Patents

Literature

42results about How to "Automatic pour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

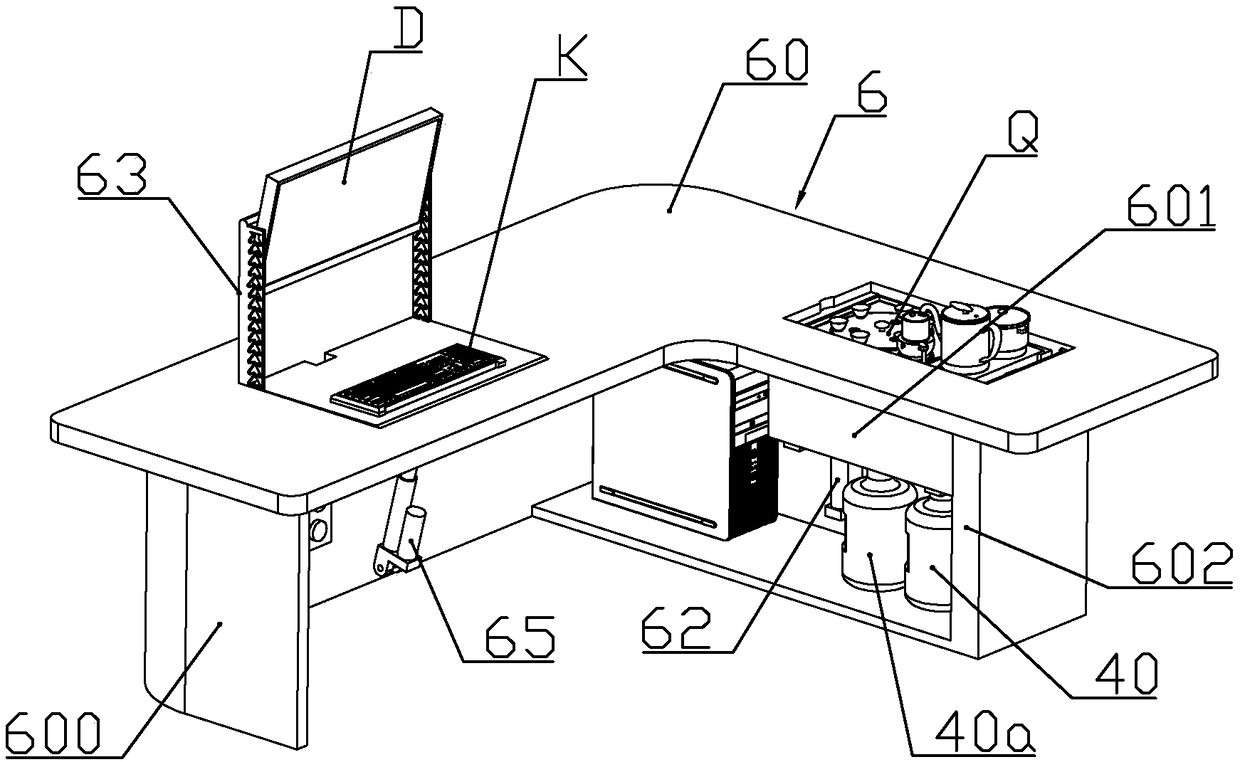

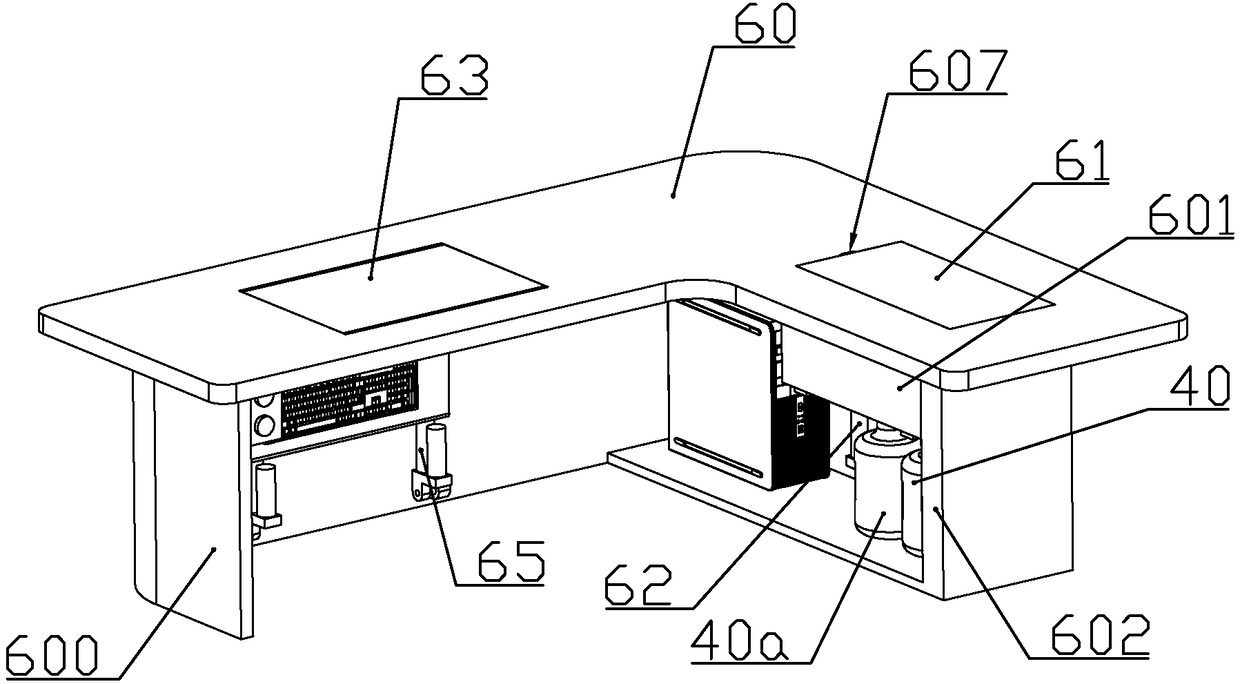

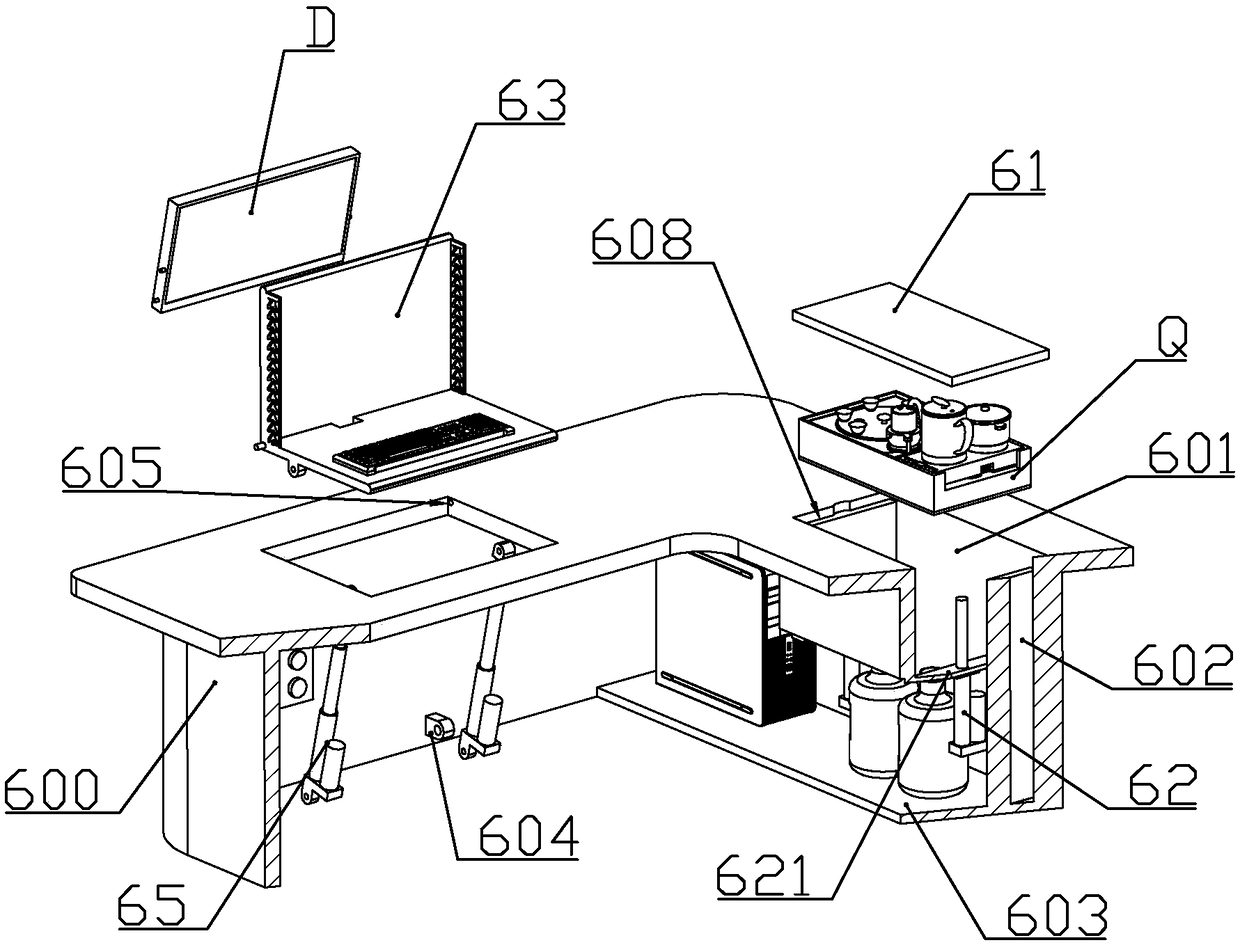

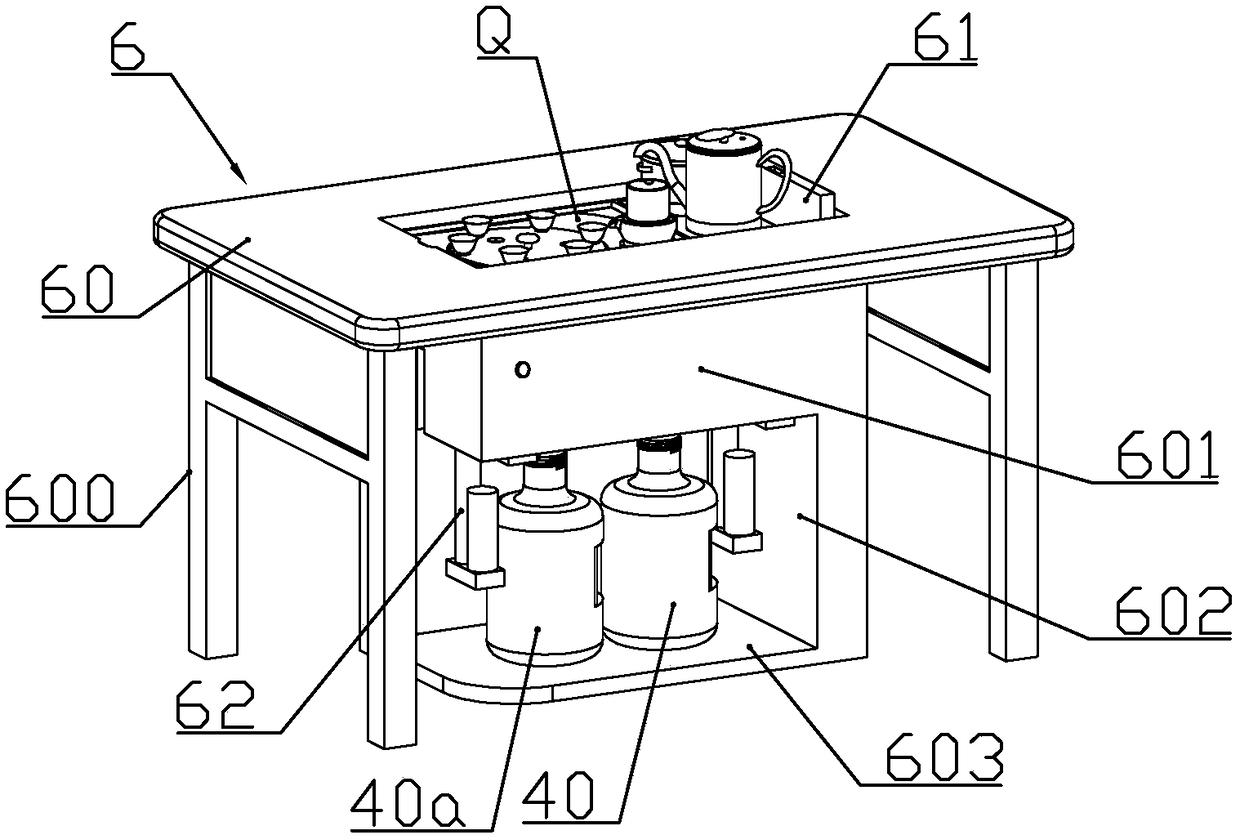

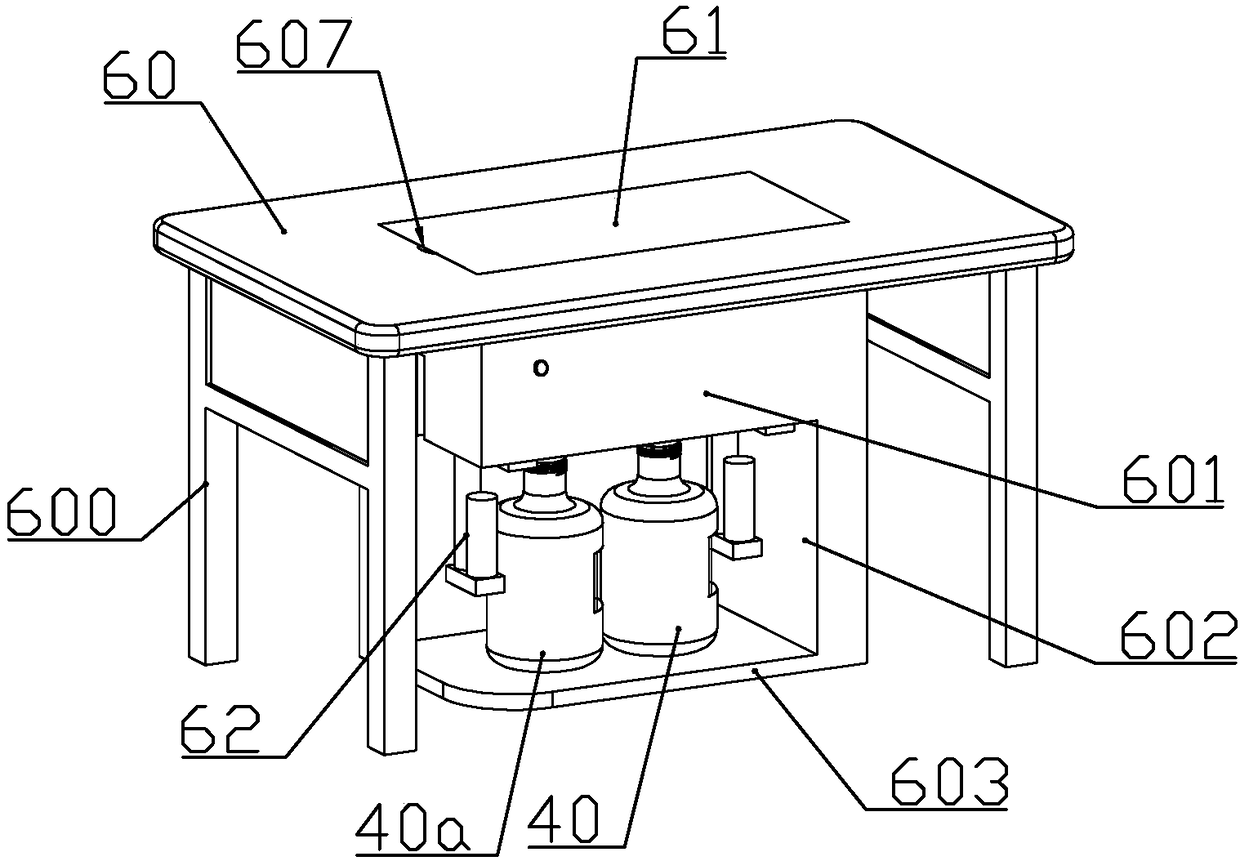

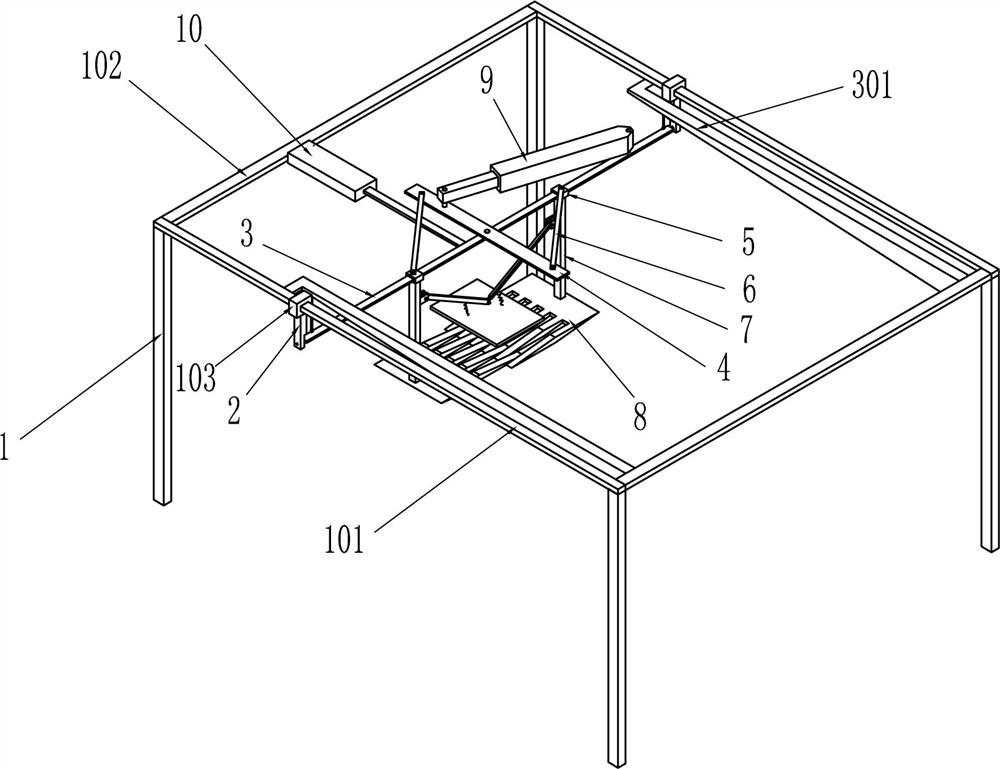

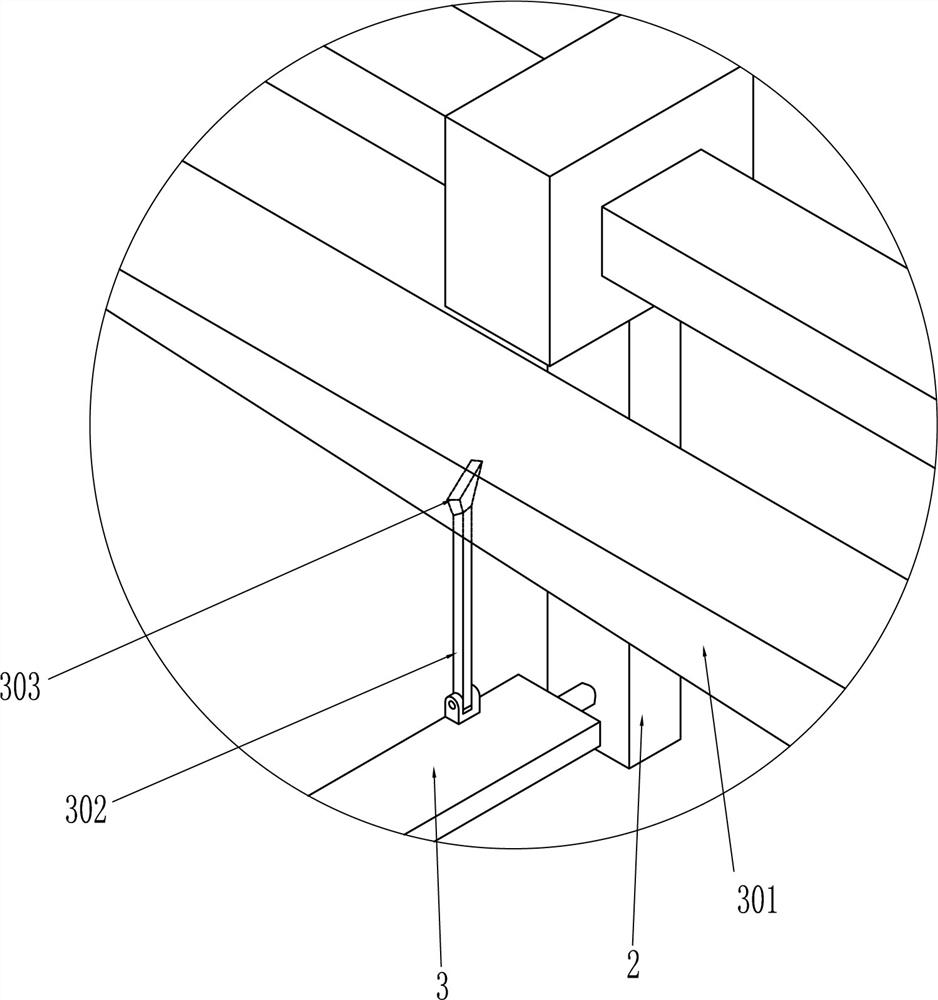

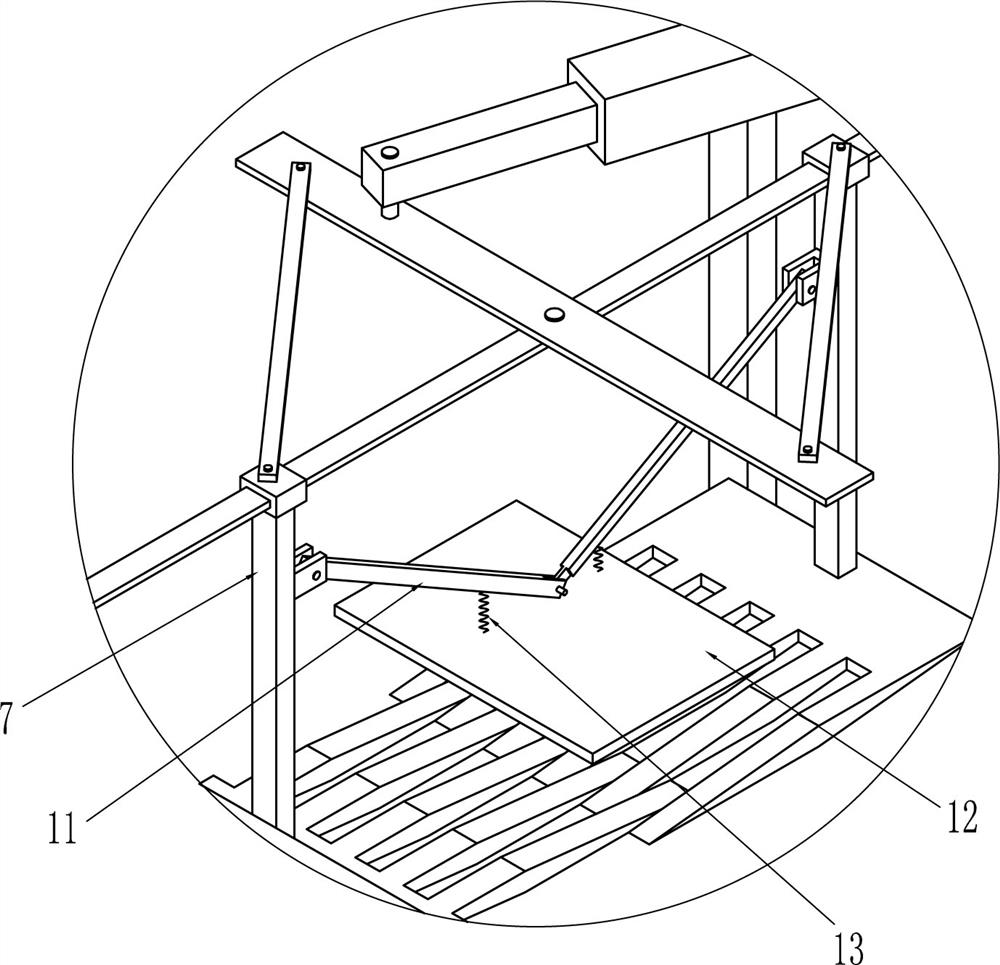

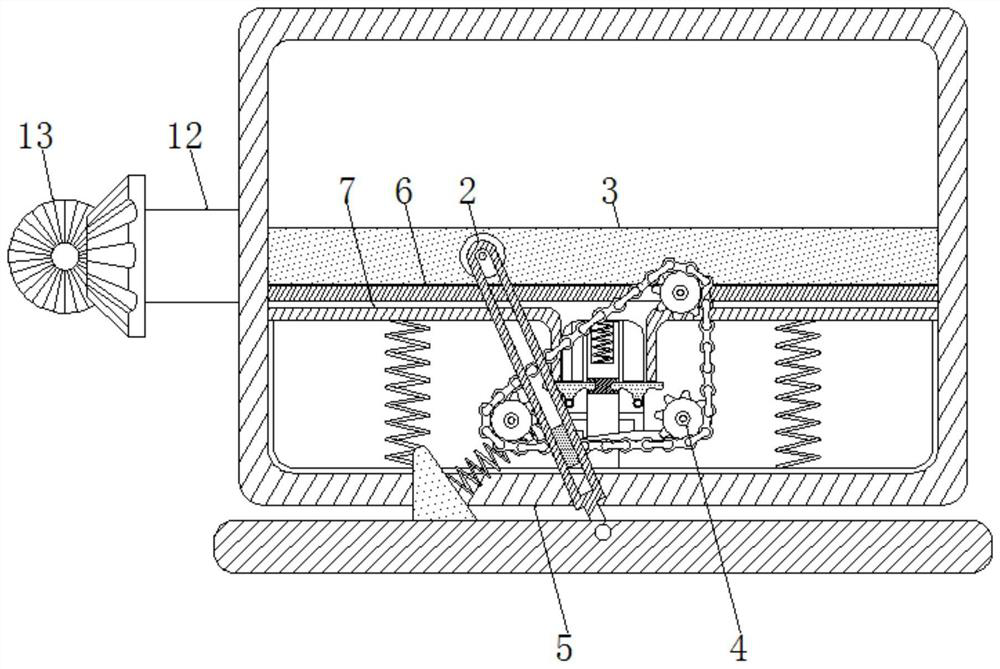

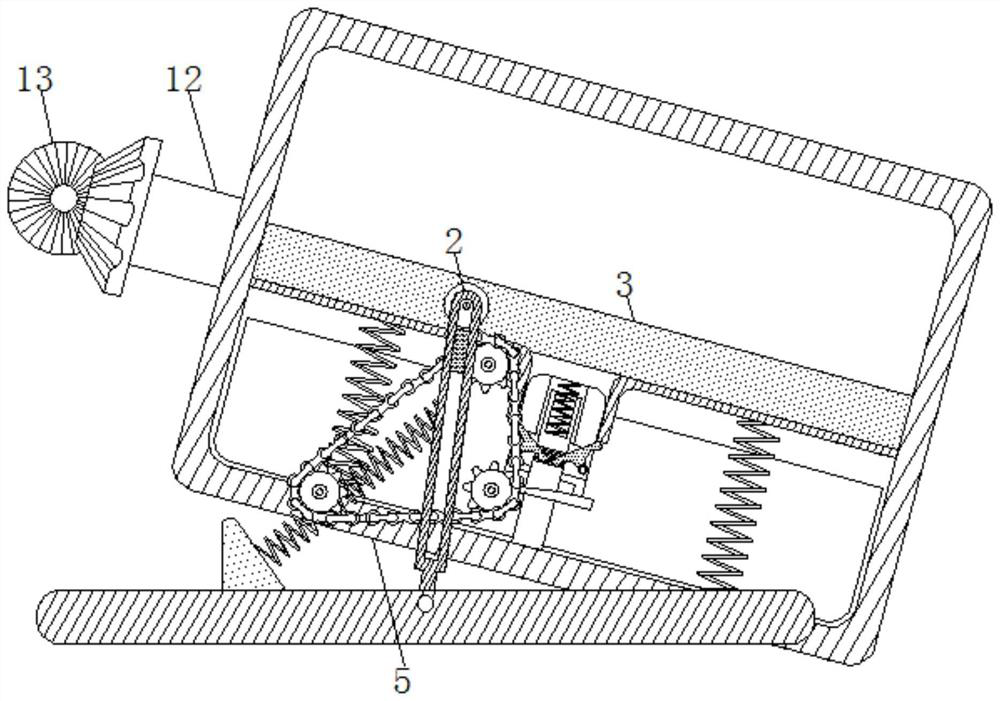

Multifunctional office table

InactiveCN108542116AFlexible adjustmentAutomatic pourOffice tablesServing tablesSoftware engineeringDisplay device

Owner:江雨涛

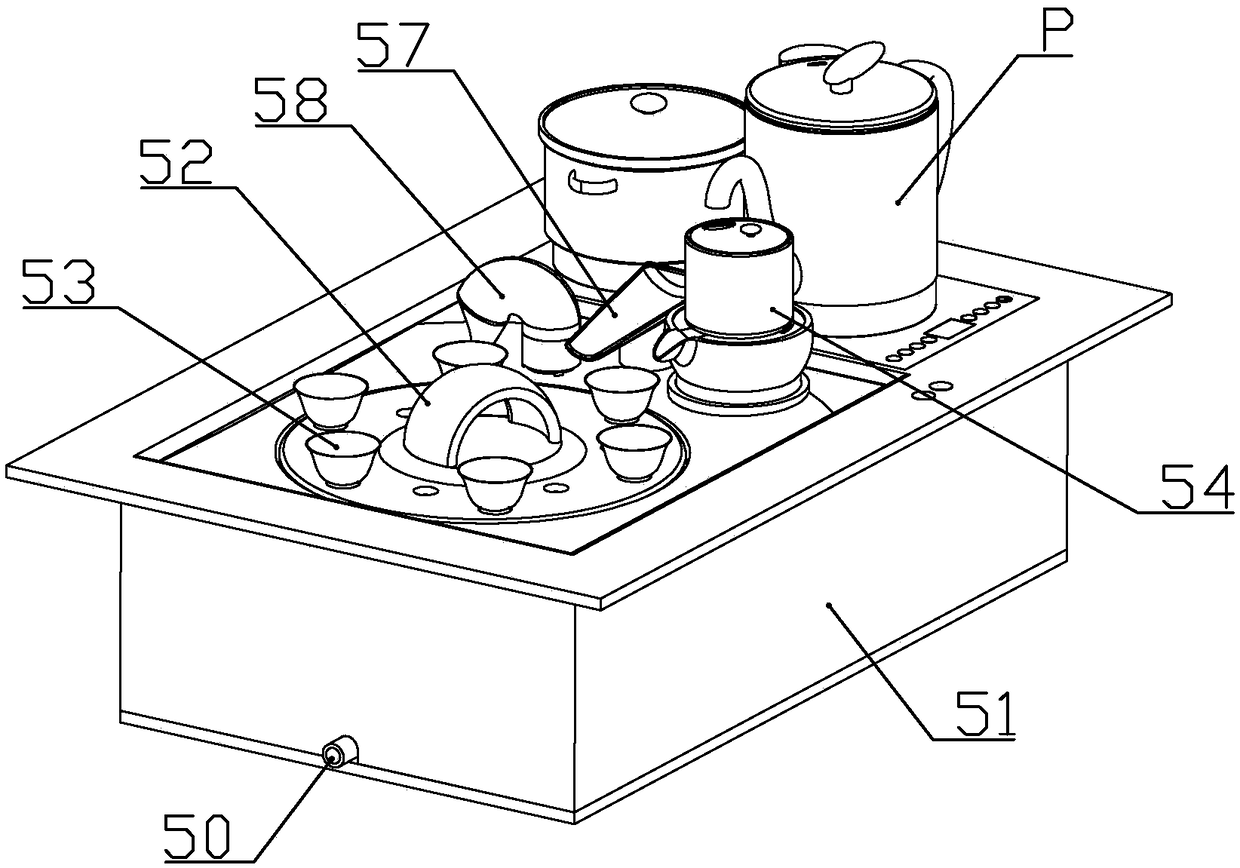

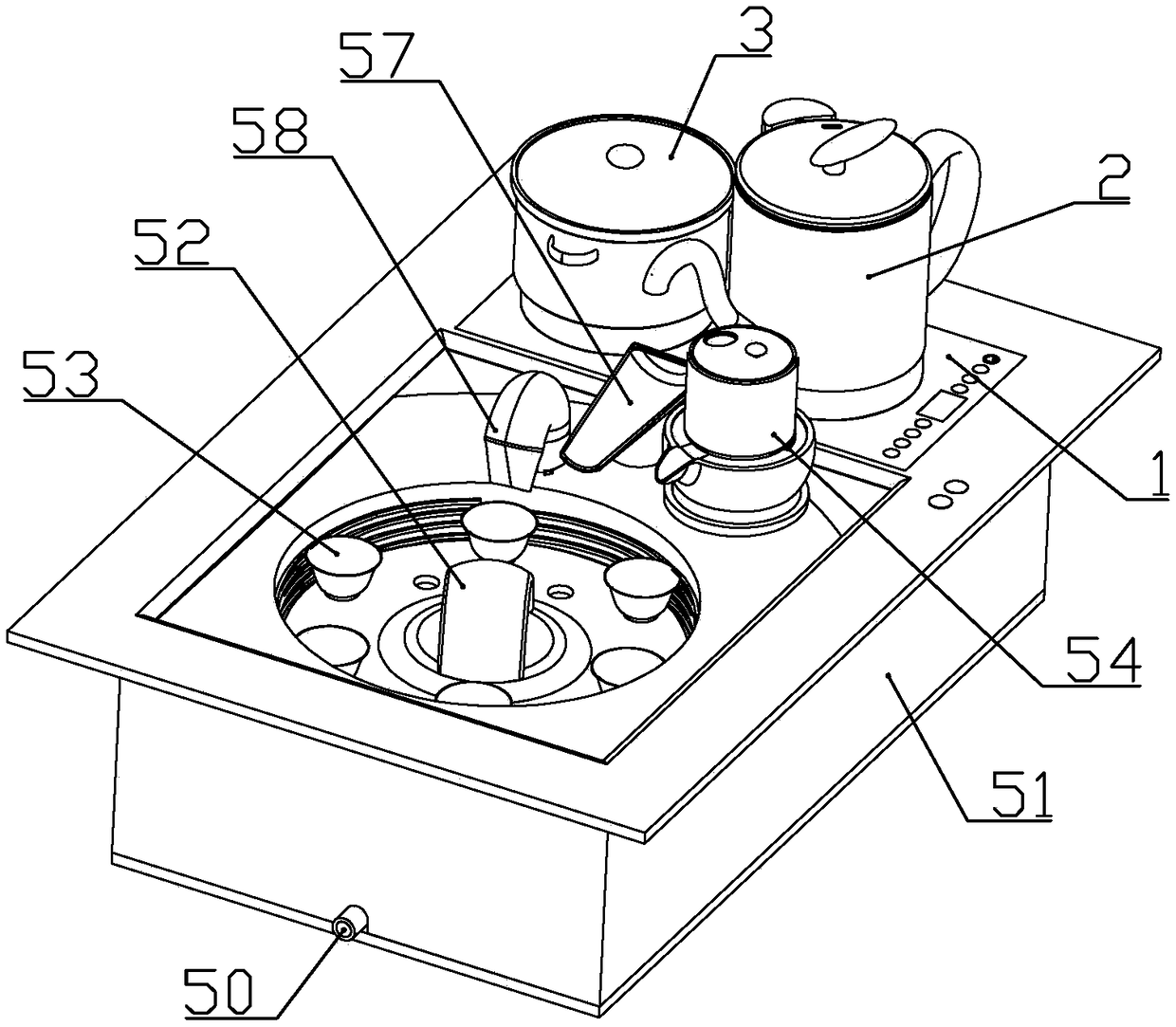

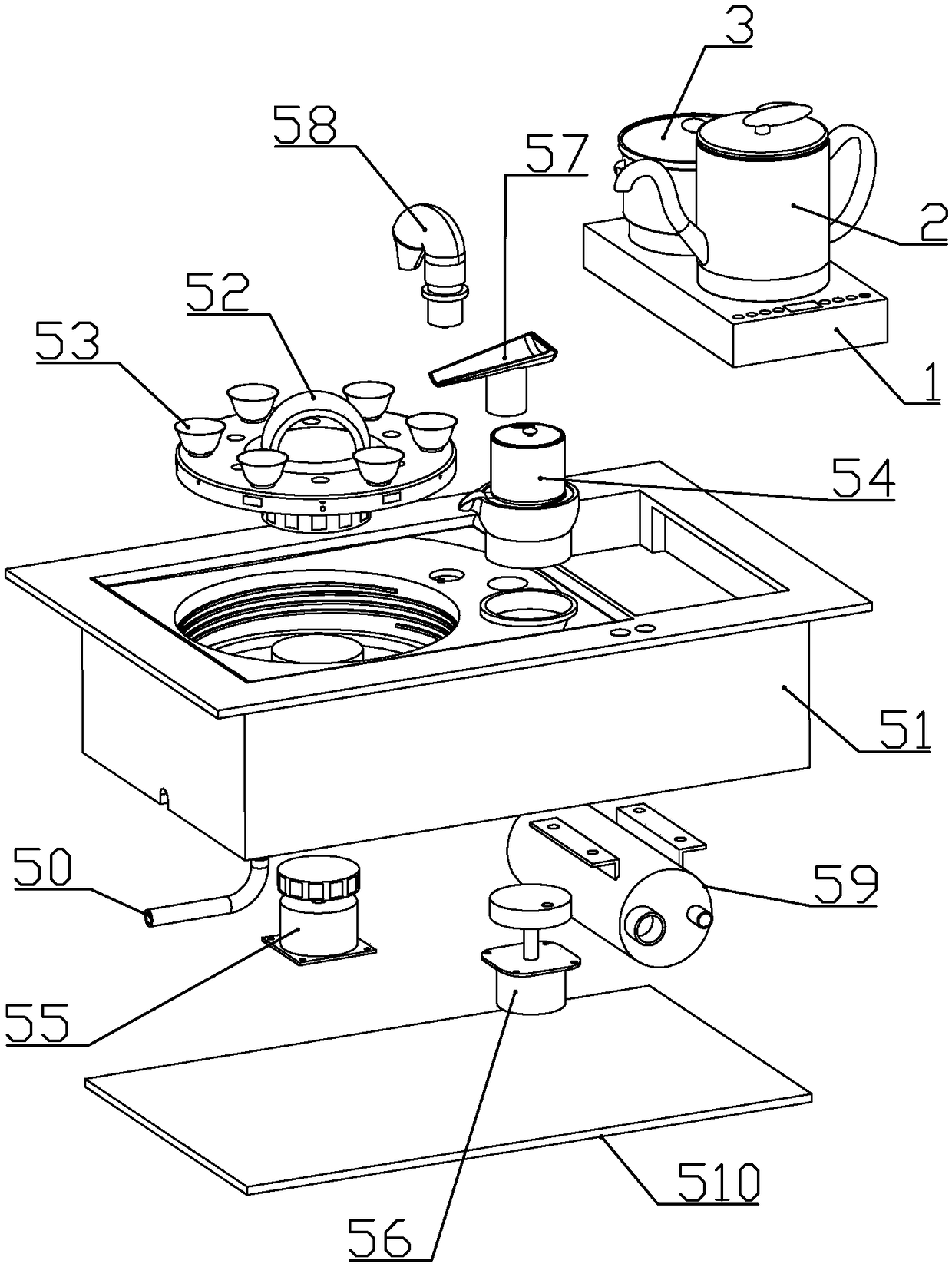

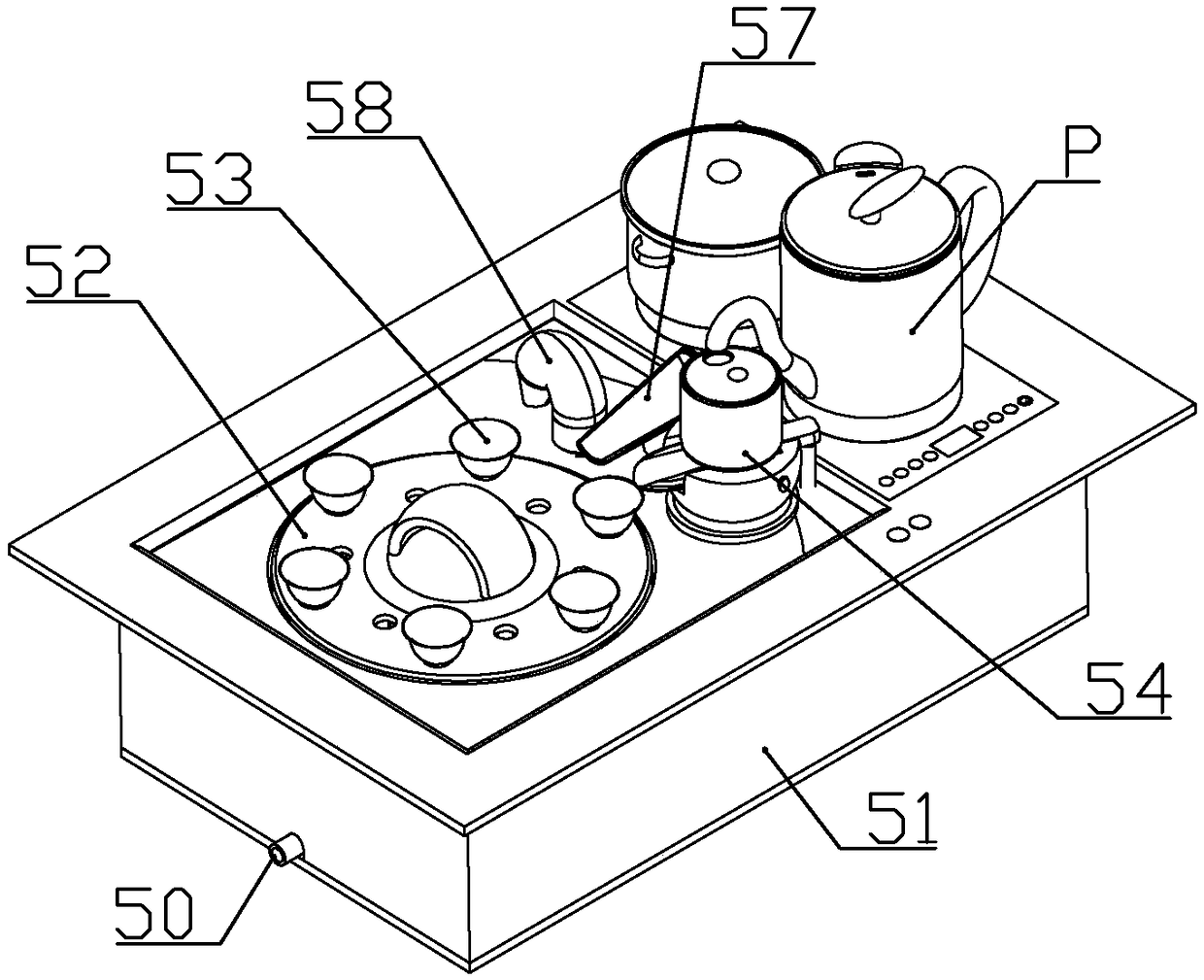

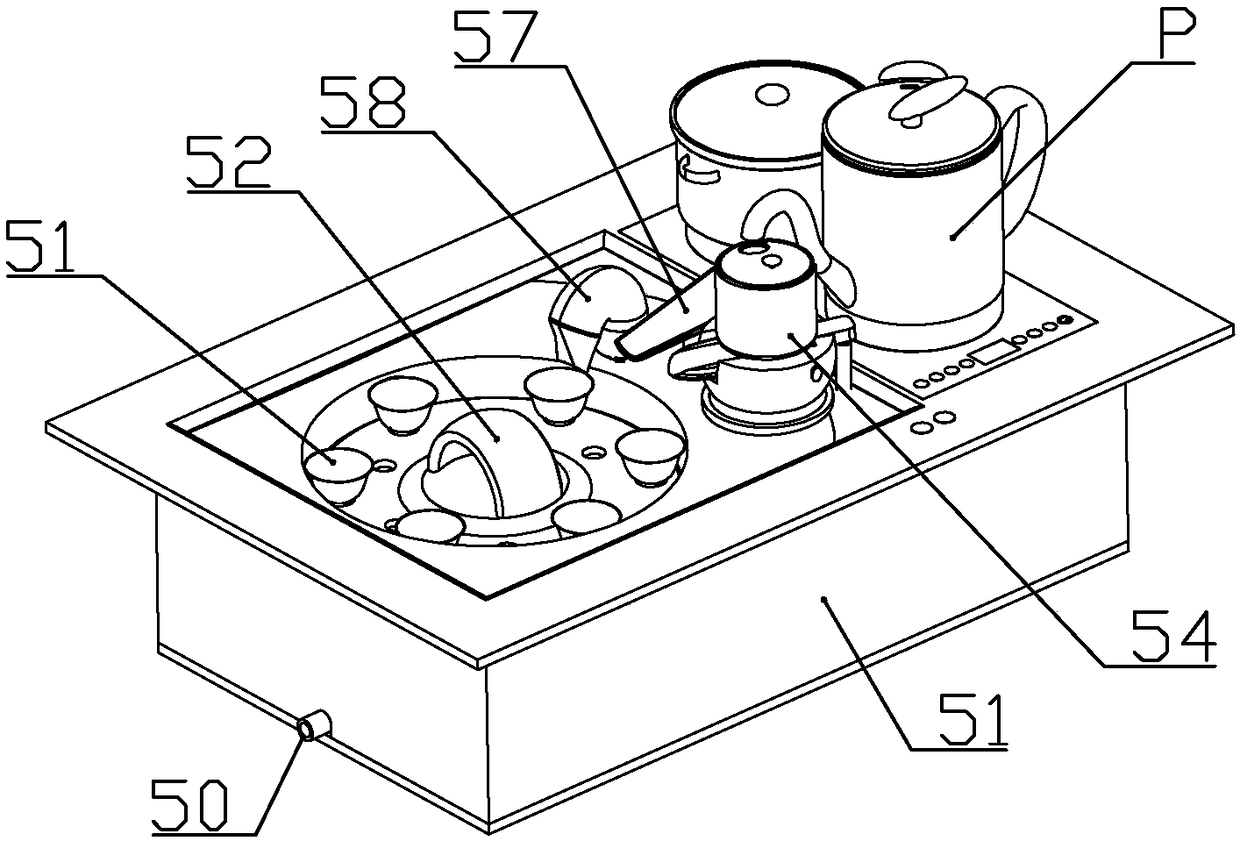

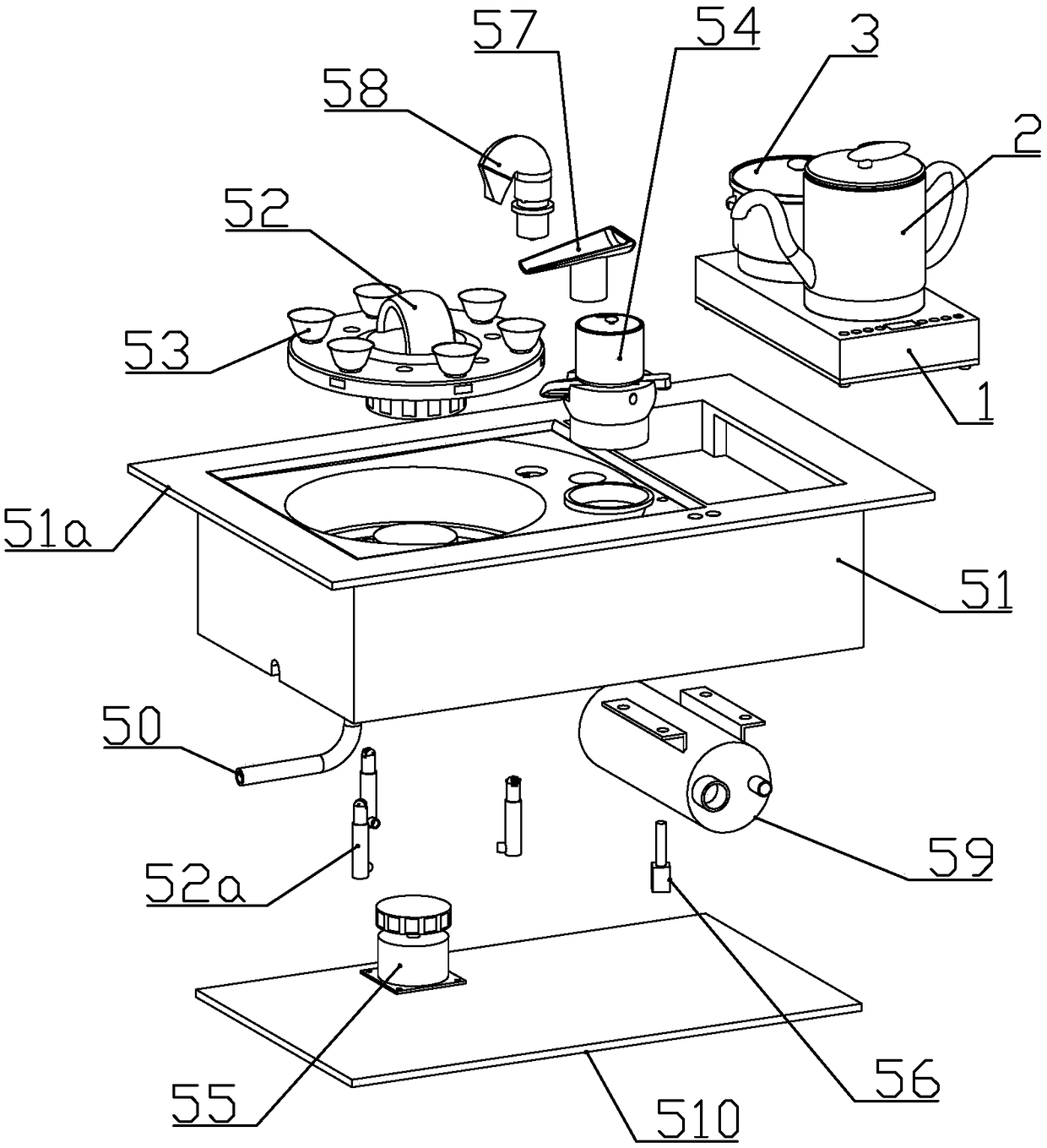

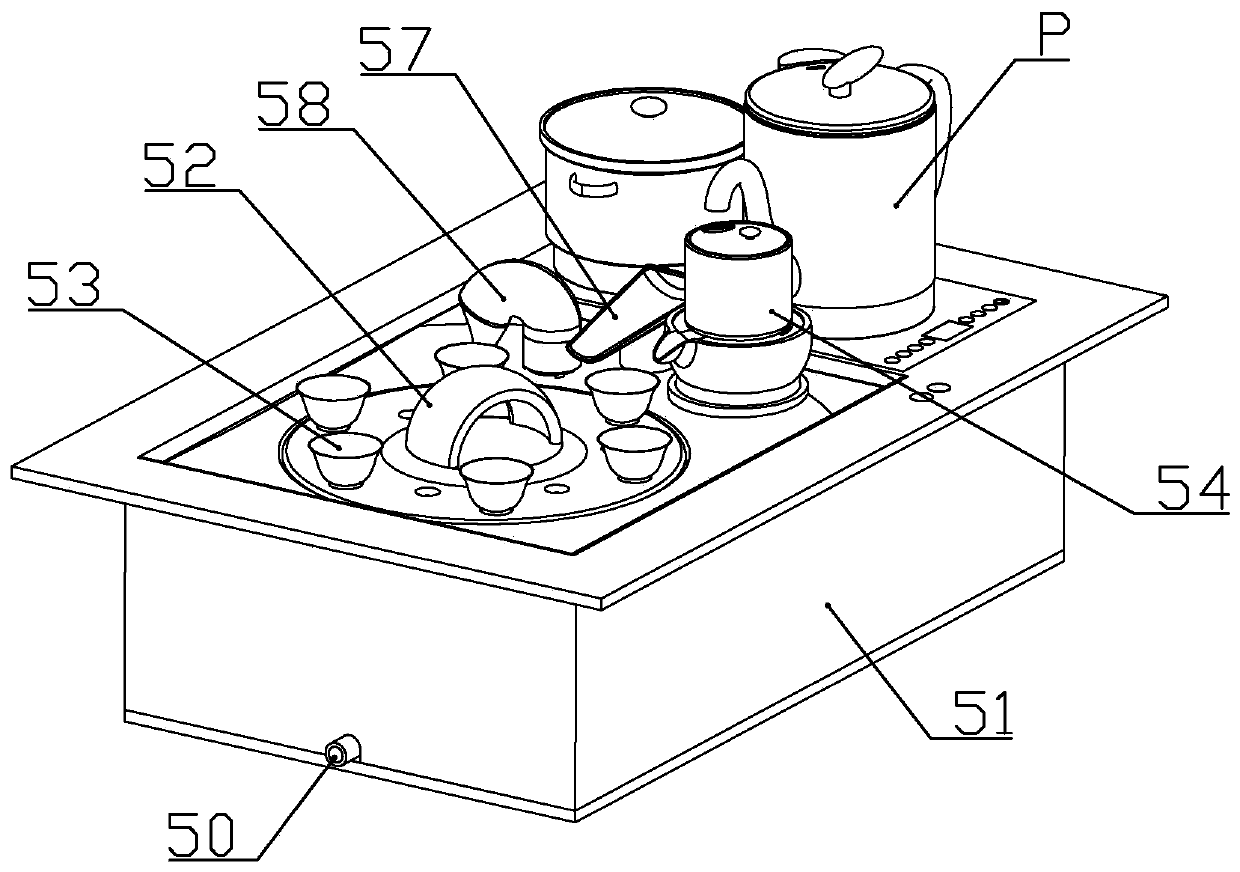

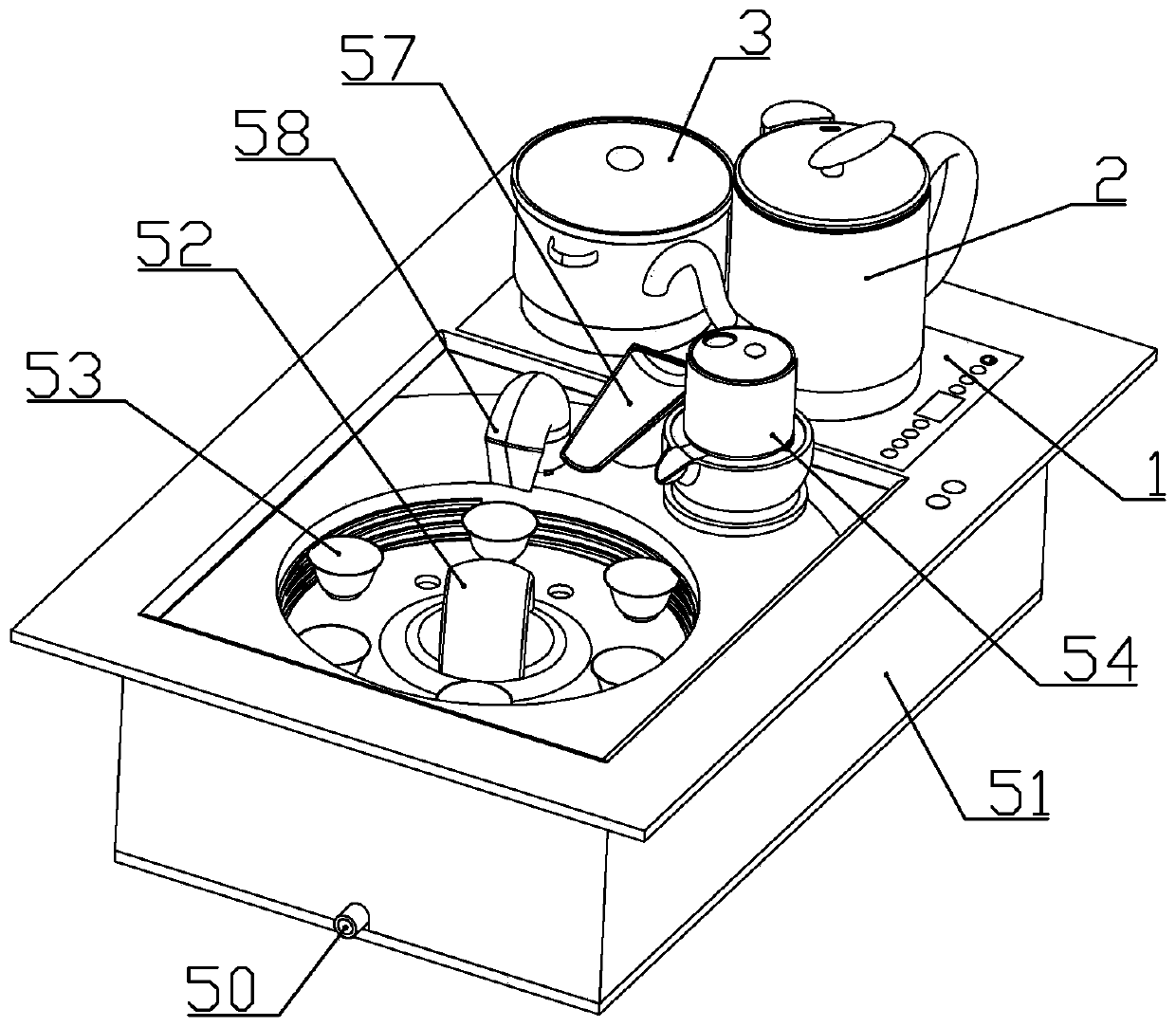

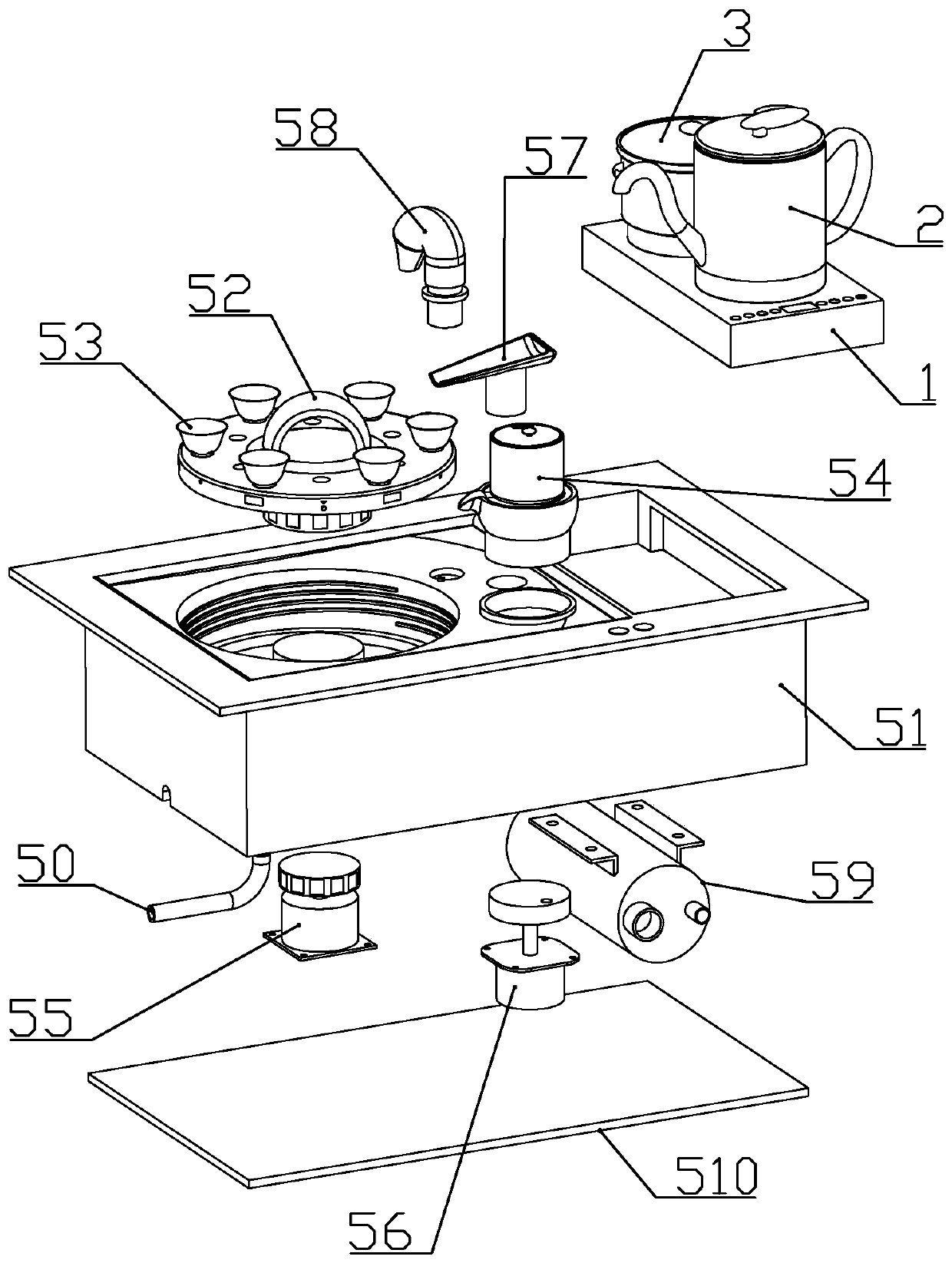

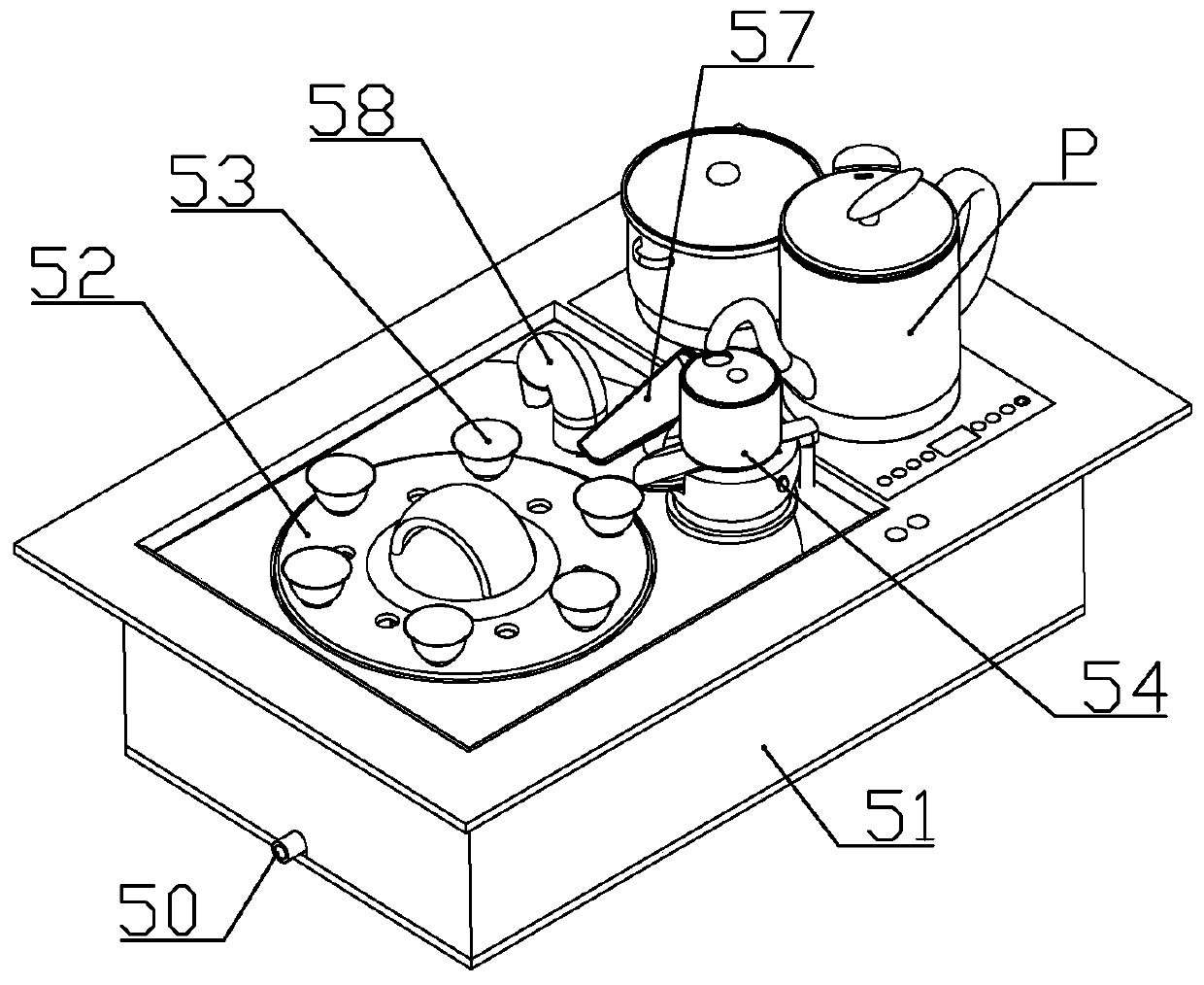

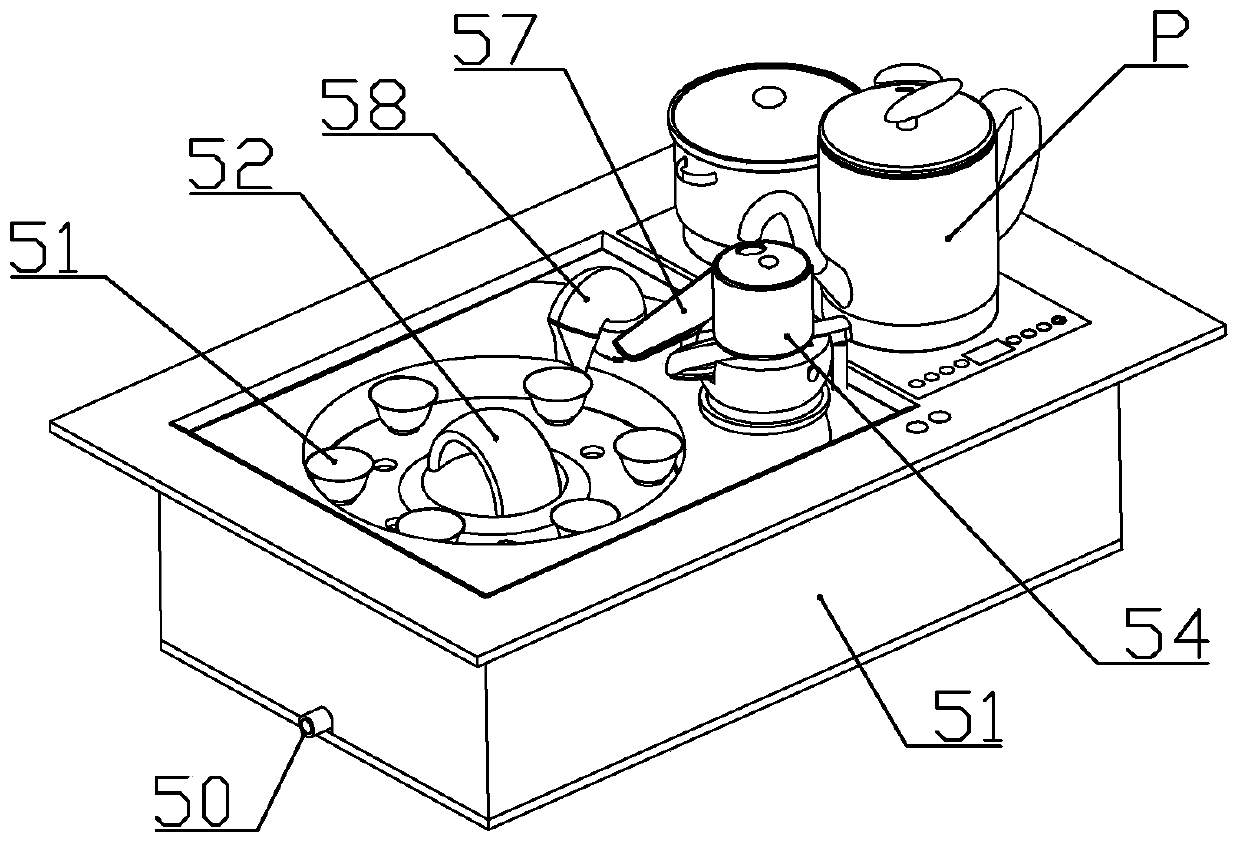

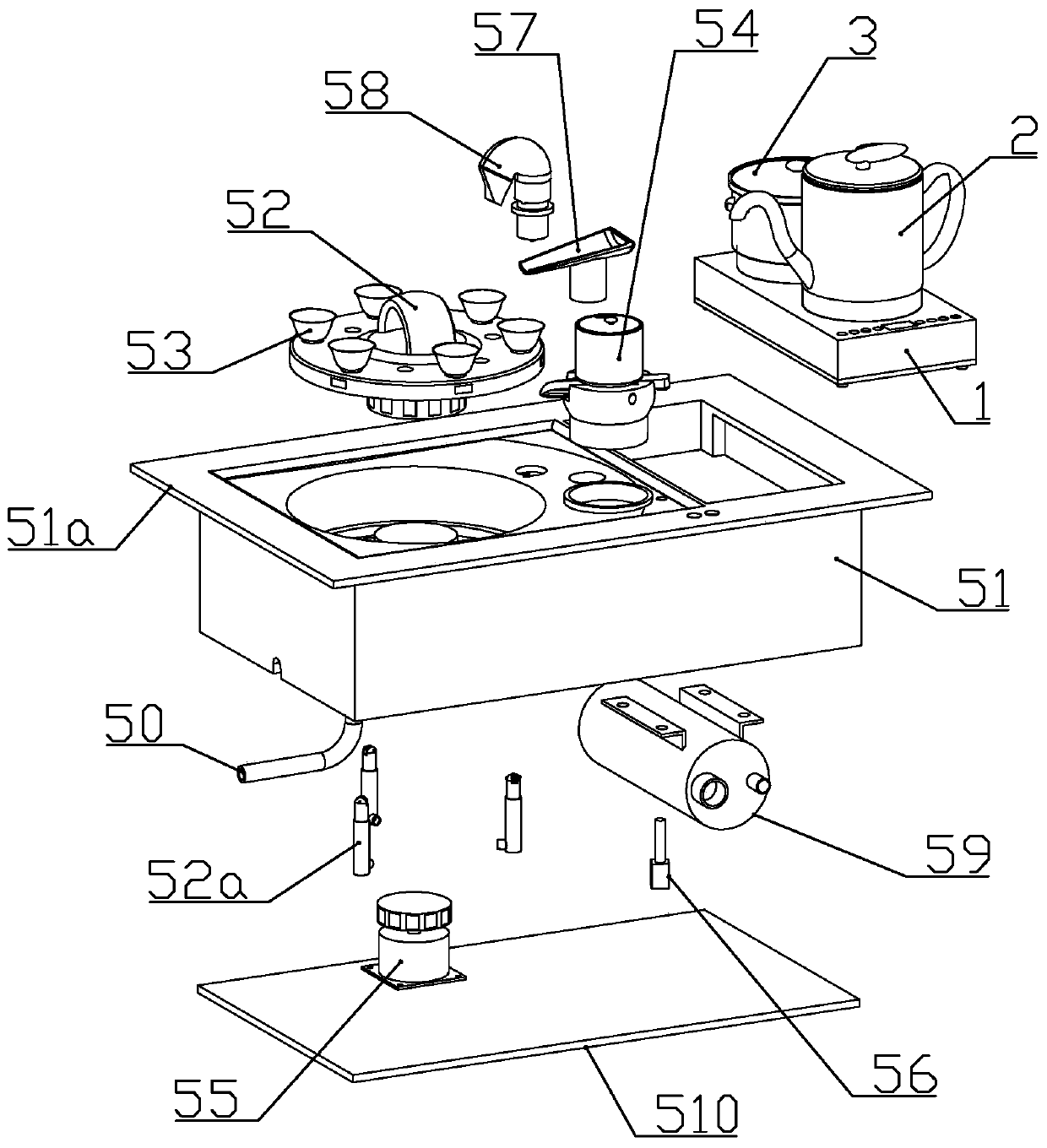

Intelligent tea set

ActiveCN108308978AAutomatic pourEasy to automate cleaningWater-boiling vesselsDomestic vesselsRotary valveEngineering

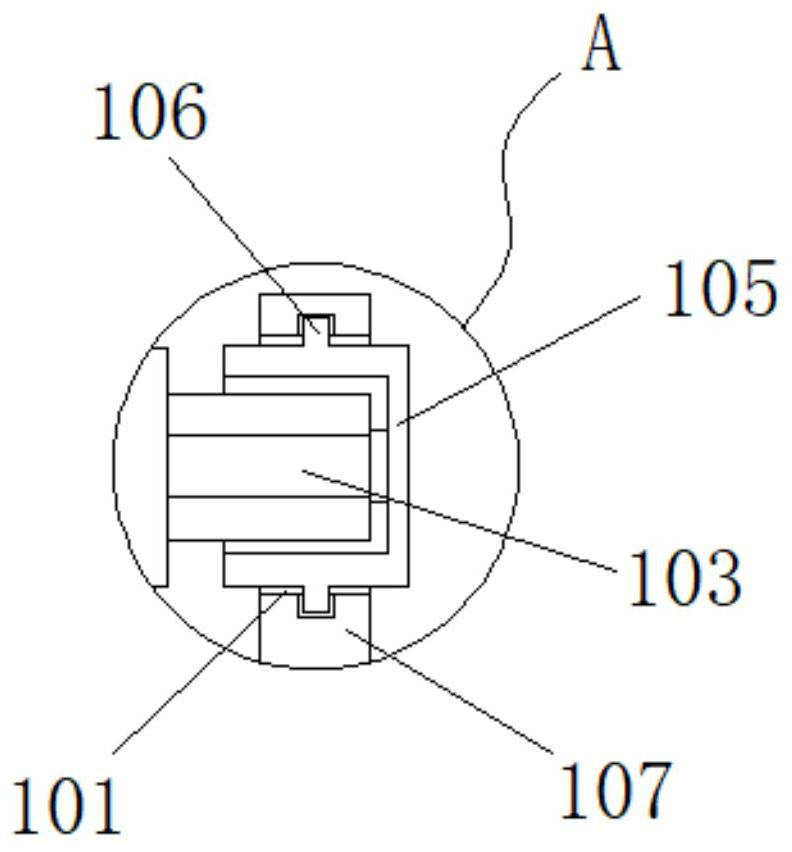

The invention discloses an intelligent tea set which comprises a tea tray, a tea kettle set, a teacup rotating disc, a plurality of teacups, a tea kettle, a cup-washing water guide plate and a blowingcomponent, wherein the tea kettle set is arranged on the right side of the tea tray; the teacup rotating disc is rotationally arranged on the left side of the tea tray; the plurality of teacups are adsorbed onto the teacup rotating disc by virtue of magnetic force; the tea kettle is mounted on the tea tray, positioned between the tea kettle set and the teacup rotating disc and is used for makingtea; the cup-washing water guide plate is used for guiding water poured out of the tea kettle into the teacups; the blowing component is used for blowing water in the teacups out of the teacups; the tea kettle set comprises the tea kettle; the side wall of the tea kettle is connected with a water outlet pipe; the tea kettle comprises a tea kettle seat inserted on a tea kettle mounting seat and a kettle body arranged at the upper end of the tea kettle seat; a tea outlet hole is formed in the bottom surface of the kettle body; a rotary valve driven by a tea outlet motor is rotationally arrangedat the upper end of the tea kettle seat. The teacup rotating disc is driven to rotate by virtue of the arrangement of the teacup rotating motor, and opening and closing of the rotary valve can be controlled by the tea outlet motor, so that tea in the tea kettle can be automatically poured into each teacup on the teacup rotating disc.

Owner:瑞安市佰乐雅工艺品有限公司

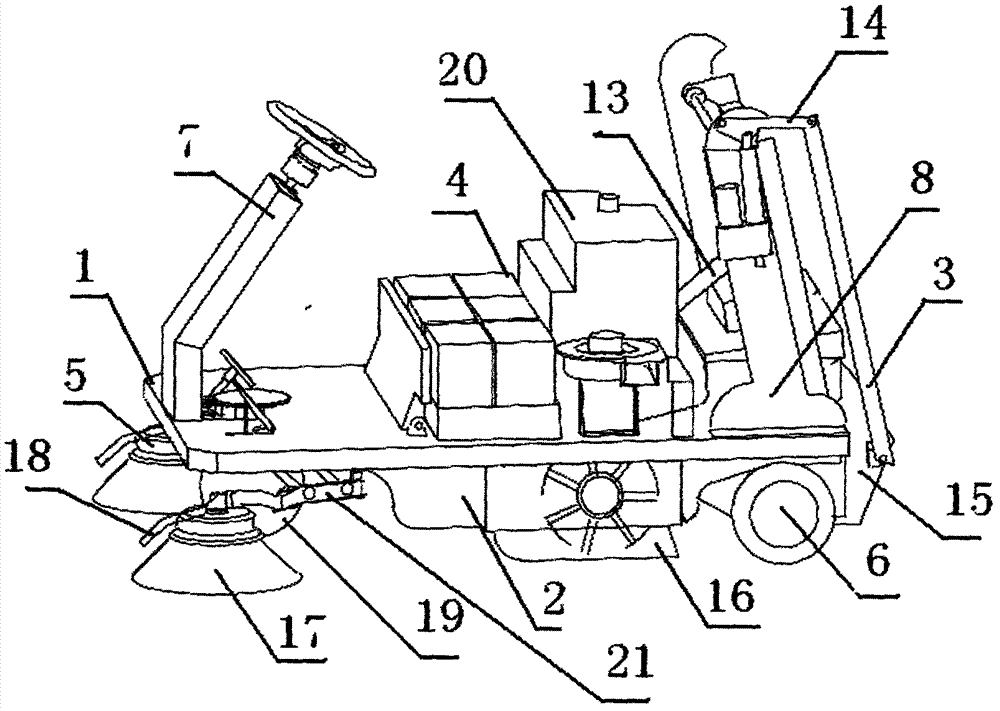

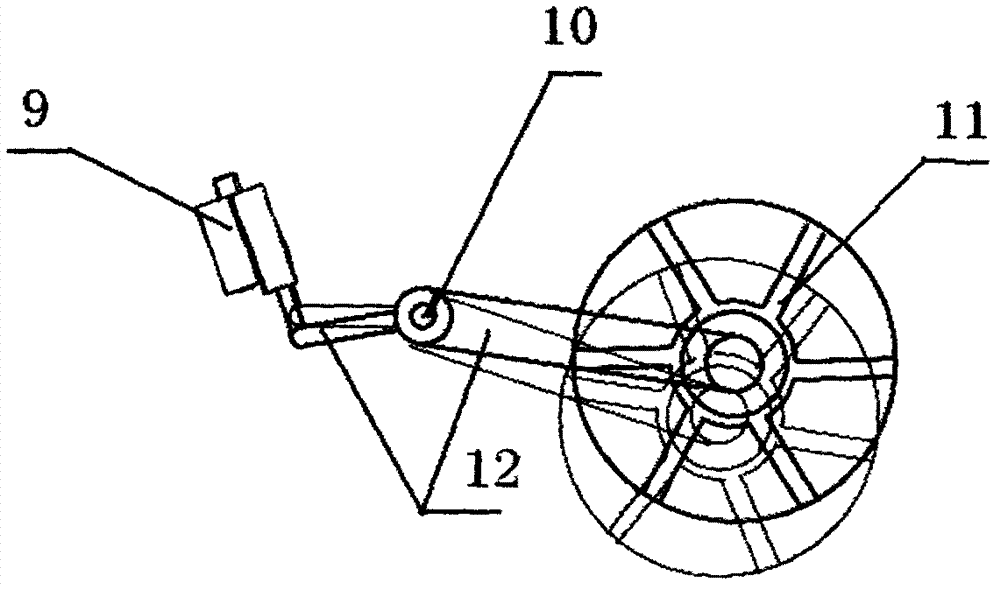

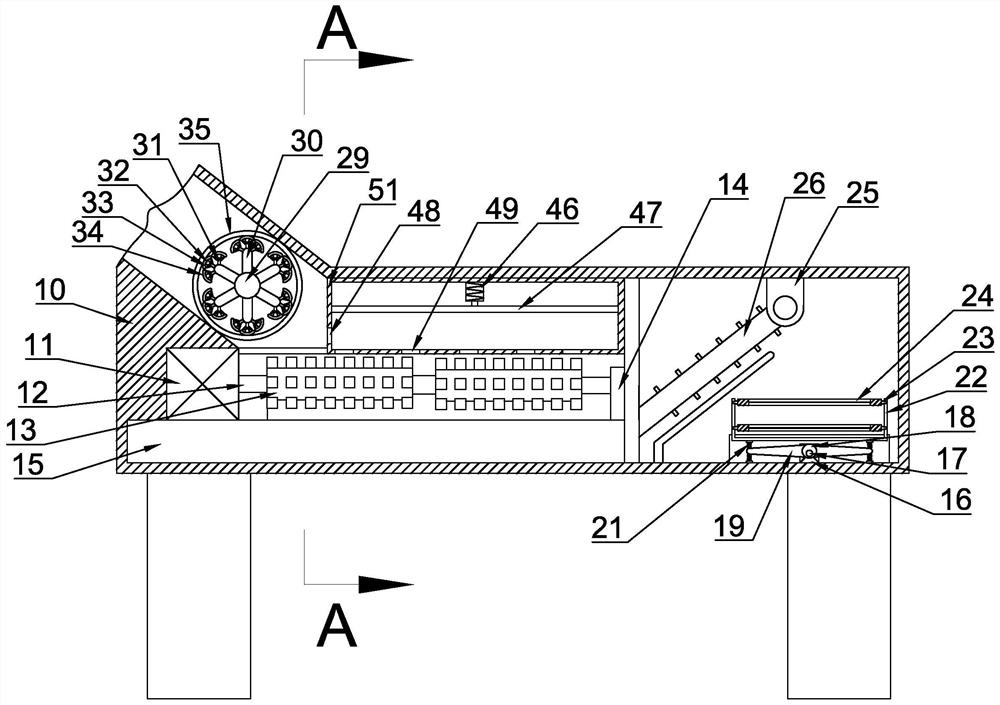

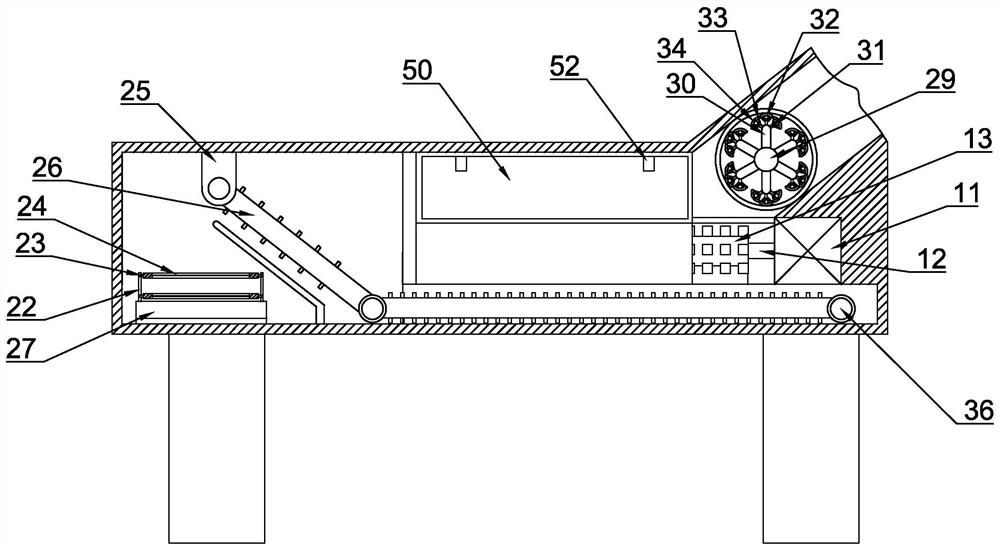

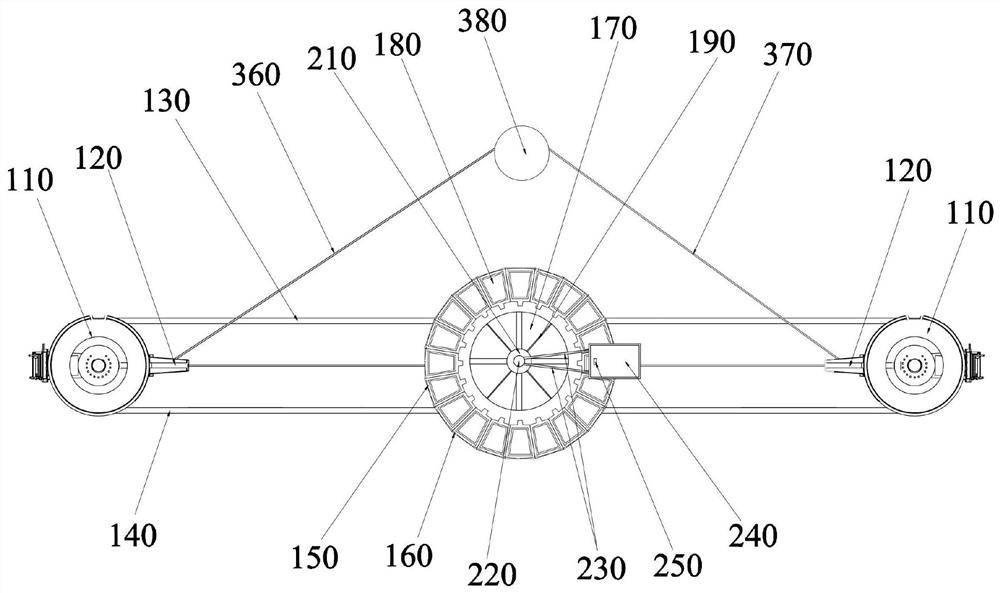

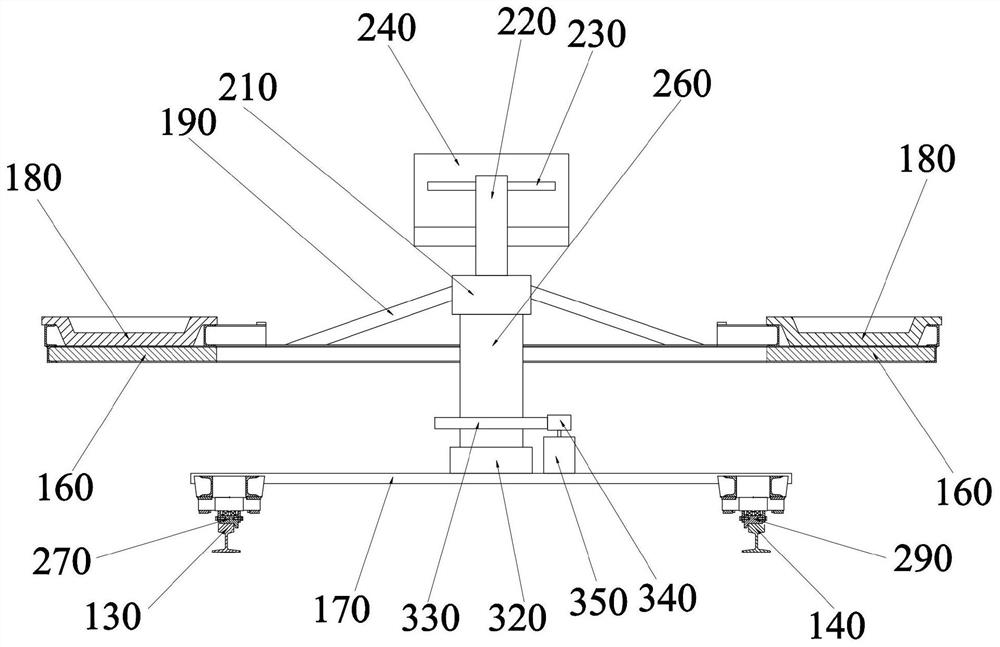

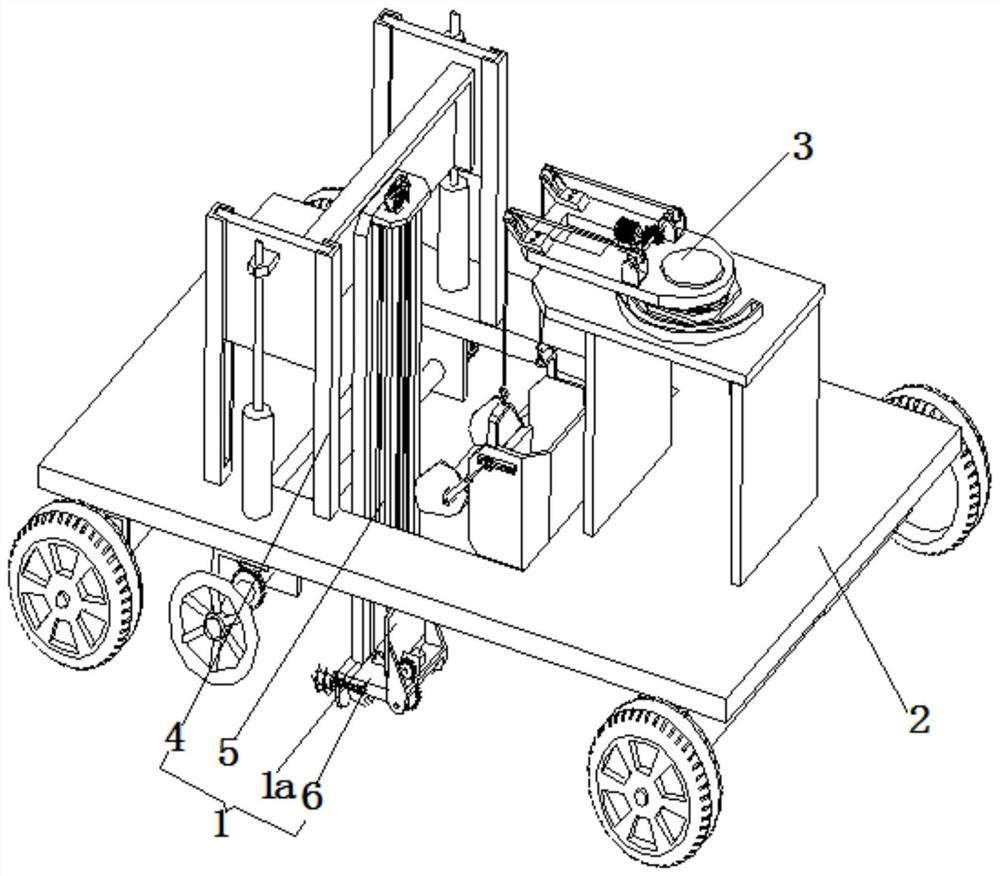

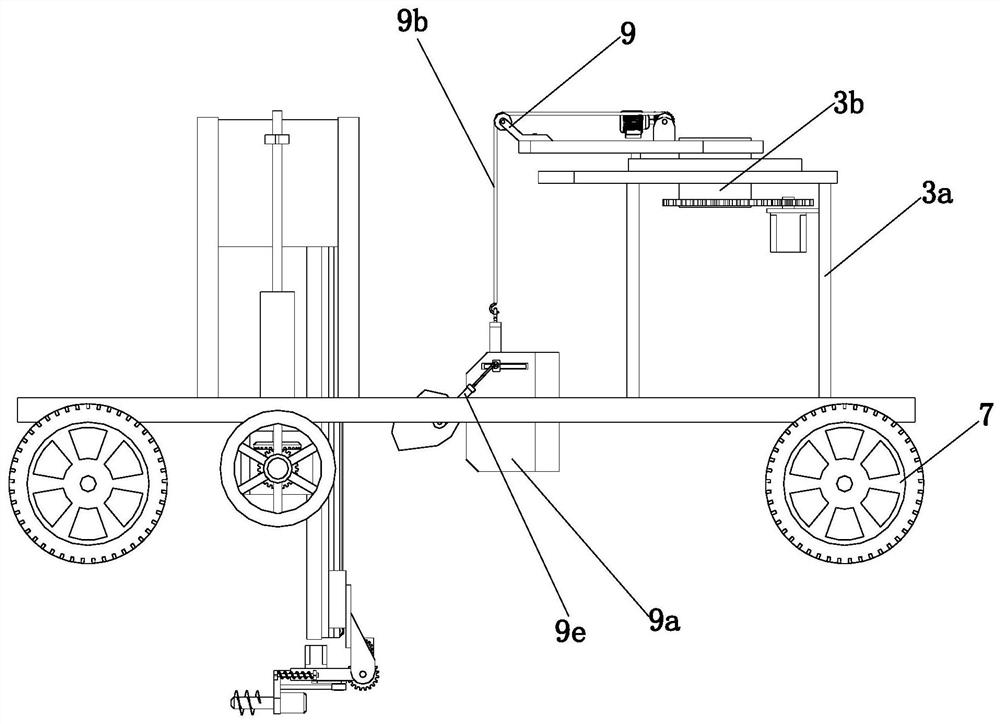

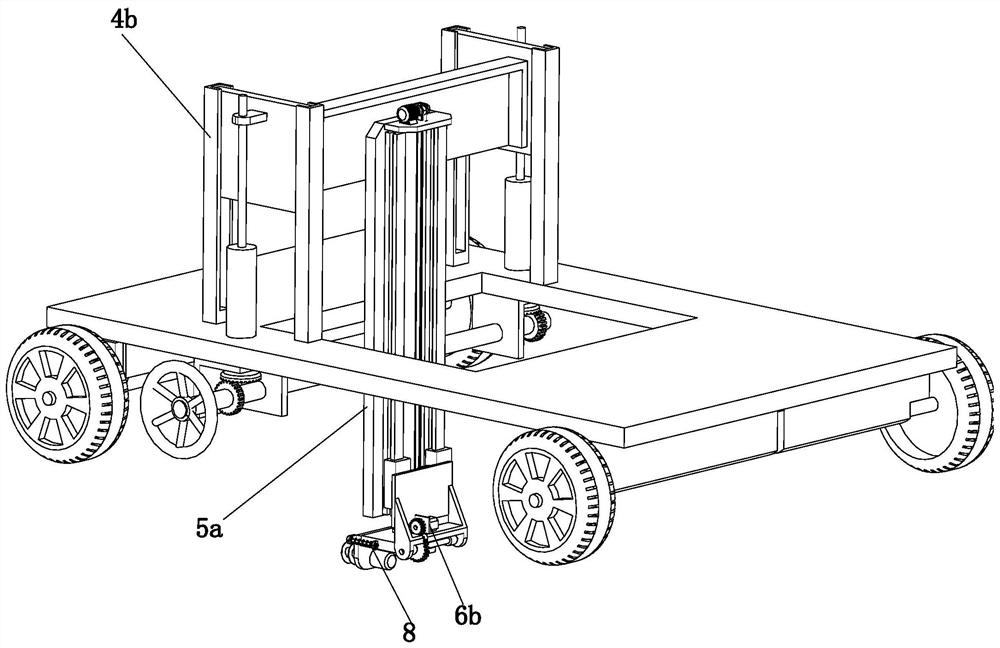

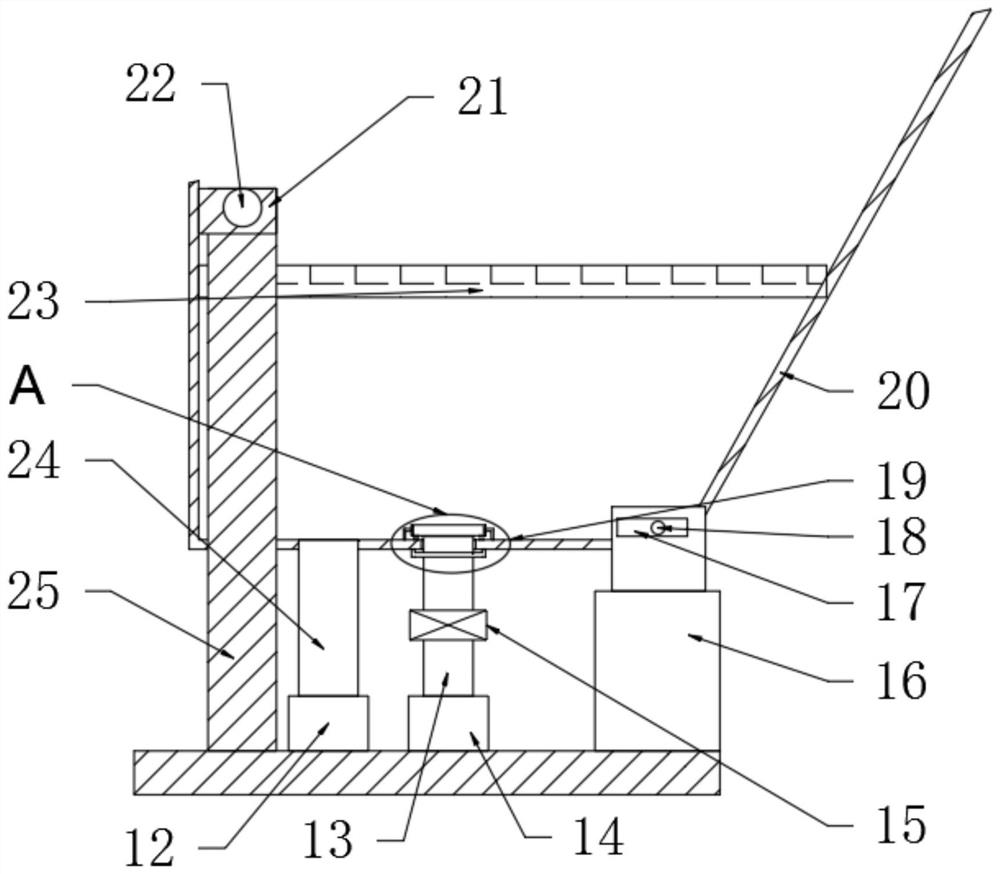

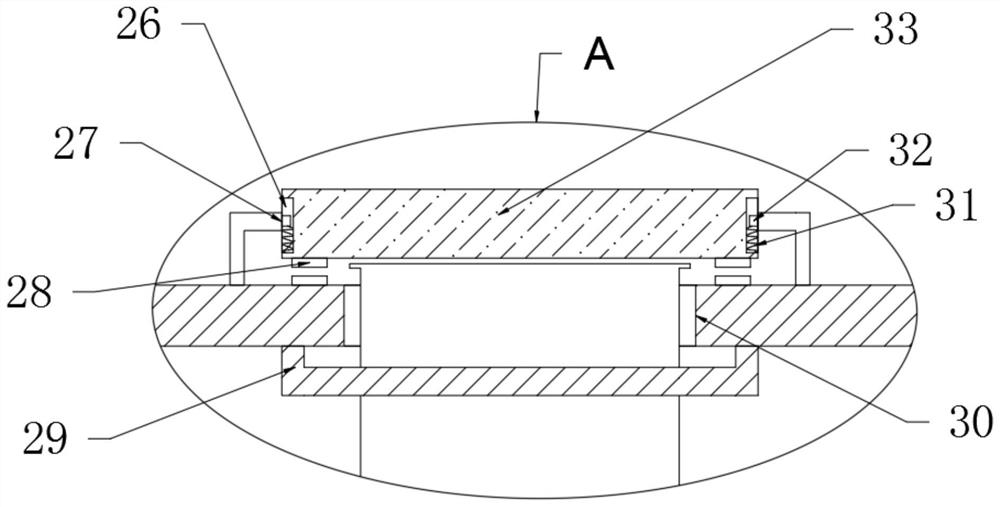

Novel road sweeper

The invention discloses a novel road sweeper. The novel road sweeper comprises a storage battery set, a chassis, a main lifting mechanism, a garbage placing device, an integrated circuit controller, a side brushing mechanism, a driving mechanism, a turning mechanism and a dust collecting mechanism, wherein the main brush lifting mechanism is located in the middle of the chassis bottom; the main brush mechanism comprises an electric pushing rod, a fixed rotation support, a roll brush and a rotary force arm; a vaporific nozzle is arranged on the front brush handle of the road sweeper, is connected to a water tank through water pipe, and is supplied with water through a water pump; the water pump adjusts and controls the water pressure state through the integrated circuit controller, so that the dust is prevented from being raised up during sweeping; the removal of raised dust caused by roll brush mainly depends on the working condition of a dust absorbing mechanism; vibratory dust removal for a filter board is added to the original dust absorbing mechanism, and the dust absorbed by the filter board is removed, so that the whole air sucking channel is clear, and the raised dust is completely eliminated; besides, the electric pushing rod is adopted to lift a garbage box, so that garbage is automatically placed into a dustbin.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

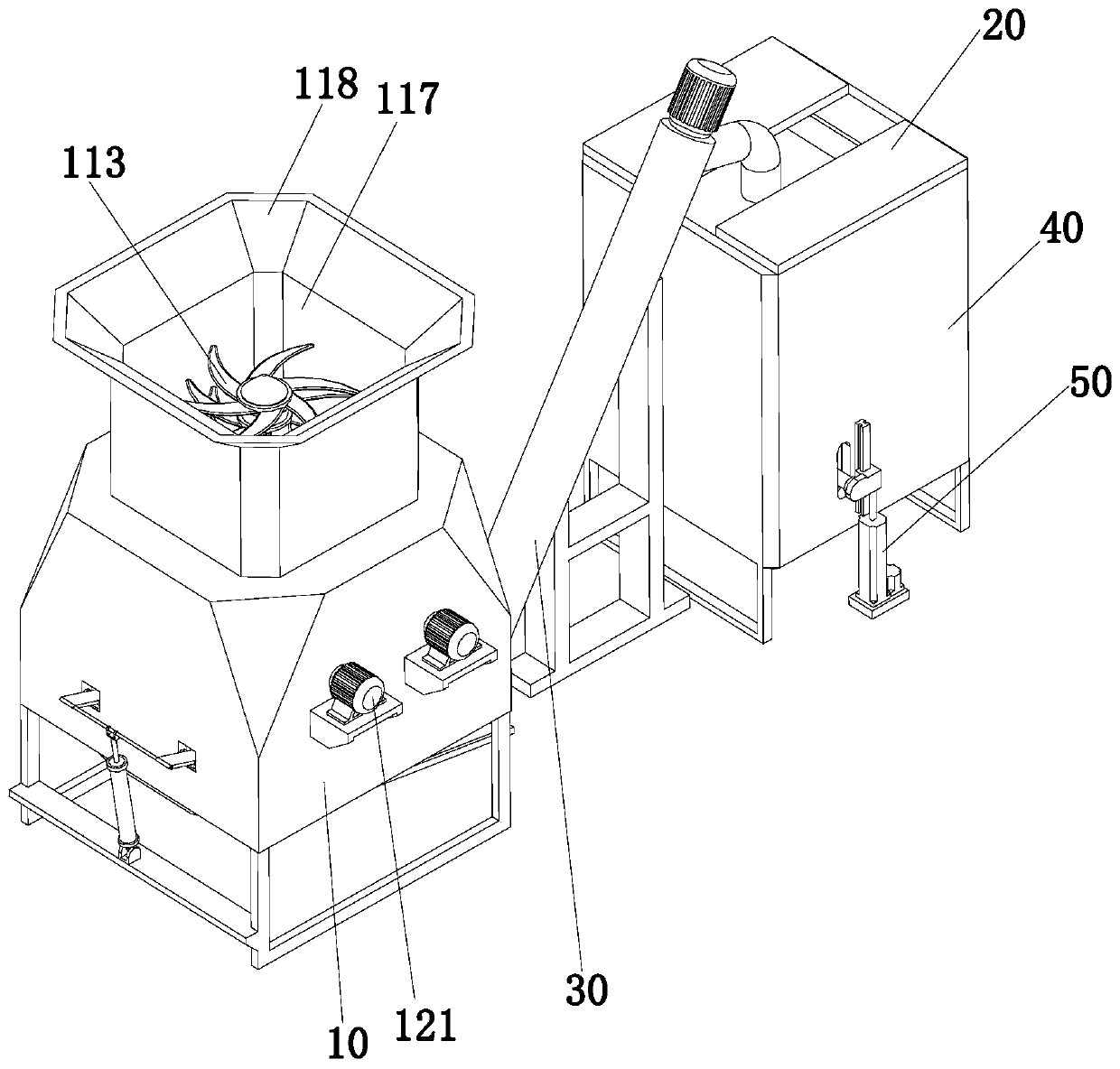

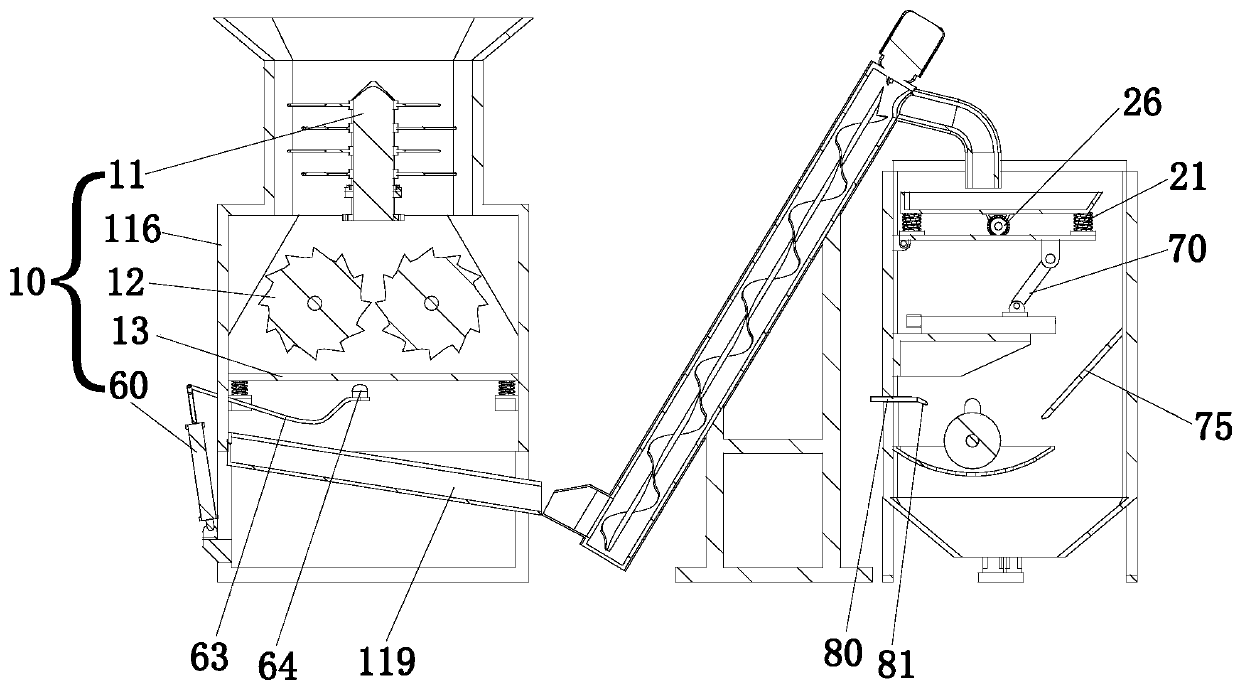

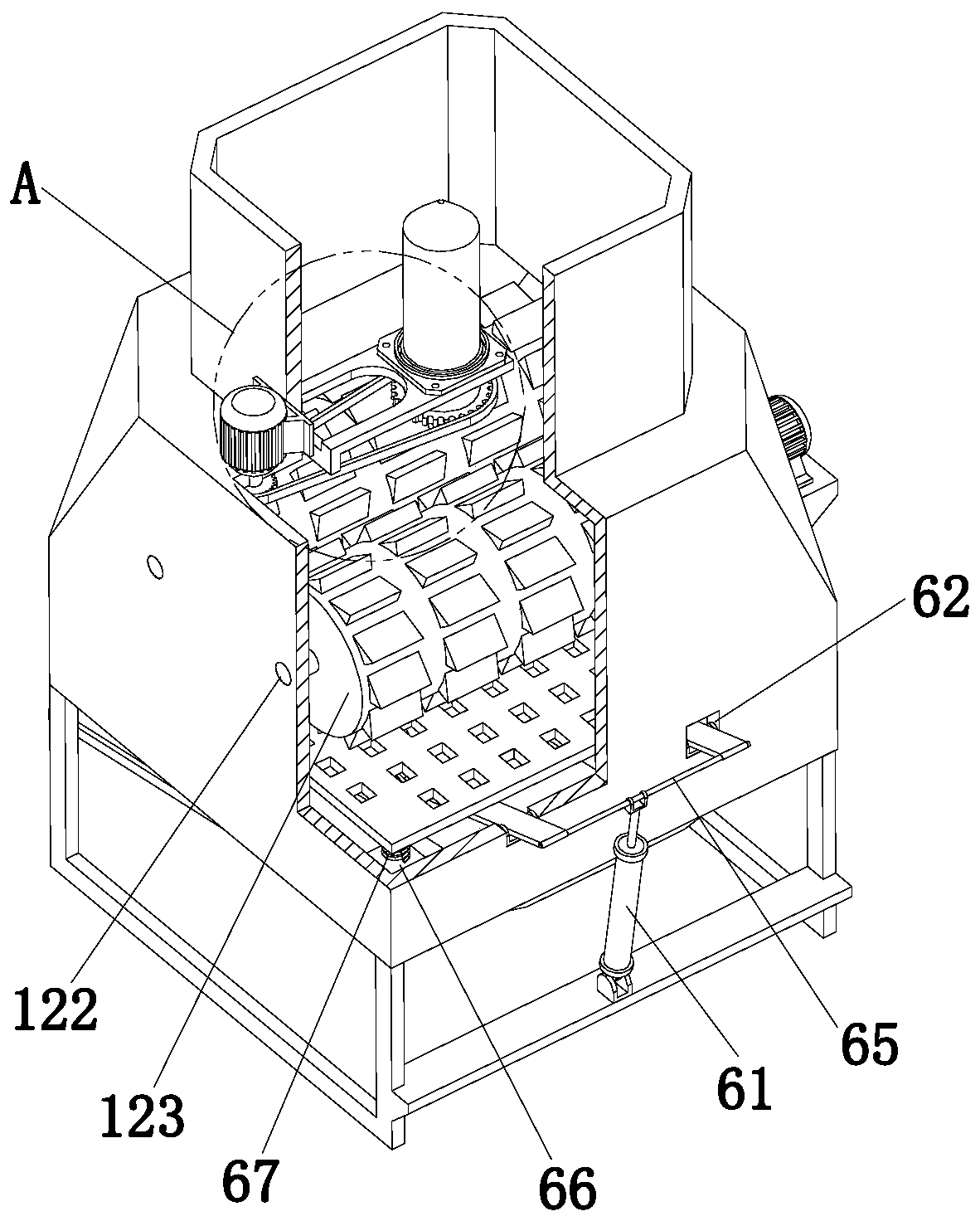

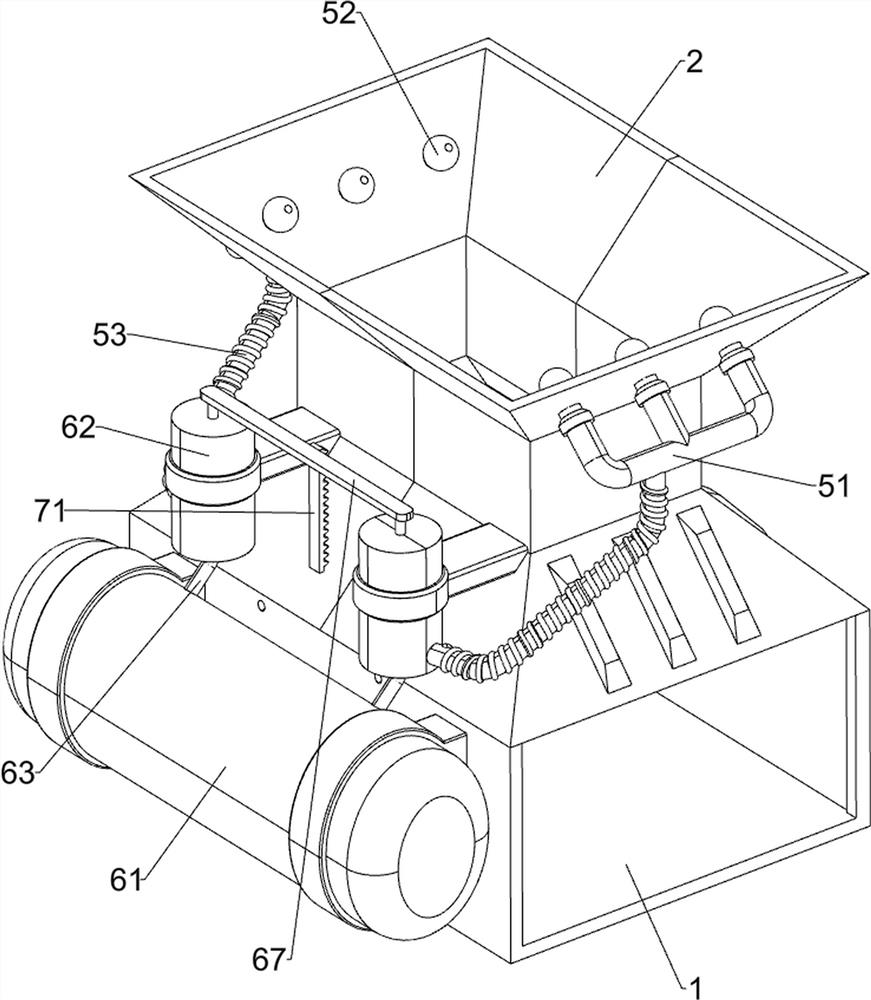

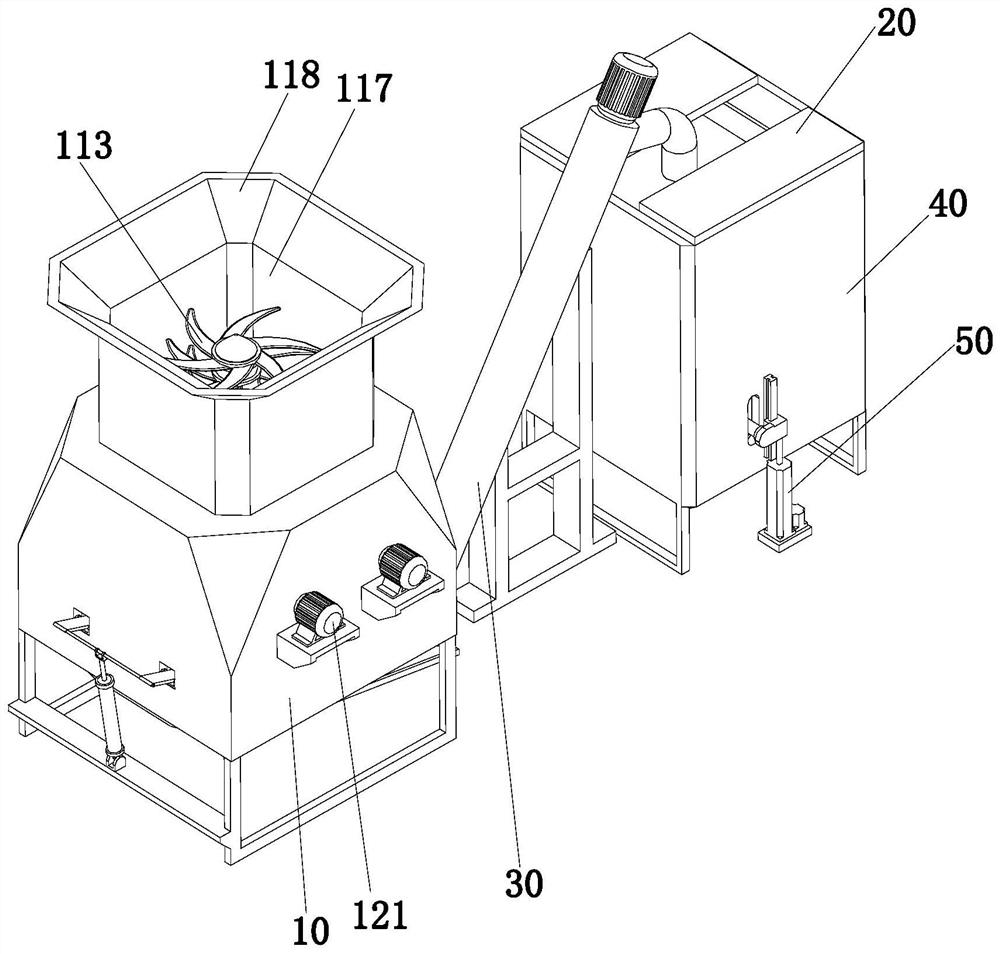

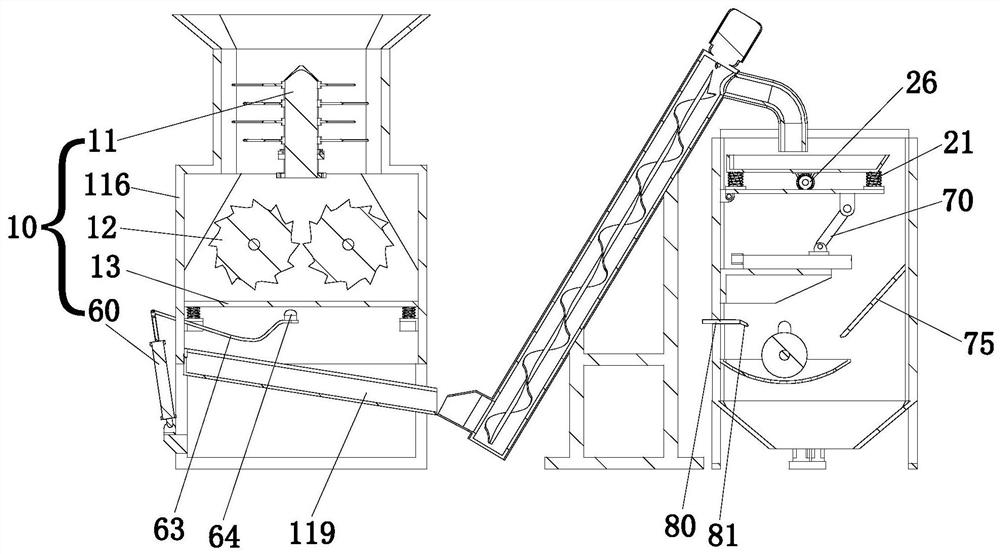

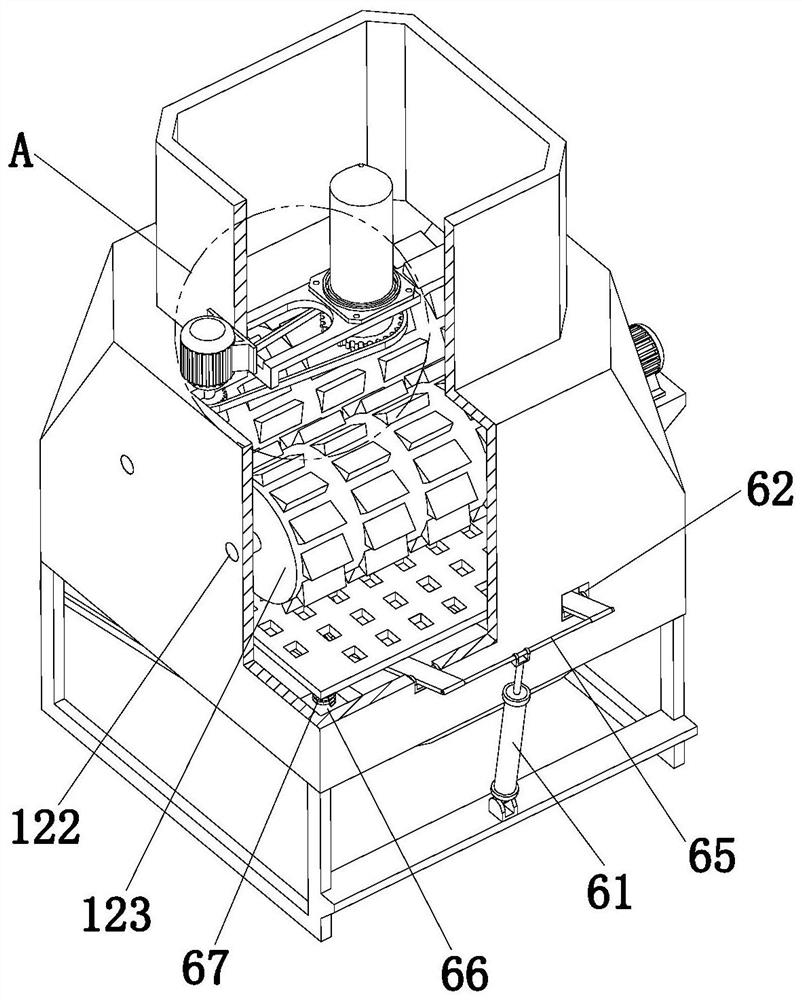

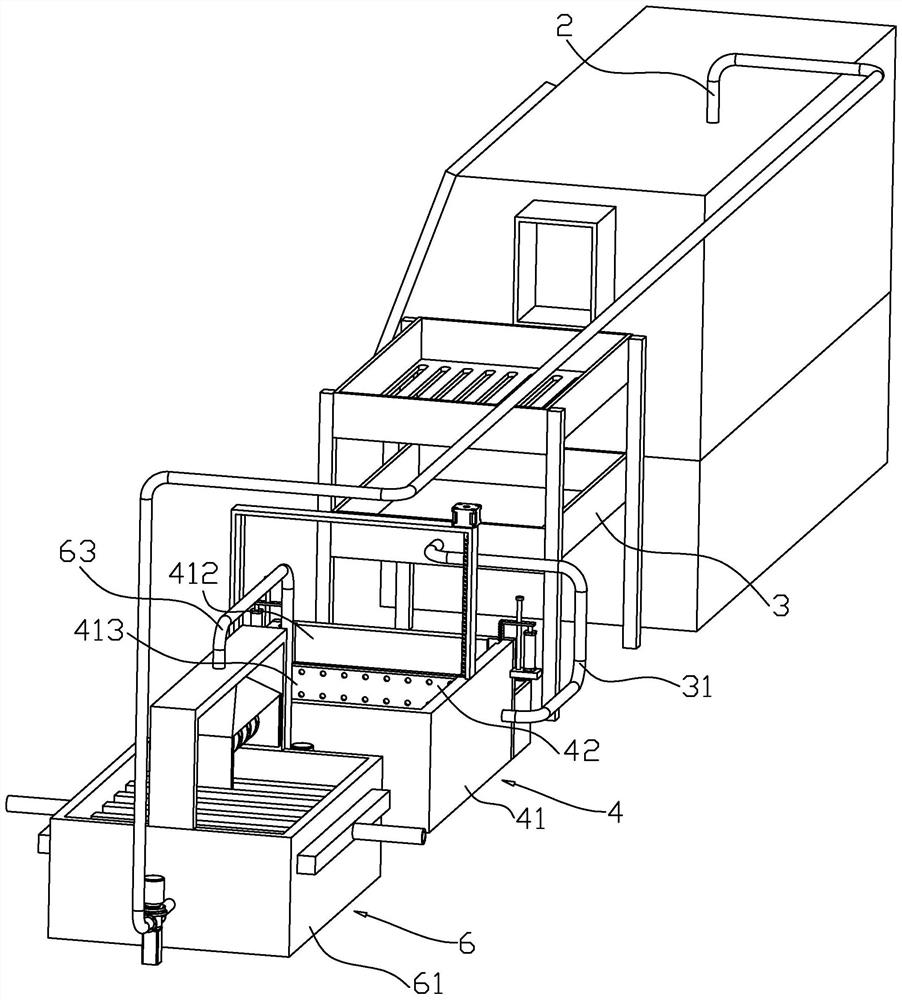

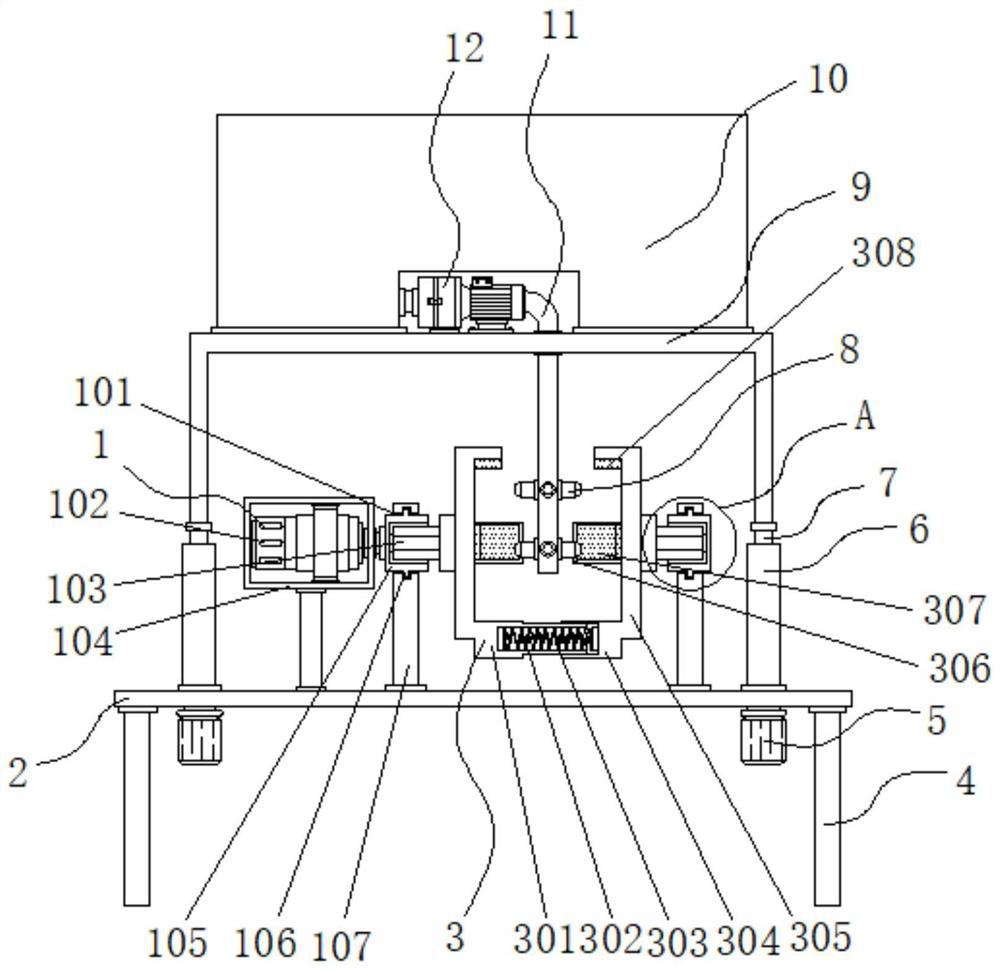

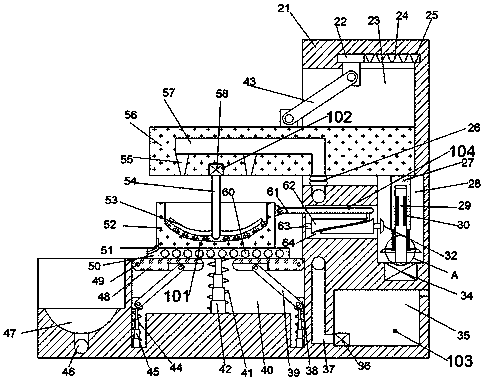

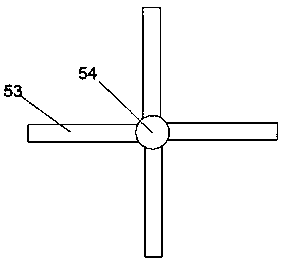

Fig fruit powder production device

The invention discloses a fig fruit powder production device, and belongs to the technical field of fig manufacturing. The fig fruit powder production device comprises a fruit crushing mechanism, a fruit particle drying mechanism, a feeding packing auger, a grinding cabinet and a fruit powdering and grinding mechanism, wherein the fruit crushing mechanism is provided with a cutting assembly, a crushing cabinet, a crushing assembly, a screening plate and a knocking vibration assembly; the top of the crushing cabinet is provided with a feeding hole and an anti-funnel; the bottom of the crushingcabinet is provided with a material conveying channel; the material conveying channel is provided with a water falling hole; the knocking vibration assembly comprises a driving air cylinder and two mounting grooves; a knocking rod is arranged in each mounting groove; a vibration hammer is arranged at the right end of each knocking rod; and a connecting rod is arranged between the left ends of thetwo knocking rods. According to the fig fruit powder production device, by knocking the vibration assembly, fig particles blocked in screening holes of a screening mesh can be vibrated out, the dryingoperation of figs can be realized through the fruit particle drying mechanism, and a drying box can be vibrated through a vibrating part, so that the figs positioned in the drying box are overturned.

Owner:义乌市昕闵日用品有限公司

Intelligent tea table

PendingCN108542124APlay a role in dustAutomatic pourWater-boiling vesselsBeverage vesselsAgricultural engineering

Owner:江雨涛

Automatic cooker

The invention relates to the field of cooking equipment, and discloses an automatic cooker. The automatic cooker comprises a rack, a wok tossing mechanism and a stir-frying mechanism, wherein the wok tossing mechanism is arranged on the rack; the stir-frying mechanism is arranged above the wok tossing mechanism; the wok tossing mechanism comprises a wok tossing driving device, a wok tossing assembly, a cooking wok assembly and a sliding block and guide rail assembly; the wok tossing driving device and the sliding block and guide rail assembly are arranged on the rack respectively; the wok tossing assembly is arranged on the rack in a rotating manner; the wok tossing driving device is used for driving the wok tossing assembly; the cooking wok assembly is hinged to a crank wheel of the wok tossing assembly and a sliding block of the sliding block and guide rail assembly. The automatic cooker can realize more cooking actions, and can reach a better cooking effect, so that the automatic cooker is relatively high in practicability.

Owner:FOSHAN POLYTECHNIC

Environment-friendly chemical waste gas detection device

ActiveCN112067760AIncrease pressureDischarge in timeDispersed particle filtrationTransportation and packagingEnvironmental engineeringChemical waste

The invention relates to an environment-friendly chemical waste gas detection device. The device comprises a temporary storage bottom box and a detection camera obscura; the temporary storage bottom box and the detection camera obscura are provided with a gas inlet device, a repeated conveying device, a monitoring device, a displacement device, a rotating device, a filtering device, a gas pushingdevice and an opening and closing device; one side of the temporary storage bottom box is fixedly connected with the detection camera obscura; the detection camera obscura is of a structure with openings in the two sides; the other side of the detection camera obscura is fixedly connected with supporting frames; a temporary storage top box is fixedly connected between the supporting frames; and the temporary storage top box is of a structure with openings in the two sides. Through cooperation of the gas inlet device, the repeated conveying device, the monitoring device, the displacement device, the rotating device, the filtering device, the gas pushing device and the opening and closing device, waste gas of all volumes can be detected in the detection and discharging process, the detectionprecision is improved, and the surrounding environment cannot be damaged.

Owner:ANHUI SHUNBANG FINE CHEM

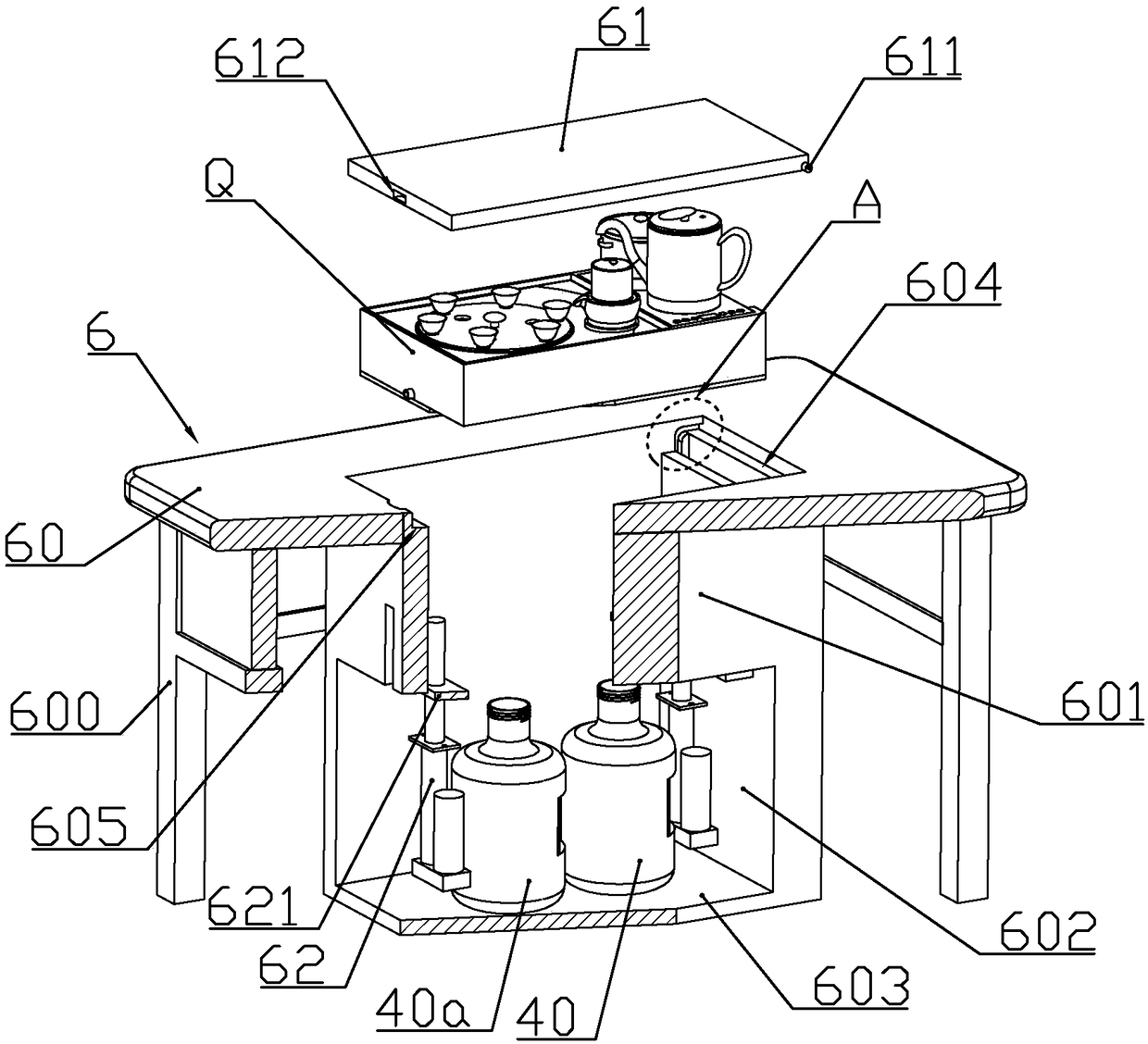

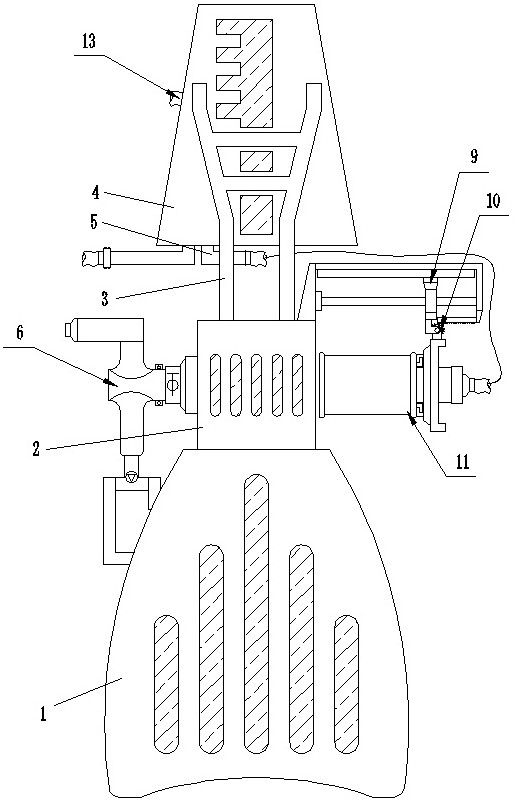

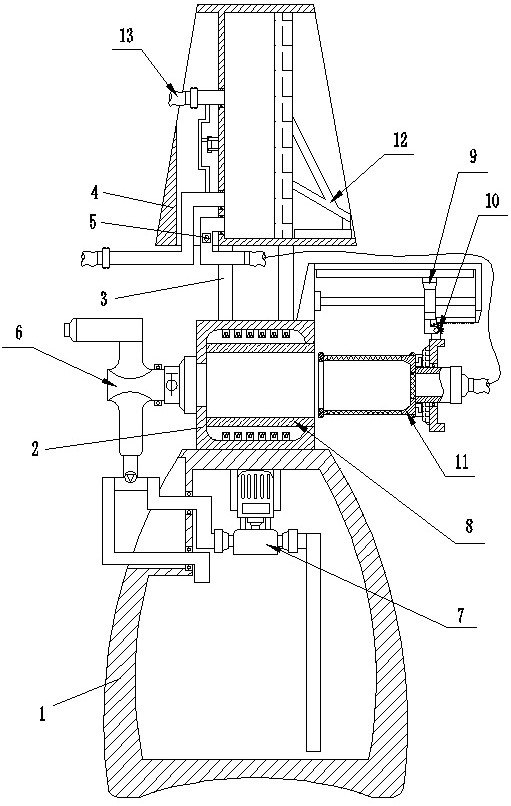

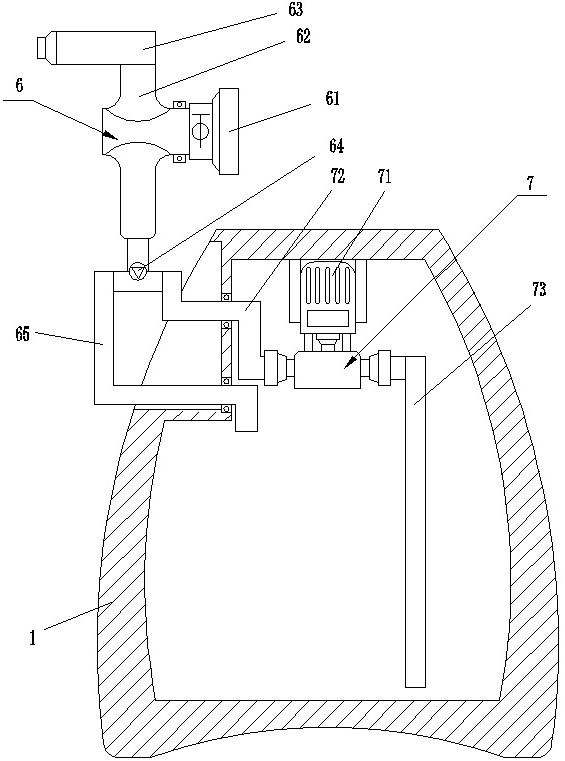

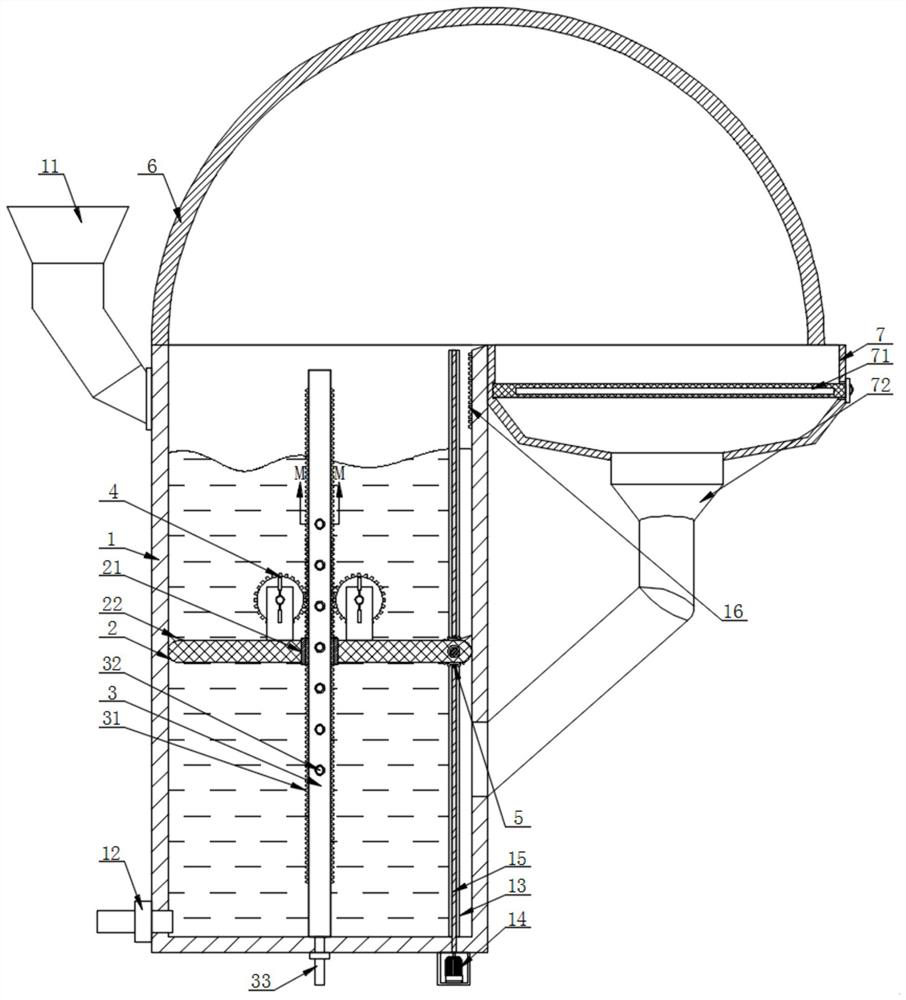

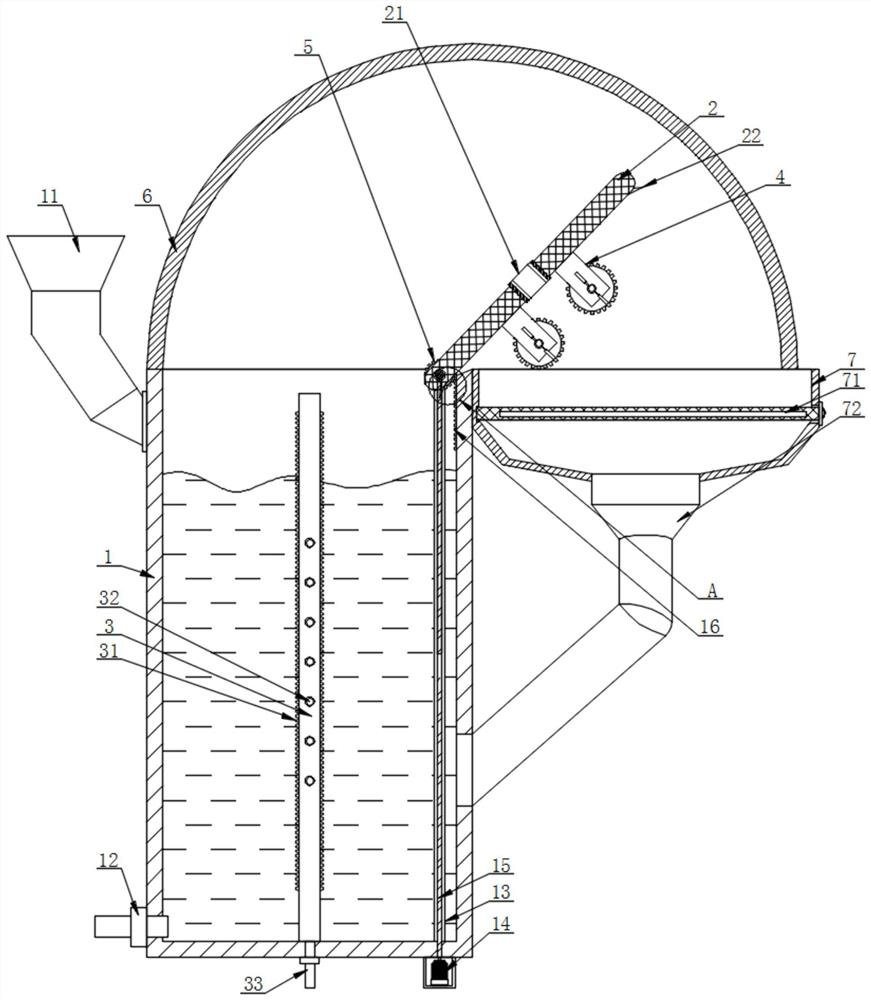

Multifunctional intelligent tea set

The invention discloses a multifunctional intelligent tea set. The tea set comprises a tea tray, a kettle set installed on the right side of the tea tray, a tea cup rotating disc rotationally arrangedon the left side of the tea tray, a plurality of tea cups arranged on the tea cup rotating disc through magnetic force, a teapot arranged on the tea tray, located between the kettle set and the tea cup rotating disc and used for making tea, a cup washing water guide plate used for guiding water poured out of the kettle into the tea cups, and an air blowing component used for blowing the water inthe tea cups out of the tea cup. The kettle set comprises a kettle body; the side wall of the kettle body is connected with a water outlet pipe; the teapot comprises a teapot base inserted into a teapot mounting base, and a teapot body arranged at the upper end of the teapot base; a tea outlet hole is formed in the bottom face of the teapot body. A tea cup rotating motor is arranged to drive the tea cup rotating disc to rotate, and opening and closing of a rotating valve plate are controlled through a tea outlet electromagnet so that tea in the teapot can be automatically poured into all the tea cups on the tea cup rotating disc.

Owner:高雅家居(安徽)股份有限公司

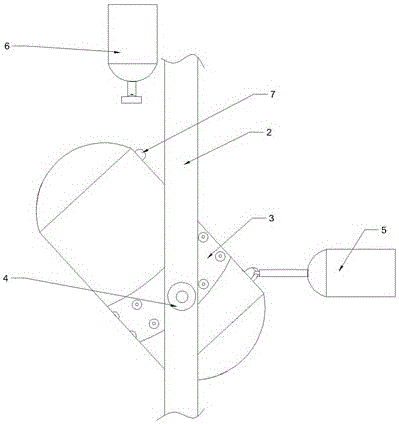

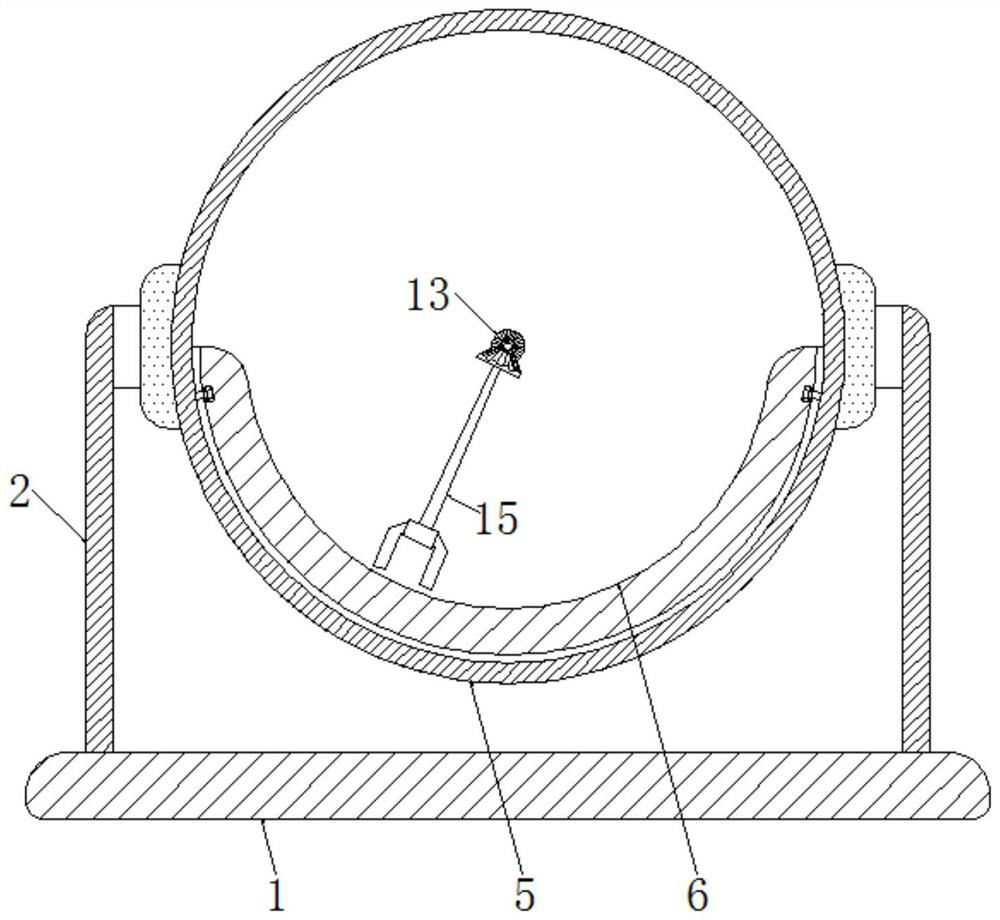

Industrial distillation still facilitating pouring-out

InactiveCN105056559AAutomatic pourSimple structureDistillation in boilers/stillsInfrared emitterDistillation

The invention discloses an industrial distillation still facilitating pouring-out. The industrial distillation still comprises a still body, a rack, a fixing mechanism and a control mechanism, wherein the fixing mechanism comprises clamping pieces fixedly connected onto the still body; rotating shafts are fixedly connected onto the clamping pieces on two opposite sides of the still body and are rotationally connected onto the rack; the control mechanism comprises a first cylinder and a second cylinder, the first cylinder is hinged to the rack, a piston rod of the first cylinder is horizontally hinged below the side wall of the still body, an infrared emitter is mounted on the still body on the same side with the first cylinder, the second cylinder is mounted on the other side of the still body and vertically mounted above the still body, a groove is formed in the bottom of a piston rod of the second cylinder, and an infrared receiver is arranged in the groove. The industrial distillation still is combined by the cylinders, the infrared emitter, the infrared receiver and the like and is simple in structure and low in cost, distillation products in the distillation still can be automatically poured out without manual fishing, the operation is convenient and fast, and labor cost is reduced.

Owner:CHONGQING CHANGFENG CHEM IND

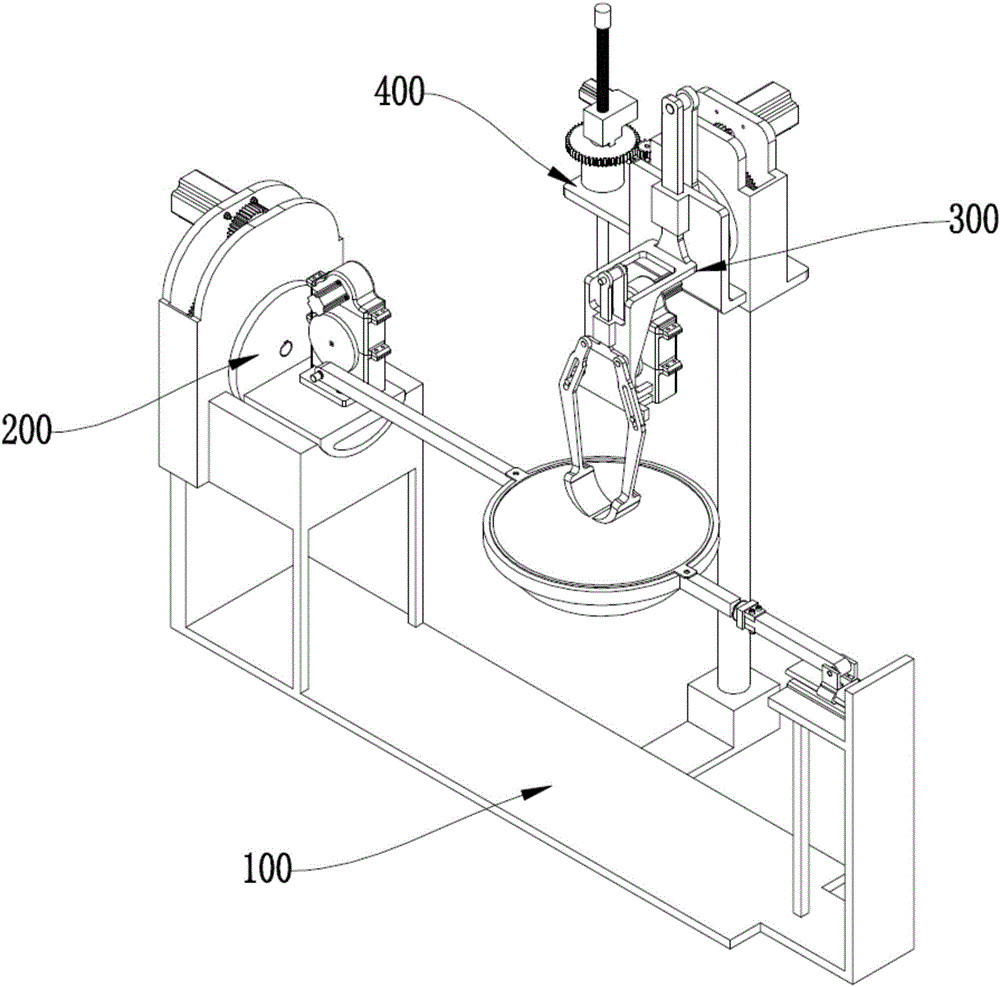

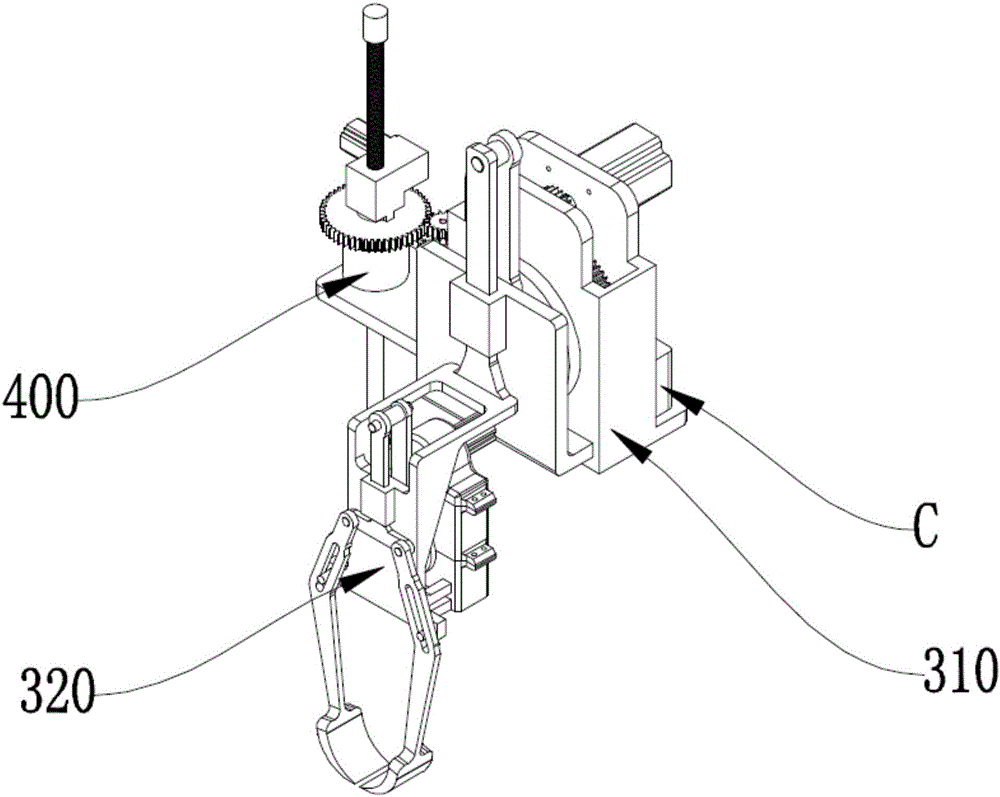

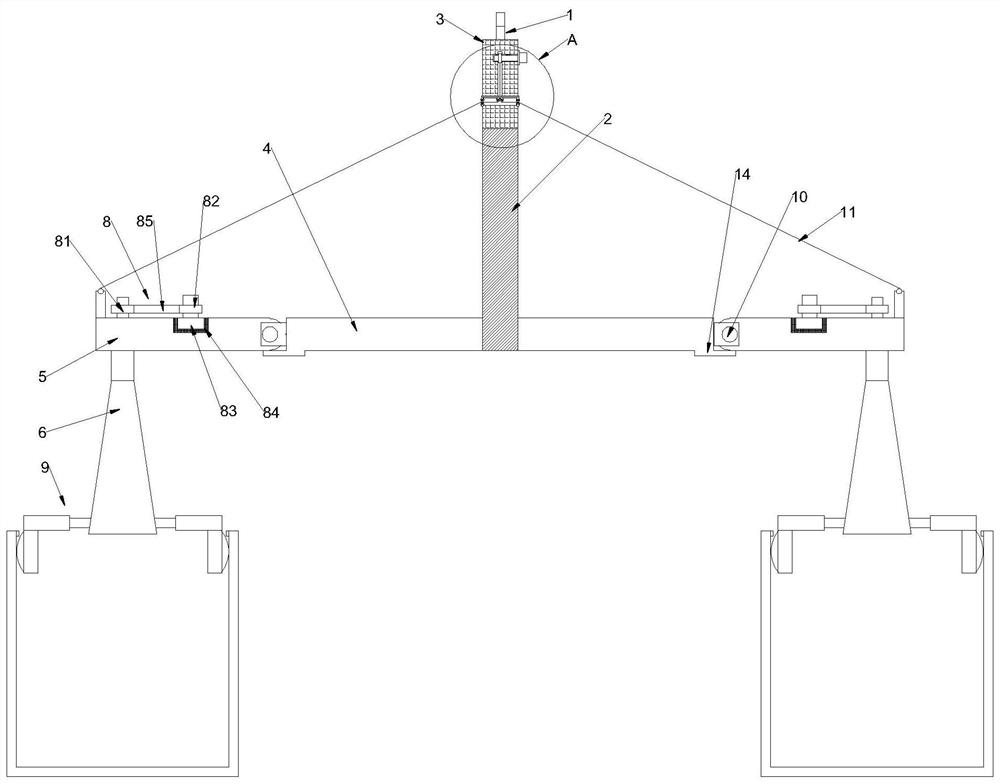

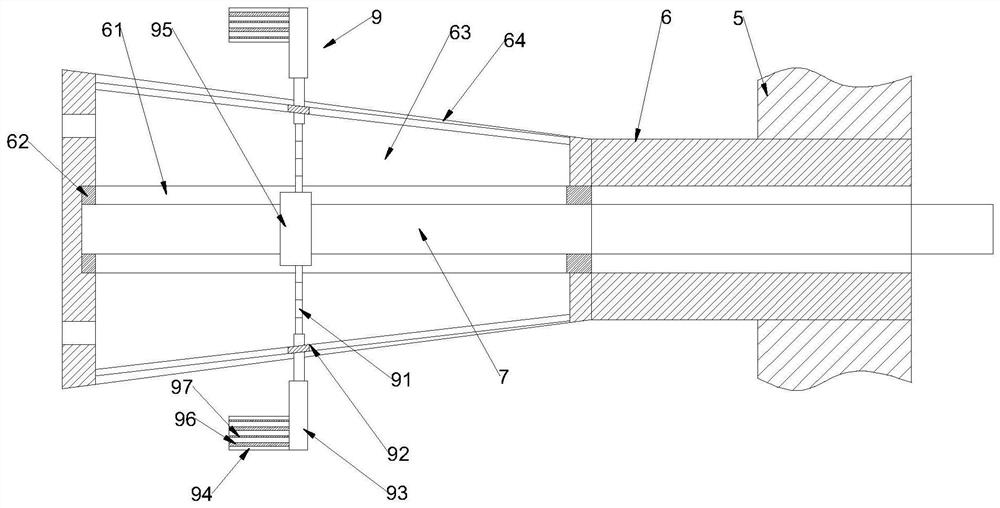

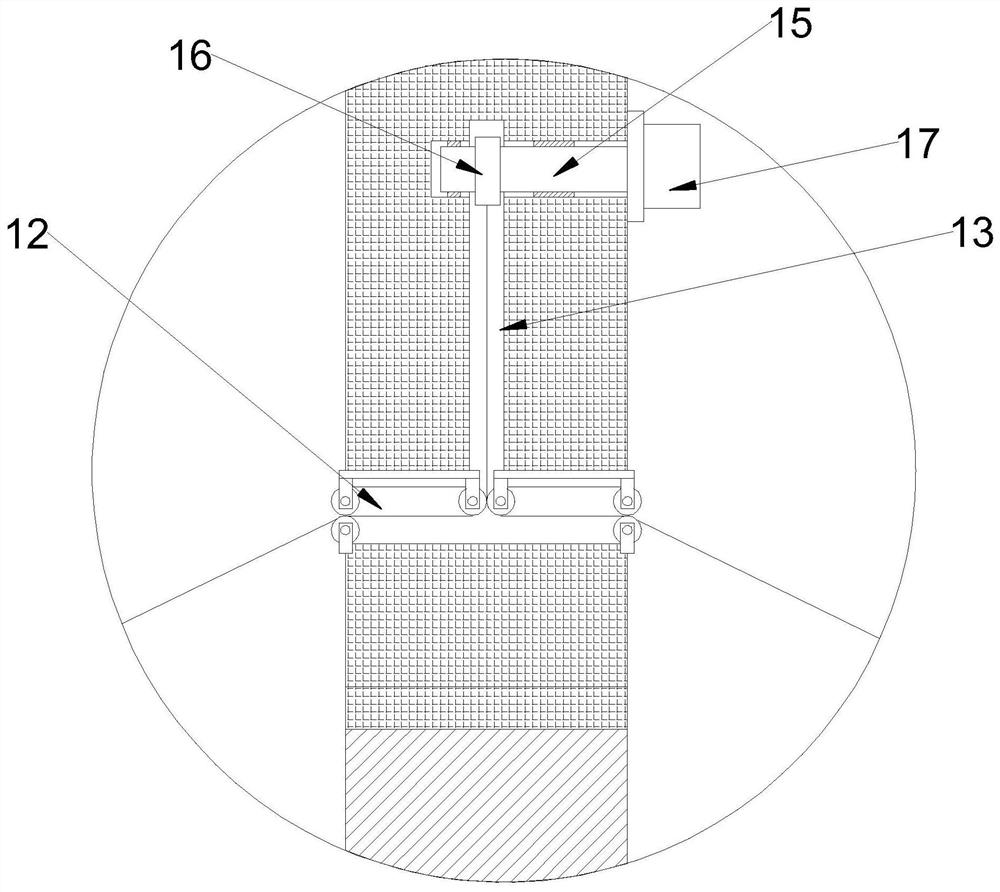

Liquid nitrogen dumping device and dumping method thereof

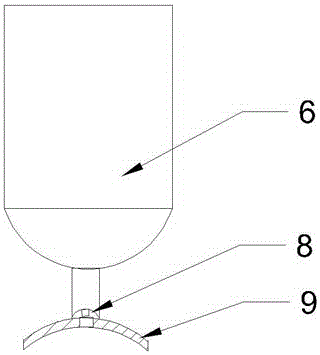

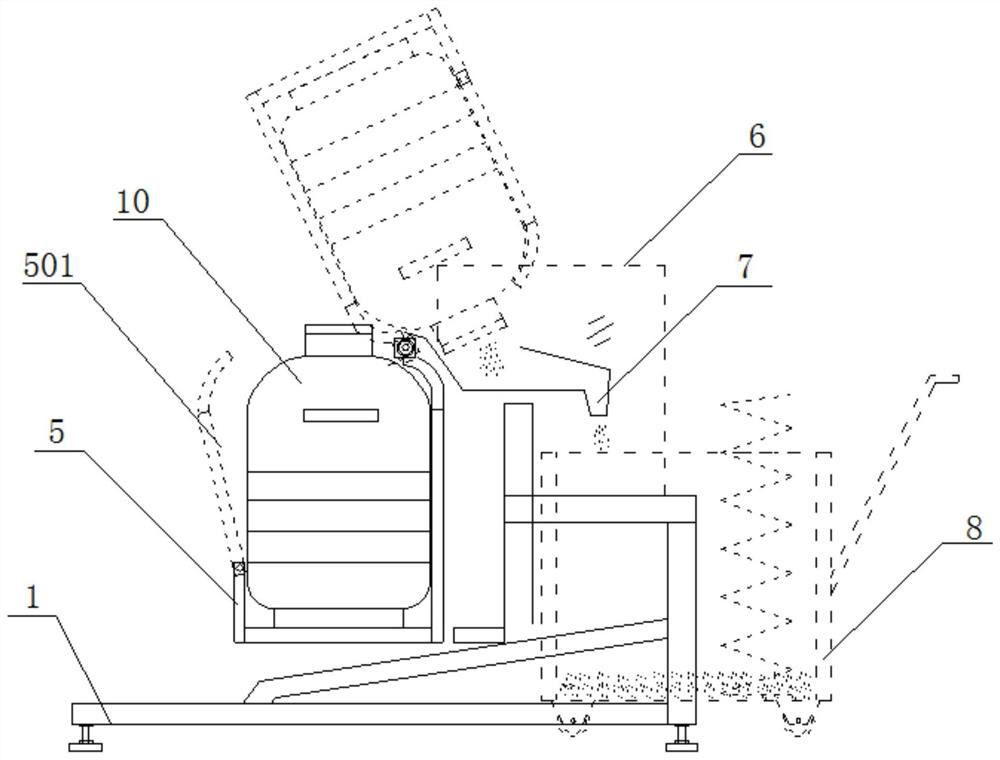

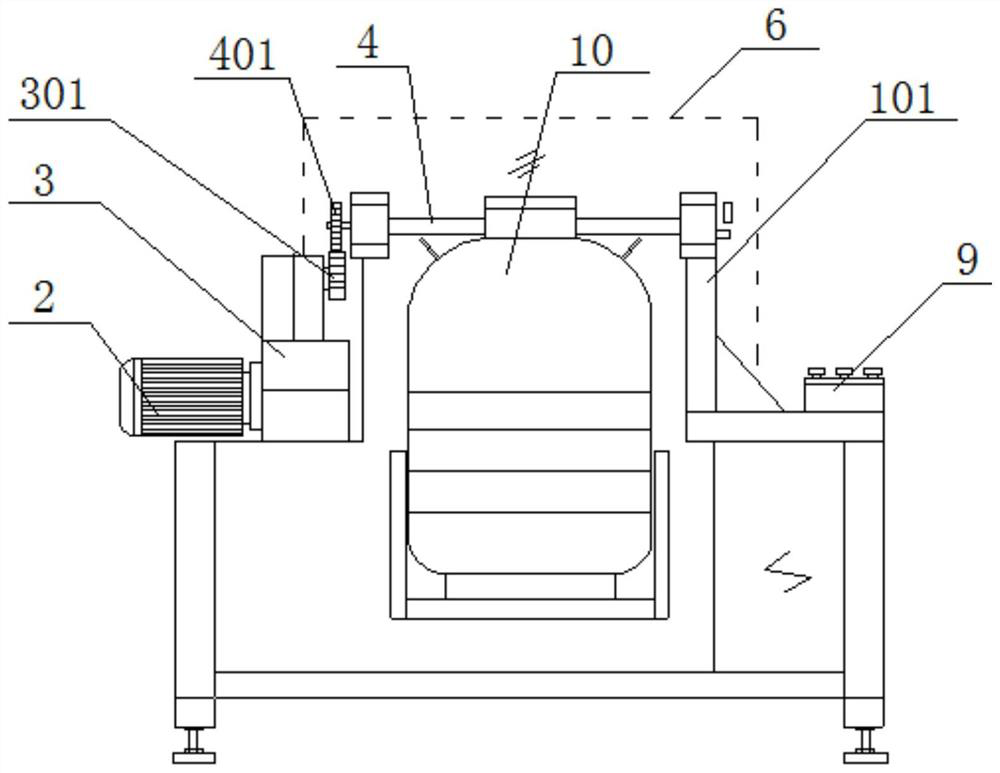

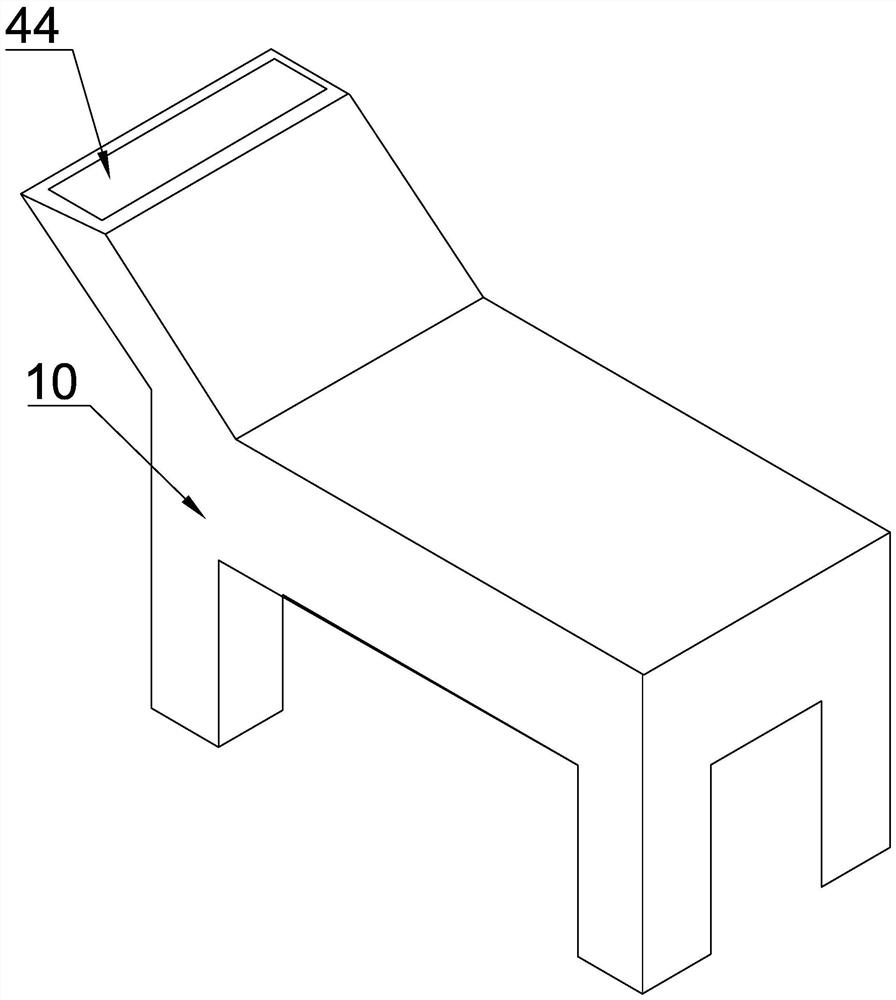

InactiveCN112628590AAutomatic pourSmooth pourVessel mounting detailsVessel geometry/arrangement/sizeLiquid nitrogen containerRotational axis

The invention discloses a liquid nitrogen dumping device and a dumping method thereof. The dumping device comprises a rack, a driving mechanism, a rotating shaft, a liquid nitrogen tank hoop locking mechanism and a liquid nitrogen funnel; a driving mechanism mounting platform and a rotating shaft supporting frame are arranged on the rack; the rotating shaft is mounted on the rotating shaft supporting frame; the driving mechanism is mounted on the driving mechanism mounting platform; the driving mechanism drives the rotating shaft to rotate; the upper end of the liquid nitrogen tank hoop locking mechanism is fixedly connected to the rotating shaft; and the liquid nitrogen funnel is installed on the rack, and when the driving mechanism drives the rotating shaft to rotate, the rotating shaft drives the liquid nitrogen tank hoop locking mechanism to rotate, so that a necking opening in the upper end of the liquid nitrogen tank hoop locking mechanism corresponds to the liquid nitrogen funnel. According to the liquid nitrogen dumping device, rapid clamping of a liquid nitrogen bottle can be achieved through the dumping device, liquid nitrogen is automatically and stably poured into a liquid nitrogen container, and the method is easy to operate, high in reliability, high in applicability and free of potential safety hazards.

Owner:CHONGQING TIEMA IND GRP

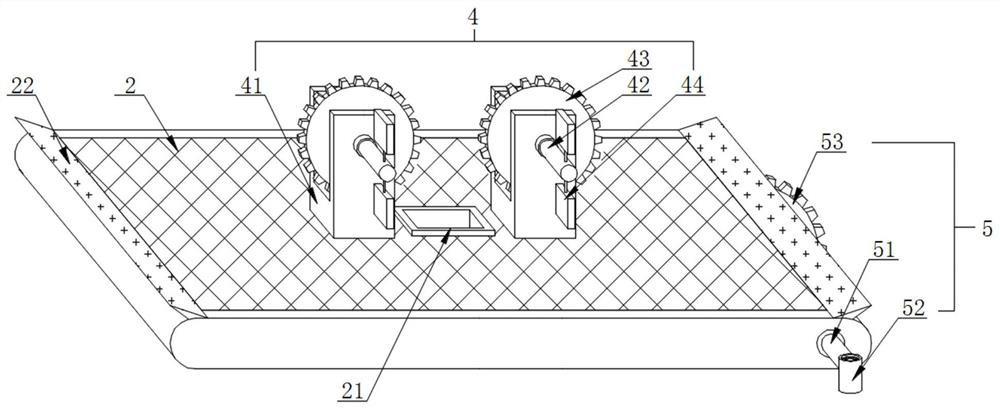

Small automatic thresher

InactiveCN113924866AIncrease in sizeAutomatic pourThreshersAgricultural scienceAgricultural engineering

The invention belongs to the field of agricultural production, and relates to a small automatic thresher which comprises a shell, wherein a feeding cavity is formed in the upper left side of the shell and used for conveying materials into a cavity, a working cavity is formed in the bottom of the shell and used for threshing rice, a garbage cavity is formed in the upper half portion of the shell, and a rice transferring device is arranged on the rear side of the shell and used for transferring the threshed rice into other cavities. The small automatic thresher plays an auxiliary role in agricultural production and can replace manpower and large-scale mechanical equipment to separate mature rice in mountainous areas where the large-scale mechanical equipment cannot enter, and compared with manual separation, the small automatic thresher greatly improves the production efficiency, reduces the work of manually screening rice grains and can screen and separate garbage and small debris particles from the rice grains.

Owner:许为科

A smart tea set

ActiveCN108308978BAutomatic pourEasy to removeWater-boiling vesselsDomestic vesselsRotary valveElectric machinery

The invention discloses an intelligent tea set which comprises a tea tray, a tea kettle set, a teacup rotating disc, a plurality of teacups, a tea kettle, a cup-washing water guide plate and a blowingcomponent, wherein the tea kettle set is arranged on the right side of the tea tray; the teacup rotating disc is rotationally arranged on the left side of the tea tray; the plurality of teacups are adsorbed onto the teacup rotating disc by virtue of magnetic force; the tea kettle is mounted on the tea tray, positioned between the tea kettle set and the teacup rotating disc and is used for makingtea; the cup-washing water guide plate is used for guiding water poured out of the tea kettle into the teacups; the blowing component is used for blowing water in the teacups out of the teacups; the tea kettle set comprises the tea kettle; the side wall of the tea kettle is connected with a water outlet pipe; the tea kettle comprises a tea kettle seat inserted on a tea kettle mounting seat and a kettle body arranged at the upper end of the tea kettle seat; a tea outlet hole is formed in the bottom surface of the kettle body; a rotary valve driven by a tea outlet motor is rotationally arrangedat the upper end of the tea kettle seat. The teacup rotating disc is driven to rotate by virtue of the arrangement of the teacup rotating motor, and opening and closing of the rotary valve can be controlled by the tea outlet motor, so that tea in the tea kettle can be automatically poured into each teacup on the teacup rotating disc.

Owner:瑞安市佰乐雅工艺品有限公司

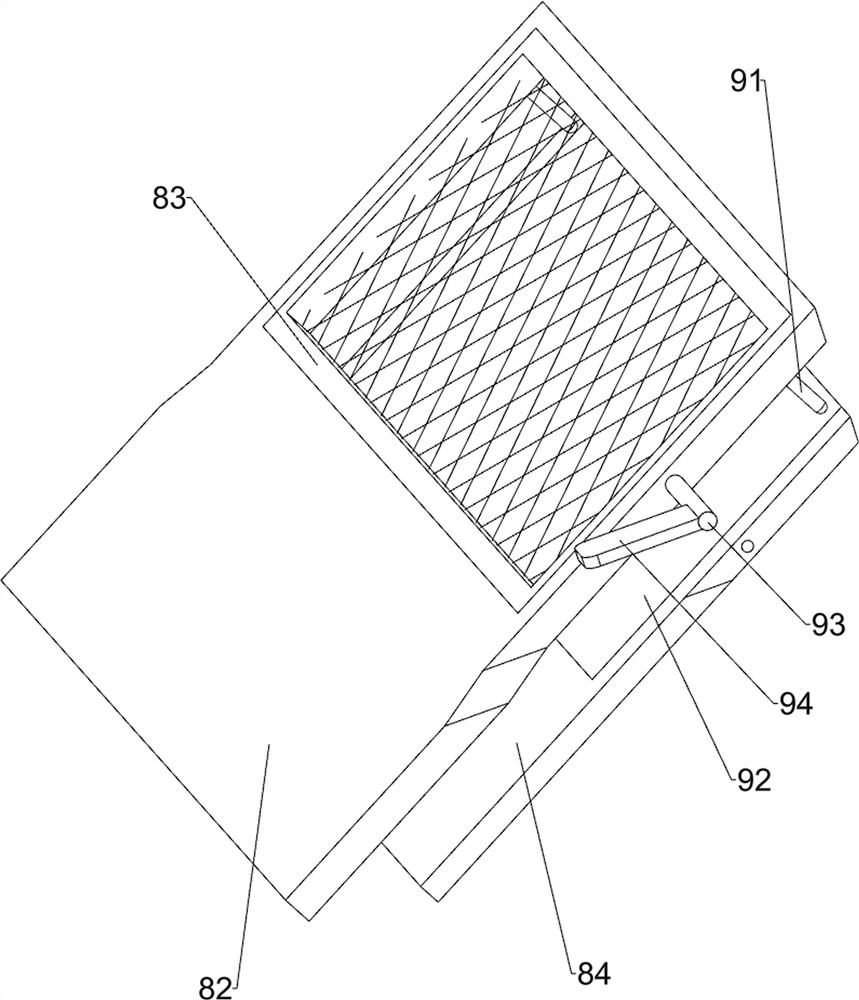

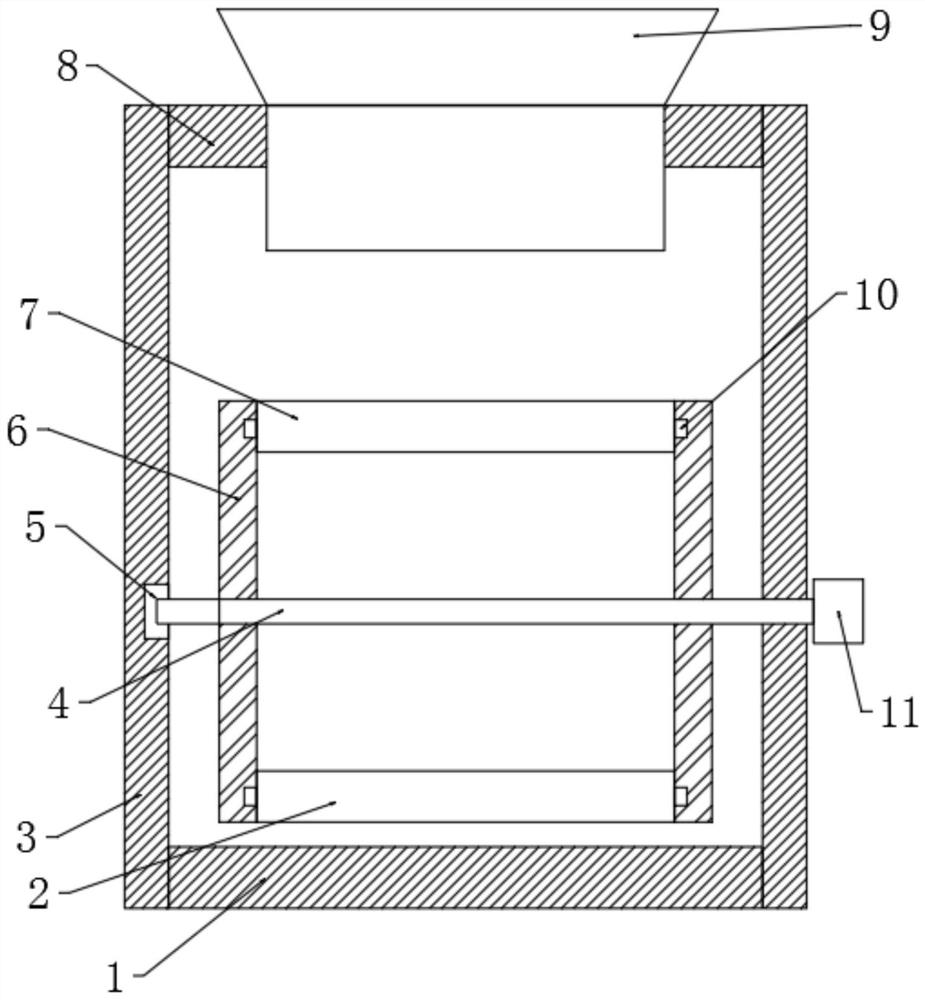

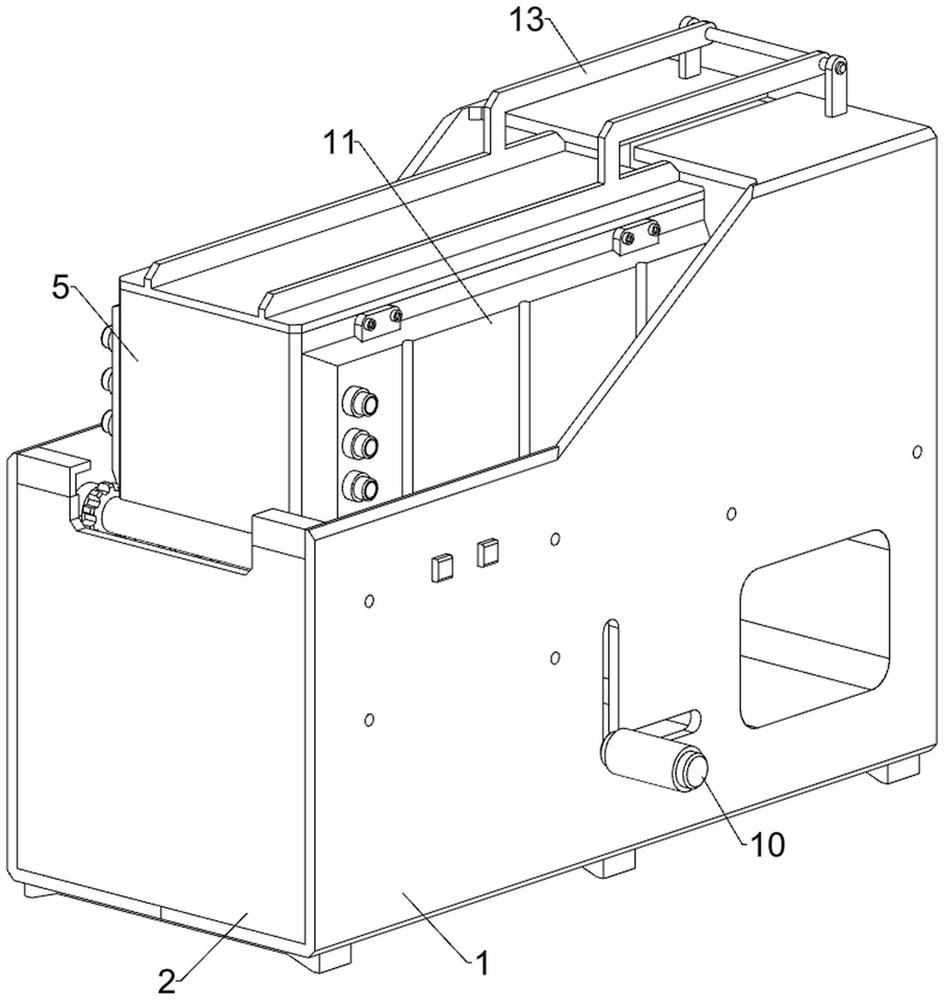

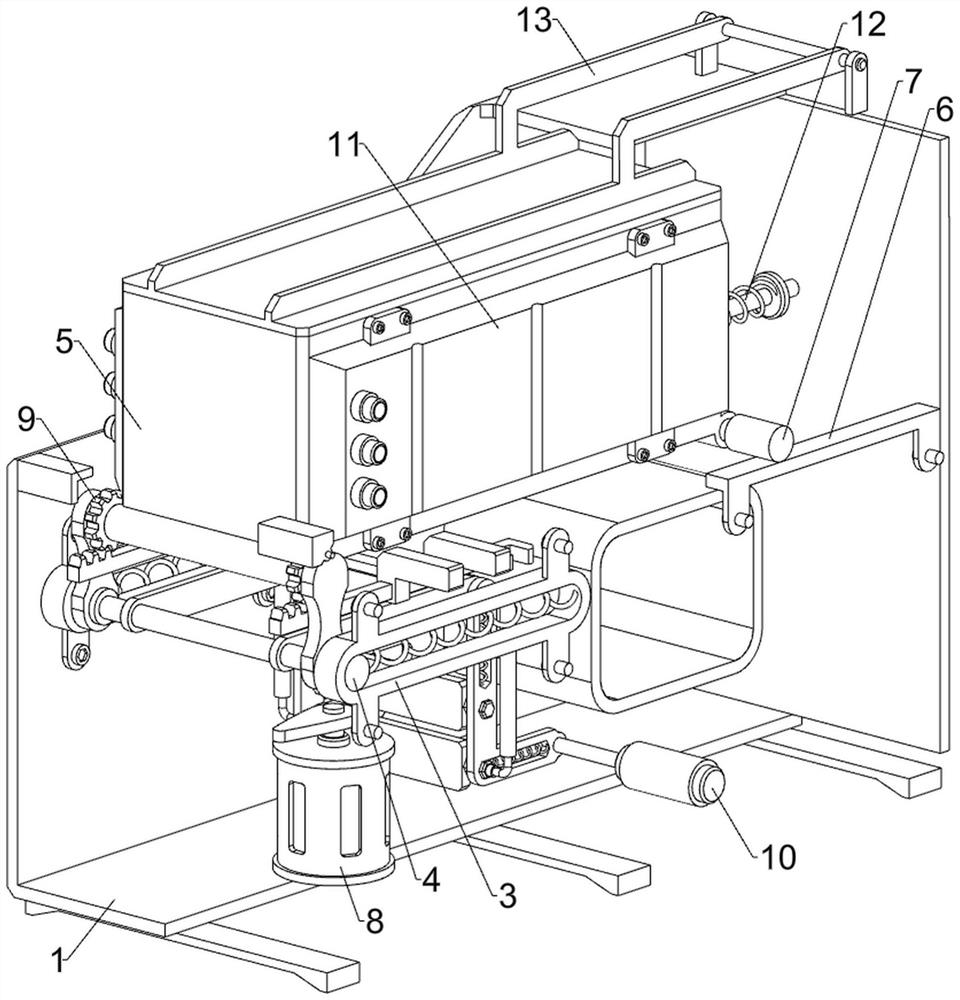

Automatic waste collecting and processing device of aluminum silicate silk floss throwing machine

InactiveCN113584640AAutomatic pourSmooth rotationArtificial filament recoveryTextile/flexible product manufactureChemistryProcess engineering

The invention relates to an automatic waste collecting and processing device, in particular to an automatic waste collecting and processing device of an aluminum silicate silk floss throwing machine. The automatic waste collecting and processing device of the aluminum silicate silk floss throwing machine can replace manual work to conduct collecting and cleaning and is high in working efficiency. The automatic waste collecting and treating device of the aluminum silicate silk floss throwing machine comprises a box body, a hopper, a collecting frame and a handle; the hopper is mounted at the top of the box body; the collecting frame is detachably mounted in the box body; and the handle is mounted on one side of the collecting frame. Waste thrown out by the throwing machine can be collected through the collecting frame, water spraying cooling can be conducted on the waste thrown out by the throwing machine through a water spraying mechanism, and a large amount of water can be stored through a water storage mechanism for cooling of the water spraying mechanism; a piston can automatically slide up and down through a lifting mechanism for water pumping; water in the waste materials can be filtered out for recycling through a blocking mechanism; and the waste materials on a net plate can be automatically poured into the collecting frame through a downward pressing mechanism.

Owner:柯玲玲

A flux smelting iron slag collection and pouring device

ActiveCN112974782BAutomatic pourAvoid close contactMould handling equipmentsMolten metal conveying equipmentsThermodynamicsSlag

The invention discloses a flux smelting iron slag collection and pouring device, comprising a furnace, a continuous casting machine, a first driving component, a second driving component, an iron discharge box and a circulating water tank; the furnace is provided with a discharge port; The machine includes a supporting circular plate, a first sliding block, a first sliding rail, a second sliding block, a second sliding rail, a bearing seat, a rotating tube, an annular supporting plate and a mold box; the number of the furnaces is 2; 2 The melting furnaces are arranged opposite to each other; the flux smelting iron slag collection and pouring device proposed by the present invention can realize automatic pouring of molten iron in the melting process into the mold box, and can also realize automatic pouring and molding, which saves time and labor, and avoids the need for It is safer for workers to have close contact with molten iron.

Owner:湖南东安湘江科技股份有限公司

Impurity recovery device in food paperboard papermaking process

PendingCN114855491AAvoid affecting the filtration separation effectAutomatic pourPaper recyclingPulp by-products recoveryPapermakingPaperboard

The invention discloses an impurity recovery device in a food paperboard papermaking process, and particularly relates to the field of papermaking, the impurity recovery device comprises a recovery box, a feeding hopper is installed at the top of one side of the recovery box in a penetrating manner, a filter screen is arranged in the recovery box, and a drainage pipe is installed at the bottom of one side of the recovery box in a penetrating manner; and positioning grooves are formed in the two inner walls of the recycling box, lead screws are movably embedded between the tops and the bottoms of the positioning grooves, a turnover mechanism is arranged on one side of the filter screen, and fixing columns are fixedly embedded in the bottom of an inner cavity of the recycling box. According to the device, the overturning mechanism is arranged, when a filter screen moves upwards till a second gear moves upwards to make contact with first gear teeth, the filter screen is driven to overturn under the action of a rotating shaft, then the function that the filter screen automatically pours out waste residues above the screen face is achieved, manual cleaning is avoided, and the practicability and the automation degree of the device are greatly improved.

Owner:五洲特种纸业(江西)有限公司

A multifunctional intelligent tea set

ActiveCN108552895BAutomatic pourFast inflowBeverage vesselsDomestic vesselsWater bottleRotating disc

Owner:高雅家居(安徽)股份有限公司

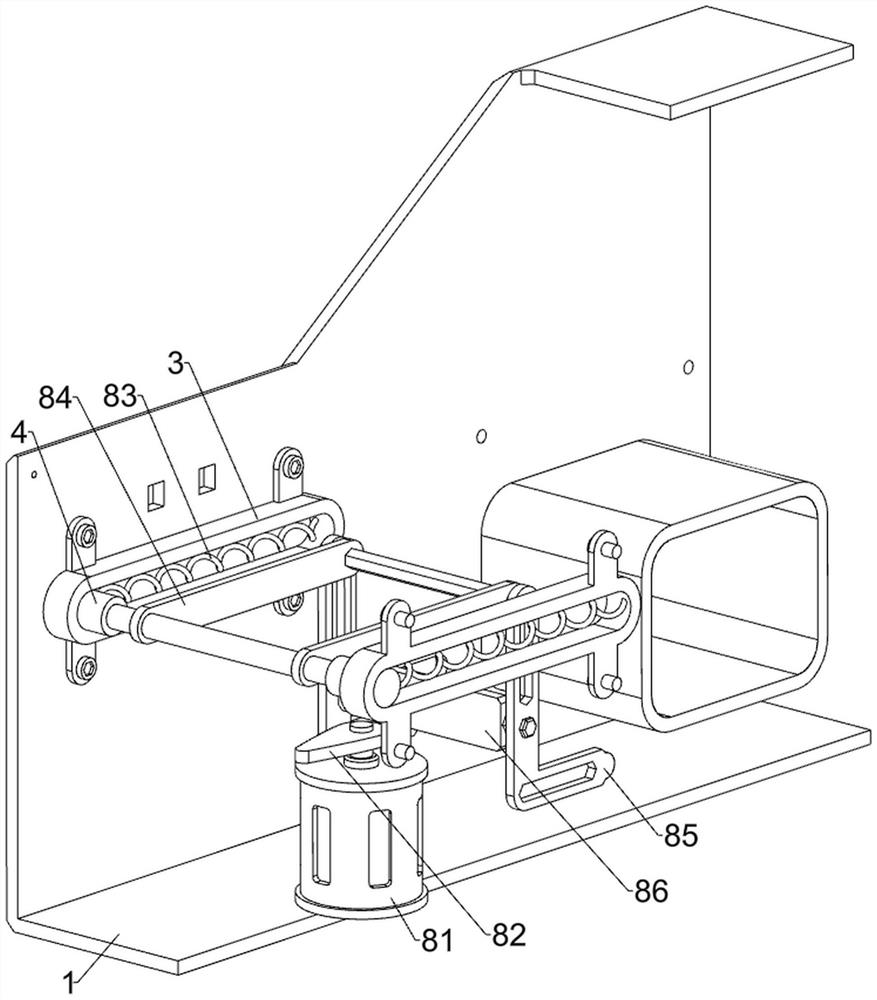

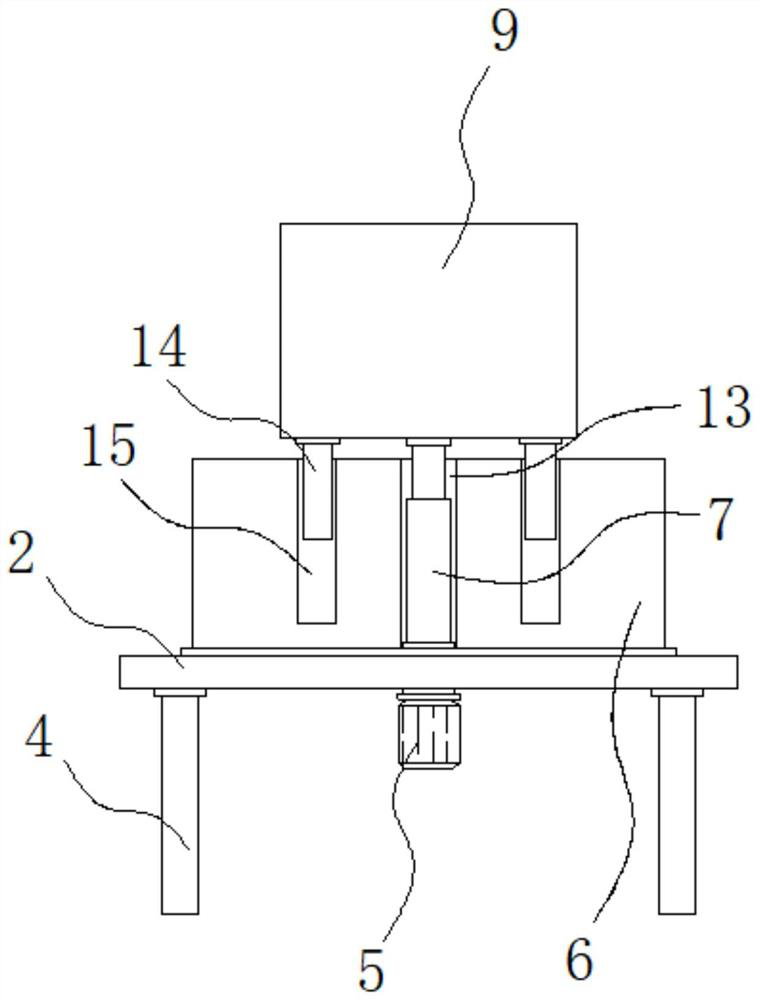

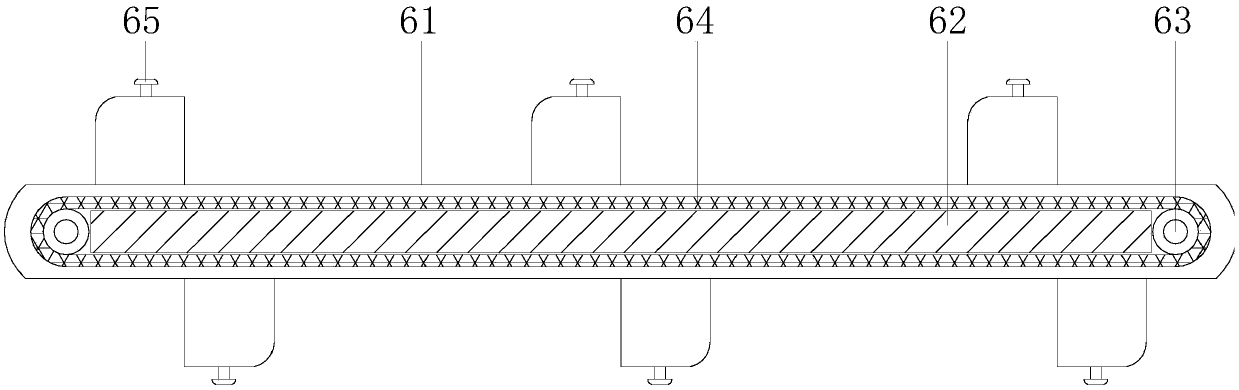

An automatic loading and unloading device placed on the assembly line

The invention relates to a loading and unloading device, in particular to an automatic loading and unloading device placed on an assembly line. The technical problem to be solved by the present invention is to provide an automatic loading and unloading device placed on an assembly line that can load and pick up more chestnuts at one time and save labor. An automatic loading and unloading device placed on an assembly line, comprising: a support frame; a first guide sleeve, which is slidably connected to a long pole of the support frame; a swing seat, which is fixedly connected to the first guide sleeve; and a flap, which is rotatably connected to the swing seat; The tipping mechanism is set on the support frame and connected with the flap; the horizontal plate is hinged in the middle of the flap; the second guide sleeve is slidably connected to the flap and is arranged on both sides of the horizontal plate; the first connecting rod has two, One end is hinged to the outside of the horizontal plate, and the other end is hinged to the second guide sleeve. The present invention can be placed on the assembly line, and a large amount of chestnuts can be easily shoveled by controlling the cylinder, and the shovel plate full of chestnuts can be pushed to the pouring position through the electric push rod.

Owner:刘太彬

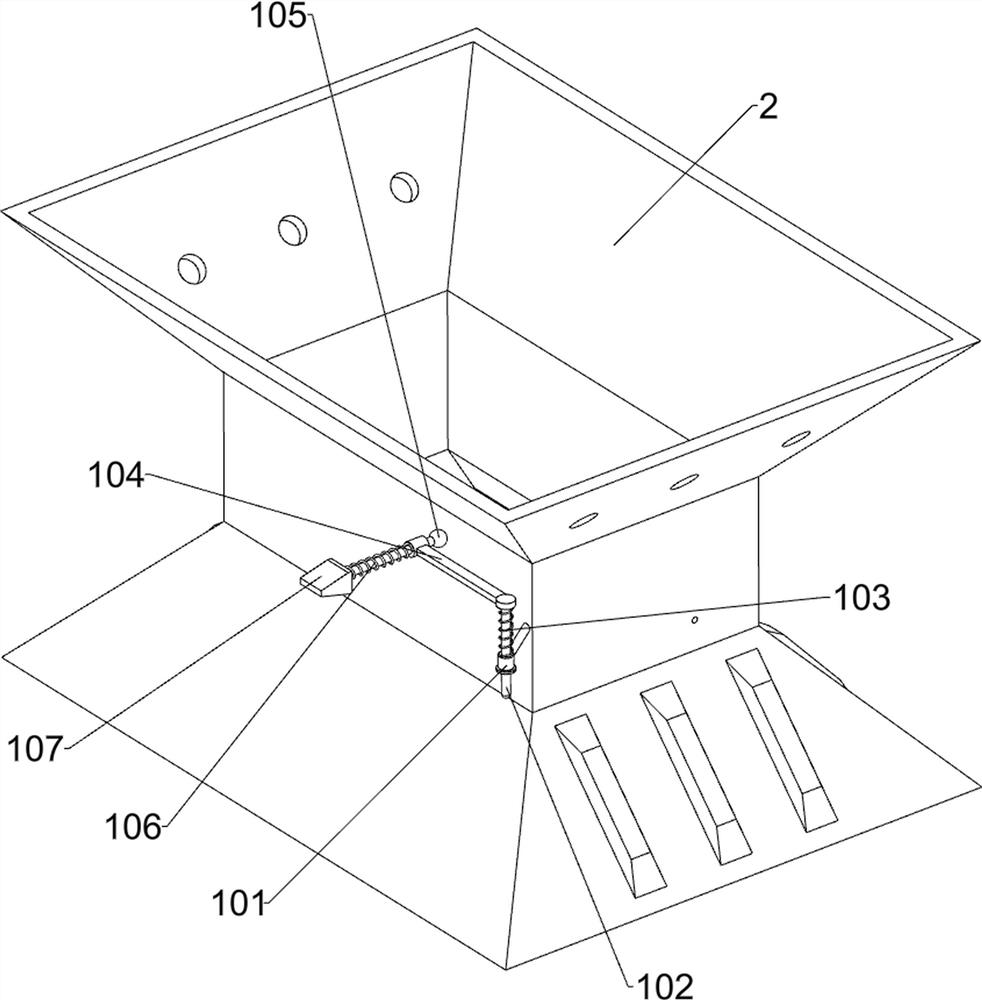

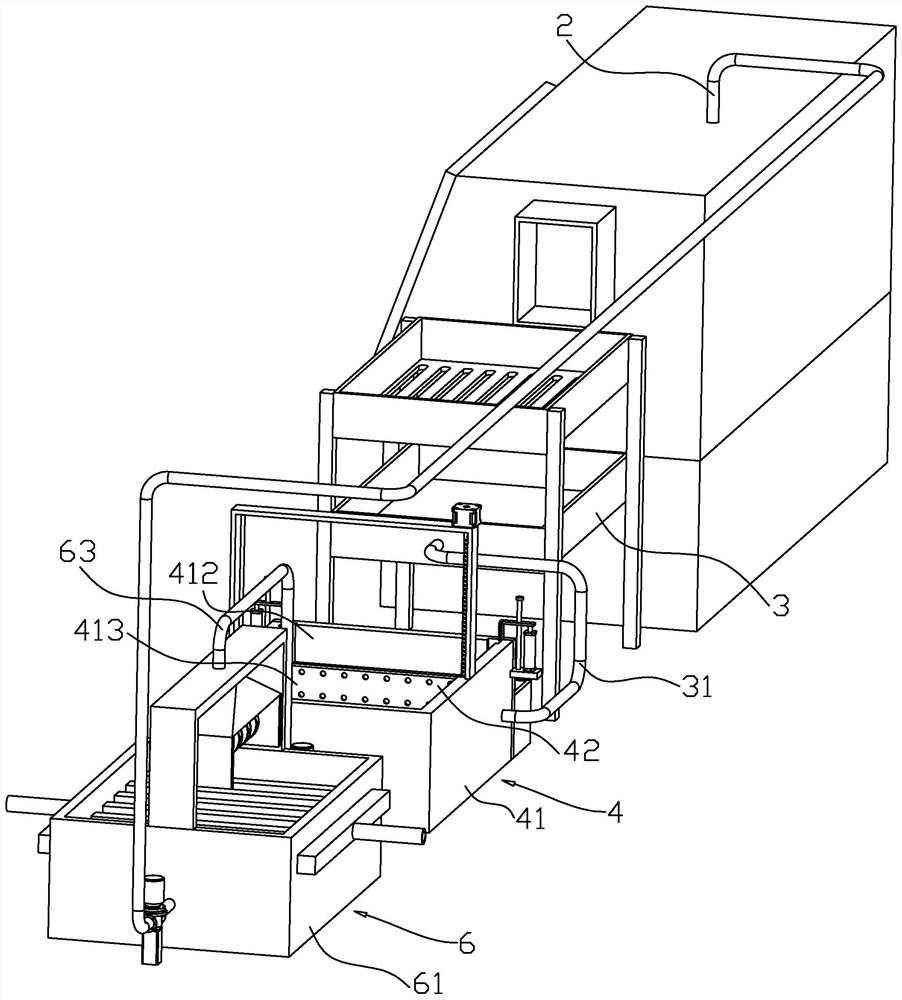

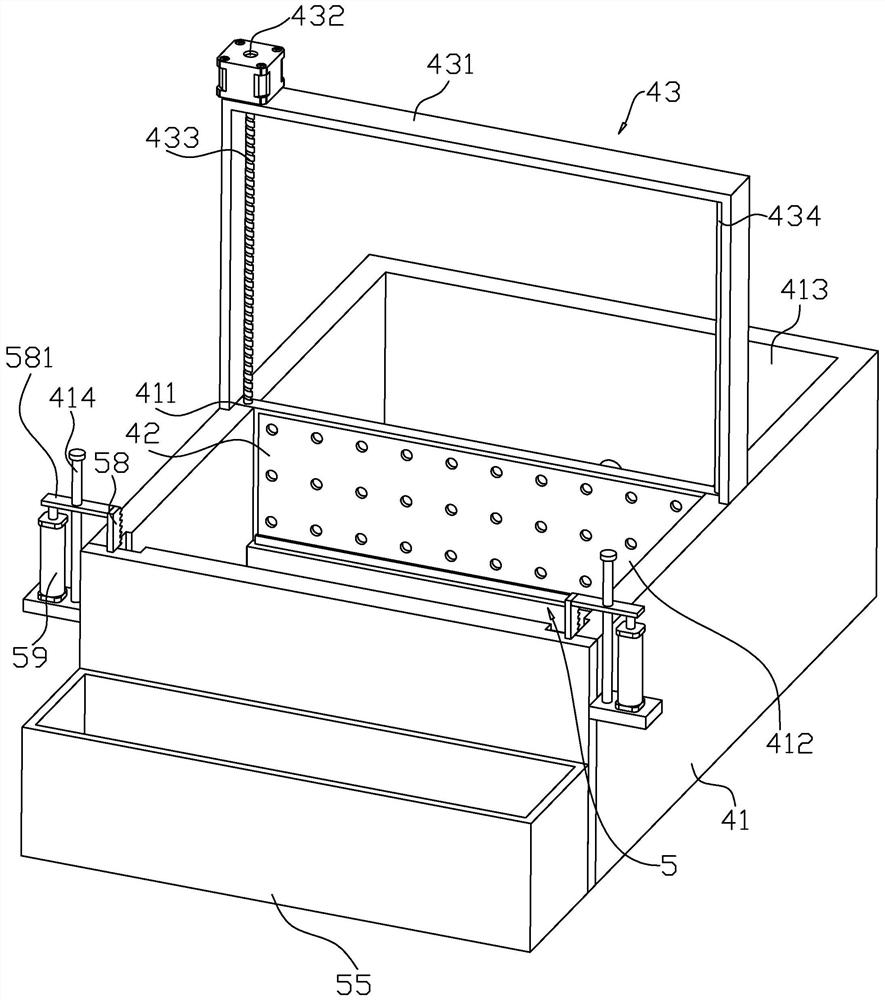

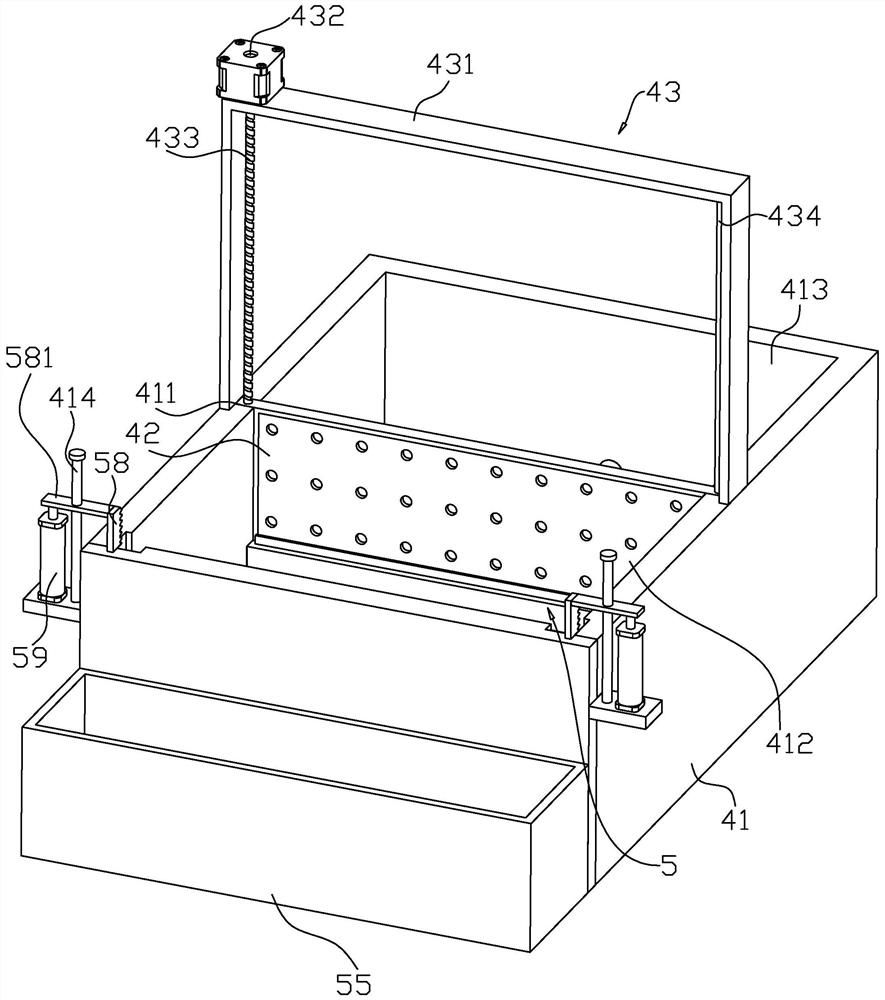

Tea drying box for quantitative drying and automatic pouring based on gravity change

InactiveCN111854351AAvoid stickingAvoid over dryingPre-extraction tea treatmentTea dryingExternal energyProcess engineering

The invention relates to the technical field of tea, and discloses a tea drying box for quantitative drying and automatic pouring based on gravity change. The tea drying box comprises a base, throughusage of a rotary plate, tea leaves adhering to the inner side are scraped by a scraper in the process of drying the tea leaves, and the situation that the tea leaves can not be automatically separated from the inner wall when adhering to the inner wall, excessive drying is caused, and the subsequent cleaning is cumbersome is avoided; through matched usage of a small gear, swing rods and first rotary wheels, movement of the swing rods is linked through gravity change, other external energy substance operation is not needed, finally the drying box automatically swings, and the dried tea leavesare automatically poured out; through matched usage of a limiting rod, the rotary plate, a vertical rod and a cross rod, the dried tea leaves are automatically poured out through gravity change, so that the purpose of quantitative drying is achieved, the situation that the tea leaves are excessively dried or insufficiently dried is avoided, other external energy substance operation is not needed,and more intelligent and environment-friendly effects are achieved.

Owner:杭州曾份科技有限公司

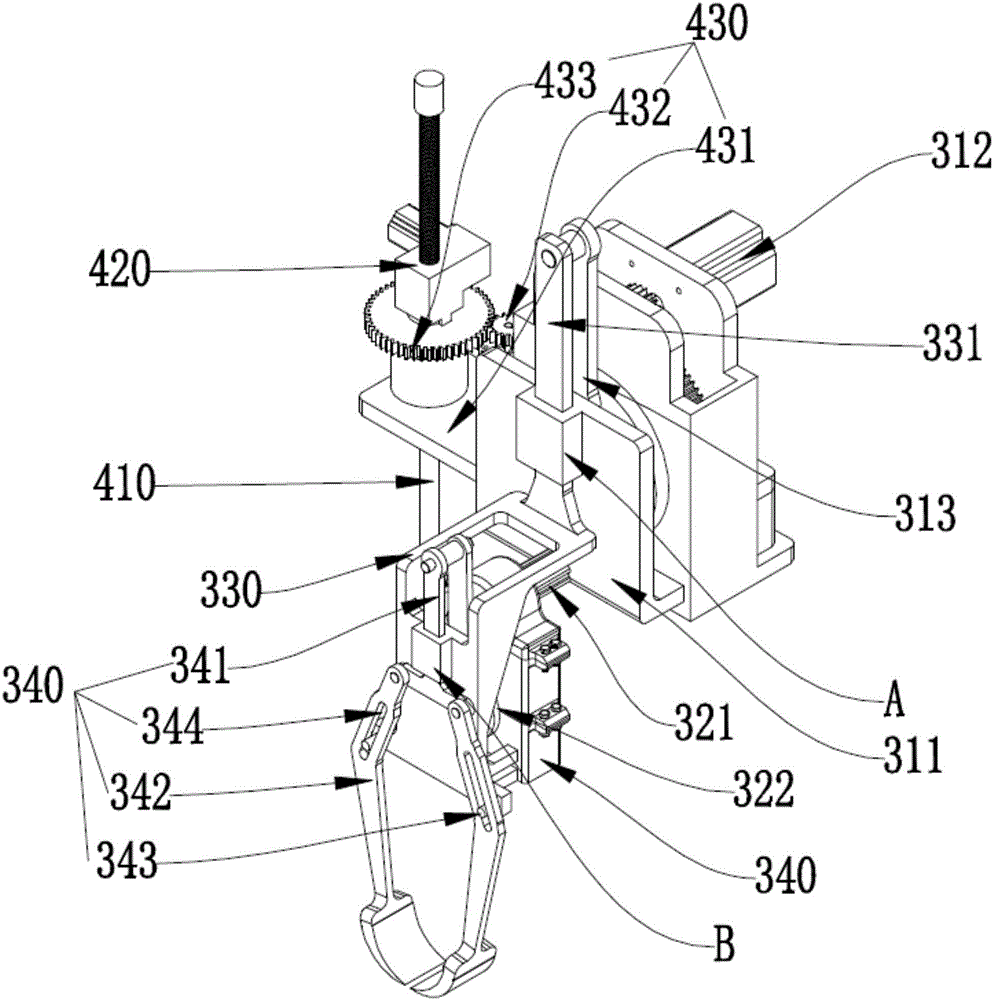

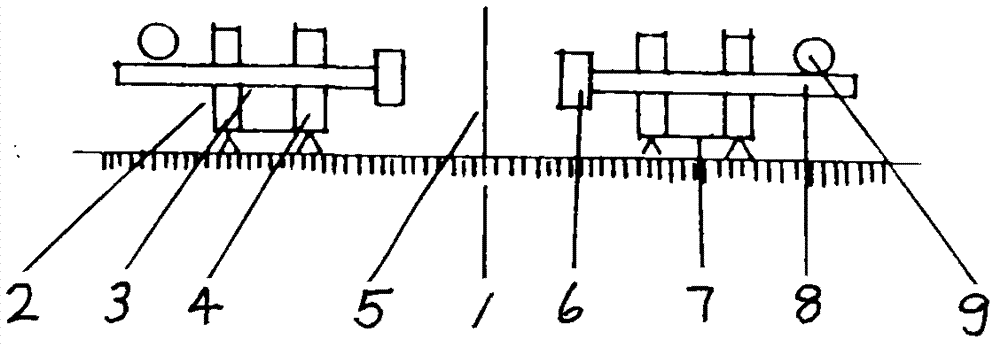

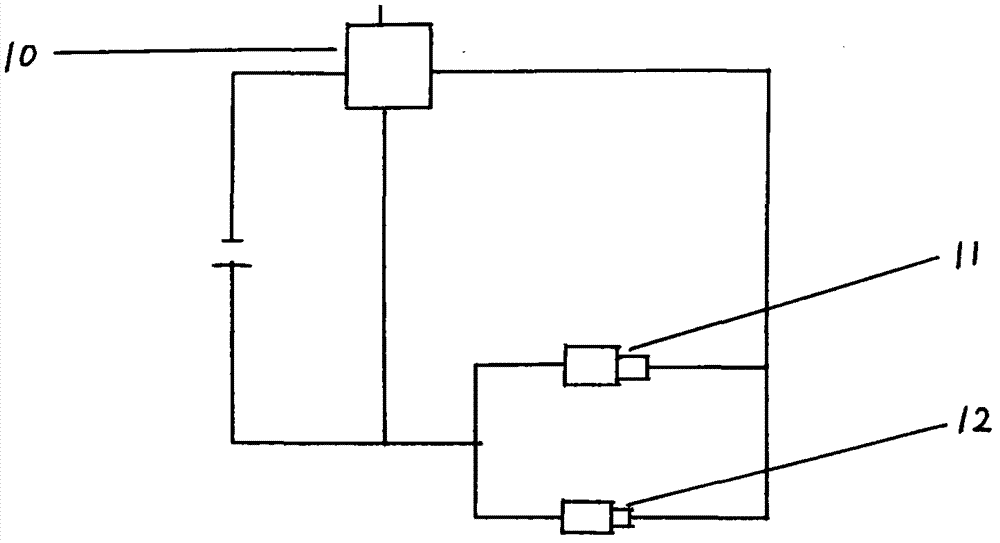

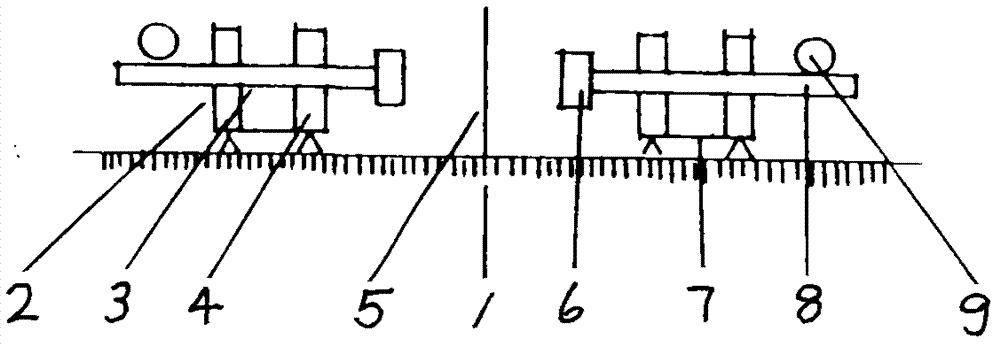

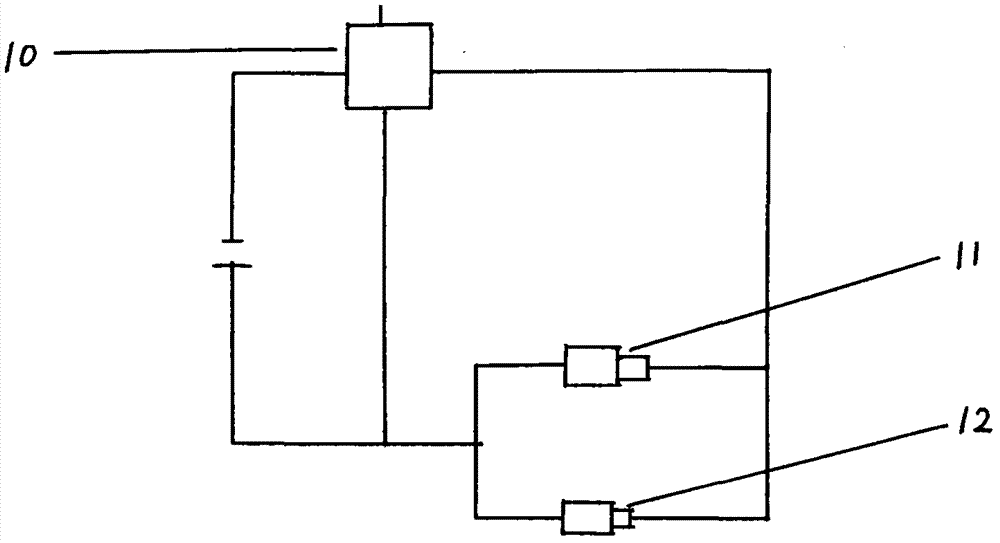

Automatic control device of reverse tubular column coupling of belt pressure operation device

The invention relates to an automatic control device of a reverse tubular column coupling of a belt pressure operation device. The automatic control device comprises a coupling notification device, a signal reception control device, a control structure, a timing switch device and a connecting piece, wherein the coupling notification device is connected below a bottom layer blowout preventer of the belt pressure operation device required to be controlled; starting and stopping of a motor which stops an upper layer blowout preventer and then starts the bottom layer blowout preventer, and a motor which stops the bottom layer blowout preventer and then starts the upper layer blowout preventer are automatically controlled by the signal reception control device on a remote control device according to a notified signal of the coupling notification device; when the tubular column coupling passes through the coupling notification device, the motor which stops the upper layer blowout preventer and then starts the bottom layer blowout preventer pushes a push block to stop the upper layer blowout preventer and then start the bottom layer blowout preventer; and after the tubular column coupling passes through the bottom layer blowout preventer and does not reach the upper layer blowout preventer, the motor which stops the bottom layer blowout preventer and then starts the upper layer blowout preventer pushes a push block to stop the bottom layer blowout preventer and then start the upper layer blowout preventer.

Owner:卞康群

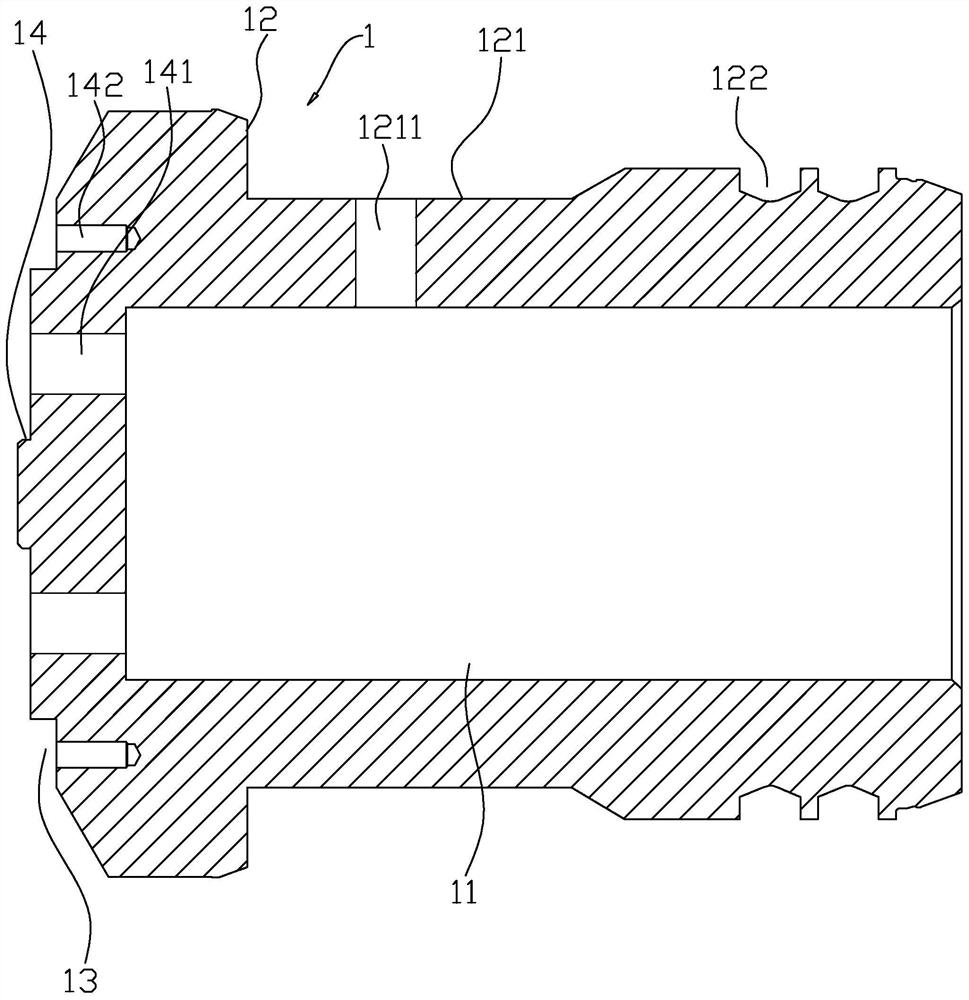

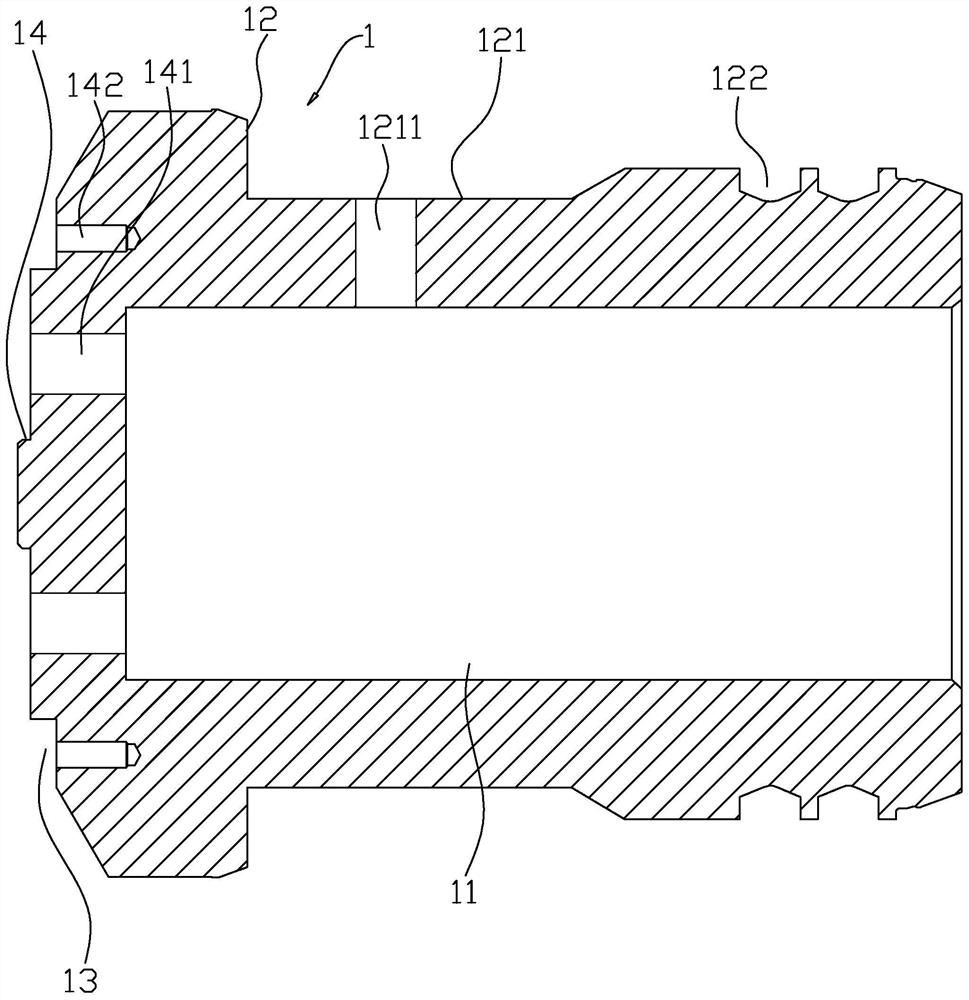

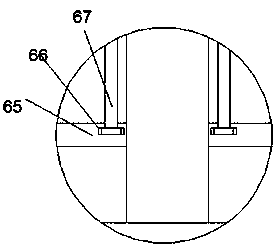

Processing technology of contact seat

The invention relates to a processing technology of a contact seat. The processing technology comprises the following steps of: S1, preparing materials; S2, turning and roughly processing: roughly processing a cylindrical hole; S3, numerically controlled turning: boring the cylindrical hole and turning a first annular groove, a second annular groove, a third annular groove, a fourth annular grooveand a fifth annular groove through a numerically controlled lathe, wherein the numerically controlled lathe comprises a turning mechanism, a bracket, a material receiving box, an oil receiving box, an oil outlet pipe and a lubricating oil pipe; a filtering device and a cooling device are sequentially arranged at one end of the oil outlet pipe; the filtering device comprises a filtering box; the filtering box communicates with the oil outlet pipe; the cooling device comprises a cooling box; the filtering box communicates with the cooling box; and the cooling box communicates with the lubricating oil pipe; S4, processing a center: processing a first through hole, a second through hole and a threaded hole; S5, performing electric engraving: performing electric engraving in a designated areaof one end part, close to the first annular groove, of the second annular groove; S6, plating silver: plating silver on the fifth annular groove; and S7, packaging. The processing technology disclosedby the invention is convenient for treating lubricating oil.

Owner:上海文秀实业有限公司

A control method of a coal mine hoist

ActiveCN109763766BEasy to unloadImprove practicalityConstructionsDerricks/mastsDrive wheelMining engineering

The invention discloses a control method of a coal mine lifting machine and belongs to the technical field of coal mining. The method is implemented on the basis of a coal mine lifting device. The coal mine lifting machine comprises a drilling mechanism, a bottom plate and a coal mine lifting mechanism; the drilling mechanism comprises a lifting assembly, a feeding assembly, a material moving plate and a coal mining assembly; four driving wheels are arranged at the bottom of the bottom plate; the coal mining assembly comprises a spiral bit, a supporting plate, a material inlet part and a position adjusting part; a sliding plate is arranged on the supporting plate; and the sliding plate is of an L-shaped structure. Through the position adjusting part, the spiral bit can perform multi-angledrilling operation; through a rotating assembly, a material receiving box can transfer to the outside of the device and a worker can feed coal in the material receiving box conveniently; and furthermore, through a material receiving part, the coal can be overturned into the material receiving box automatically, the worker does not need to overturn the materials manually, and the labor amount of the worker is reduced.

Owner:陕西安标检验认证有限公司

Garbage recycling device for environment-friendly machinery

InactiveCN111871927AEffective wash and dry operationAutomatic pourDrying solid materials without heatCleaning using liquidsWater flowElectric machinery

The invention discloses a garbage recycling device for environment-friendly machinery. The garbage recycling device comprises a base, a rotating structure and a treatment structure, and the treatmentstructure comprises an upper treatment plate, a lower treatment plate, a treatment plate rotating shaft and a treatment mechanism; and the treatment mechanism comprises a containing box, a water inletstructure, a rotating shaft, a sliding groove, an electric telescopic rod, a water outlet structure, a screen, a fixed seat and a top rotating shaft, and the rotating structure comprises a side edgemotor, a middle rotating shaft, a side edge supporting rod, a rotating disc, a tail device, a top plate and a garbage inlet. According to the garbage recycling device, the two sets of treatment platesare arranged, so that garbage can be effectively cleaned and aired; and meanwhile, water flow enters from the bottom and flows out from the bottom, the screen can be prevented from being blocked, thegarbage can be automatically poured out through the containing box, and convenience is achieved.

Owner:李秀英

Mixing device for polyolefin production

PendingCN113694817AAutomatic pourReduce workloadShaking/oscillating/vibrating mixersMixer accessoriesPolymer sciencePolyolefin

The invention relates to a mixing device, in particular to a mixing device for polyolefin production. The invention provides a mixing device for polyolefin production, which is simple to operate and integrates heating, melting and stirring. The invention discloses a mixing device for polyolefin production. The mixing device comprises a shell; two side plates which are installed on the two sides of the shell. two guide rails which are arranged on one side in the shell; a sliding rod which is mounted between the guide rails in a sliding manner; and a mixing frame that is rotationally mounted on the sliding rod. In the invention, the cam rotates to drive a first contact plate to move left and right, so that a sliding rod moves left and right to drive a mixing frame to shake left and right to mix polyolefin, and a rack slides rightwards to be meshed with a gear, so that the mixing frame is turned upwards to pour out the mixed polyolefin; finally, the pull rod is engaged with the rack by pulling the grip to move upwards.

Owner:宁波威克丽特功能塑料有限公司

A kind of fig fruit powder production device

ActiveCN110479462BEasy to cleanImprove filtering effectSievingScreeningBiotechnologyMechanical engineering

The invention discloses a fig fruit powder production device, which belongs to the technical field of fig production and includes a fruit crushing mechanism, a fruit particle drying mechanism, a feeding auger, a grinding cabinet and a fruit powder making and grinding mechanism. The fruit crushing mechanism includes a cutting component, crushing cabinet, crushing component, screening plate and percussion vibration component, the top of the crushing cabinet is provided with a feed inlet and anti-funnel, the bottom of the crushing cabinet is provided with a material conveying channel, and the conveying channel is provided with a water drop hole. The vibration assembly includes a driving cylinder and two installation slots, each installation slot is equipped with a knock rod, the right end of each knock rod is equipped with a vibrating hammer, and the left end of the two knock rods is provided with a connecting rod . The invention can shake out the fig particles blocked in the sieve holes of the screening net by knocking the vibrating components, realize the drying operation of the figs by the fruit particle drying mechanism, and vibrate the drying box by the vibration components The figs in the drying box were turned over.

Owner:义乌市昕闵日用品有限公司

A processing technology of a contact seat

This application relates to a processing technology of a contact seat, which includes the following steps: S1, material preparation; S2, rough machining of turning: rough machining of cylindrical holes; S3, numerical control turning: boring of cylindrical holes and turning of the first ring by CNC lathe groove, the second annular groove, the third annular groove, the fourth annular groove and the fifth annular groove; the CNC lathe includes a turning mechanism, a support, a material receiving box, an oil receiving tank, an oil outlet pipe and a lubricating oil pipe; one end of the oil outlet pipe is provided with The filter device and the cooling device, the filter device includes a filter box, the filter box is connected with the oil outlet pipe, the cooling device includes a cooling box, the filter box is connected with the cooling box, and the cooling box is connected with the lubricating oil pipe; S4, machining center: processing the first A through hole, a second through hole and a threaded hole; S5, electro-engraving; electro-engraving at a designated area at the end of the second annular groove close to the first annular groove; S6, silver plating: plating the fifth annular groove Silver treatment; S7, packaging. This application facilitates the treatment of lubricating oil.

Owner:上海文秀实业有限公司

Automatic control device for reverse pipe string coupling of working device under pressure

The invention relates to an automatic control device of a reverse tubular column coupling of a belt pressure operation device. The automatic control device comprises a coupling notification device, a signal reception control device, a control structure, a timing switch device and a connecting piece, wherein the coupling notification device is connected below a bottom layer blowout preventer of the belt pressure operation device required to be controlled; starting and stopping of a motor which stops an upper layer blowout preventer and then starts the bottom layer blowout preventer, and a motor which stops the bottom layer blowout preventer and then starts the upper layer blowout preventer are automatically controlled by the signal reception control device on a remote control device according to a notified signal of the coupling notification device; when the tubular column coupling passes through the coupling notification device, the motor which stops the upper layer blowout preventer and then starts the bottom layer blowout preventer pushes a push block to stop the upper layer blowout preventer and then start the bottom layer blowout preventer; and after the tubular column coupling passes through the bottom layer blowout preventer and does not reach the upper layer blowout preventer, the motor which stops the bottom layer blowout preventer and then starts the upper layer blowout preventer pushes a push block to stop the bottom layer blowout preventer and then start the upper layer blowout preventer.

Owner:卞康群

Container flushing device for medical department

InactiveCN112792078AAchieve fixationAutomatic pourHollow article cleaningEngineeringMedical department

The invention discloses a container flushing device for a medical department, and relates to the technical field of medical material cleaning. The container flushing device comprises a transverse plate and supporting legs, wherein the four corners of the bottom end of the transverse plate are fixedly connected to one group of supporting legs separately; the top end of the transverse plate is equipped with a pouring mechanism; and one side of the pouring mechanism is equipped with a clamping structure. A gas cylinder, a mounting plate, a telescopic pole, a through slot, a dowel pin and a limiting slot are arranged, so that while a medical container needs to be flushed, the gas cylinder is started to push the telescopic pole and a lifting frame at the top end of the telescopic pole to lift, and thus, a water outlet tube and a spray hole outside the water outlet tube are driven to rise; and the container can be fixed to the bottom end of the water outlet tube, and the gas cylinder is started for driving the lifting frame at the top end to descend for inserting the water outlet tube and the spray hole outside the water outlet tube into the container; and the water pump is started for extracting water inside a water tank, and the water is finally sprayed out to flush the container through the water outlet tube and the spray hole, so that flushing inside the container can be realized.

Owner:杭州云丽医疗器械有限公司

Automatic cooking robot for large canteen

ActiveCN111035229AAutomatic pourSave manpower and material resourcesCooking vessel constructionsProcess engineeringMaterial resources

The invention discloses an automatic cooking robot for a large canteen. The automatic cooking robot comprises a machine body, and a supporting space with an upward opening is formed in the machine body. A heating device for cooking is arranged in the supporting space; when dish frying is needed, first of all, a heating coil is opened, therefore, the inside of a frying pan is heated, the automaticcooking robot can be applied to large canteens; full-automatic stir-frying is carried out on meals; compared with traditional manual stir-frying, manpower and material resources can be saved, operation is easier, meanwhile, compared with an existing small cooking robot, a large number of meals can be stir-fried at a time, the stir-fried meals can be automatically poured out, and therefore the operation that people put a large pot of meals into a basin is omitted.

Owner:聊城市敏锐信息科技有限公司

A flip-type electroplating hanger

ActiveCN113136614BAutomatic pourAchieve positioningElectrolysis componentsMechanical engineeringPhysics

The invention provides a flip-type electroplating hanger, which includes a hook, a vertical rod, a vertical extension rod, a horizontal rod, a horizontal extension rod and a positioning group; the hook is fixed on the top of the vertical extension rod, and the bottom end of the vertical extension rod is connected to the vertical rod Above, the end of the horizontal rod is fixed with a rotating shaft, and the rotating shaft is connected to one end of the horizontal extension rod. The other end of the horizontal extension rod is provided with a positioning ring, and a pull rope is connected inside the positioning ring. The horizontal hole penetrated, and a central hole connected with the horizontal hole is also provided in the vertical extension rod. A winding assembly is installed on the top of the central hole, and one end of the pull rope enters the central hole through the horizontal hole to connect the winding assembly. It includes a positioning block fixed in the horizontal extension rod, a driving screw connected in rotation in the positioning block, a driving part connected with the driving screw and driven by the driving screw to expand outward and squeeze and position in the workpiece cylinder. As for the clamping part, the present invention can realize automatic turning over and has better stability, and is suitable for electroplating operation of cylindrical workpieces.

Owner:扬中市宏飞镀业有限公司

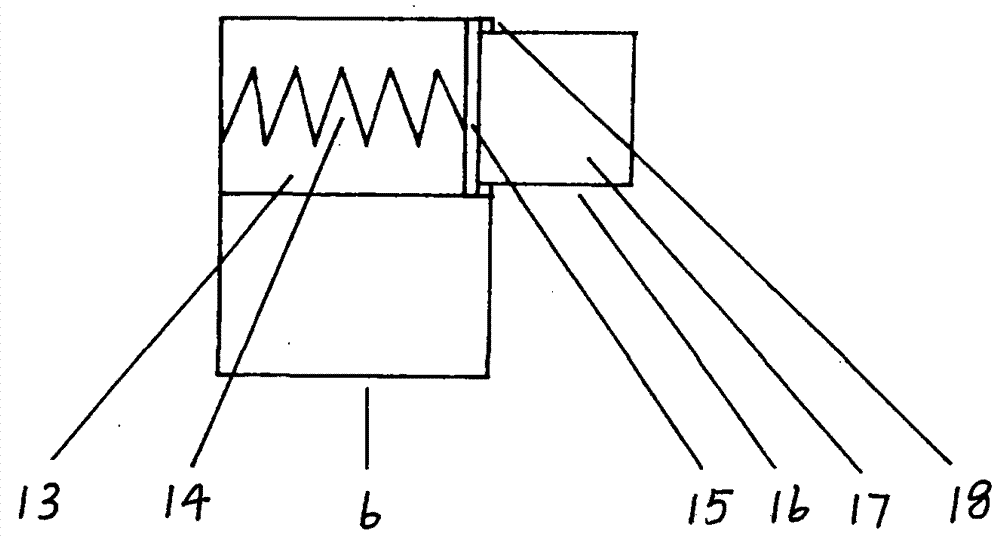

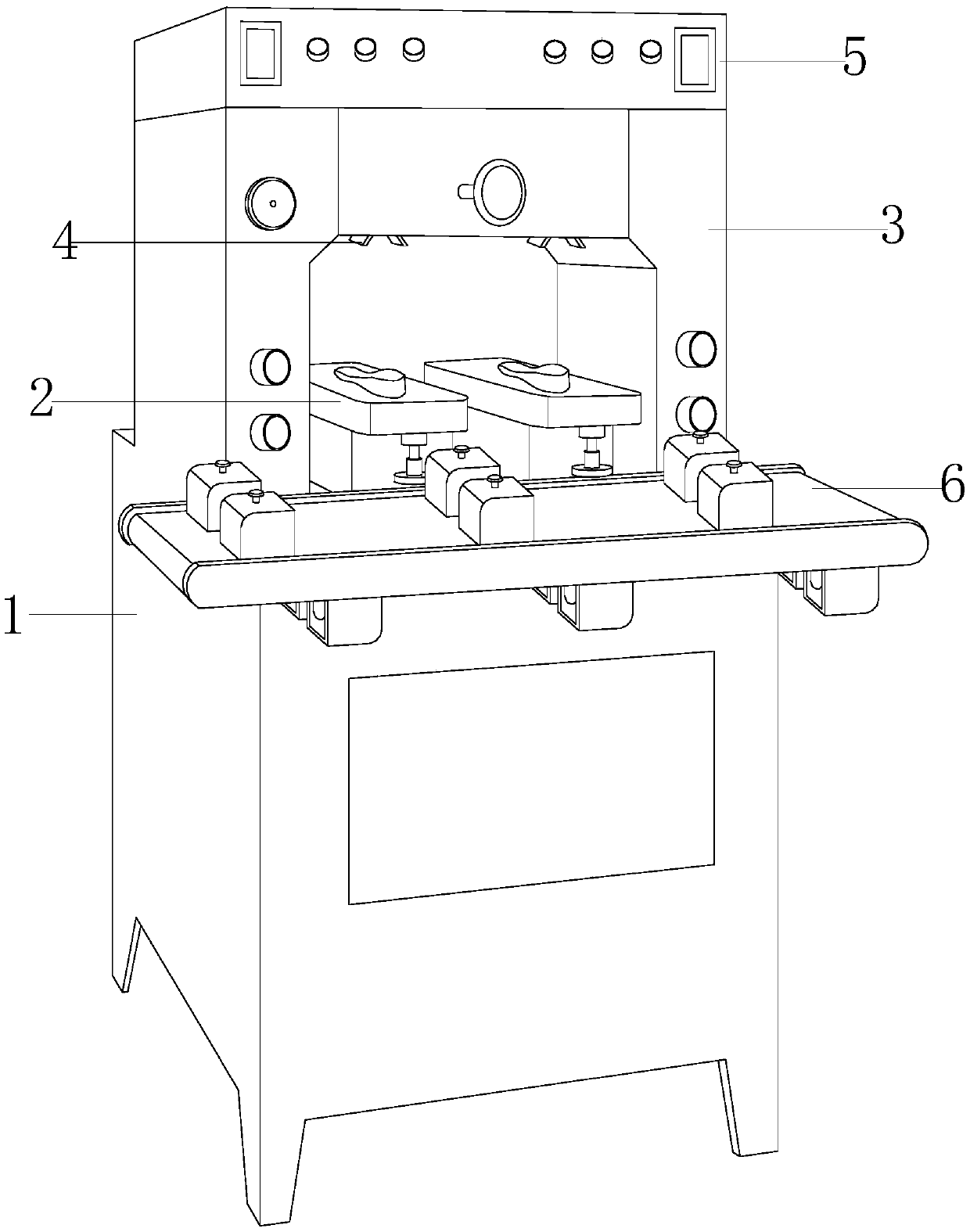

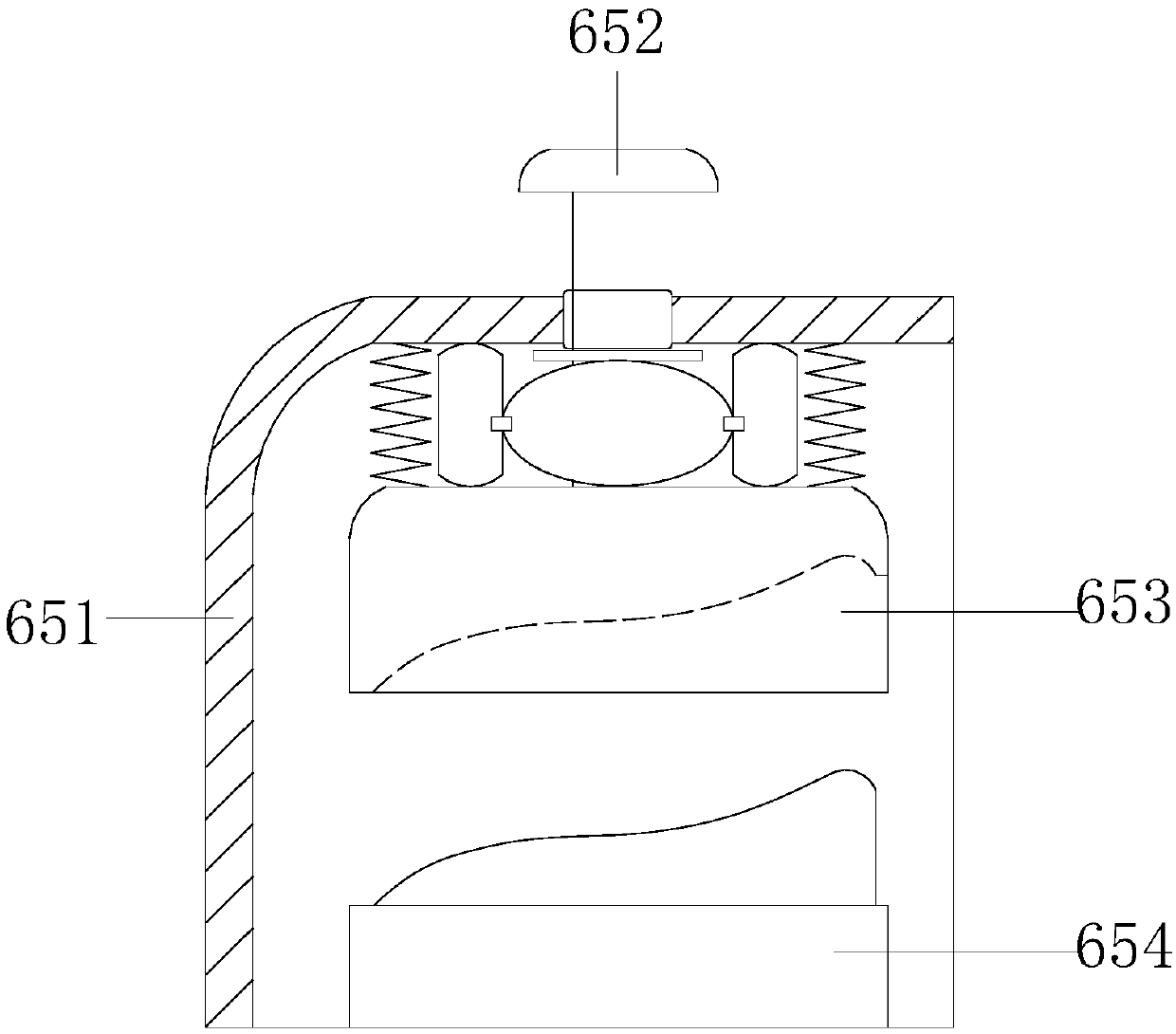

Leather shoe vamp setting machine capable of achieving secondary slow retreating type pressing setting

ActiveCN109527716AGuaranteed styling effectReduce the temperatureInsolesUpperElectric controlSelf weight

The invention discloses a leather shoe vamp setting machine capable of achieving secondary slow retreating type pressing setting. The leather shoe vamp setting machine structurally comprises a supporting electric cabinet, a setting model table, an electronic control U-shaped frame, an electric heating hydraulic mechanism, an operation panel and a secondary slow retreating type pressing setting device. The supporting electric cabinet is of a rectangular structure, the supporting model table is arranged above the supporting electric cabinet, and the electronic control U-shaped frame is reverselyarranged above the supporting electric cabinet. According to the leather shoe vamp setting machine, by arranging the secondary slow retreating type pressing setting device, a leather shoe vamp subjected to electric heating setting can be subjected to secondary pressing setting, cooling is carried out based on certain time of the vamp, the vamp is automatically poured out of the right side of thedevice, the leather shoe vamp can be subjected to secondary setting at this moment, the temperature is low, deformation is not likely to be caused by self weight of the vamp or manual pressure duringstacking, and the setting effect of the leather shoe vamp is guaranteed.

Owner:温州卡雁鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com