Garbage recycling device for environment-friendly machinery

A technology of recycling and garbage, which is applied in cleaning methods and utensils, cleaning methods using liquids, drying solid materials, etc., can solve problems such as complex recycling structures, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

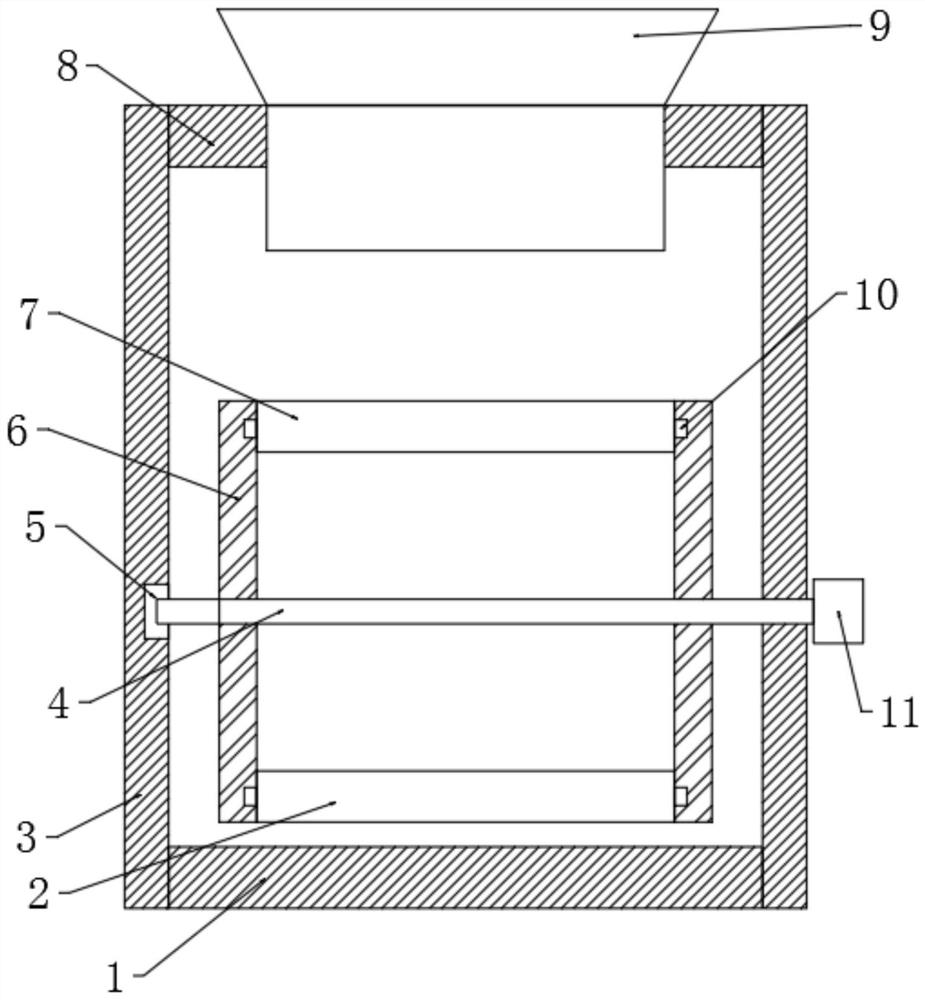

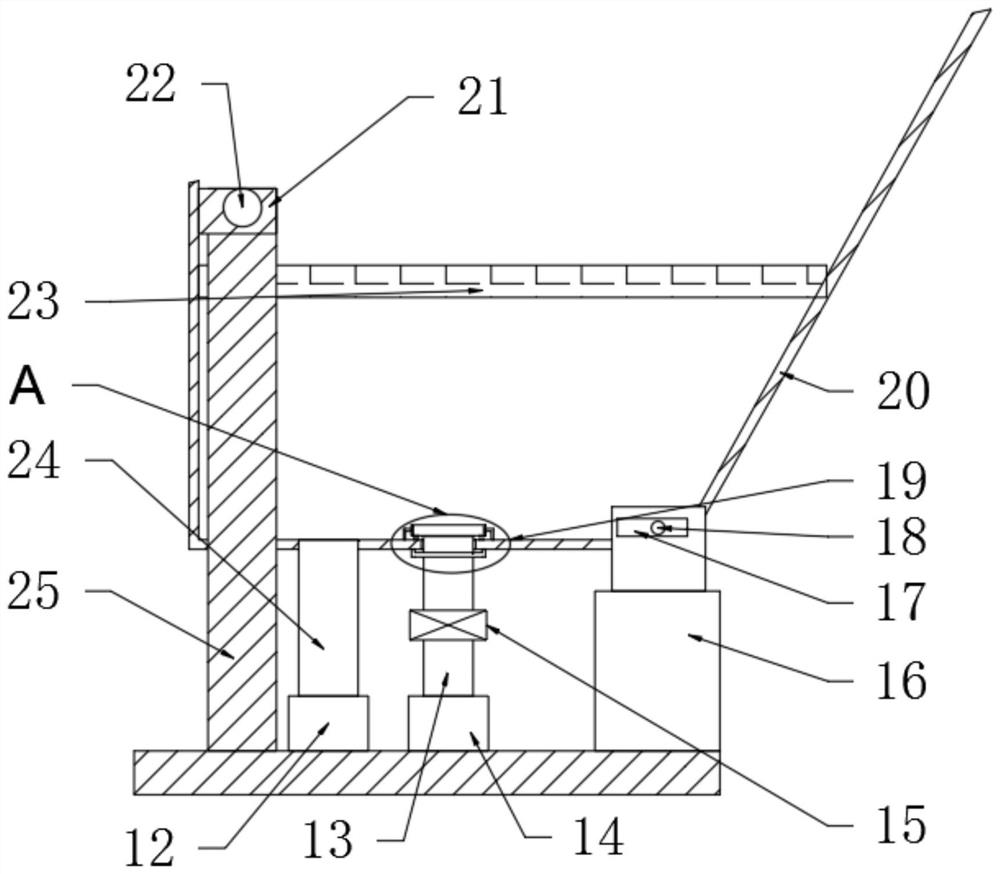

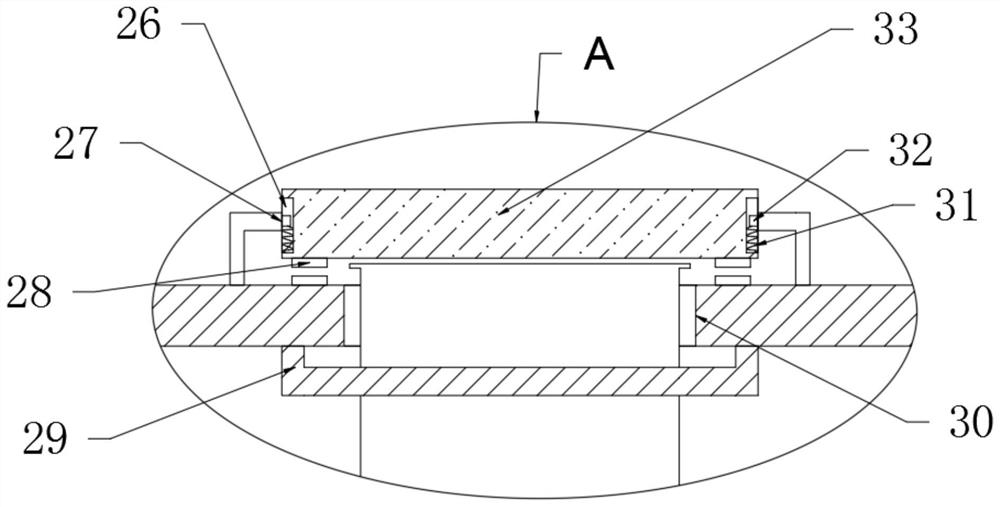

[0021] see Figure 1-5 , a garbage recovery treatment device for environmental protection machinery, including a base 1, a rotating structure and a processing structure, the base 1 is fixedly provided with a rotating structure, and the rotating structure is provided with a processing structure (the rotating structure is used to drive The processing structure is rotated), the processing structure includes an upper processing board 7, a lower processing board 2, a processing board rotating shaft 10 and a processing mechanism, and the upper processing board 7 and the lower processing board 2 are respectively arranged on the upper and lower sides of the rotating structure. The processing plate 7 and the lower processing plate 2 are connected by a processing plate rotating shaft 10 and a rotating structure, and a processing mechanism is fixed above the upper processing plate 7 and the lower processing plate 2 (the upper processing plate 7 and the lower processing The plate 2 is kep...

Embodiment 2

[0028] Compared with Embodiment 1, the improvement of this embodiment is that: the bottom of the flowing water treatment tank is provided with a detachable net plate 36, the top of the detachable net plate 36 is slidingly provided with a collection water pipe 24, the detachable The screen plate 36 is detachable relative to the flowing water treatment tank.

[0029] The working principle of the present invention is: firstly, rubbish is placed on the screen 23 from the garbage inlet 9, and water is fed from the water inlet structure 19 until the water flow does not pass through the screen 23 inside the placement box 20, and then soak and rinse. Use the rotating structure to rotate another group of processing plates to a suitable position, perform the above operations, then the rotating structure continues to rotate, use the water outlet structure to discharge water, put the garbage on the screen 23 to dry, and then use the electric telescopic rod 16 to pull the rotating shaft 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com