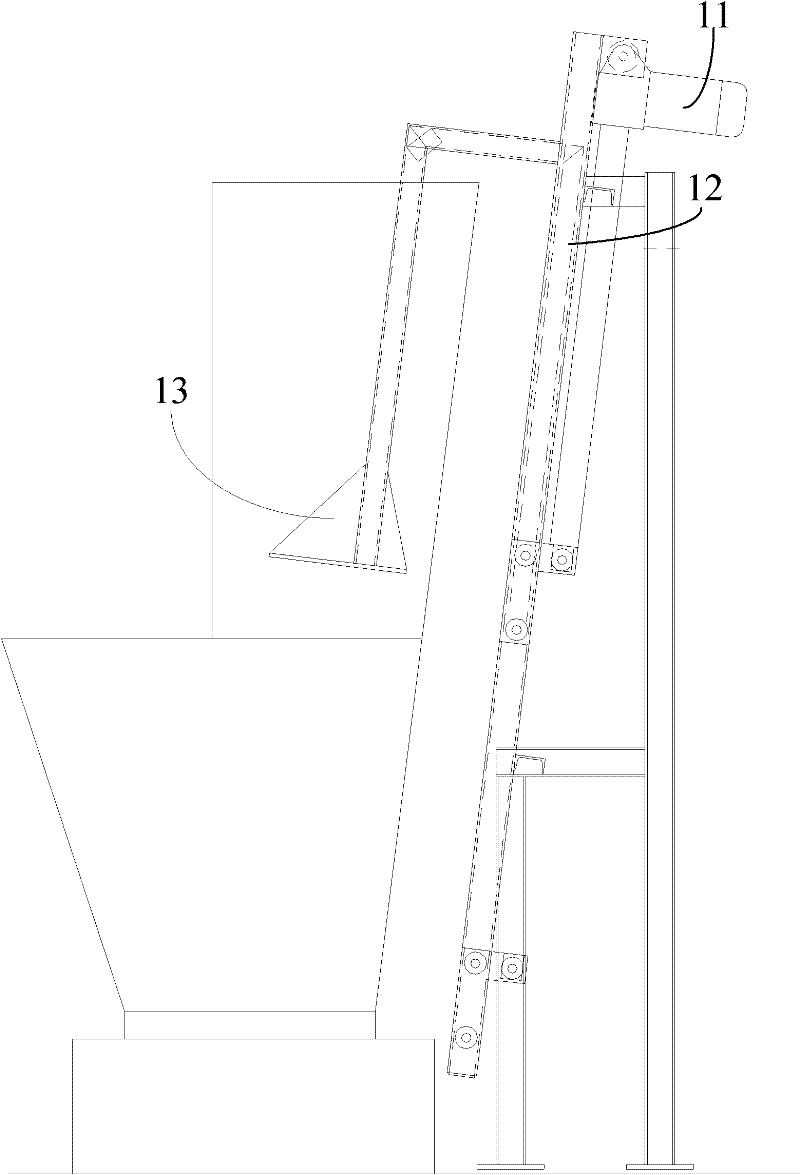

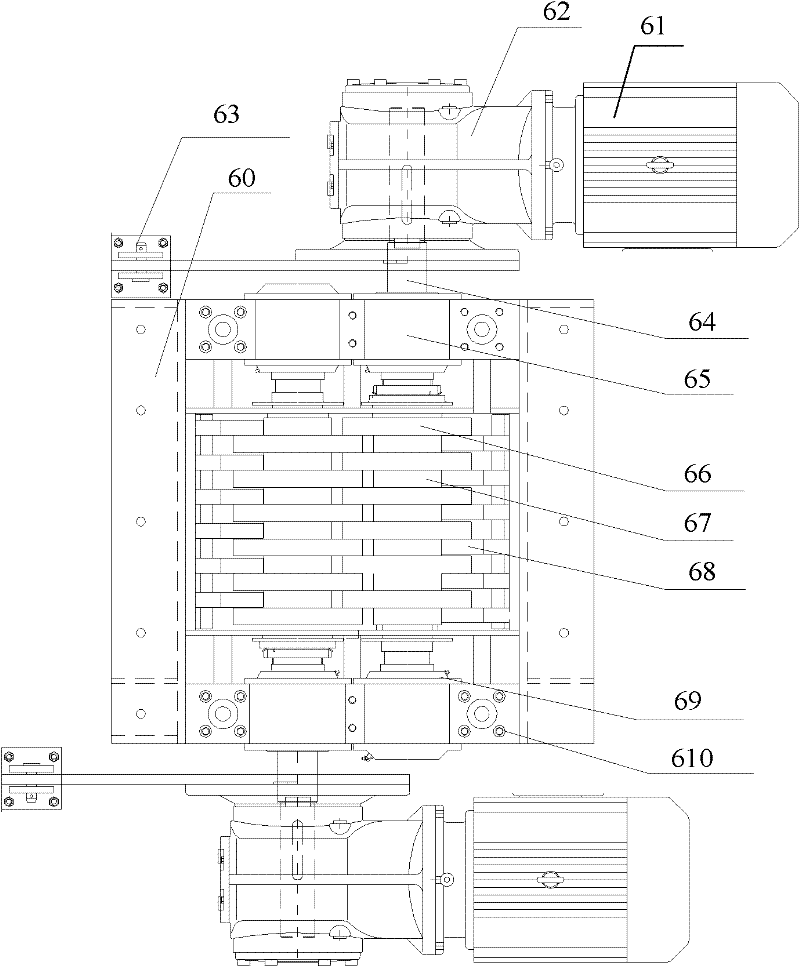

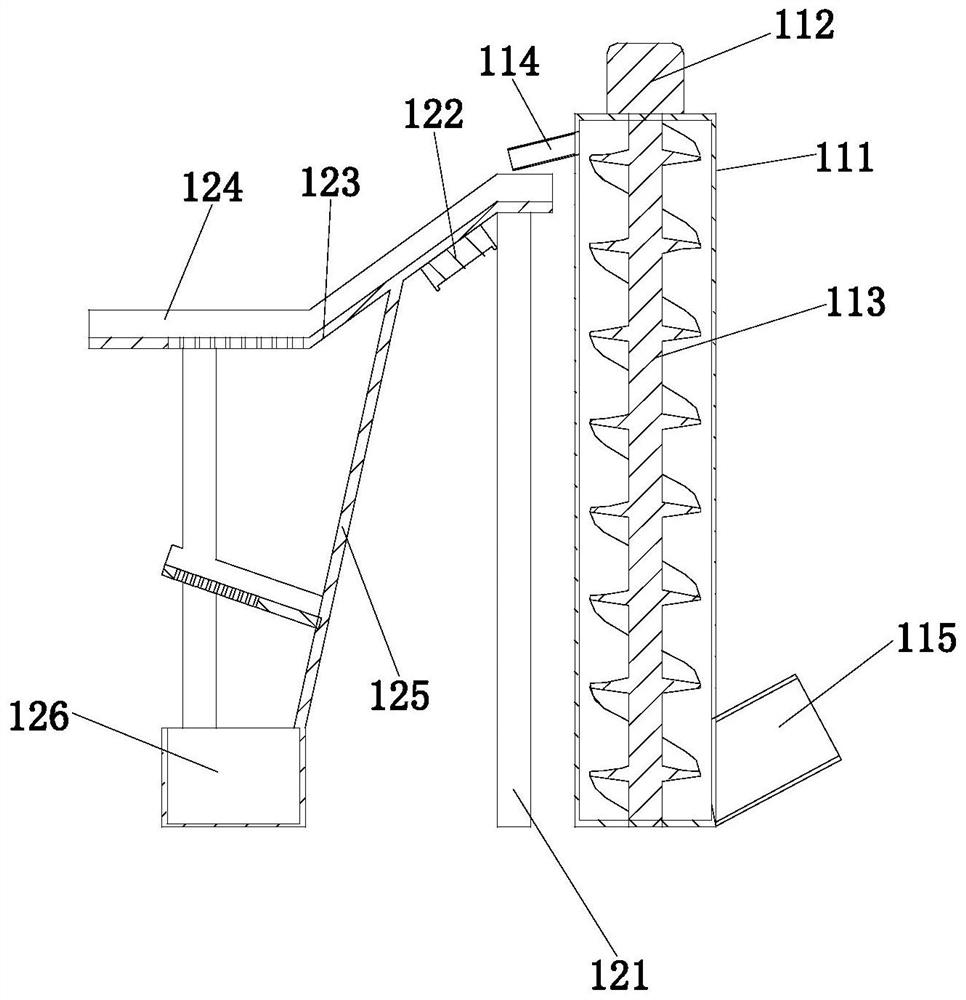

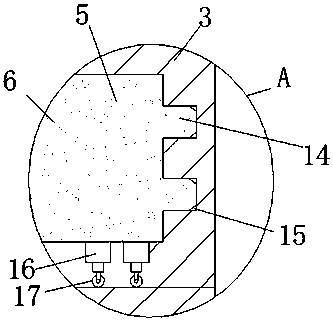

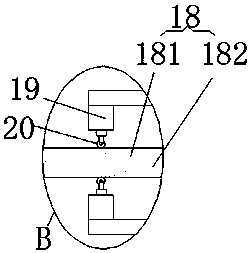

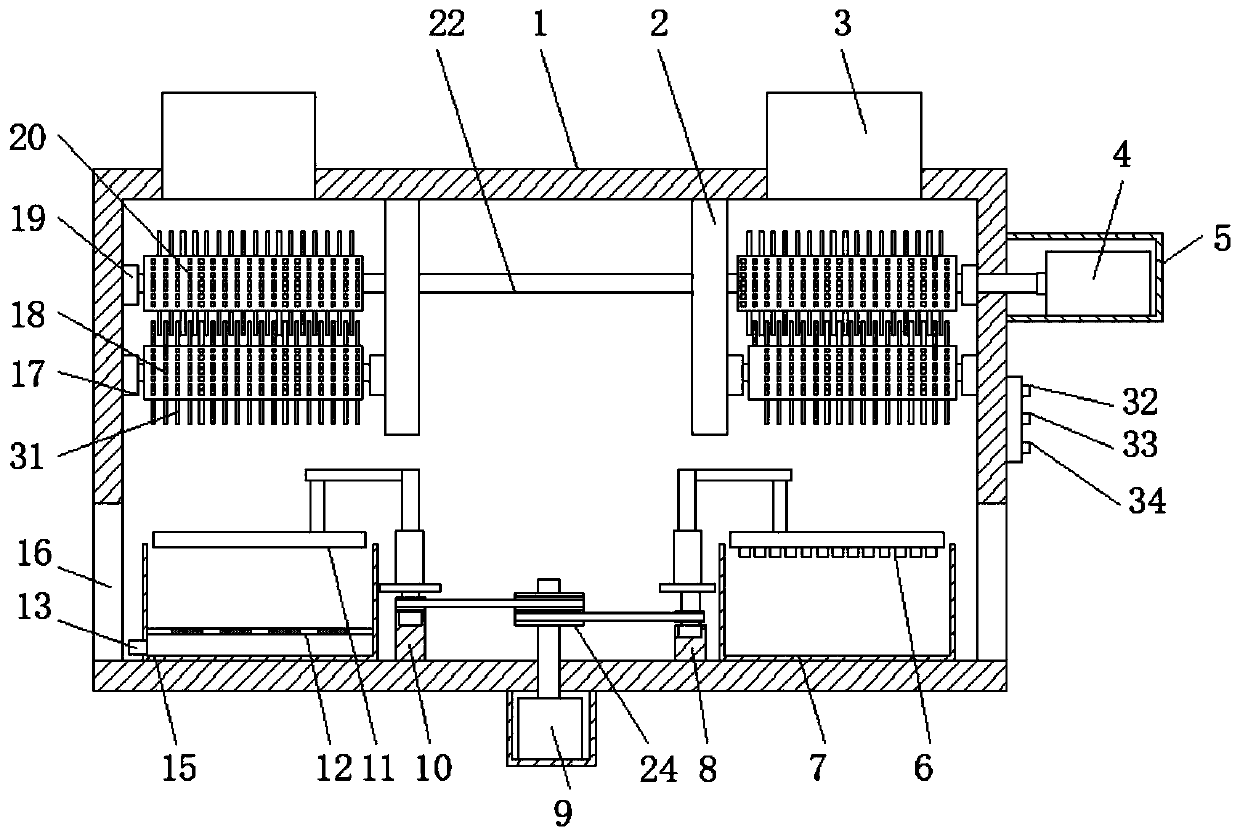

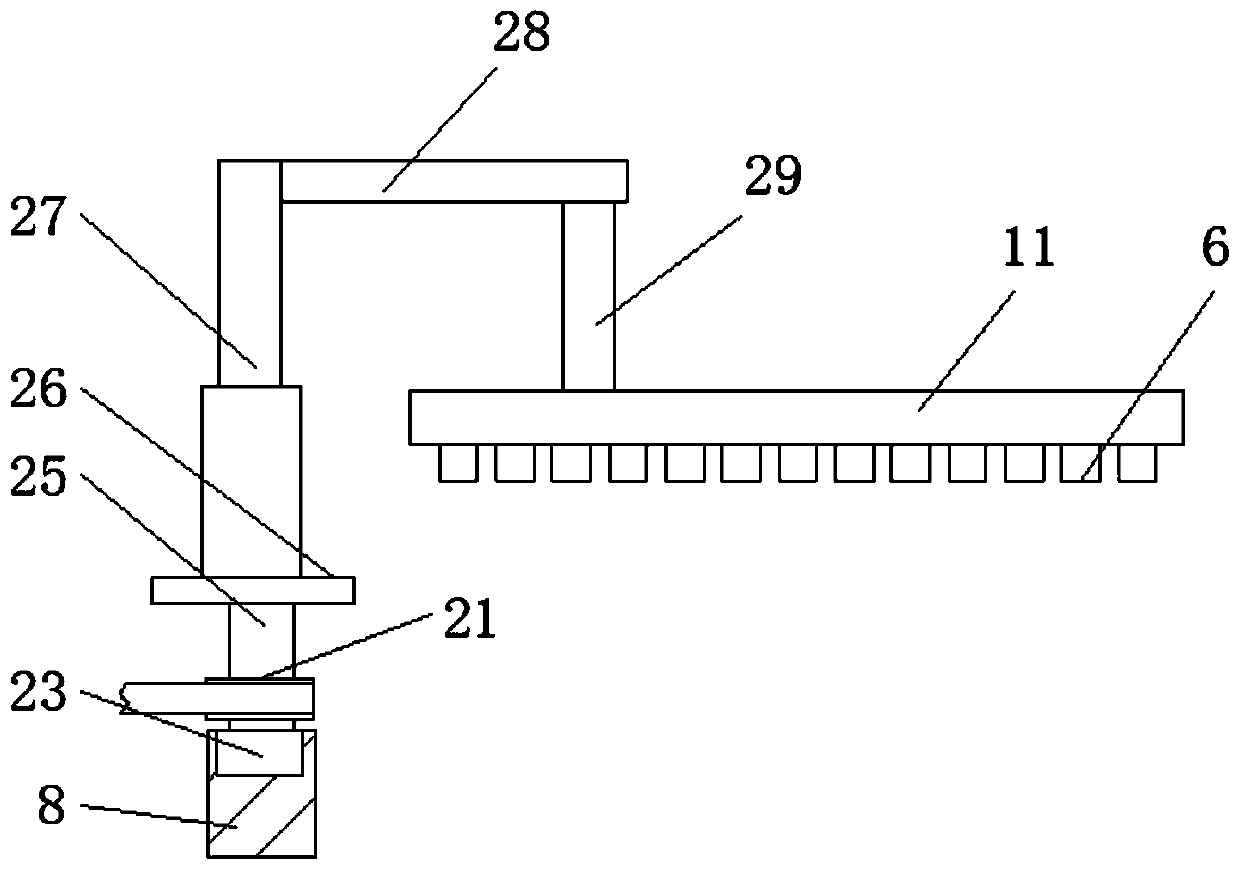

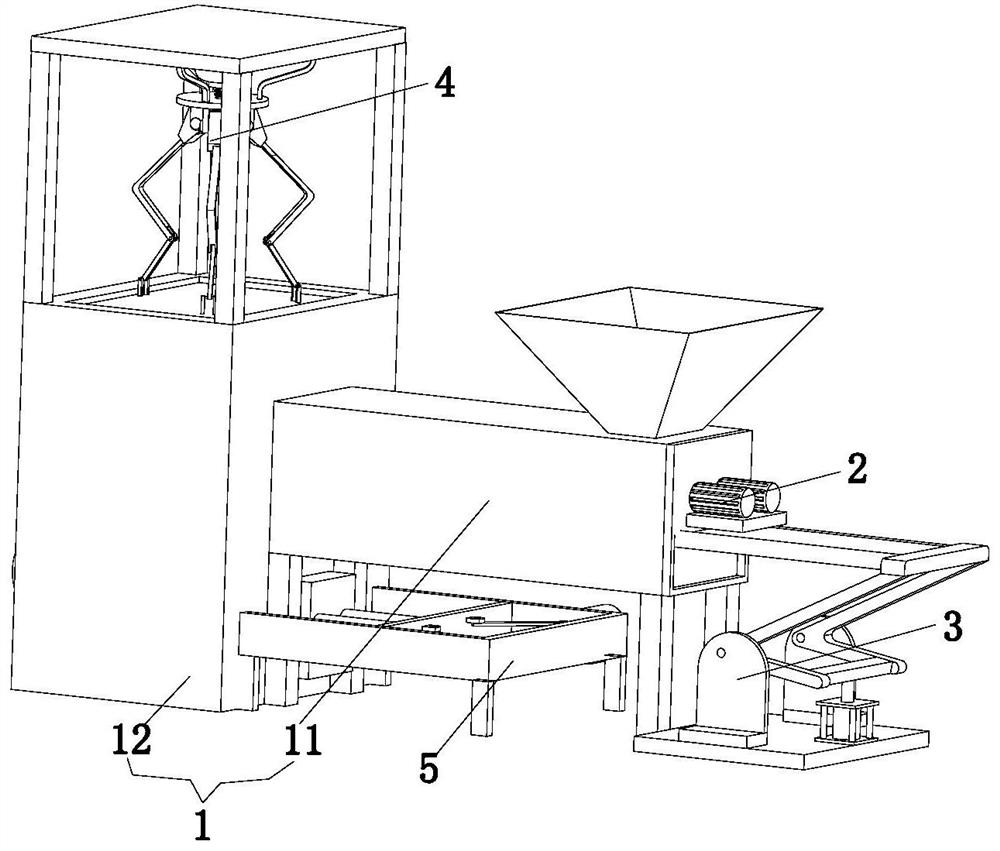

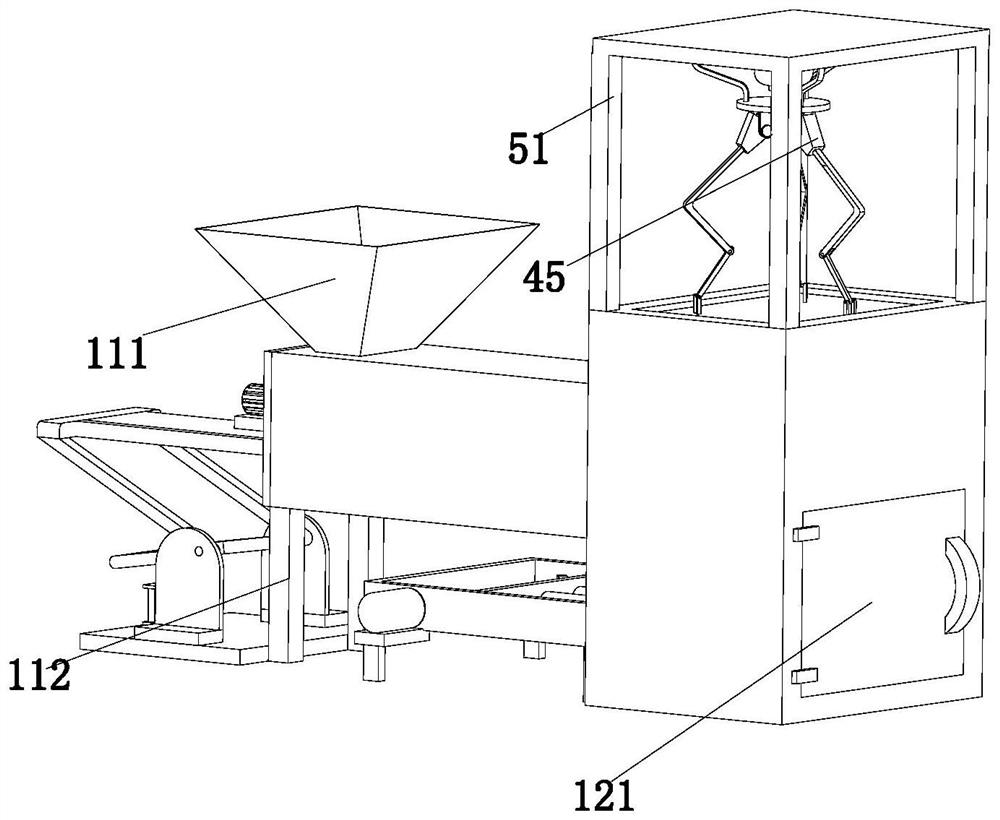

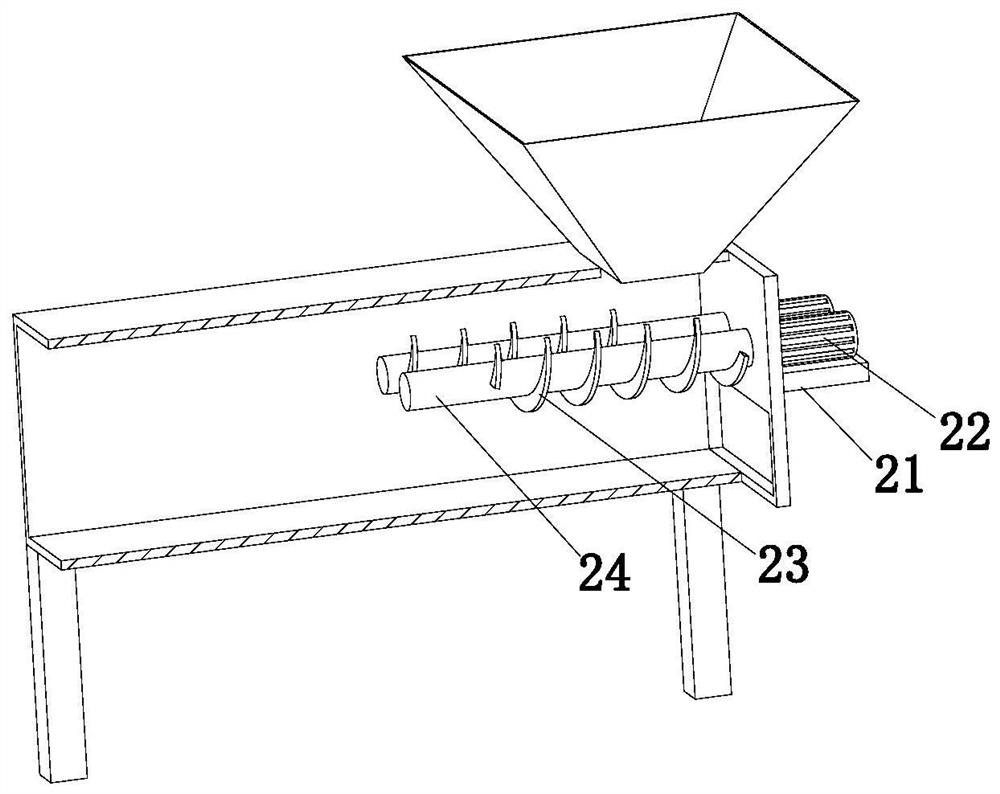

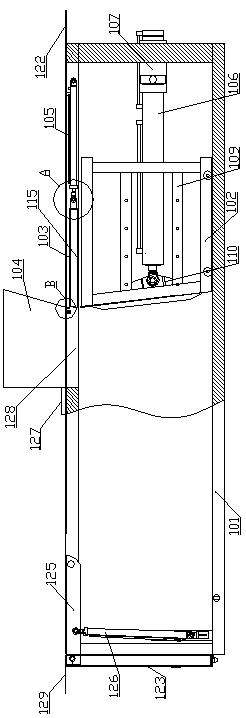

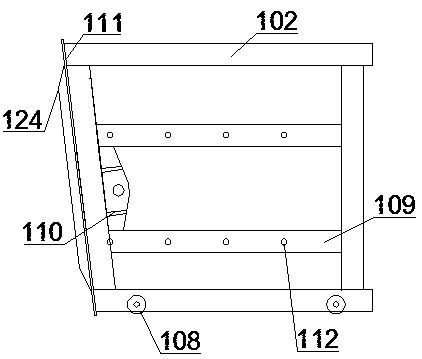

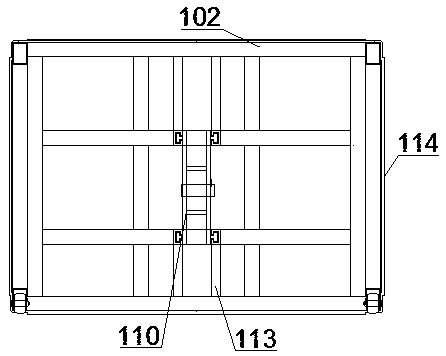

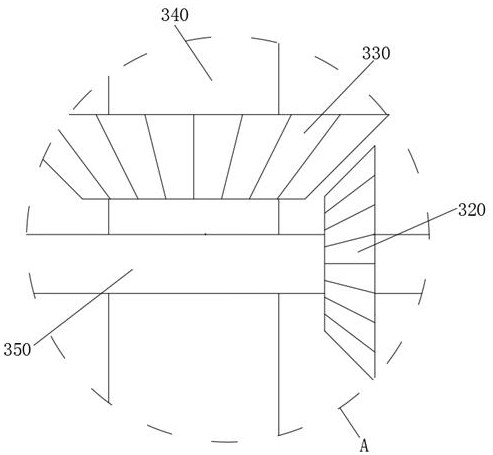

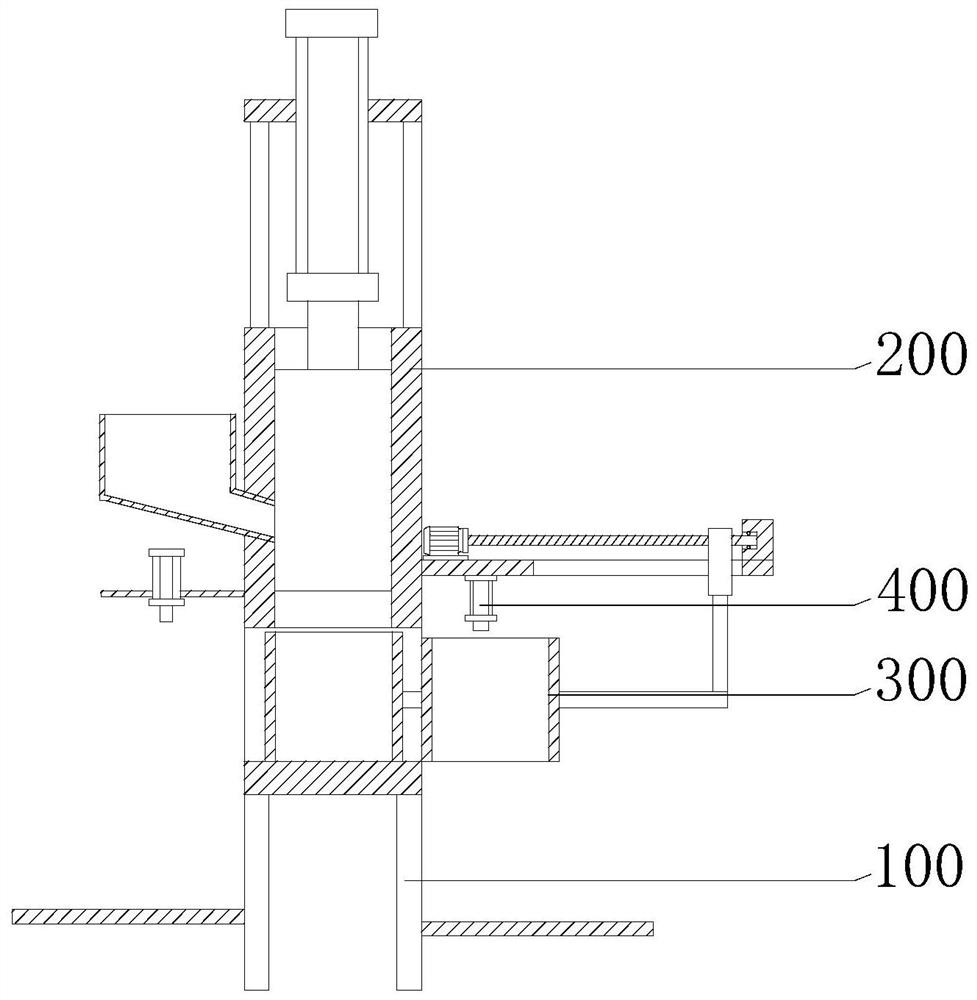

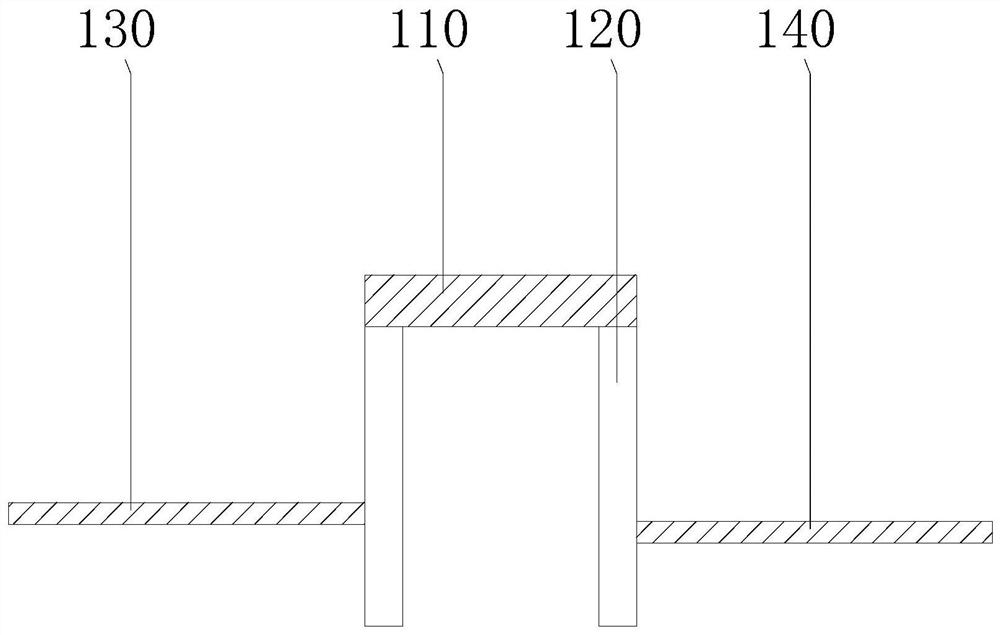

Medical waste garbage crushing equipment

The invention discloses medical waste garbage crushing equipment, and belongs to the field of garbage treatment equipment. The equipment comprises an upper stander, a lower stander, a first-stage crusher, a second-stage crusher, a pushing mechanism, a feeding mechanism and an electric control device, wherein the upper stander is arranged on the lower stander; the first-stage crusher is arranged on the upper stander; the feeding mechanism is arranged at a feed port of the first-stage crusher; the upper stander above the feeding mechanism is provided with the pushing mechanism; the lower stander below the first-stage crusher is provided with the second-stage crusher; a feed port of the second-stage crusher corresponds to a discharge port of the first-stage crusher; and the electric control device for controlling working states of the first-stage crusher and the second-stage crusher is connected with control ends of the first-stage crusher and the second-stage crusher respectively. The crushing equipment can be used for carrying out two-stage crushing, coarse crushing and fine crushing on medical waste garbage, so that the space and the size for filling, the transport volume and the transport cost are reduced, and waste compaction for filling is facilitated. The crushing equipment has the advantages of easiness and convenience in operation, high efficiency, good crushing effect and the like.

Owner:SOUND ENVIRONMENTAL RESOURCES

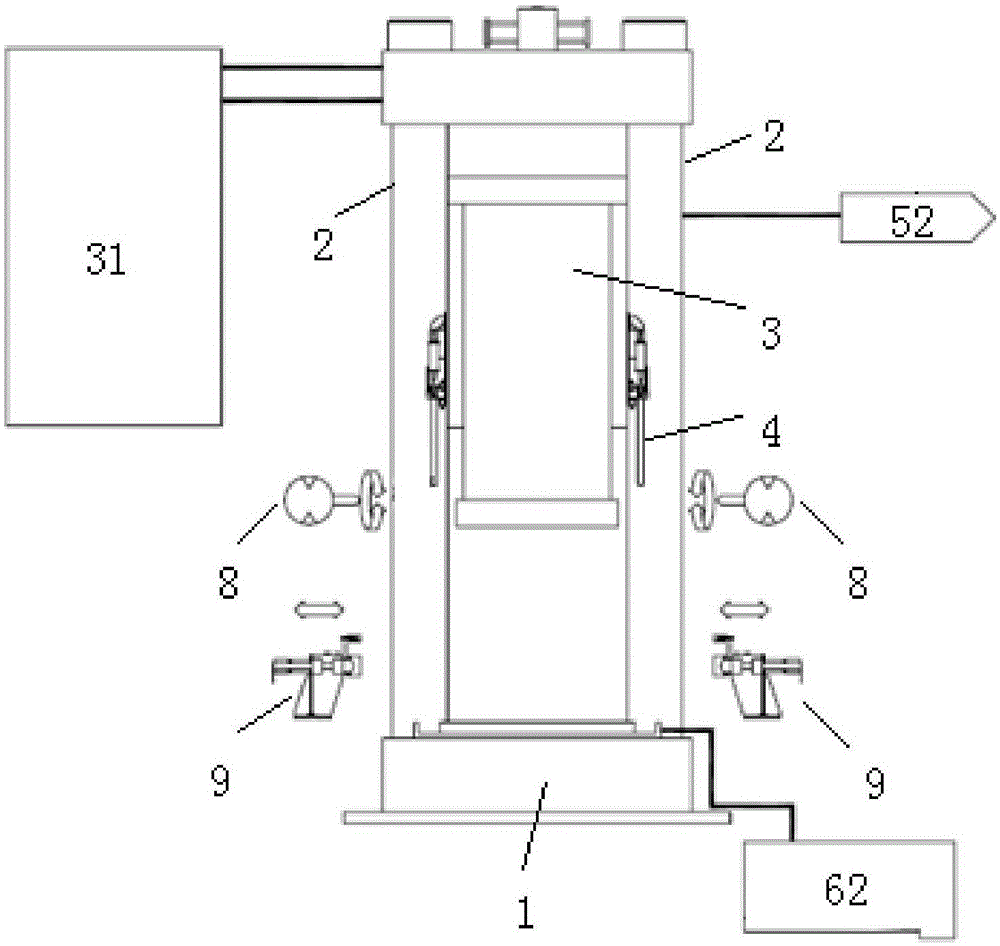

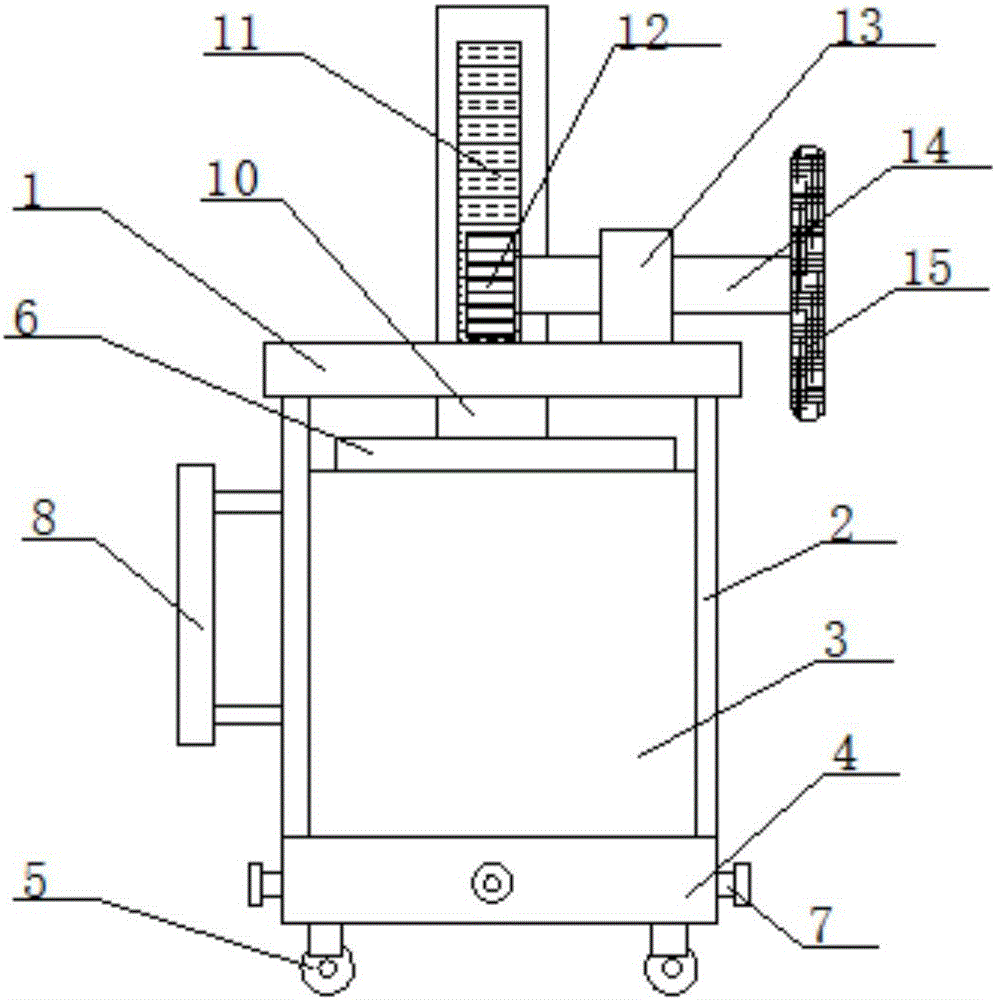

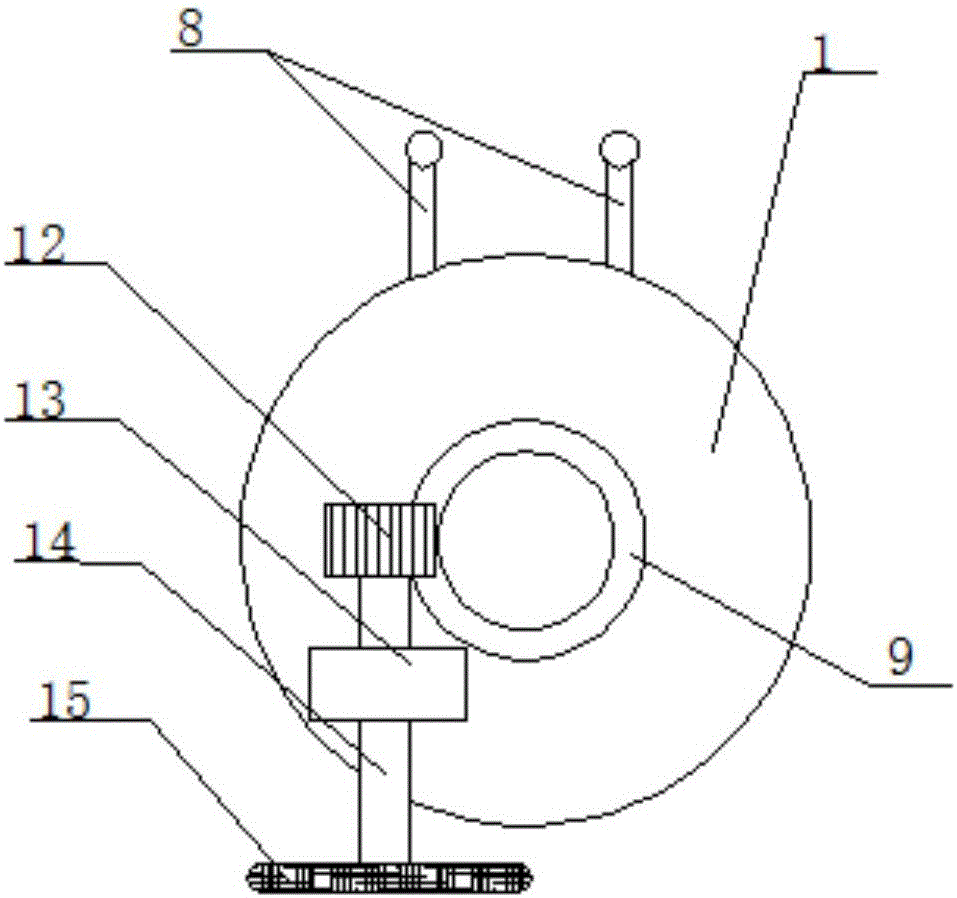

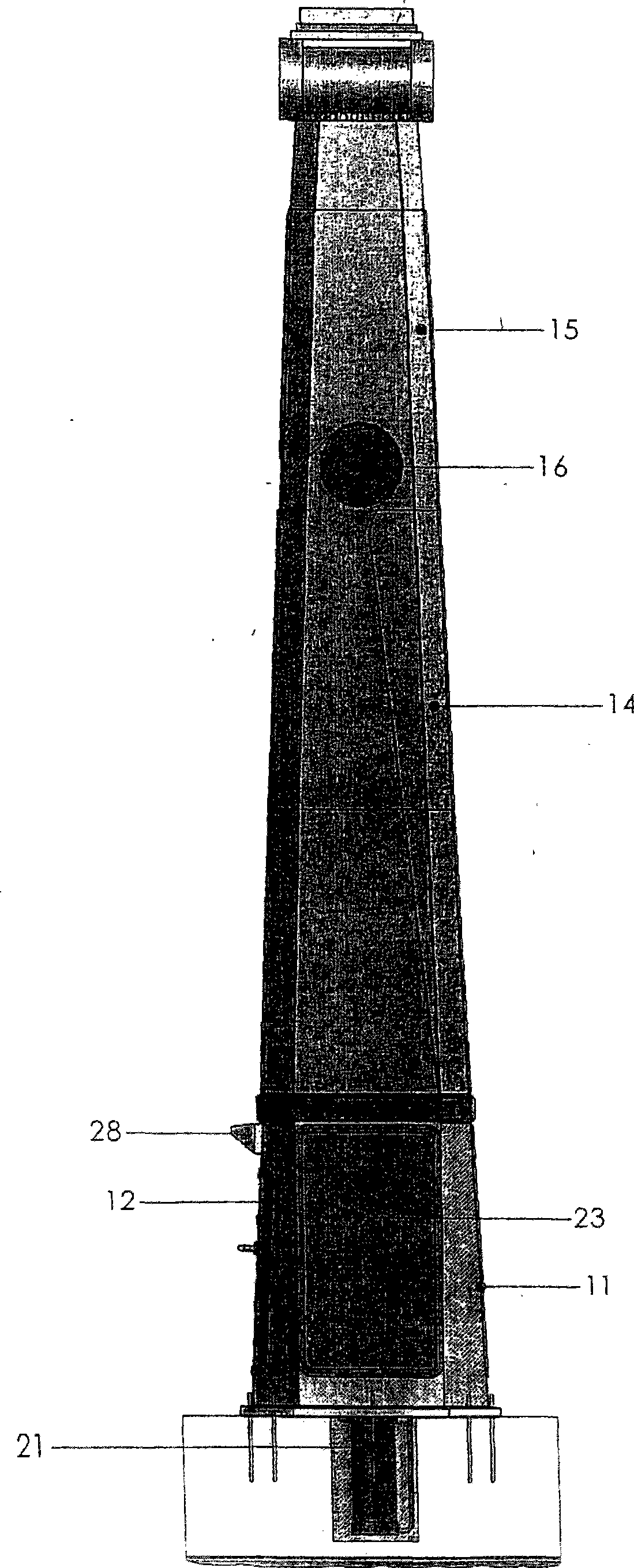

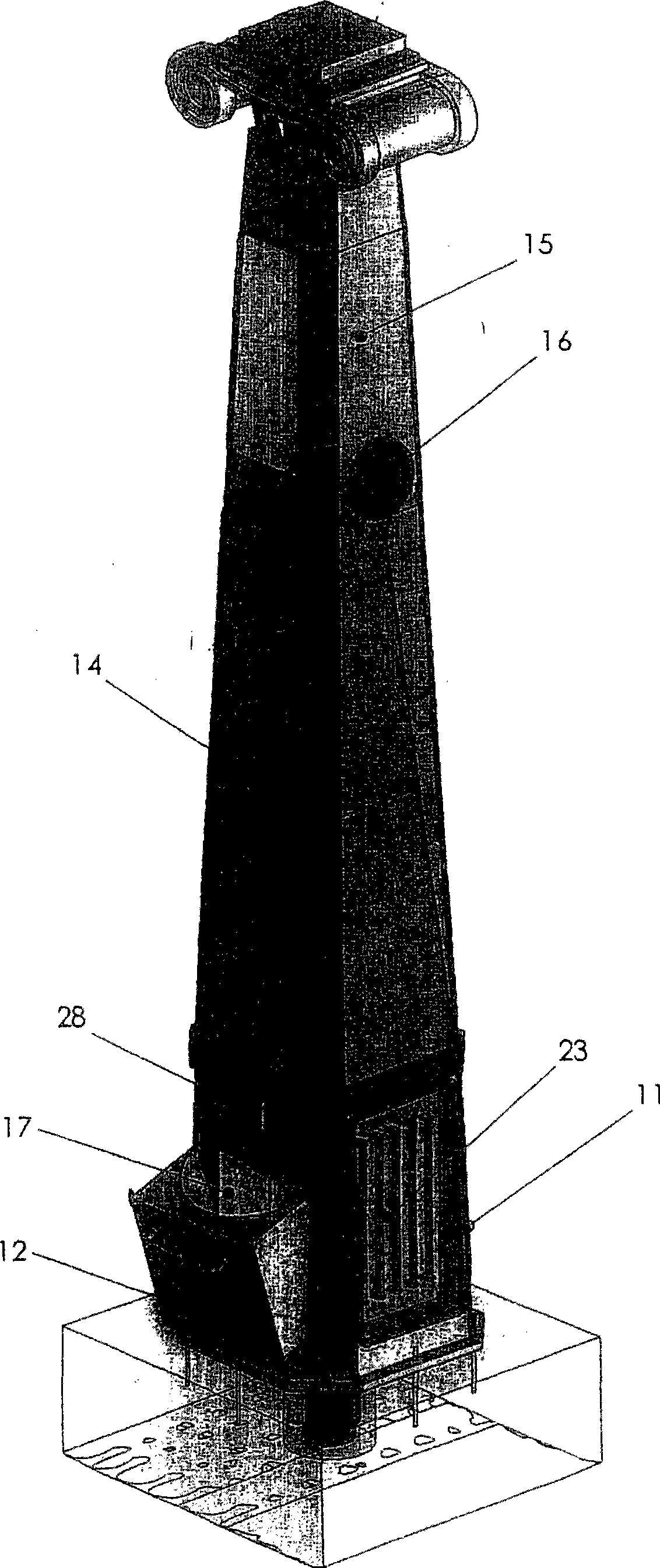

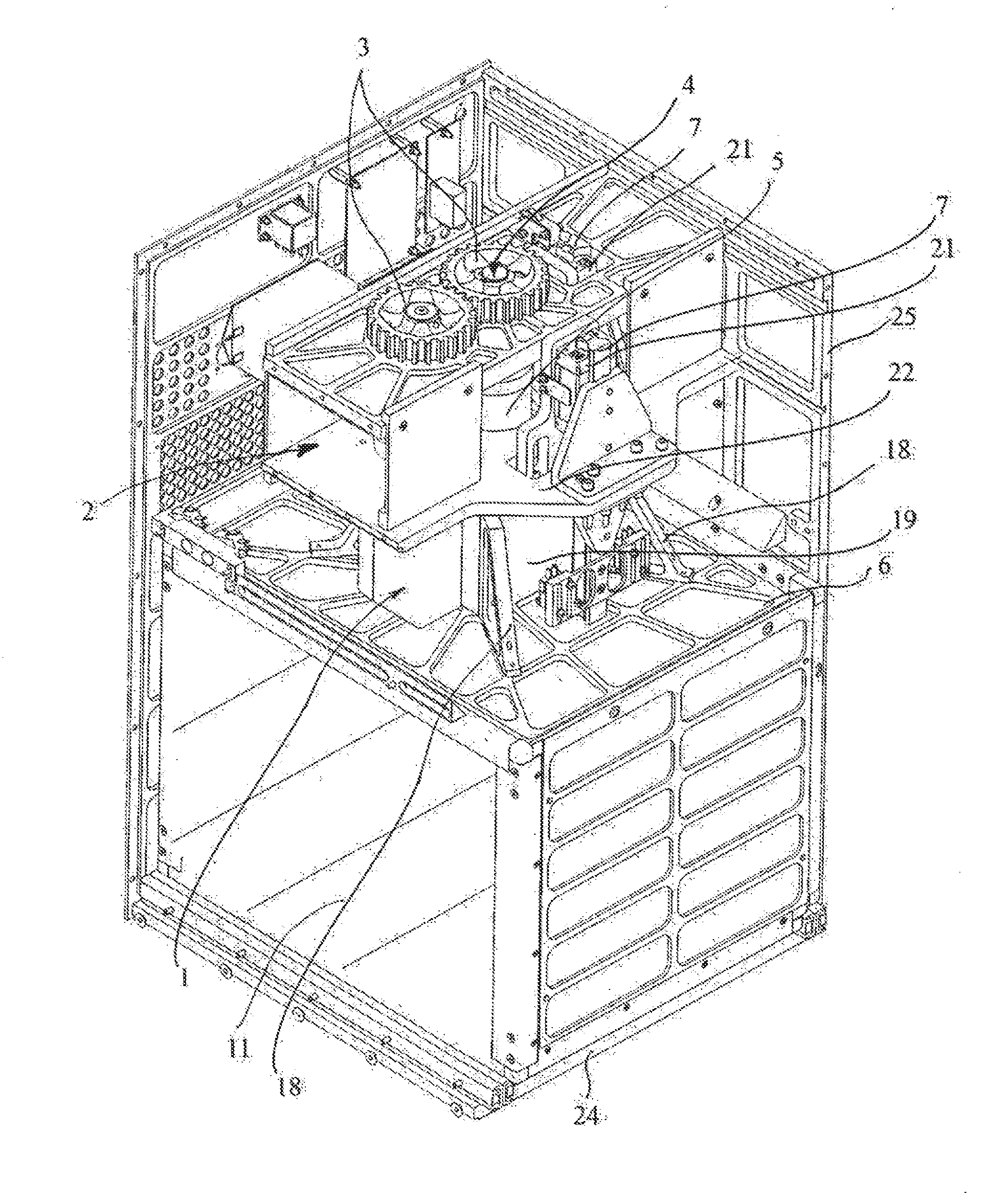

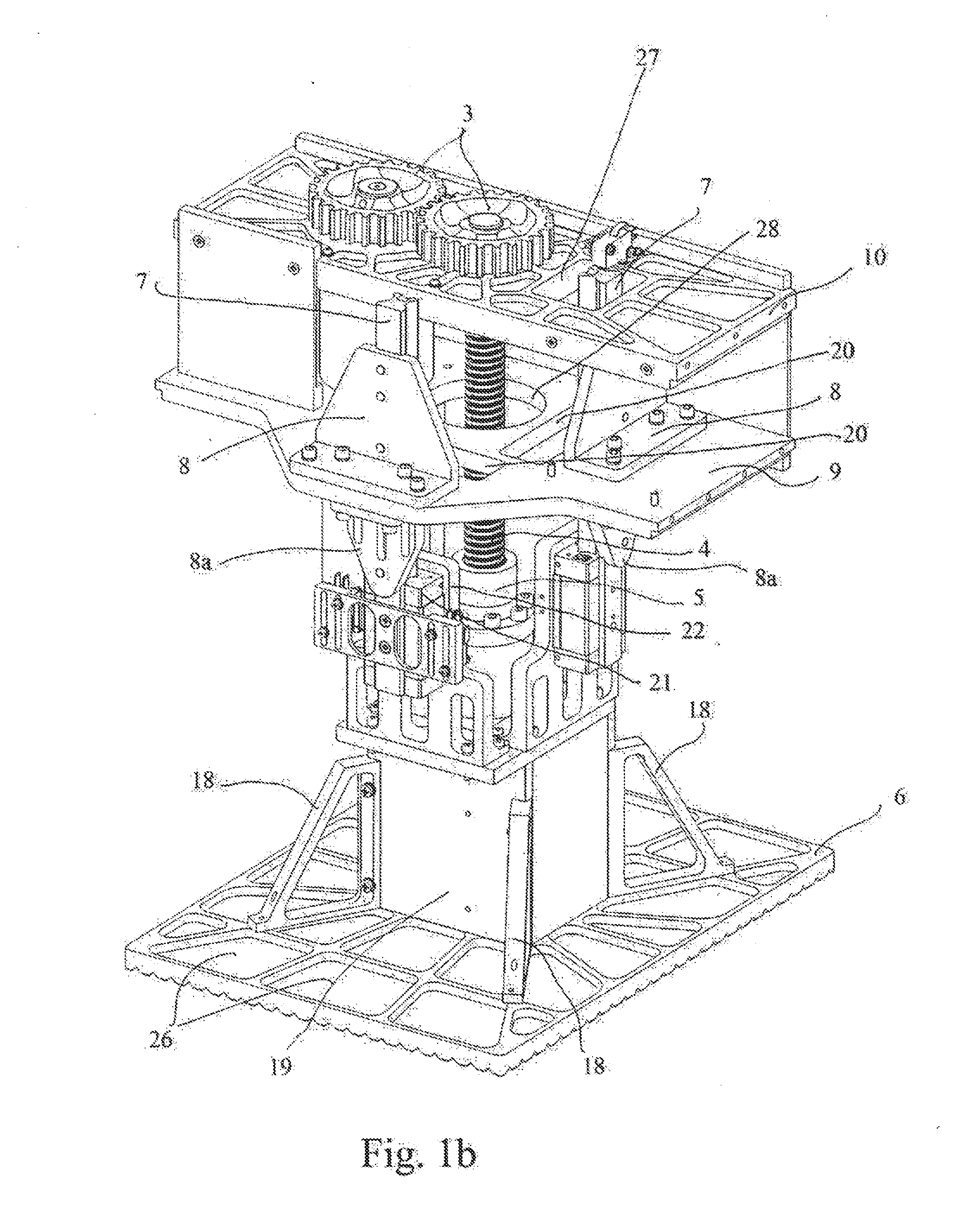

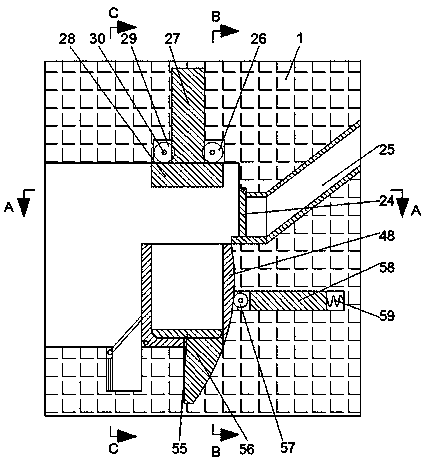

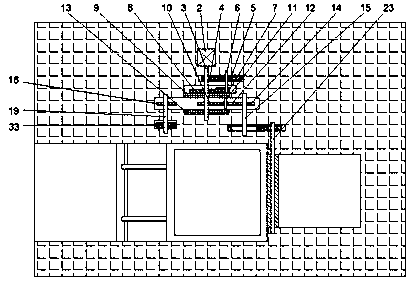

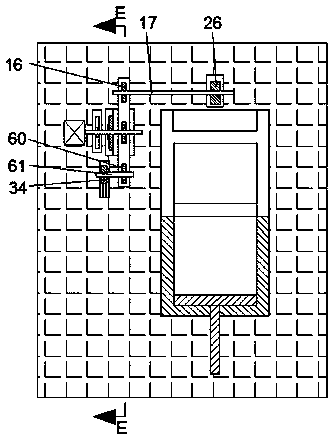

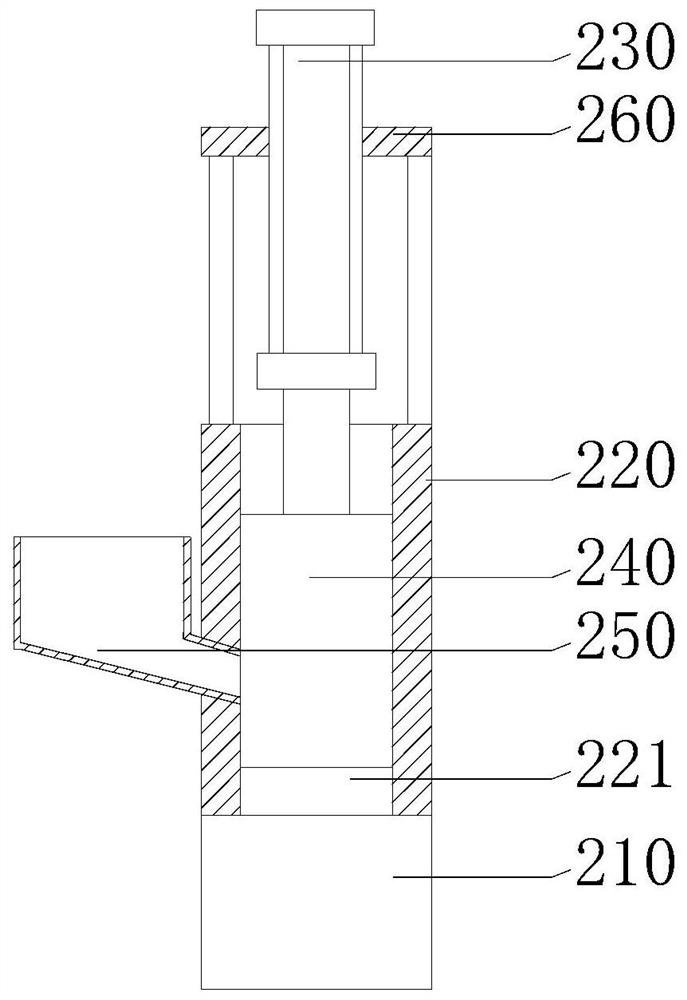

Super compacting machine used for compacting radioactive solid waste of nuclear power plant

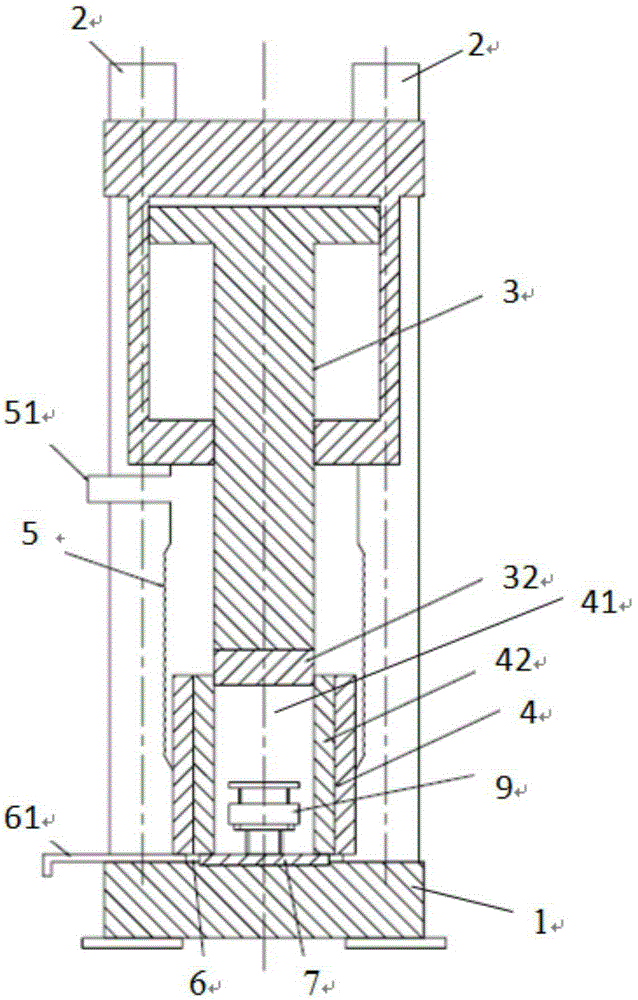

PendingCN105109083ASmall footprintHigh capacity reduction ratioPressesNuclear powerRadioactive waste

The invention provides a super compacting machine used for compacting radioactive solid waste of a nuclear power plant. The super compacting machine comprises a base, a piston and a mould. Structure columns are arranged on the base. The piston is driven by a hydraulic unit to ascend and descend along the structure columns. The mould is driven by the hydraulic unit to ascend and descend along the structure columns and provided with a containing cavity used for containing the to-be-compacted waste. The mould descends to the lowermost point and surrounds the to-be-compacted waste placed on the base so that the to-be-compacted waste placed on the base can be contained in the containing cavity. The piston is inserted into the containing cavity after descending so as to press the to-be-compacted waste contained in the containing cavity towards the base. Through the super compacting machine used for compacting the radioactive solid waste of the nuclear power plant, the solid waste can be compacted into cakes, so that space occupied by the solid waste generated by the nuclear power plant in transportation and storage is greatly reduced.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

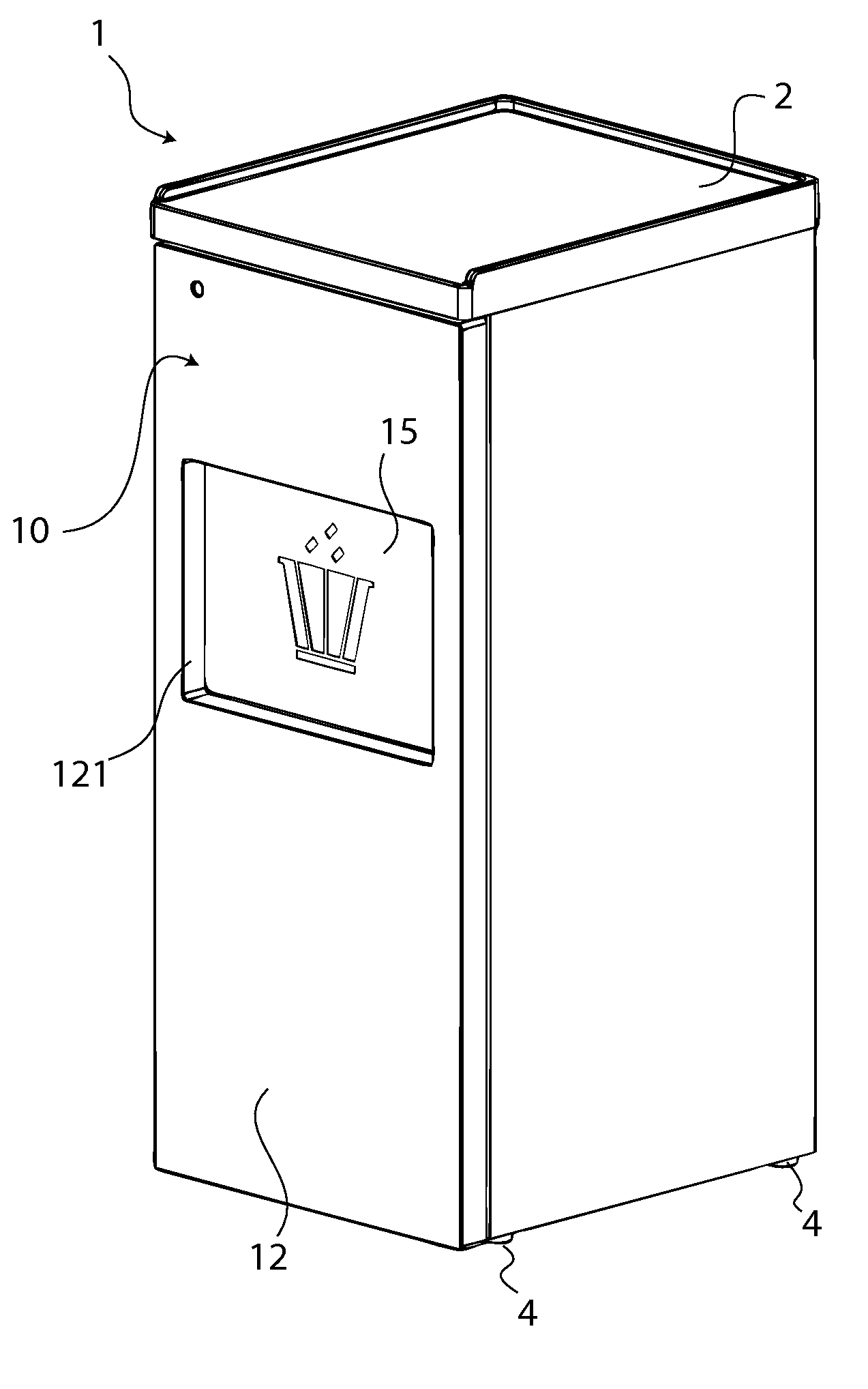

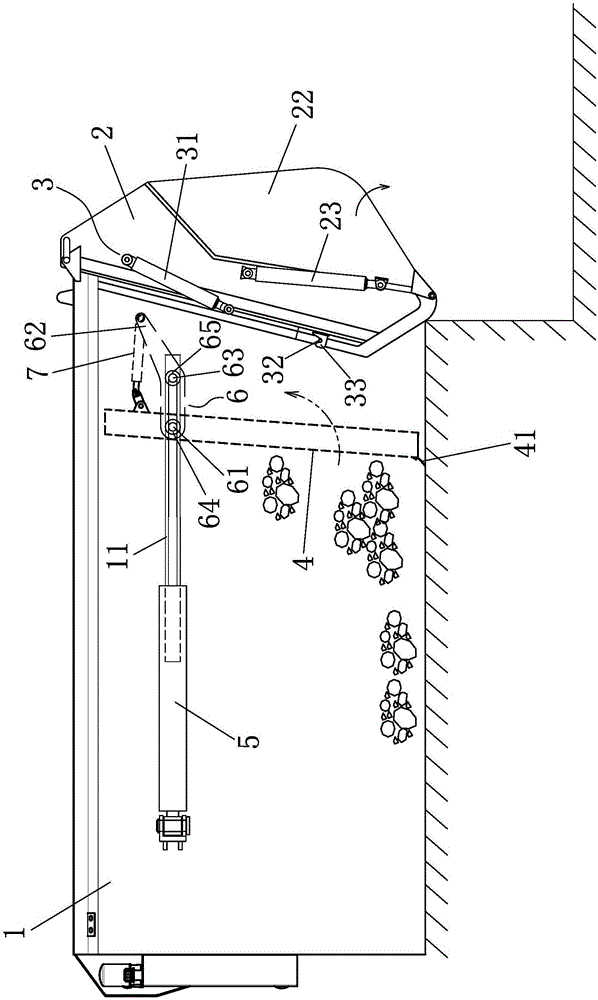

Waste compaction and lift gate mechanism

A waste bin with an automated waste compaction mechanism and a automated gate lifting mechanism for convenience usage. The present invention makes use of sensors and switches to allow the compaction and gate mechanism to operate automatically. The unique combination of components also ensures the reliability of the mechanism.

Owner:KACHKOVSKY OLIVER

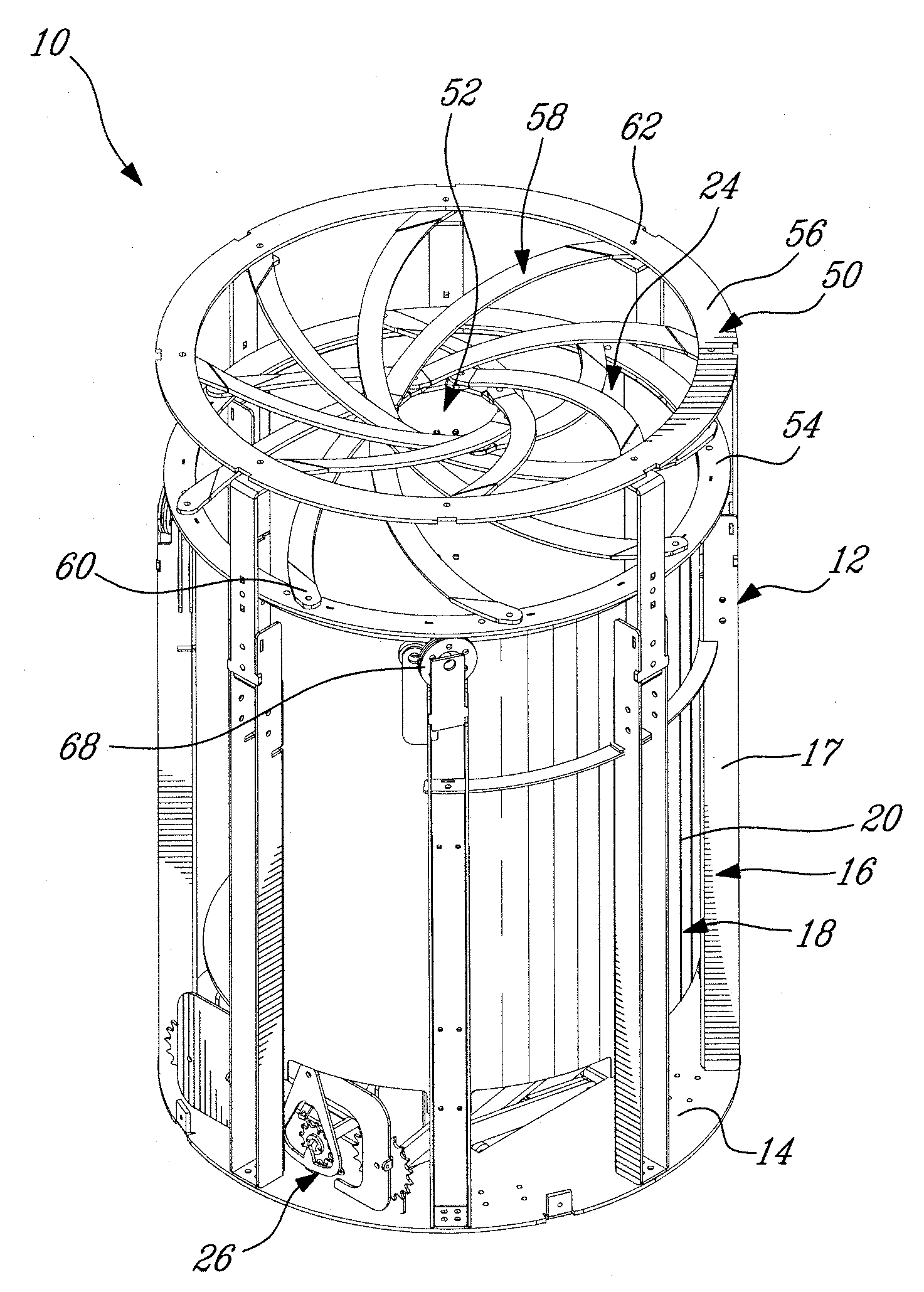

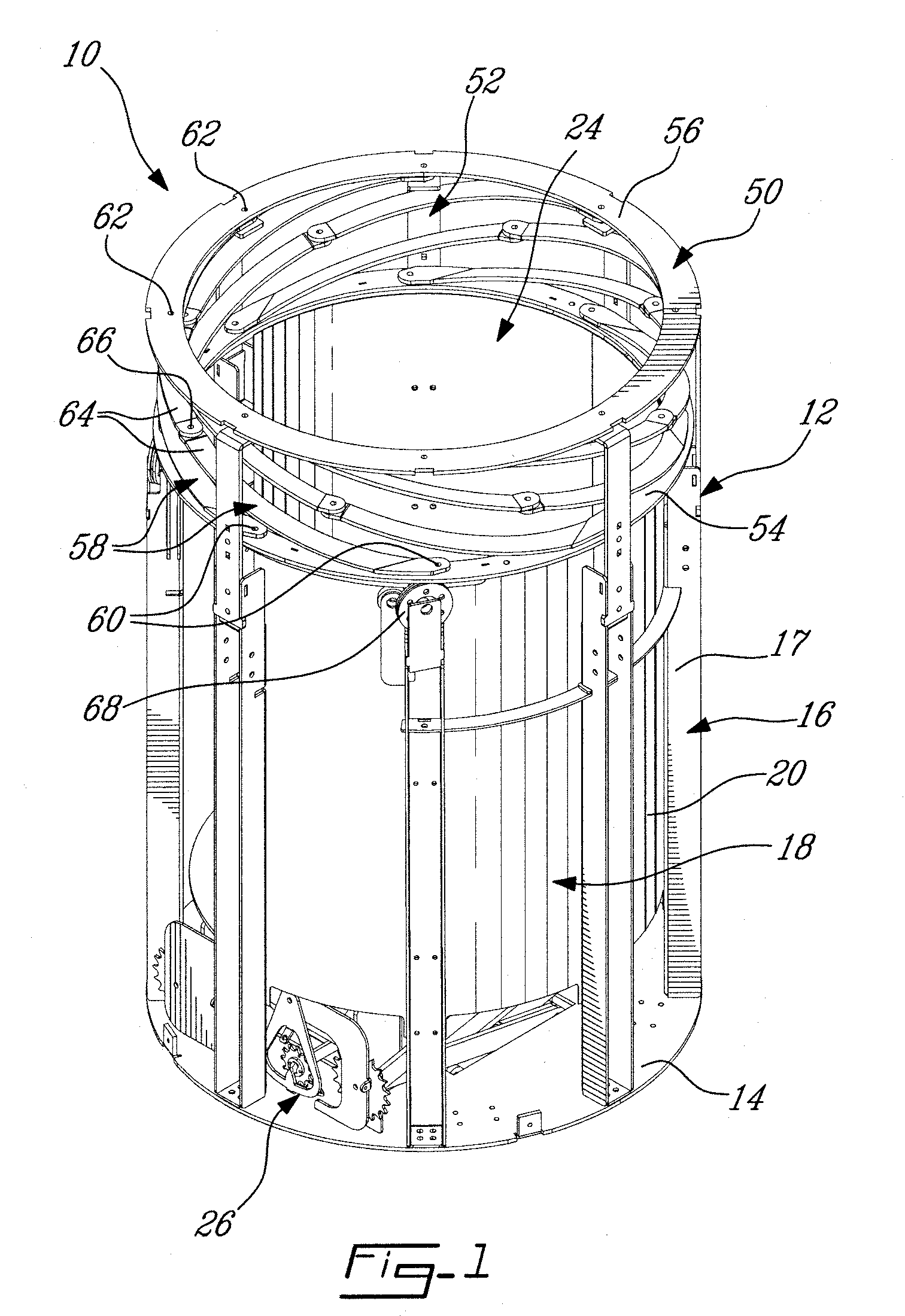

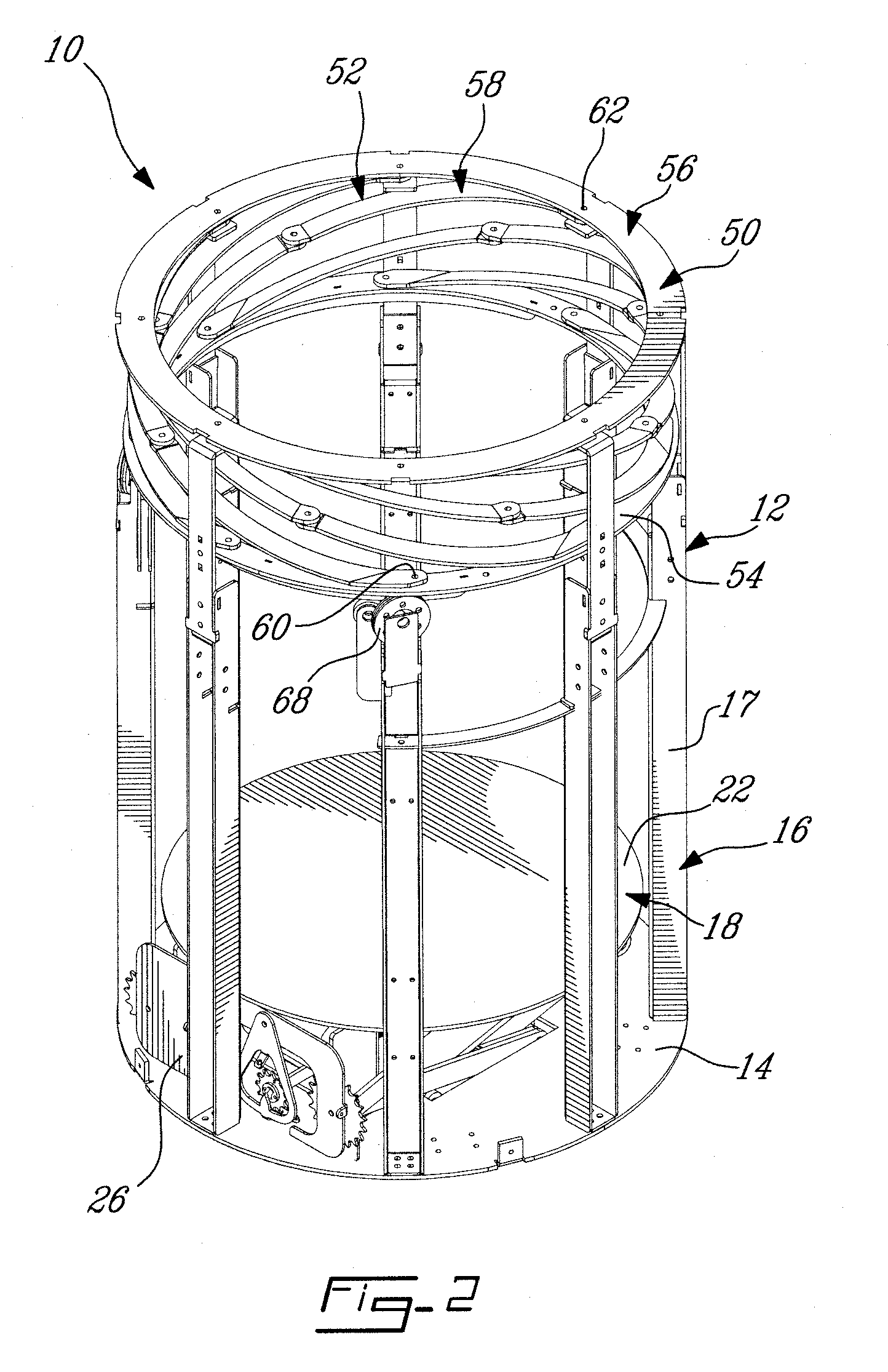

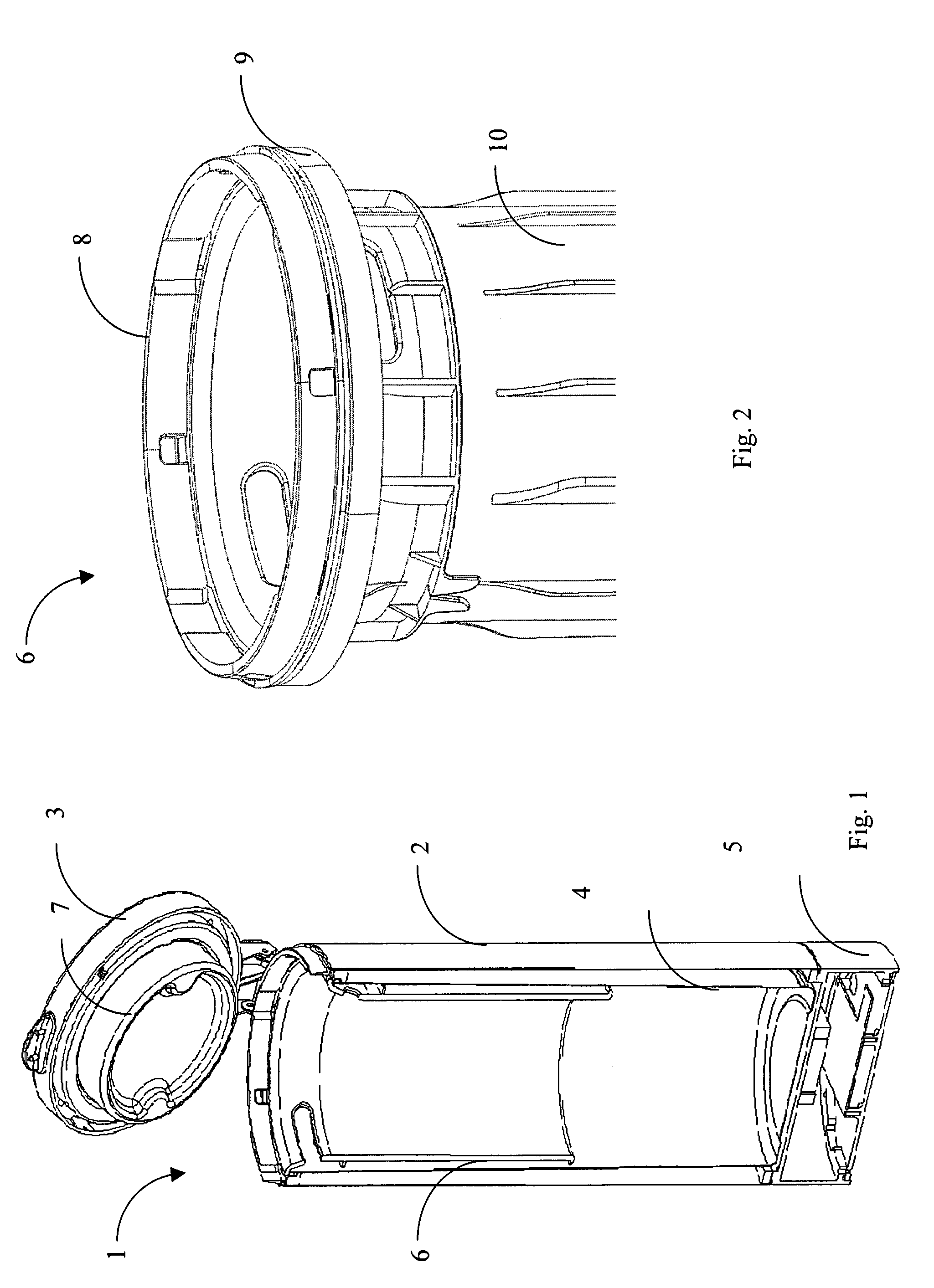

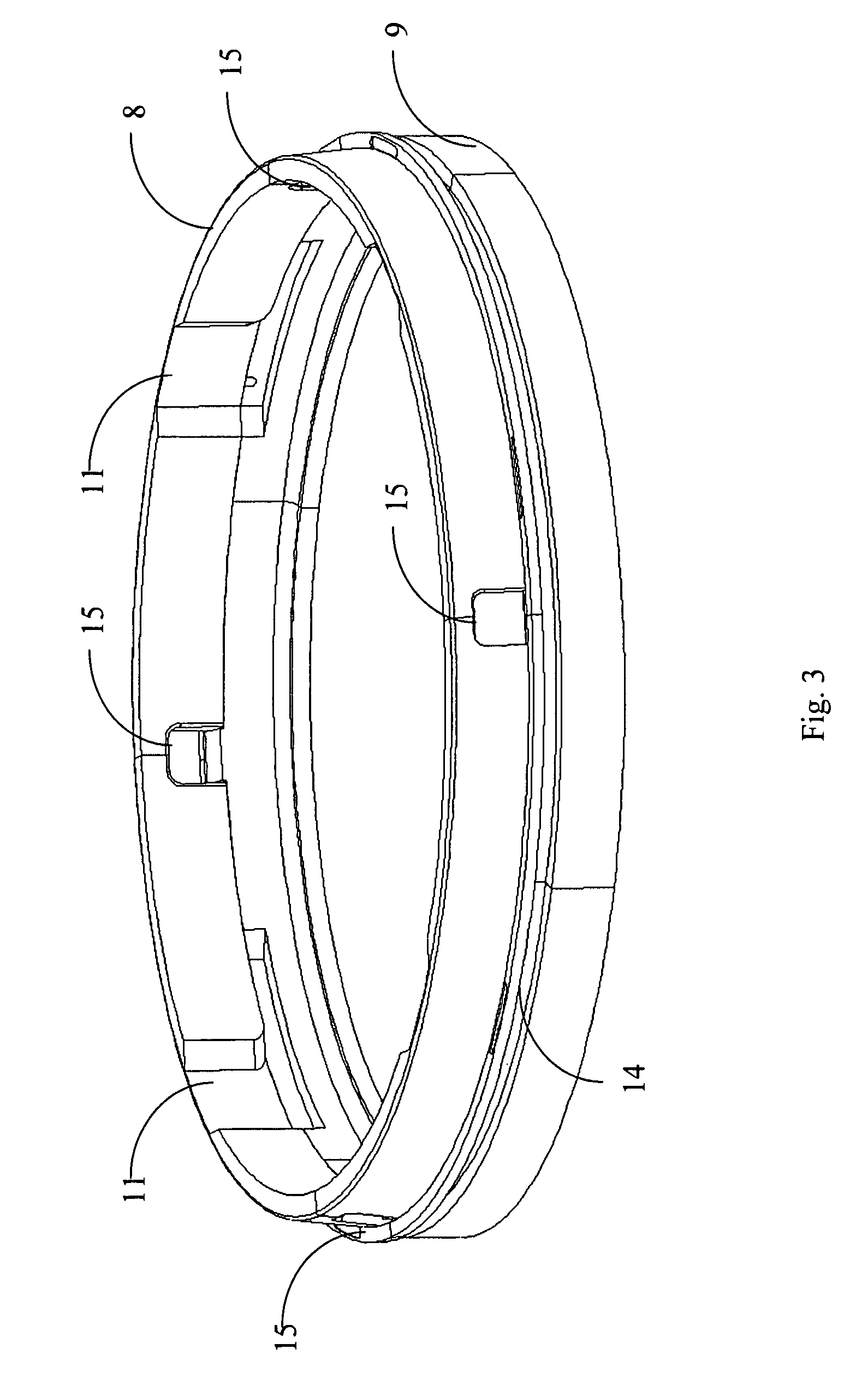

Closure mechanism and waste compaction system including same

A waste compaction system which includes a body defining a waste-receiving receptacle having a perimeter defining an open top end. A bottom wall of the receptacle is vertically movable by a driving system to produce an upwardly directed compaction force within the receptacle. An iris-type closure mechanism extends over the open top end and is displaceable between a first, open position where the closure mechanism surrounds the open top end and a second, closed position where the opening is at least partially closed by the closure mechanism. In the second position of the closure mechanism, the driving system displaces the bottom wall upwards thereby compacting the waste contained within the receptacle against the closure mechanism.

Owner:BERNABE GEMMA

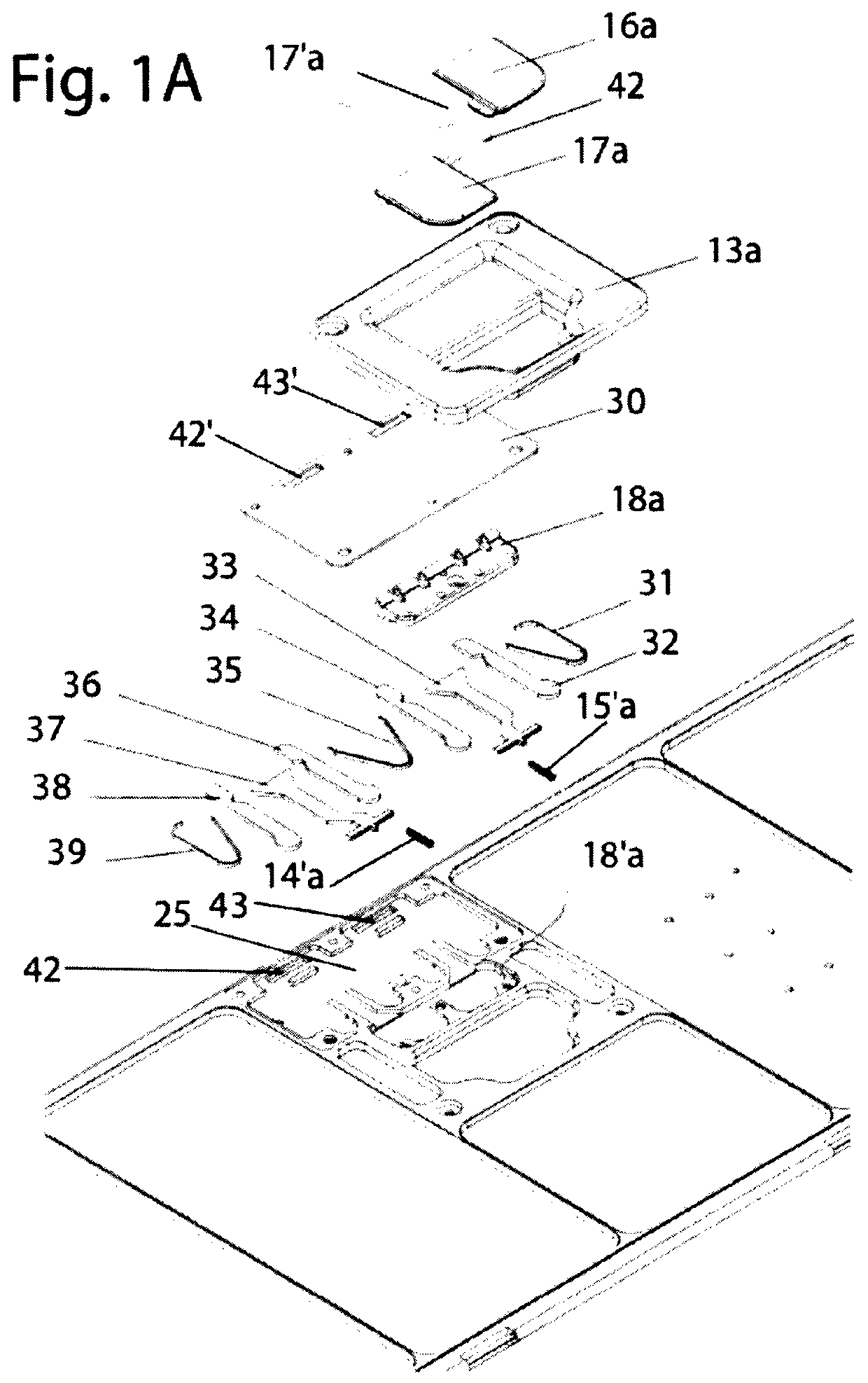

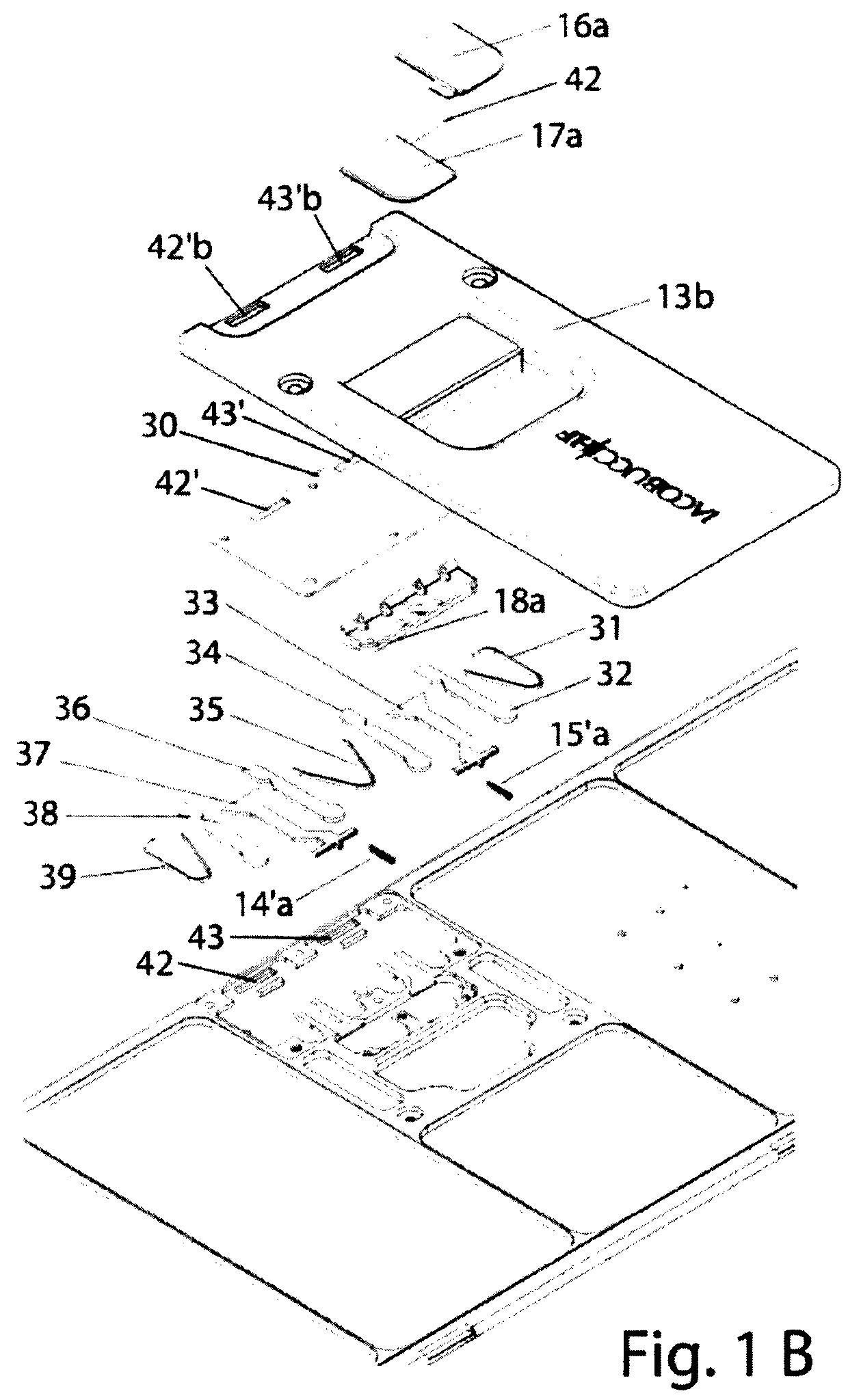

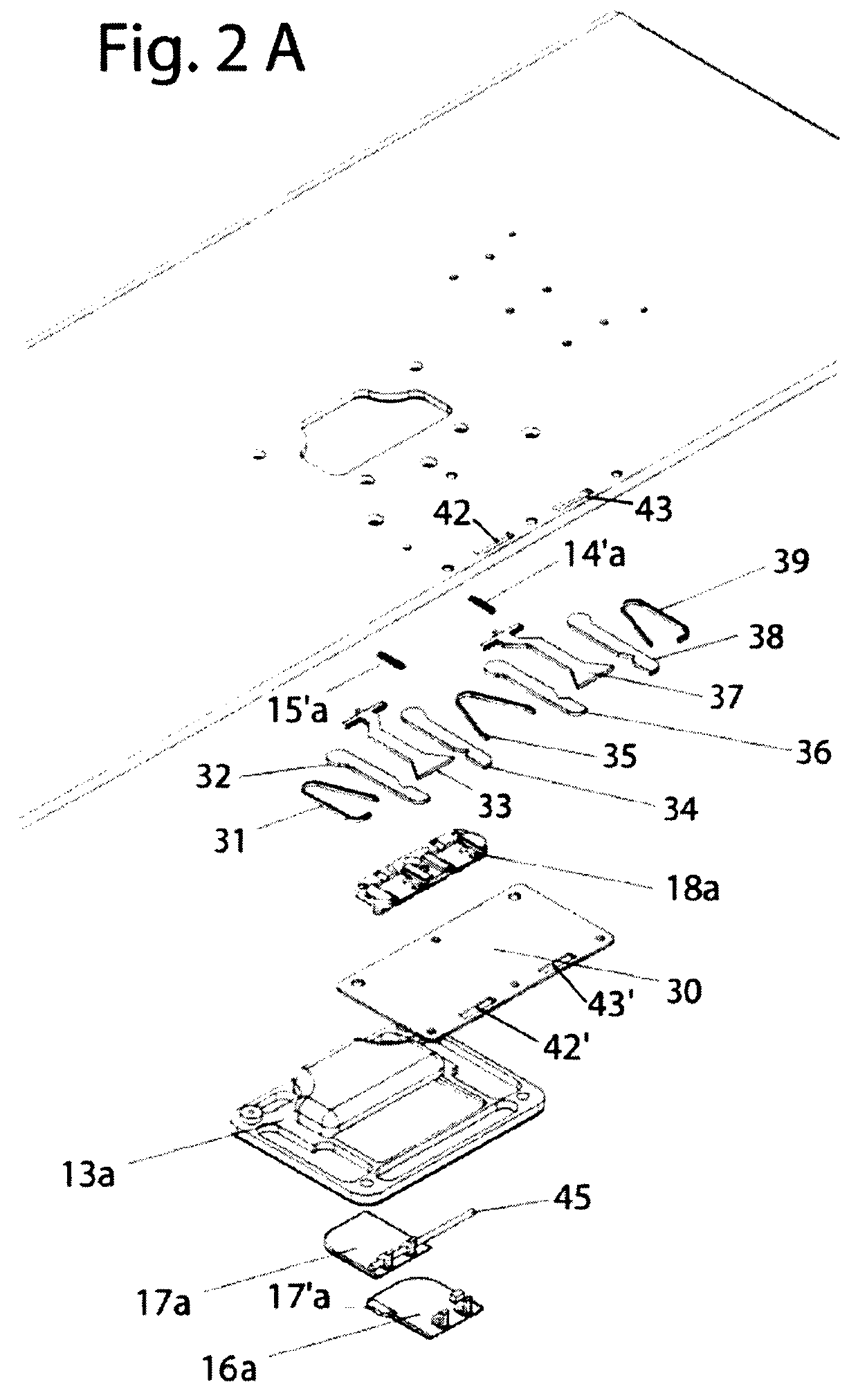

Double-latch closing system for aeronautical equipment, such as trolleys having ultralight composite panels

InactiveUS20160052231A1Improve mechanical propertiesLayered productsBuilding locksAviationEngineering

The present invention relates a double-latch closing system which may be advantageously applied to aeronautical devices such as trolleys, ovens, waste compactors, galley inserts and standard units. It comprises a pair of tongues (33, 37), each operationally connected to a handle (16a, 17a). One handle (17a) is provided with a locking and safety means (17′a) which acts on the other handle (16a). Particularly preferred is the use of said closing system for aviation trolleys made with ultralight composite panels having superior mechanical properties as regards aeronautical standards. The panels may be advantageously used to construct food and beverage trolleys to be used in the aviation sector.

Owner:IACOBUCCI HF ELECTRONICS

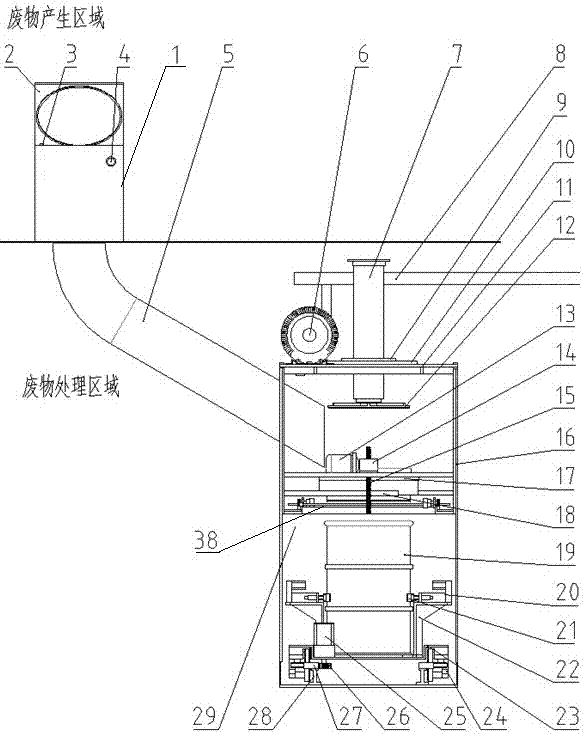

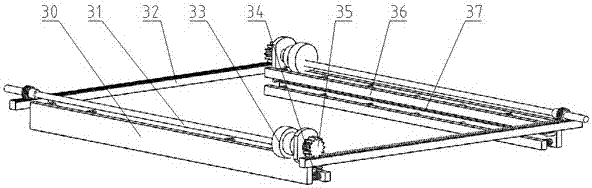

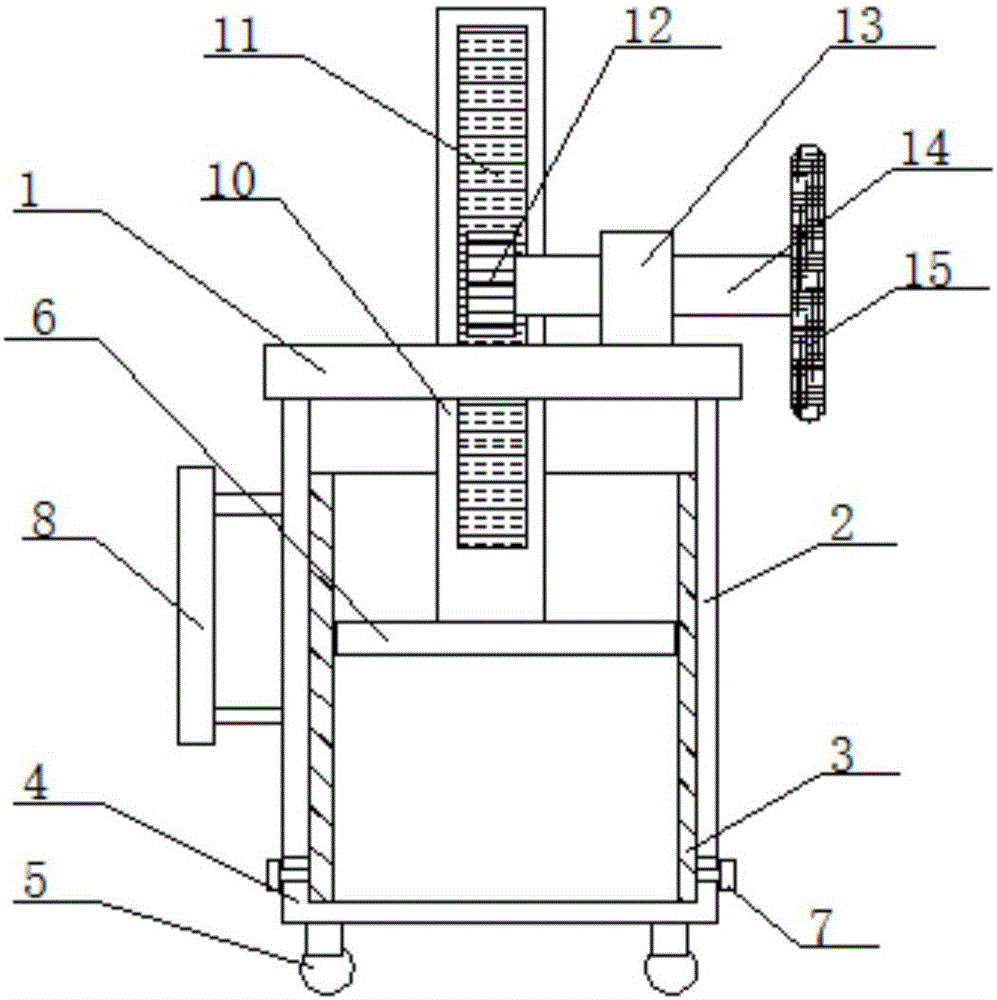

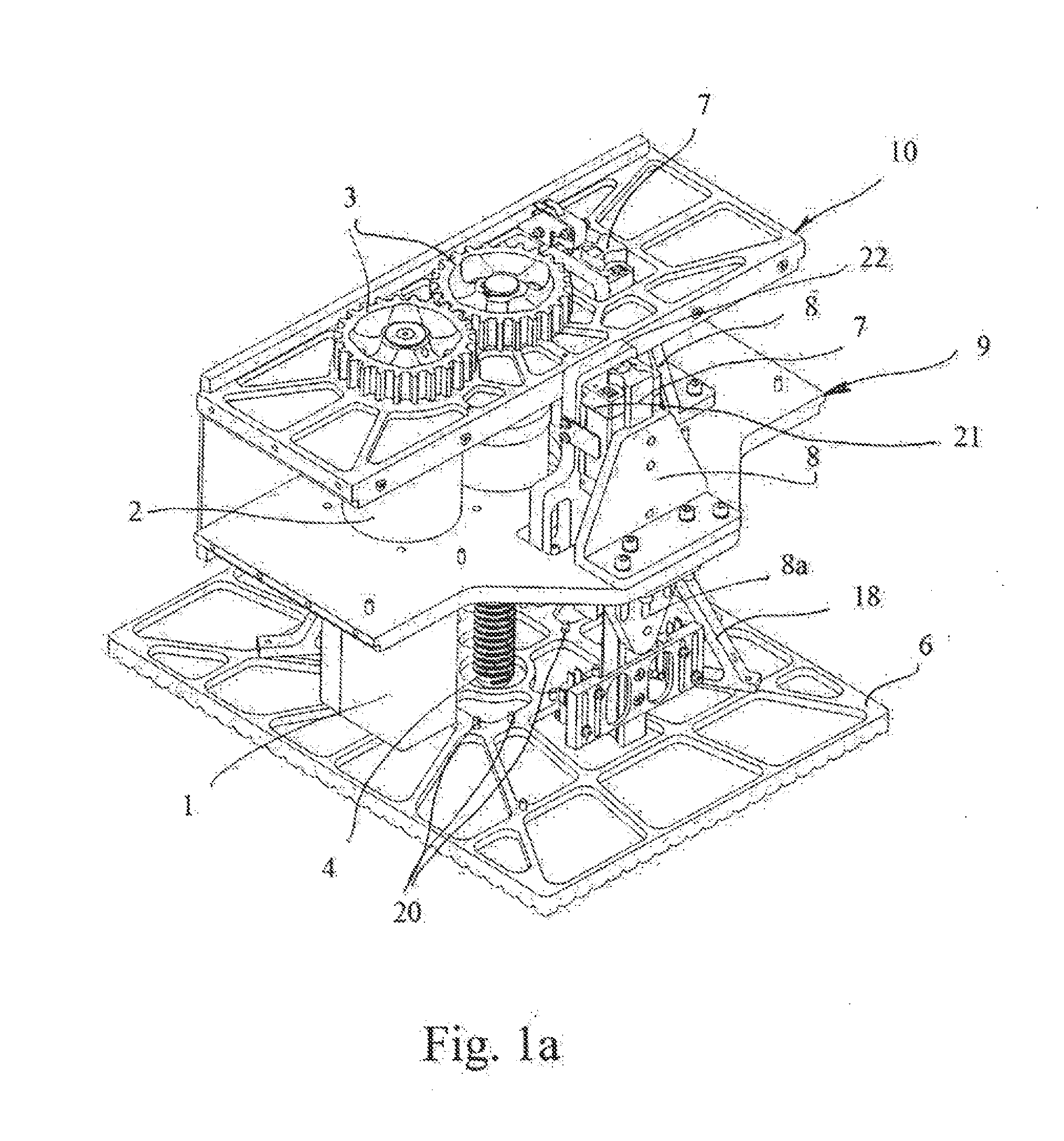

In-barrel compacting device for radioactive solid waste

PendingCN107887048ASmall footprintShortened installation lengthRadioactive decontaminationRadioactive contaminationEngineering

The invention relates to a solid waste compacting device, and provides an in-barrel compacting device for radioactive solid wastes used in small space. The device comprises a rack, a feed opening arranged on a waste generating region, a waste slide communicating the rack and the feed opening, a damper gate of a rack in-and-out barrel panel, a linear guide rail arranged on the bottom of the rack todelivery in and out a steel barrel, a multi-stage electric cylinder which is on the top of the rack and is connected with a compacting disk, a high-pressure vortex fan which is on a corner of the topof the rack and is connected with an exhaust port, a garbage bag holding box in the rack, an automatic bag cutting and sealing mechanism, and a 200L steel barrel. The device is convenient in operation, proper in appearance dimensions, and high in reliability, and effectively reduces generation of secondary wastes, and reduces contact of workers on radioactive contamination.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Waste collection and disposal apparatus

InactiveUS20050028689A1Easy to installSimple structureRefuse receptaclesRefrigeration componentsPistonWaste compaction

An apparatus for collection and disposal of waste, comprising a container with a lid fastened by hermetic closure elements, with a piston inside that can slide and forms a hermetic chamber; and waste compaction and fluid discharge elements, that comprise first air and liquid suction elements connected to a space between a detachable collecting flexible container arranged inside the hermetic chamber, and the walls of the hermetic chamber, and second air and liquid suction elements connected to the inside of the flexible container.

Owner:ROSOLINI

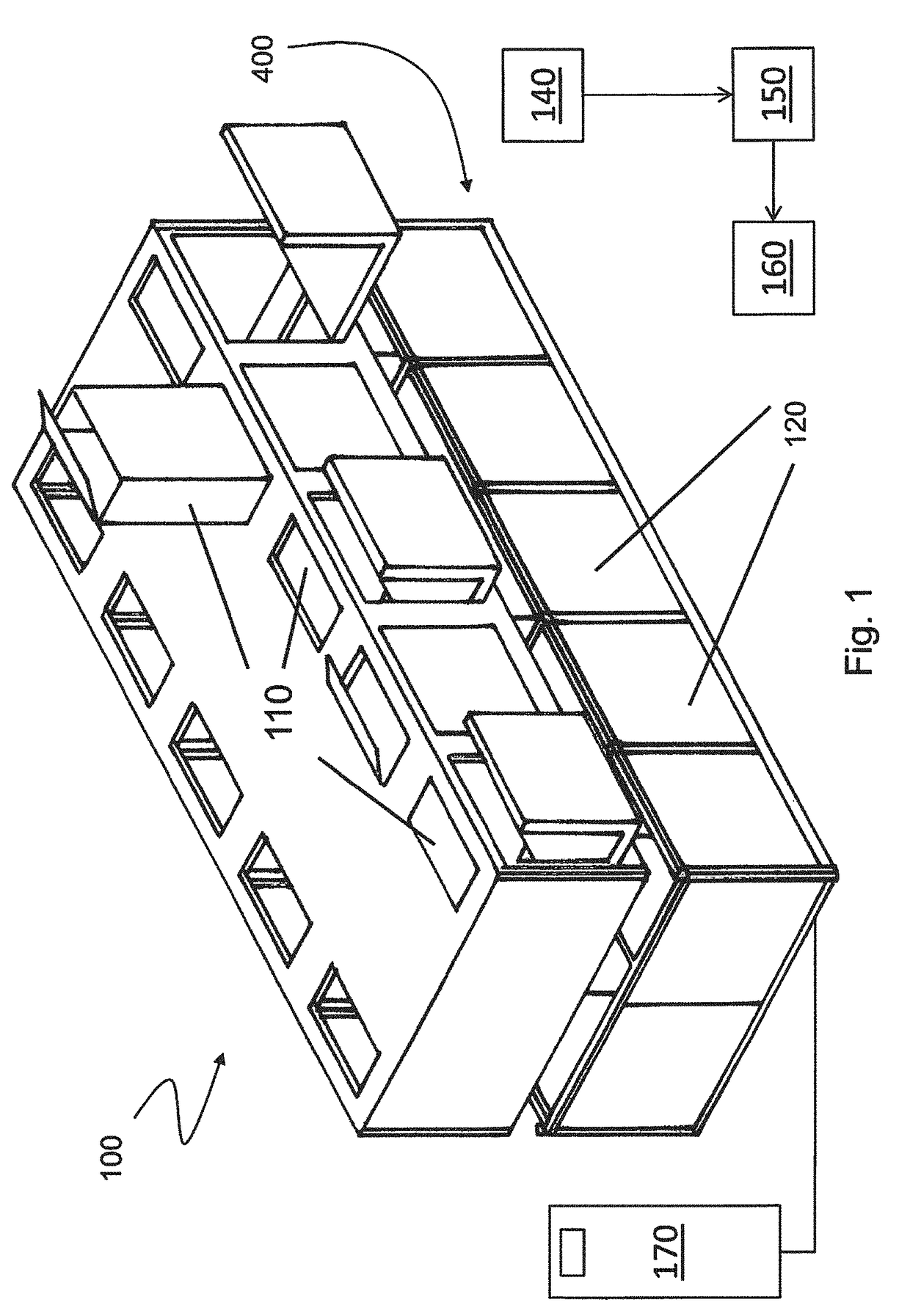

Dynamic movable integrated system for waste collection

Movable integrated system for waste collection, including a container structure, adapted to be installed at least partially above ground, the structure including a plurality of access doors to a plurality of waste collection compartments or containers contained in the container structure that are made of two-dimensional modular structure; the container structure integrates a waste compaction unit supplied by a respective access hatch and transferring compacted waste into the collection containers.

Owner:DALLARMI PIETRO

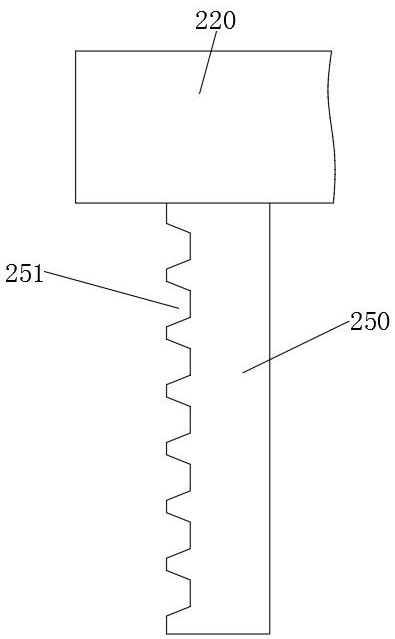

Screw machining waste compaction device used in small-scale industry

InactiveCN106626494AReasonable designSimple structurePress ramPulp and paper industryWaste compaction

The invention relates to a screw machining waste compaction device used in small-scale industry. The screw machining waste compaction device comprises a top plate, a supporting rod, a steel cylinder, an end cap, universal wheels, a pressure plate, connecting pins, a pushing handle, a linear movable bearing, a pressure shaft, a rack, a gear, a connecting bearing, a transmission rod and a driving handle, wherein the bottom of the top plate is fixedly connected with the supporting rod, the pushing handle is fixedly connected to one side of the supporting rod, the bottom of the supporting rod is fixedly connected with the end cap, the steel cylinder is arranged at the top of the inner side of the end cap, and the connecting pins are evenly distributed on the outer wall of the end cap. The screw machining waste compaction device used in the small-scale industry is simple in structure, the pressure shaft can be driven to move by manually turning the driving handle so as to push the pressure plate for movement, then compaction treatment is conducted on machining waste in the steel cylinder, the steel cylinder can be taken down after the connecting pins are taken down, accordingly the compacted machining waste in the end cap can be taken out, and machining waste compaction work can be completed.

Owner:李国朋

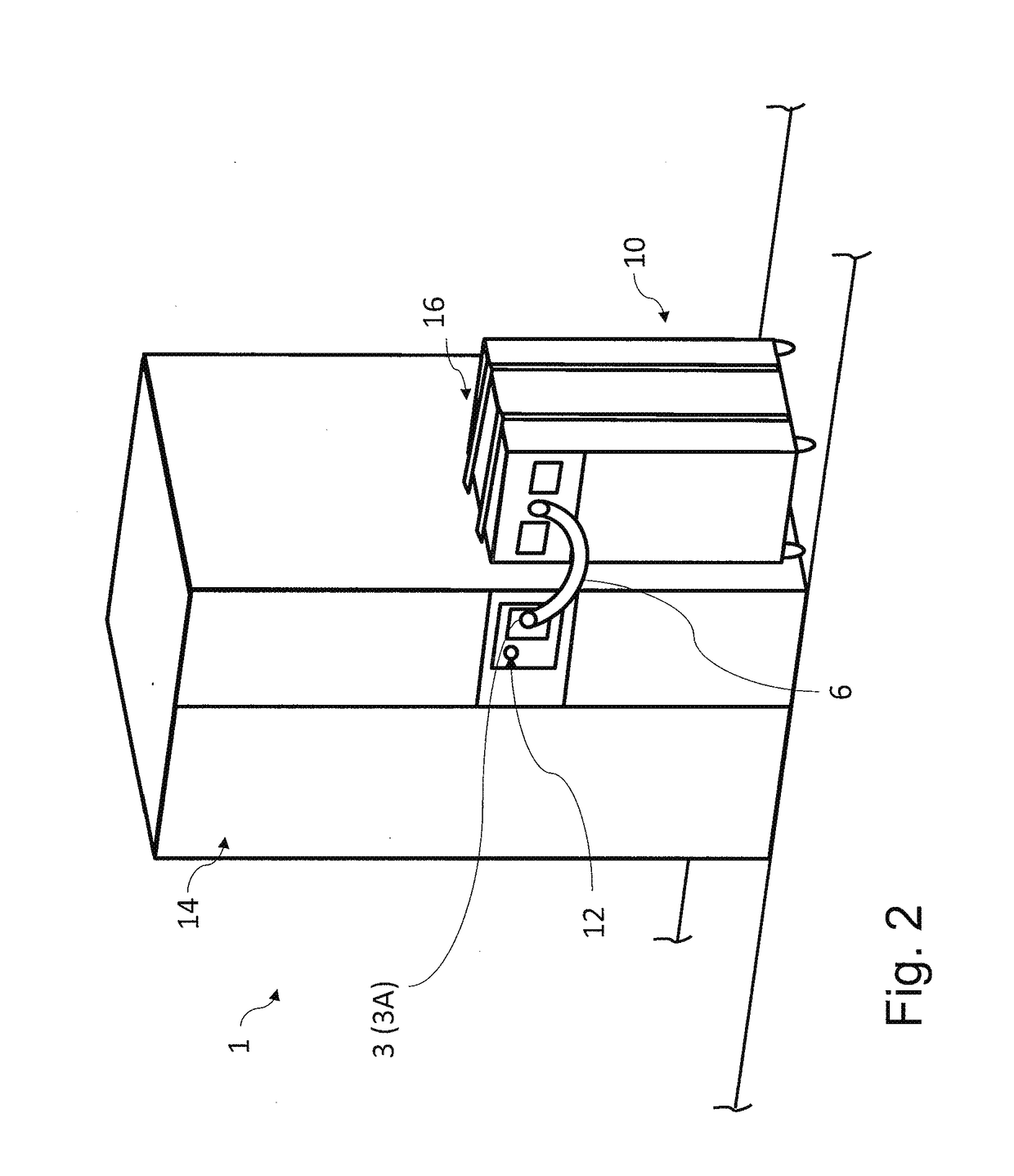

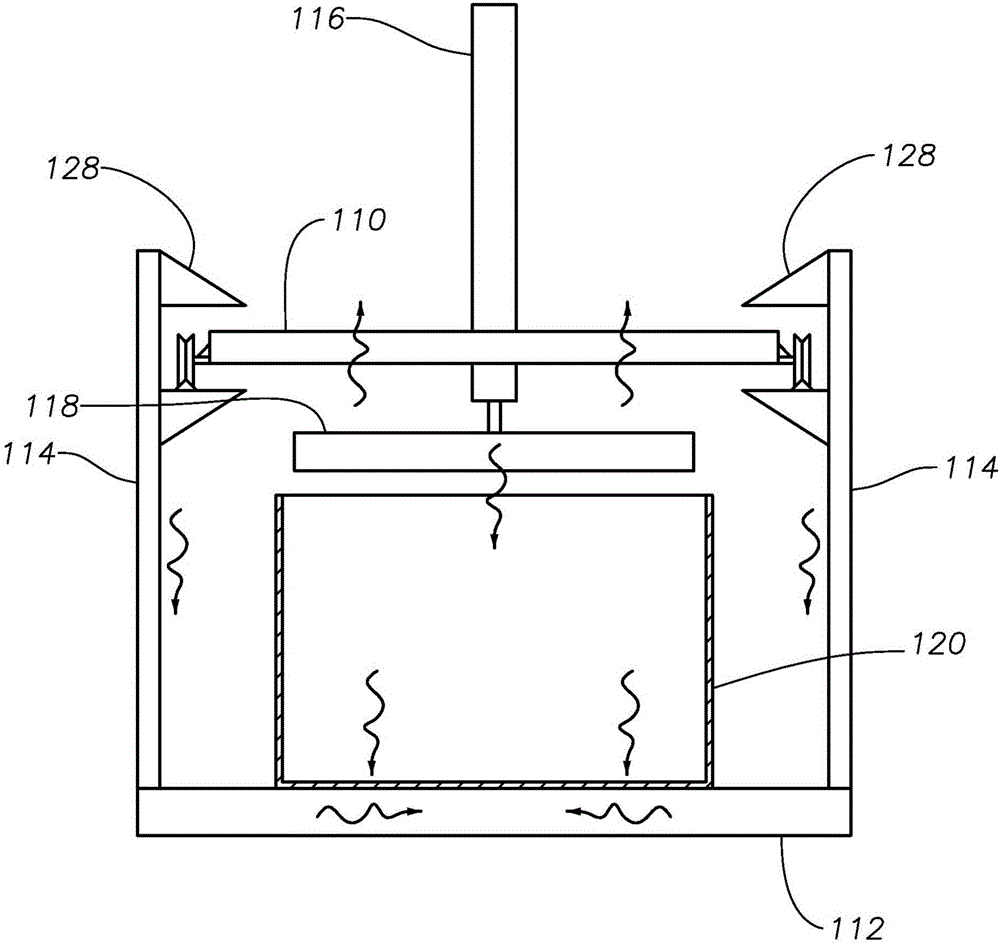

System for suctioning a fluid as well as a vehicle having such a system

ActiveUS20180134391A1Facilitate flexible handlabilityEnhanced couplingGalleysRefuse receptaclesEngineeringControl valves

A system for suctioning fluid is disclosed. In a cabin monument, a vacuum source and a vacuum interface unit is provided. At least one flexible hose provides a connection to the vacuum interface unit, having at least one first fluid line having a connection element. The end connection element connects to a unit to be evacuated. The vacuum interface unit includes an adapter for connection to the at least one fluid line, and a trigger unit. At least one valve unit and a control unit for controlling the at least one valve unit reside in the cabin monument. The control unit controls the valve unit at least indirectly based on a trigger signal generated by the trigger unit. Thus, a flexible positioning of a unit to be evacuated for waste compaction is possible. The disclosure also relates to a vehicle, in particular an aircraft, having such a suctioning system.

Owner:AIRBUS OPERATIONS GMBH

Solid waste compacting device

InactiveCN112793212ANo manual feeding operation requiredSave human effortDispersed particle filtrationIncinerator apparatusRefuse DisposalsMechanical engineering

The invention discloses a solid waste compacting device, and belongs to the technical field of garbage disposal. The solid waste compacting device comprises a feeding mechanism, a waste disposal mechanism, a compacting mechanism and a pushing mechanism, wherein the feeding mechanism is arranged on one side of the pushing mechanism, the waste disposal mechanism is arranged in the middle of the pushing mechanism, and the compacting mechanism is fixedly arranged on the other side of the pushing mechanism. The waste disposal mechanism comprises a feeding hopper, a crushing assembly, an incineration box body, a smoke filtering assembly and an opening and closing assembly, wherein the incineration box body is fixedly arranged above the pushing mechanism, the crushing assembly is arranged on the upper side of the incineration box body, the feeding hopper is arranged on the crushing assembly, the smoke filtering assembly is arranged on the incineration box body, and the opening and closing assembly is arranged on the outer side wall of one side of the incineration box body. According to the solid waste compacting device, the feeding assembly is arranged and used for automatically and quantitatively feeding solid waste, manual feeding is not needed, so that manpower is saved, and the working efficiency is improved; and a draining assembly is used for conducting dry-wet separation on the solid waste.

Owner:王子腾

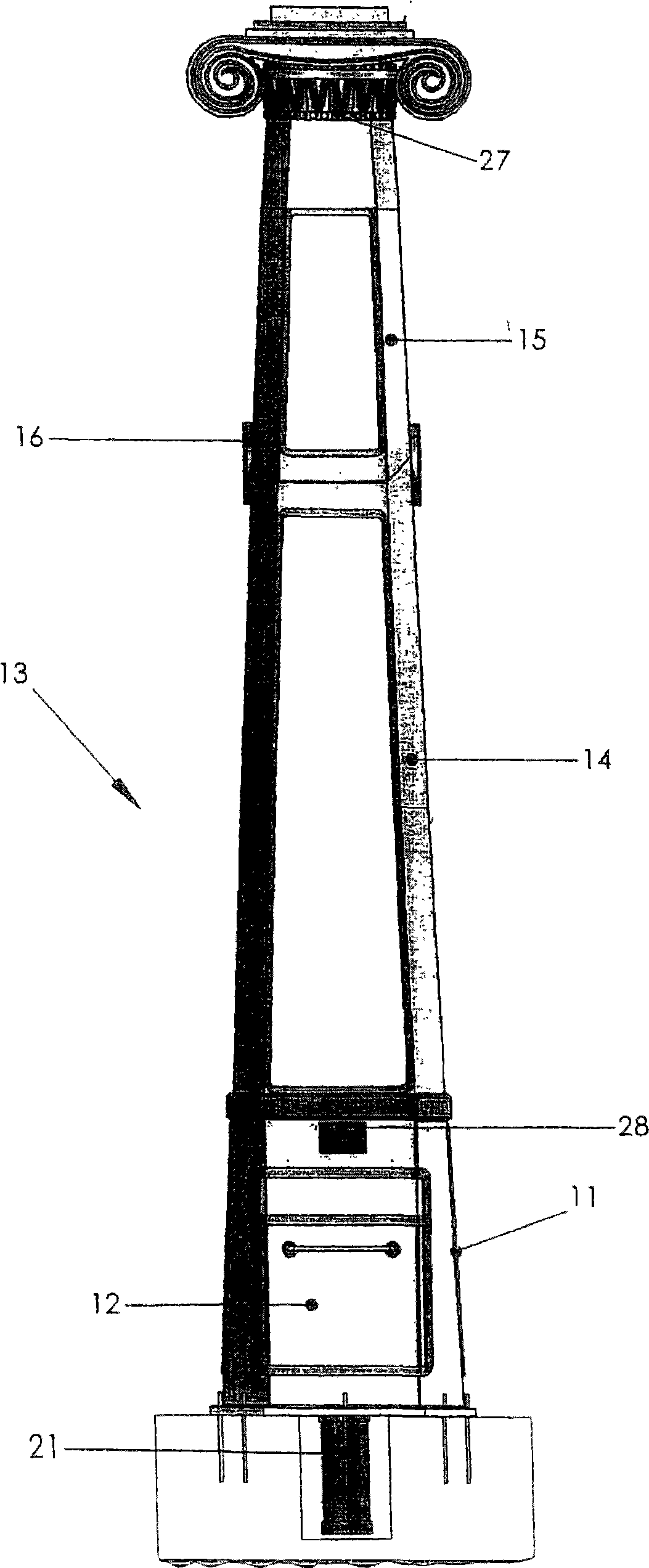

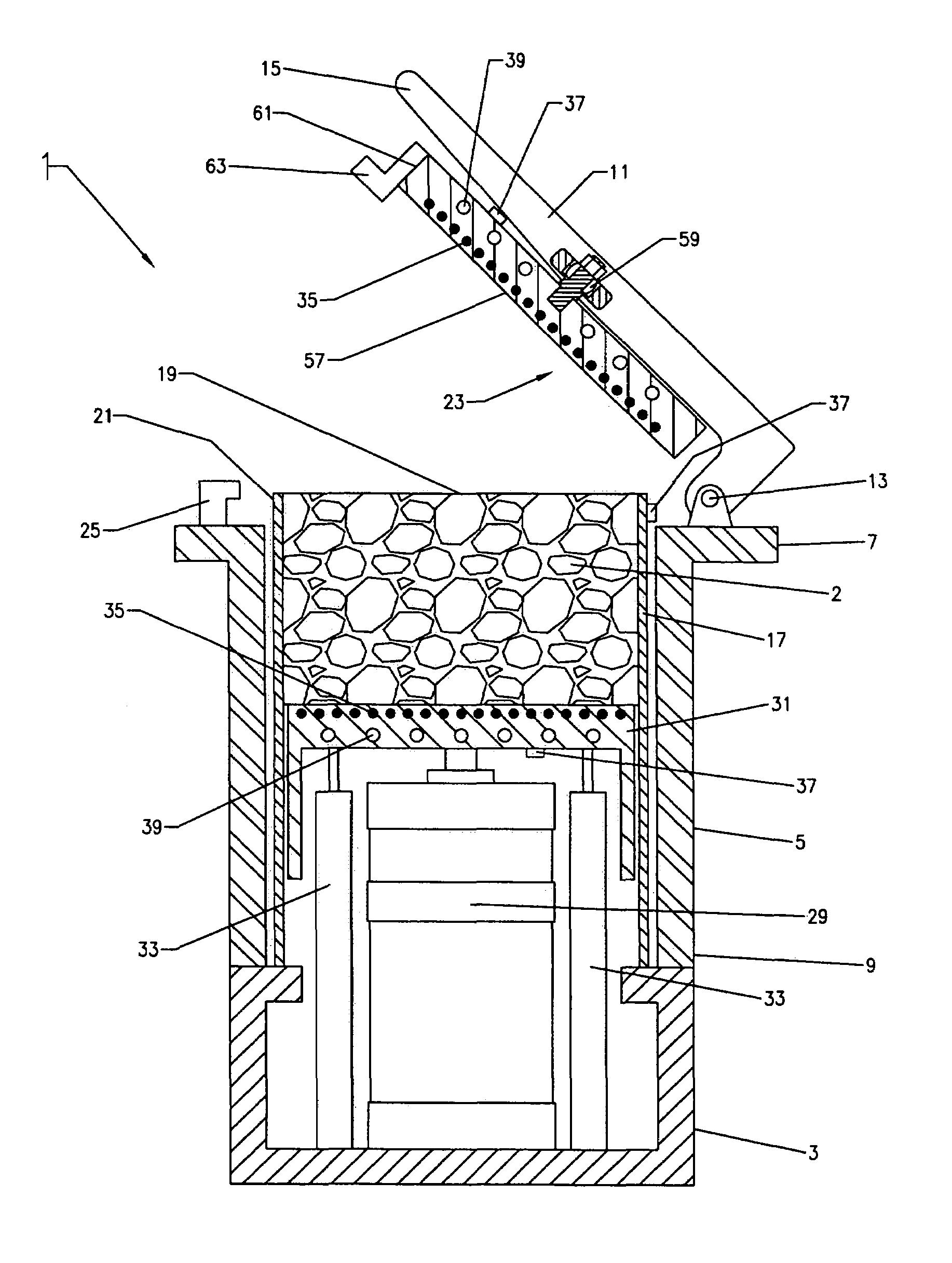

Device for collecting and pressing waste

InactiveCN101535150ASuitable for the surrounding environmentNo burdenRefuse receptaclesRefuse cleaningBasementRefuse collection

The device is suitable for being used as a station of concentration and storage of a large volume of waste that emanates from houses, shops, etc., without environmental problems being created. It achieves the waste compaction, the ecological management, as well as disinfection of the waste. It provides large surfaces (23) for advertising displays. It allocates a large capacity of waste storage (5 up to 10 m3). It comprises a main pivotal member (13) that includes at least one chamber of waste compaction (18) at the interior thereof. The pivotal member (13) is constituted by a fixed member (14) and a moving member (15). It is constituted by a central supporting basement (11) of pivotal member (13), a chamber (17) of waste disposal, as well as at least one system of waste lifting and controlled compaction (20). The collecting is realised automatically with the waste collection vehicles already available. It may be provided with double, triple or quadruple positions of waste disposal for the recycling of materials.

Owner:SOUKOS ENVIRONMENTAL SA

Plastics waste processor

Owner:LEIDOS

Compactor system and method

A compactor system for use on board marine vessels and offshore installation. The compactor has a cart with bottom and side members capable of withstanding a compaction force. The upper rim of the cart has a lip. The system has a compaction unit formed of a movable upper frame with a shoulder and a lower fixed frame. During waste compaction, the moveable upper frame moves in an upward direction to a point where the shoulder engages the cart's lip to establish a force-distribution loop among the upper frame and the side and bottom members of the cart. The cart's wheels are not subjected to the compaction force.

Owner:TECH OIL PROD INC

Trash compactor

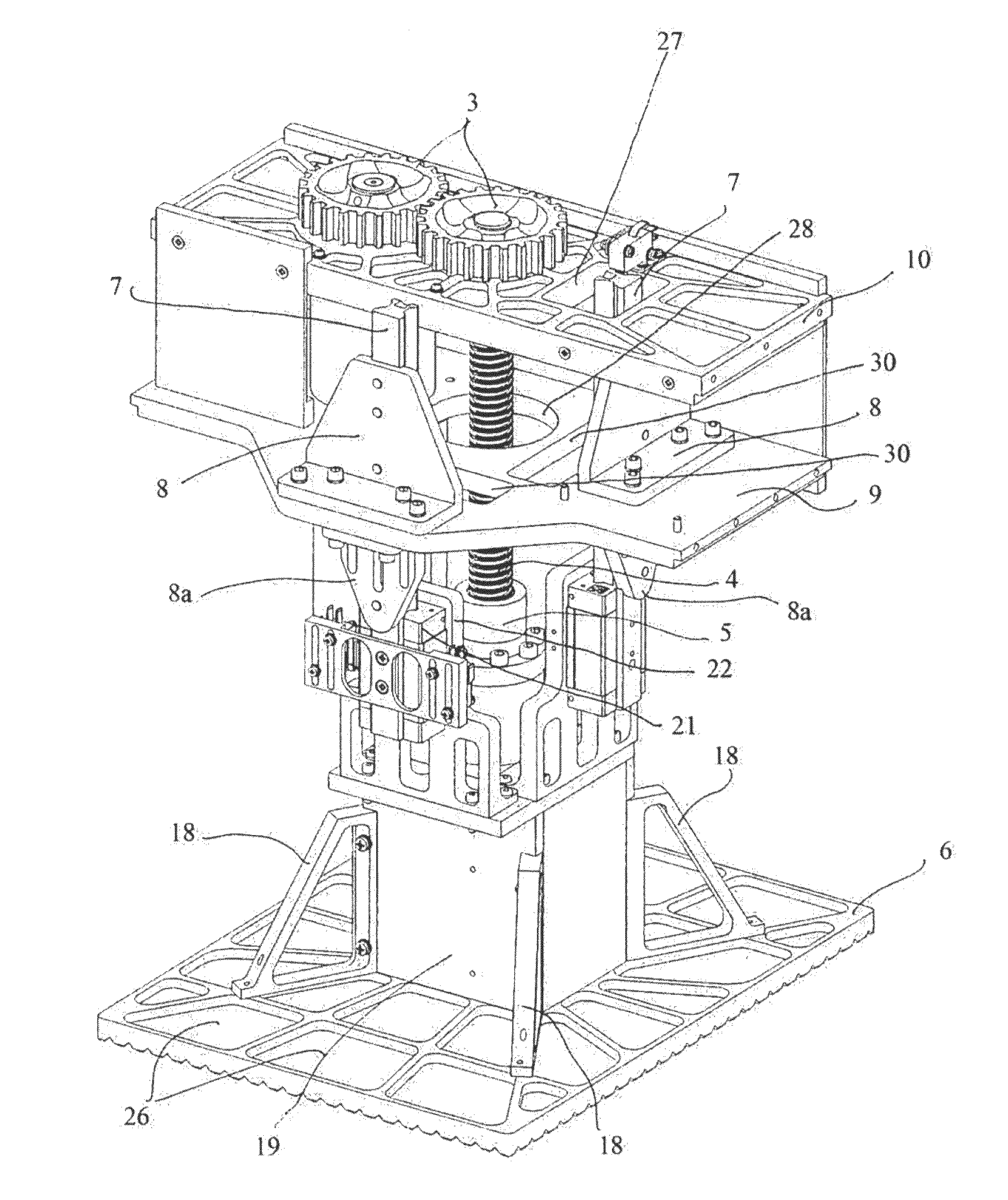

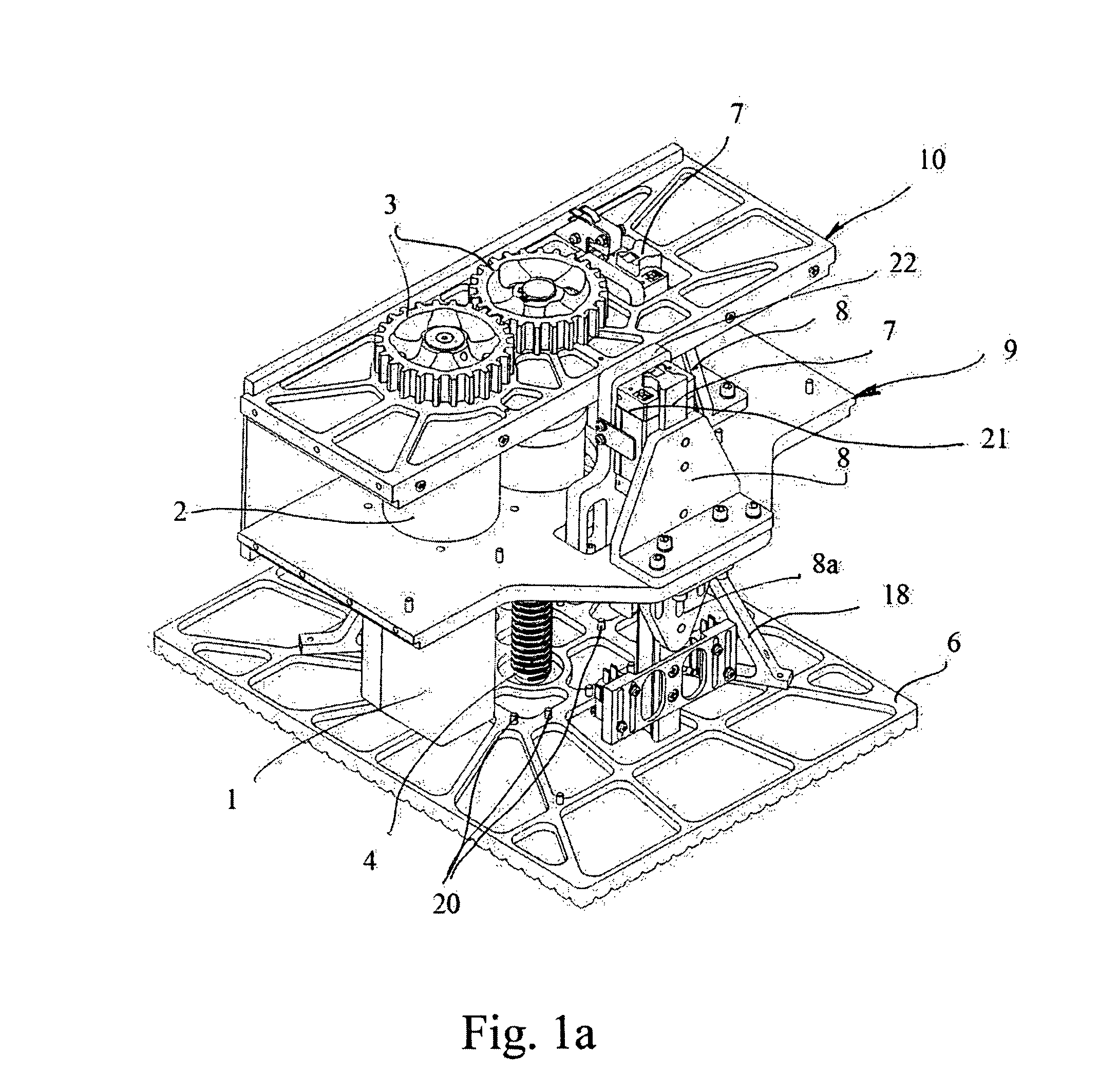

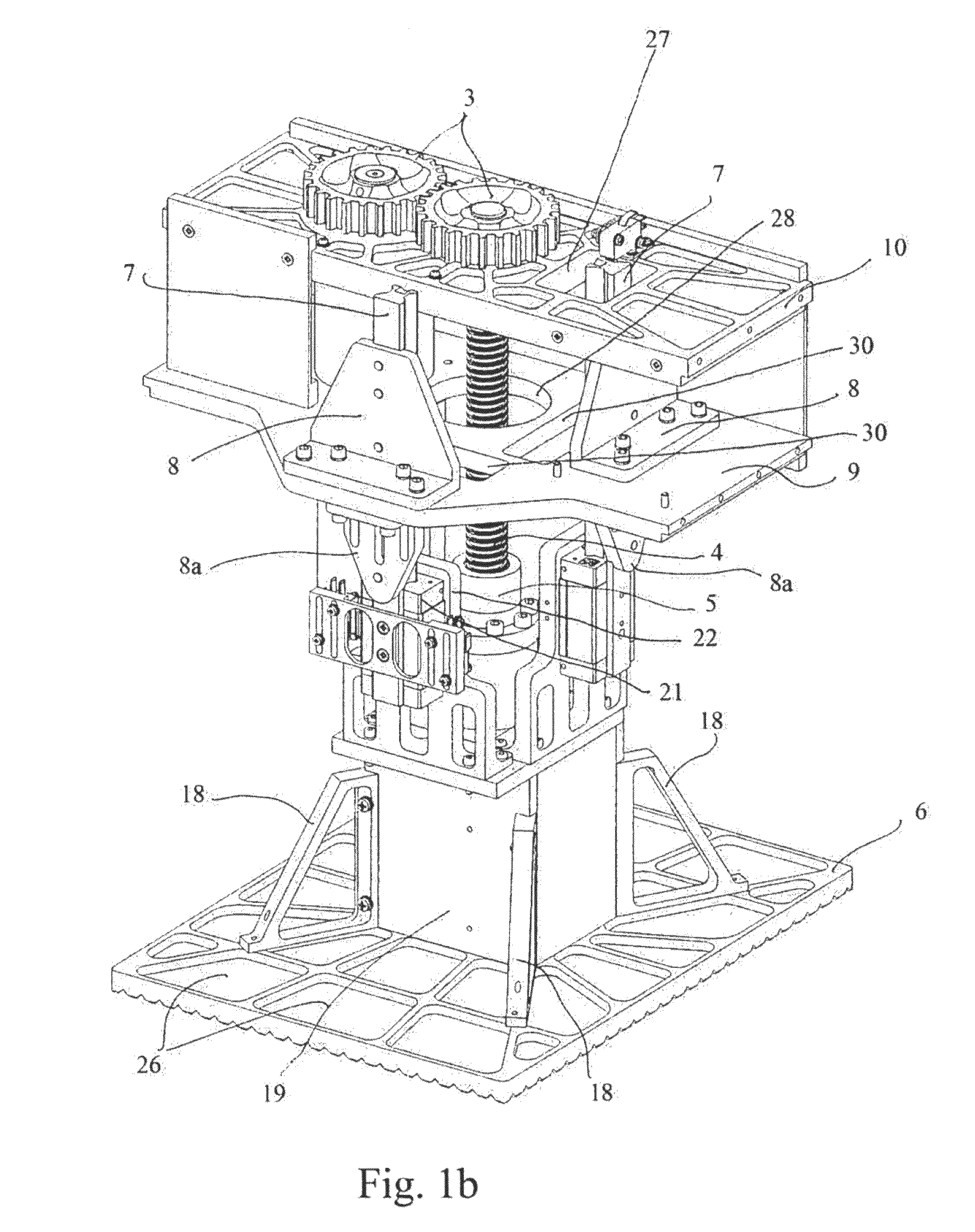

Provided are electro-mechanical waste compactors which can operate also with 28 V power and of particularly reduced dimensions and weight. Provided are waste compaction devices which can be employed for civil uses, auxiliary service equipment, as, for example, trains, ships and vessels in general, aircrafts, coaches, caravans etc. Provided are compaction devices that can be conveniently installed in appropriate bays, fixed or movable on wheels, such as a trolley, to allow its ease of movement, and its insertion in the appropriate service spaces.

Owner:IACOBUCCI HF ELECTRONICS

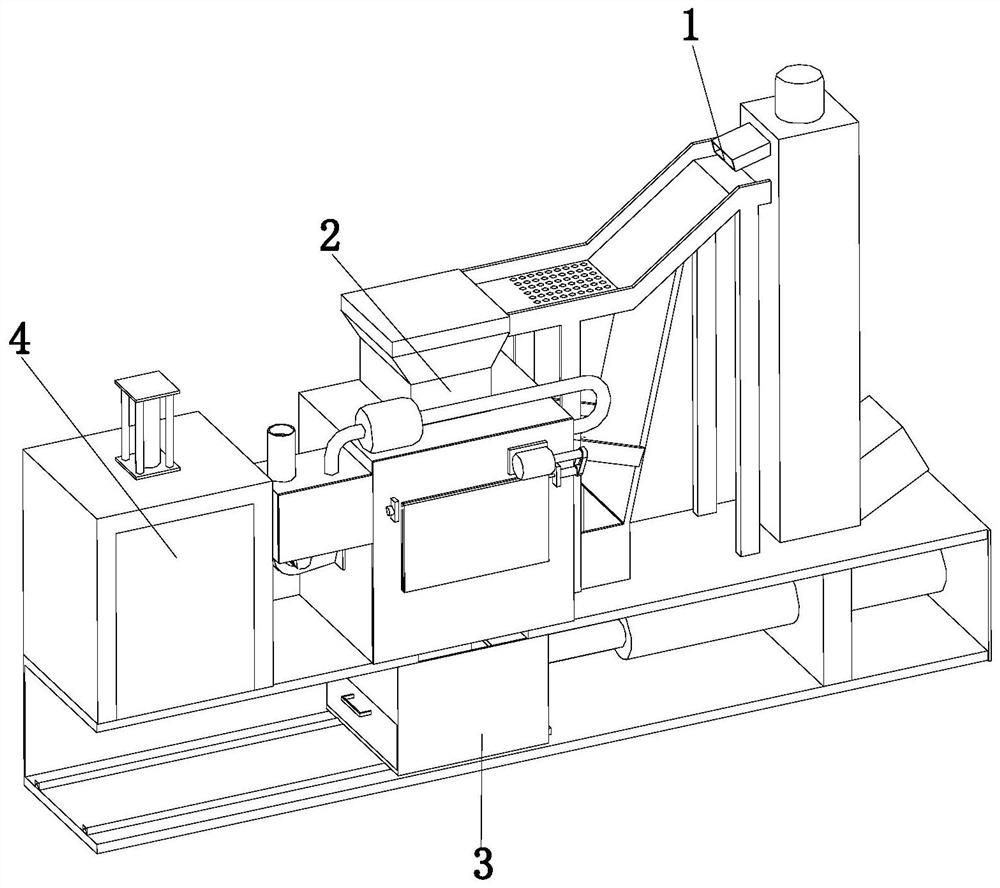

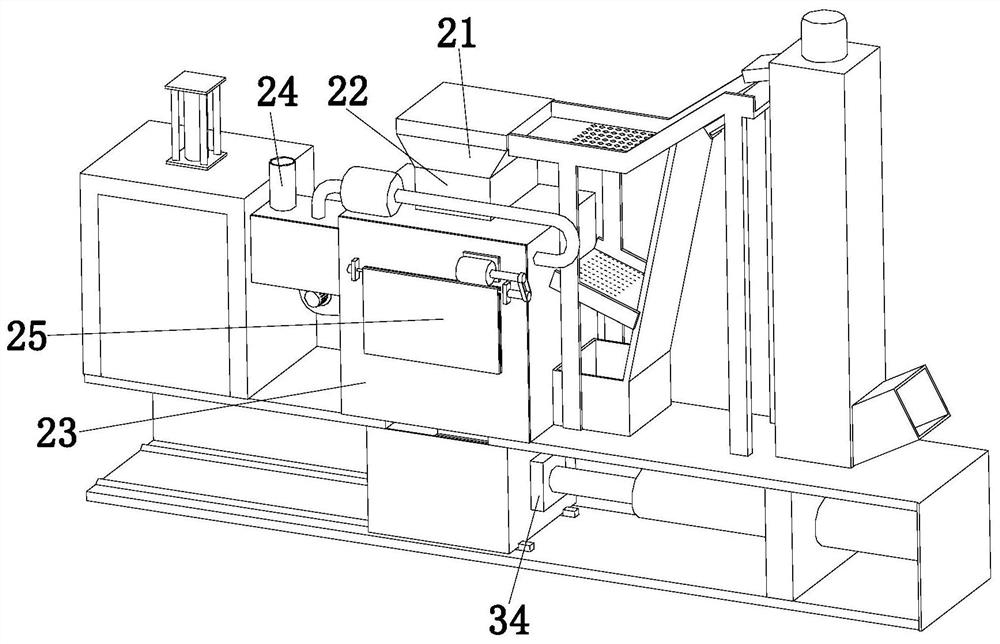

Environmental protection machine for waste compaction

The invention discloses an environmental protection machine for waste compaction. A rectangular pipe is welded on a bottom plate through a supporting rod, a rectangular hole is formed in the bottom ofthe left side wall of the rectangular pipe, a rectangular groove is formed in the bottom of the right inner wall of the rectangular pipe, the right end of a rectangular plate penetrates the rectangular hole and is inserted into the rectangular groove, the right end of a piston rod of the first cylinder is welded with the middle of the left side wall of the rectangular plate, a horizontal plate iswelded on the right side of the upper end surface of the bottom plate through a vertical plate, the lower end of a piston rod of a second cylinder is welded with the middle of the upper end surface of an extruding plate, inserting connection rods are integrally formed on the right side wall of the rectangular plate, inserting connection grooves in one-to-one correspondence to the inserting connection rods are formed in the right inner wall of the rectangular groove, and the inserting connection rods are inserted into the inserting connection grooves. The environmental protection machine for waste compaction is simple to operate, high in extruding efficiency, good in extruding quality and suitable for large-scale popularization.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

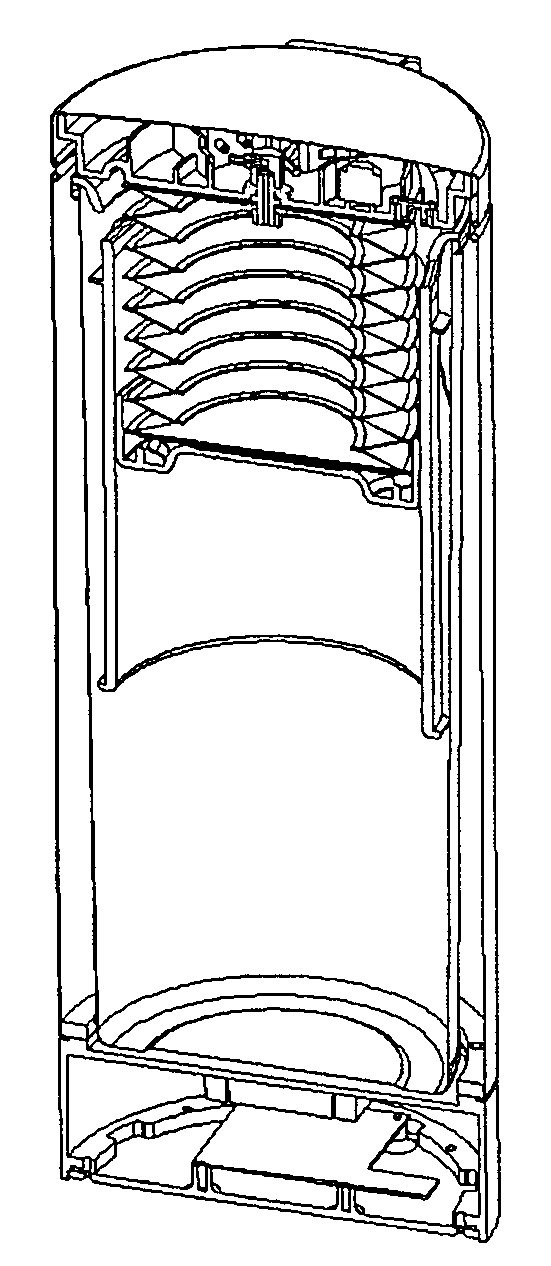

Trash compactor

The present invention relates to an electro-mechanical waste compactor which can operate also with 28 V power and of particularly reduced dimensions and weight. In particular, the invention relates to a waste compaction device which can be employed for civil uses, in particular for domestic use or on board of all the transportation means that require a big space economy for the auxiliary service equipment, as, for example, trains, ships and vessels in general, aircrafts, coaches, caravans etc. The compaction device of the invention can be conveniently installed in appropriate bays, fixed or movable on wheels, such as a trolley, to allow its ease of movement in a transportation means, and its insertion in the appropriate service spaces.

Owner:IACOBUCCI HF ELECTRONICS

Waste compaction unit

A unit for compacting waste prior to disposal provides a waste compaction unit for fitting into a housing comprising a lid and an interior for collecting waste. The compaction unit comprises a plunger comprising bellows housed in the lid; a pneumatic locking mechanism housed in the lid; and a pump connected to the plunger via the locking mechanism wherein the pump is arranged in operation to activate the locking mechanism prior to inflating the bellows to extend the plunger axially towards the interior of the housing such that any waste collected therein is compacted.

Owner:SPACEMAKER BINS

Solid waste compaction apparatus

The invention discloses a solid waste compaction apparatus. The solid waste compaction apparatus comprises a power mechanism arranged in a machine body. The power mechanism is provided with a feedingmechanism, a compaction mechanism and a discharging mechanism in a connected manner. The power mechanism comprises a motor arranged on the upper part of the machine body. The motor is provided with afirst rotary shaft in a connected manner. The first rotary shaft is rotationally installed in the machine body. The first rotary shaft is provided with a first gear. The first gear is engaged with a second gear. The second gear is installed on a second rotary shaft. The second rotary shaft is rotationally installed in the machine body. According to the solid waste compaction apparatus, three steps, including feeding, compaction and discharging, are taken to carry out compaction treatment on solid waste, the feeding quantity is controlled by having control over the opening time of a blocking door during feeding, the manner of physical stamping is taken during compaction, and the waste can be automatically poured out after being compacted so that the procedure or compaction on the next batchof waste can be carried on.

Owner:温州市博迈环保科技有限公司

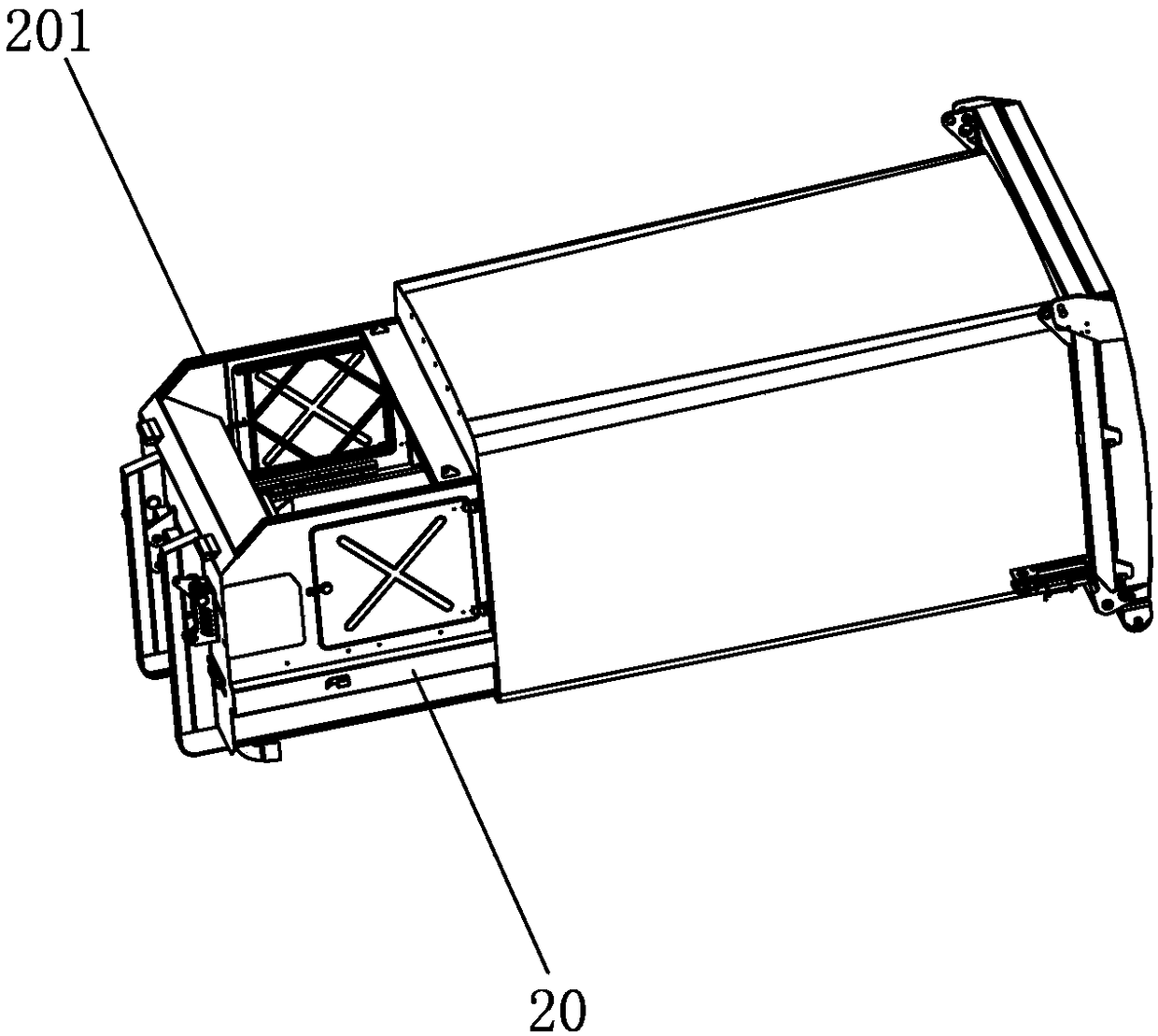

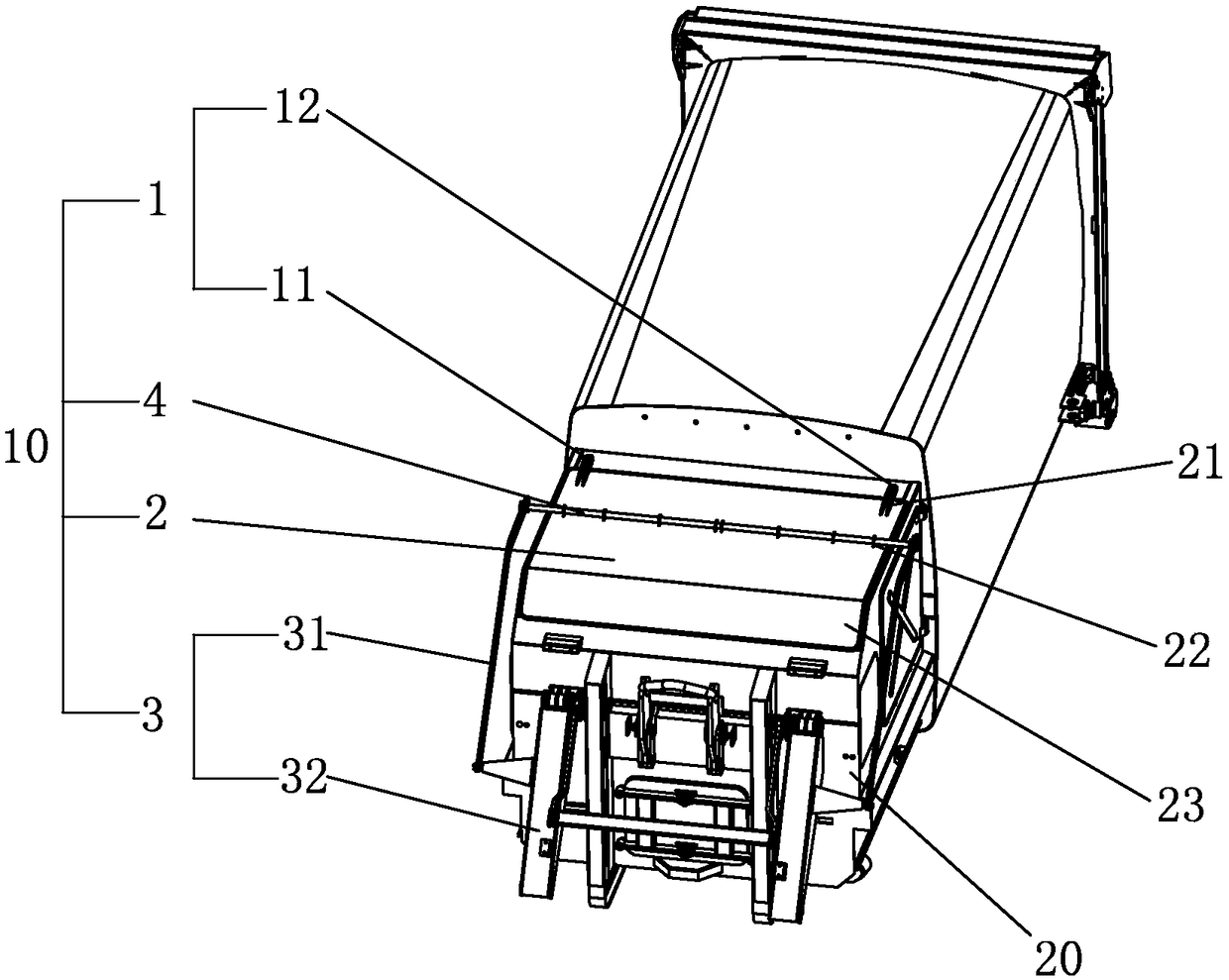

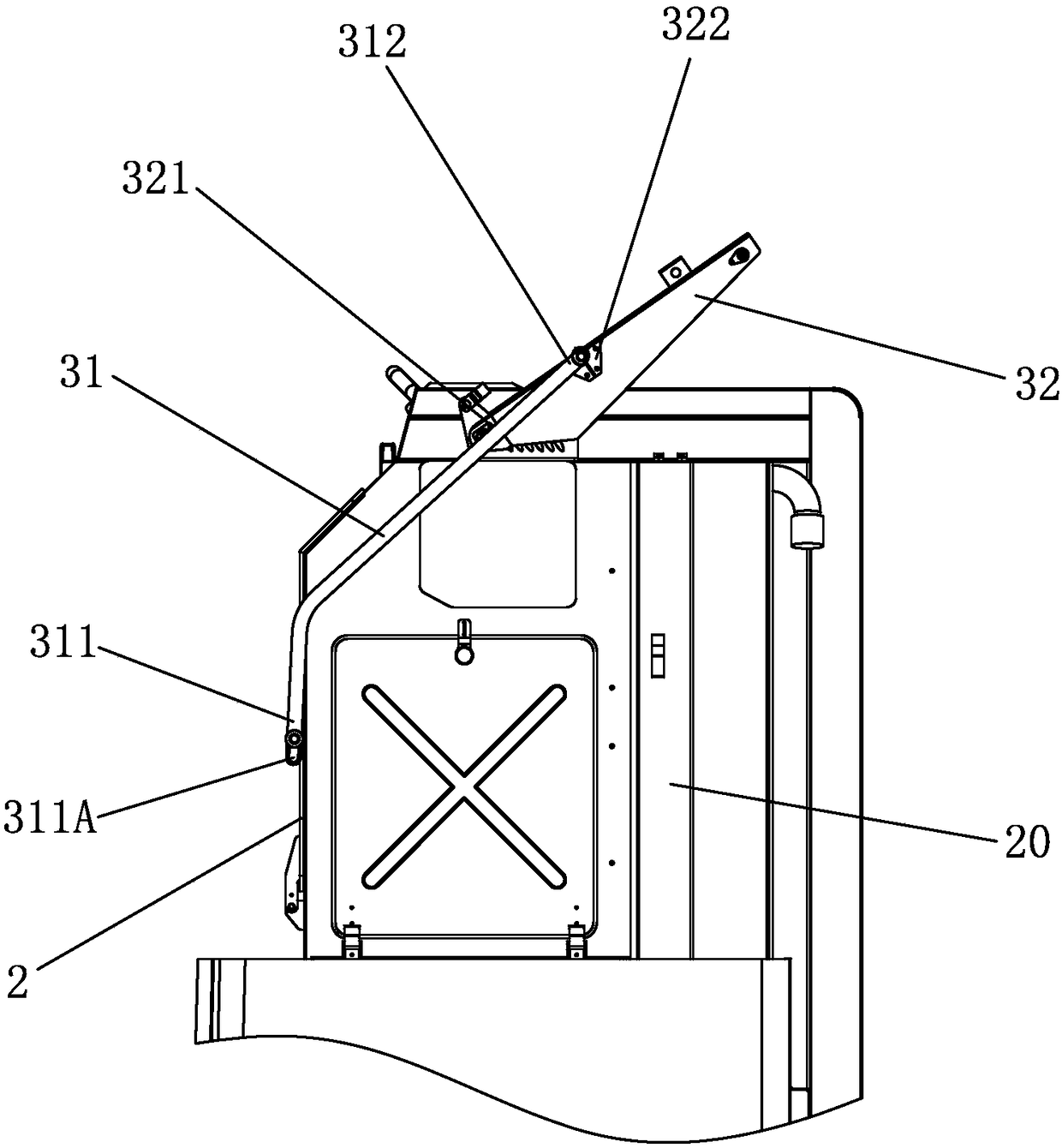

Waste compaction device and back-loaded compaction type waste truck

The invention discloses a waste compaction device which comprises a box body. A rear door is hinged to the rear portion of the box body. A waste inlet is formed in the rear door. A push plate is arranged in the box body. Two driving parts are symmetrically installed on the two outer side faces of the box body. Long-strip-shaped transverse through holes are formed in the positions, corresponding to the driving parts, of the two side faces of the box body. Each long-strip-shaped through hole is provided with a moving assembly. The outer sides of the moving assemblies are connected with the driving parts, the driving parts drive the moving assemblies to move along the long-strip-shaped transverse through holes, the inner sides of the moving assemblies and the side face of the push plate are hinged through first pin shafts, a rotating oil cylinder is installed between the inner side of each moving assembly and the rear side of the push plate, one end of each rotating oil cylinder is hinged to the inner side of the corresponding moving assembly, the other end of each rotating oil cylinder is hinged to the rear side of the push plate, and the push plate can be driven to rotate along the first pin shafts when the rotating oil cylinders act. By means of the waste compaction device, the waste bearing space can be enlarged, and the waste collection capacity of the box body can be improved. The invention further provides a back-loaded compaction type waste truck. The back-loaded compaction type waste truck comprises an automobile chassis. The automobile chassis is provided with the waste compaction device.

Owner:XIAMEN YULONG MACHINERY

Fixed waste resource recycling device and recycling method thereof

InactiveCN110947481AReduce volumeTransport moreGrain treatmentsPressesHydraulic cylinderResource recovery

The invention discloses a fixed waste resource recycling device and a recycling method thereof. The fixed waste resource recycling device comprises a box body, wherein two sides of the inner bottom wall of the box body are respectively provided with a first recycling box and a second recycling box; after wastes are crushed, the dry crushed objects enter the first recycling box, the wet wastes enter the second recycling box, a second motor drives two first belt pulleys to rotate through a second belt pulley, the first belt pulleys, a rotating rod, a third bearing and a fixing plate are matched,a hydraulic cylinder drives a pressing plate to move to the upper part of the recycling box through a supporting plate and the connecting rod, the supporting plate and the connecting rod are driven to move downwards through the hydraulic cylinder, wastes in the first recycling box and the second recycling box are compacted, the compacted waste liquid in the second recycling box flows into the bottom of the second recycling box through grids, box doors on two sides of the box body are opened, the first recycling box and the second recycling box can be taken out respectively, the volume of thewastes is reduced, more wastes can be transported during transportation, and therefore the transportation cost is reduced.

Owner:李建辉

Solid waste compaction device

InactiveCN112571842AImprove compactionImprove work efficiencyGrain treatmentsPressesWaste treatmentMechanical engineering

The invention relates to the technical field of solid waste treatment, in particular to a solid waste compaction device which comprises a work box, a crushing device, a pushing device, a compaction device and an unloading device. The crushing device is horizontally arranged on the horizontal plane; a feeding hopper is arranged at the top of the crushing device and communicates with the crushing device; the pushing device is arranged beside the crushing device; the pushing end of the pushing device is arranged at the input end of the crushing device; the work box is arranged beside the crushingdevice and communicates with the output end of the crushing device; the compaction device is arranged at the top of the work box; the compaction end of the compaction device is vertically downward; the unloading device is arranged beside the work box and located at the bottom of the crushing device; solid waste is placed in the work box and is crushed through the crushing device; the crushed waste is conveyed into the work box through the pushing device; the waste in the work box is compacted through the compaction device; and the compacted waste is pushed out of the work box through the unloading device.

Owner:芜湖锋珉信息科技有限公司

Environment-friendly waste compaction device

The invention belongs to the technical field of environment-friendly devices, and discloses an environment-friendly waste compaction device. The environment-friendly waste compaction device comprisesa foundation pit. An integrated box is arranged in the foundation pit. A lifting device is connected to the integrated box. The environment-friendly waste compaction device further comprises a hydraulic device connected with the integrated box. The bottom of the foundation pit is connected with a blowdown system. A safety device is connected to the integrated box. The integrated box comprises a box body. The environment-friendly waste compaction device is simple in structure, capable of saving energy and high in efficiency and has good environmental friendliness.

Owner:河南前景电子科技有限公司

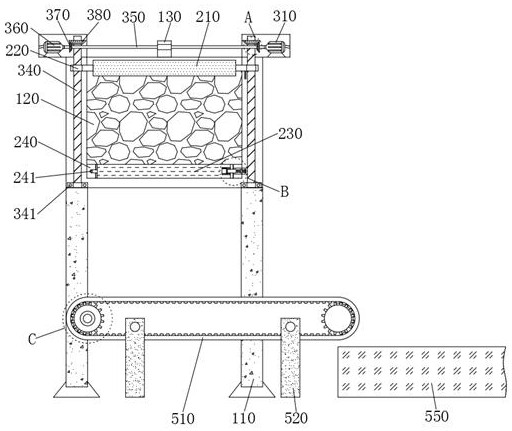

Environment-friendly waste compaction treatment device for soil and water loss control

PendingCN113492549AEasy extractionEasy to achieve extractionPressesElectric machineryEnvironmental engineering

The invention relates to the technical field of waste compaction treatment devices, in particular to an environment-friendly waste compaction treatment device for soil and water loss control. The waste compaction treatment device comprises a device body, wherein the device body comprises a support, a compaction bin and a first supporting plate; the compaction bin is arranged at the top end of the support; the first supporting plate is arranged at the top end of the compaction bin; a stamping mechanism is arranged inside the compaction bin; the stamping mechanism comprises a compaction plate, sliding blocks, an adjusting plate, a fixing block and a rack plate; the compaction plate is arranged at the bottom end of the first supporting plate; the two ends of the compaction plate are both fixedly connected with the sliding blocks; the inner surfaces of the sliding blocks are provided with threads; and the adjusting plate is arranged at the bottom end of the compaction bin. A threaded cap is driven by a rack to rotate so as to enable a second threaded rod to move towards the side close to an elastic block, so that waste in the compaction bin is extracted. A conveyor belt is driven by a third motor to rotate so as to drive the waste to enter the interior of a collection bin to be stored, so that the transfer and storage of the waste are achieved.

Owner:蒋涛涛

Solid waste pre-compaction device

InactiveCN112277366AImprove compaction efficiencyEasy to collectPressesWaste productEnvironmental engineering

The invention provides a solid waste pre-compaction device, and belongs to the technical field of waste recovery. The waste compaction device comprises a supporting base, a compacting assembly and a material storing and discharging assembly. The compacting assembly comprises a first fixing plate, a connecting sleeve, a first air cylinder, a compression block and a feeding funnel, and the materialstoring and discharging assembly comprises a first material storing barrel, a second material storing barrel, an electric guide rail and a first connecting rod. During usage, the first air cylinder drives the compression block to move upwards, so that the compression block does not block the discharging end of the feeding funnel any more, then waste in the feeding funnel can fall into the first material storing barrel through a first sliding groove, then the first air cylinder drives the compression block to move downwards to compress the waste in the first material storing barrel, at the moment, the compacted waste in the second material storing barrel can be automatically discharged under the action of gravity, then, manual unloading is not needed, a large amount of manpower can be saved, and therefore the compaction efficiency of the waste compaction device can be improved.

Owner:叶其胜

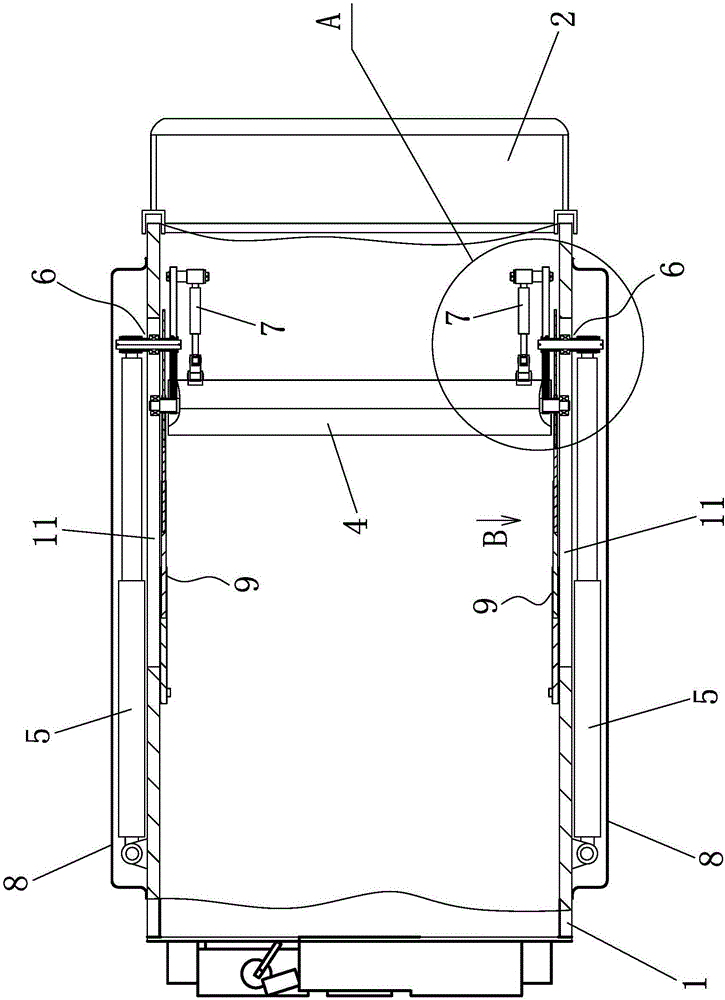

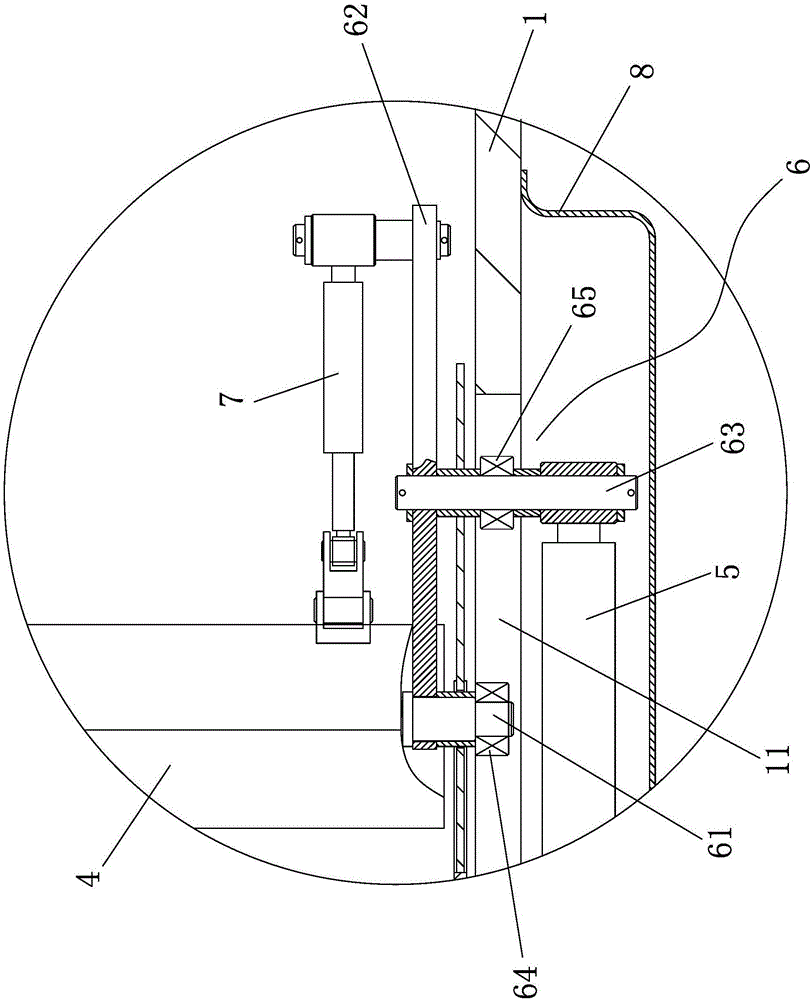

Door opening mechanism of waste compaction box

PendingCN108529077AAvoid inhalationReduce labor intensityRefuse receptaclesWaste compactionAutomation

The invention relates to a door opening mechanism of a waste compaction box. The waste compaction box is provided with a box body, and a feed port is formed in the top of the box body. The door opening mechanism of the waste compaction box comprises a first hinge base set, a cover plate and a transmission assembly which are fixed to the box body and are arranged on one side of the feed port; the cover plate is provided with a first hinge end and a second hinge end, wherein the first hinge end is used for being connected to the first hinge base set in a rotating mode, and the second hinge end is far away from the first hinge end; and the transmission assembly comprises a connecting part and a driving part. According to the door opening mechanism of the waste compaction box, the cover plateis driven to move through the rotation of the driving part, so that the purpose of covering / opening the feed port of the cover plate can be achieved, the cover plate capable of covering / opening the feed port is not required to be manually opened, the labor intensity can be lowered, an operator does not need to operate at the feed port, so that the phenomenon that air in the feed port is directly inhaled can be avoided, and the automation degree is high.

Owner:SHENZHEN ZHISHI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com