Patents

Literature

71results about How to "Guaranteed styling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

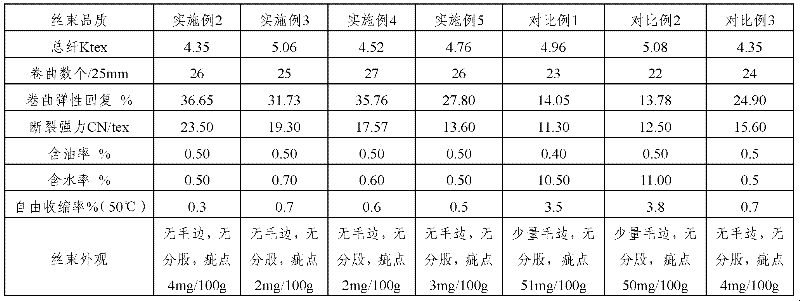

Method for preparing environment-friendly cigarette tows

ActiveCN102493003AReduce surface moistureReduce moisture contentTobacco smoke filtersMelt spinning methodsMelt spinningEnvironmental resistance

The invention relates to a method for preparing environment-friendly cigarette tows, which comprises the following steps of: drying and crystallizing, melting spinning, drafting and tension-finalizing, crimping, drying and thermal finalizing, wherein the drafting and tension-finalizing step employs a roller built-in heating way. The cigarette tows prepared by the method disclosed by the invention are higher in temperature of the crimping and the drying and thermal finalizing process steps in the preparation of the tows, shorter in production period, and improved in quality. And meanwhile, control of moisture can facilitate hot processing de-polymerization and hydrolysis degrees of polylactic acid, as a result, the spinning performance of the modified polylactic acid and the performance of tow products are improved.

Owner:马鞍山同杰良生物材料有限公司

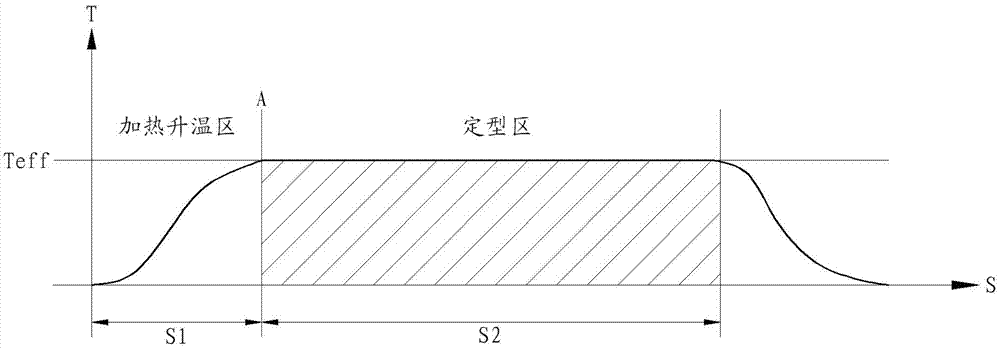

Fabric thermosetting intelligent control method and setting machine adopting same

InactiveCN106948117AImprove drying efficiencySave energyHeating/cooling textile fabricsSimultaneous control of multiple variablesProcess engineeringHeat setting

The invention discloses an intelligent control method for fabric heat setting and a setting machine adopting the method. The intelligent control method for fabric heat setting includes a step of heating the fabric impregnated with a process liquid in an oven of the setting machine and heating the fabric. The heat setting step of the fabric after the temperature rise, the method also includes the step of setting the running speed of the fabric according to the setting temperature Teff and the setting time S2 of the process requirements before the heating step, and during the heat setting step, according to the on-line monitoring setting The fabric temperature at the starting point of the zone, by adjusting the temperature in the oven in real time, makes the fabric temperature reach the required setting temperature Teff step of the process requirements after heating up; constant. The invention can accurately control the setting temperature of the fabric and the setting time at the setting temperature, improves the setting quality of the fabric and the drying efficiency of equipment, and saves energy.

Owner:CHANGZHOU HONGDA INTELLIGENT EQUIP IND DEV RES INST CO LTD

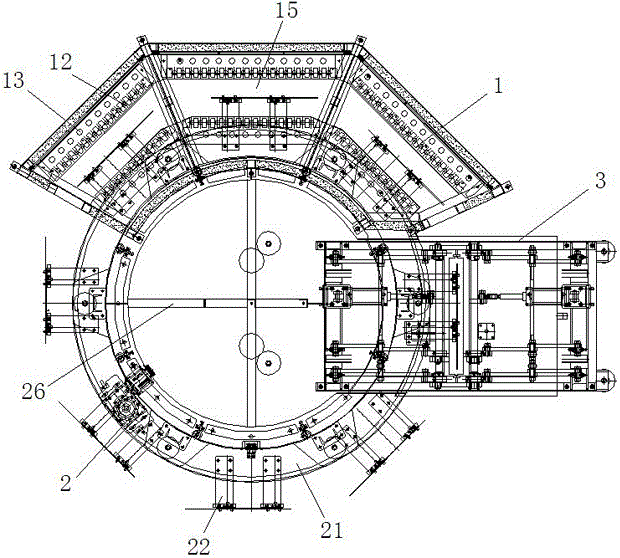

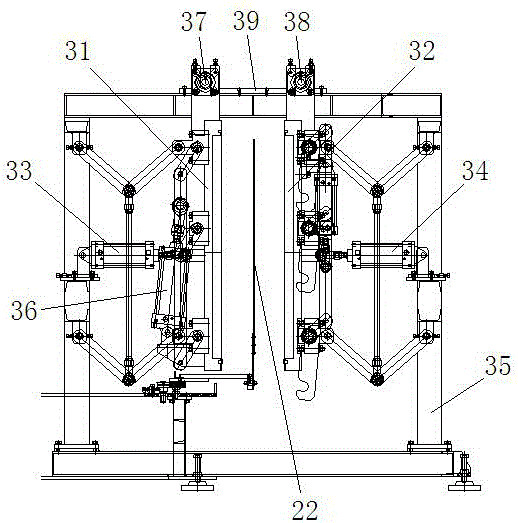

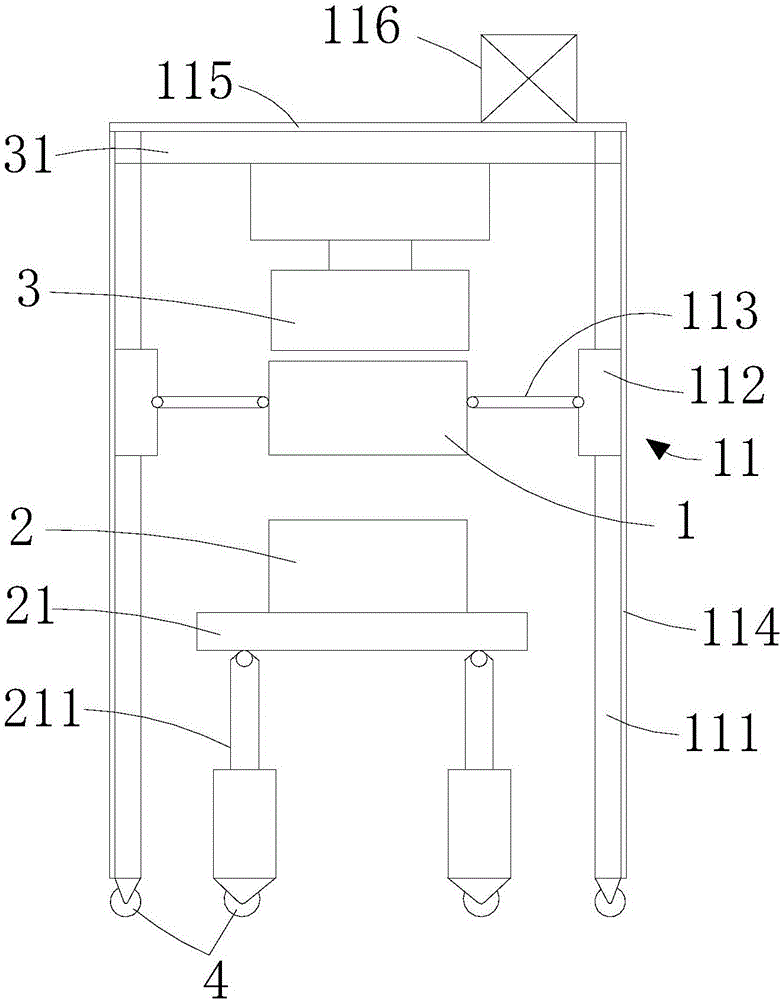

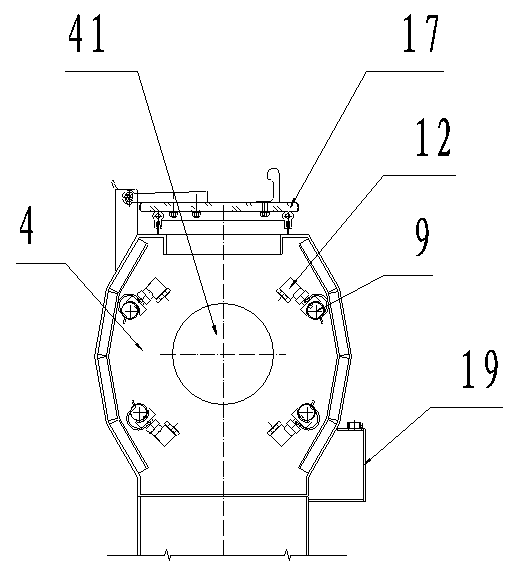

Sock shaping machine

ActiveCN106835583ASmall footprintSimple structureHeating/cooling textile fabricsShaping/stretching tubular fabricsAgricultural engineering

The invention provides a sock shaping machine. The sock shaping machine occupies less space, is low in cost and has a good shaping effect. A turntable is horizontally and rotatably arranged on a turntable frame; a formwork is vertically fixed on the turntable; a turntable driving mechanism is connected with the turntable; a left shaping plate and a right shaping plate are both arranged on a shaping frame in a sliding form; a left shaping chamber is arranged in the left shaping plate; a left steam inlet and a left steam outlet are formed in the left shaping chamber; a right shaping chamber is arranged in the right shaping plate; a right steam inlet and a right steam outlet are formed in the right shaping chamber; a left shaping plate driving mechanism is arranged on the shaping frame and is connected with the left shaping plate; a right shaping plate driving mechanism is arranged on the shaping frame and is connected with the right shaping plate; an eccentric shaft cylinder is connected with an eccentric shaft through an eccentric shaft connecting rod; a blocking hook cylinder is connected with a blocking hook through a blocking hook connecting rod; the eccentric shaft is detachably connected with a blocking slot of the blocking hook; a drying chamber is arranged in a drying bracket; and a heating pipe is fixedly arranged on the drying bracket, is located in the drying chamber and is located on the two sides of a drying position.

Owner:浙江容易富机械科技有限公司

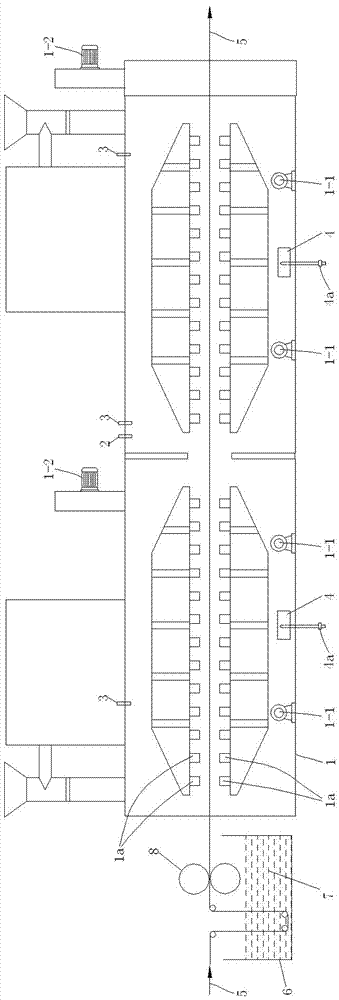

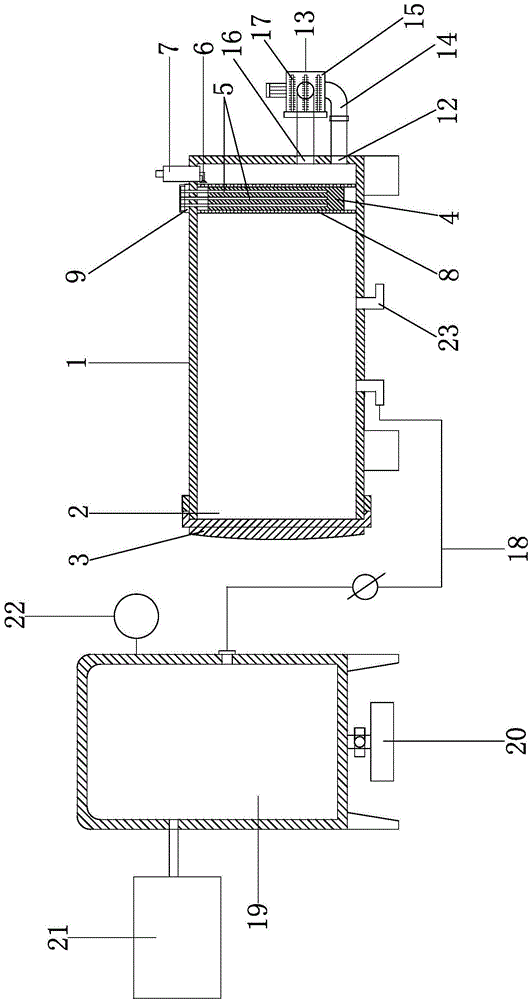

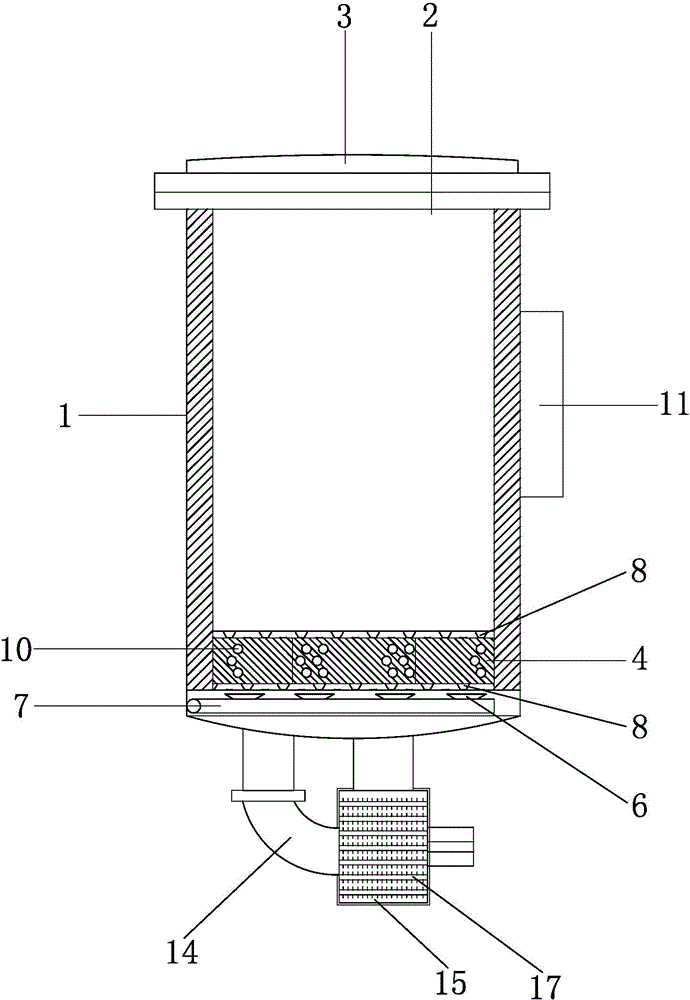

Stream setting machine

ActiveCN104593979AEfficient conversionImprove evaporation efficiencyTextile treatment containersHeating/cooling textile fabricsEngineeringVacuum pump

The invention provides a stream setting machine, and belongs to the technical field of a setting machine. The stream setting machine solves the problems that the heating speed of the existing structure is slow, the steam quantity cannot be easily controlled, the whole machine size is bulky and the existing structure does not have heat storage function, and the like. The stream setting machine is characterized in that a sealed cap is arranged at the open end of the front side of a tank body, a high temperature heat storage plate is arranged in the tank body, a heating pipe is detachably arranged in the high temperature heat storage plate, a plurality of spray headers that can spray water to the high temperature heat storage plate are arranged on one side of the high temperature heat storage plate, spray headers are all connected to a water inlet pipeline; a circulating heating mechanism is arranged at the rear end of the tank body, a vacuum tank that the interior is in a negative pressure condition is connected with the tank body by a pressure relief control pipeline, a condensate water collecting tank is arranged on the bottom of the vacuum tank, a vacuum pump is connected with the vacuum tank, and a pressure gauge is installed on the vacuum pump. The stream setting machine has the advantages that the steam can be effectively converted, the heat in the tank body is uniform, the setted objects can be dried fast, and the usage of power shortage areas can be met.

Owner:TIANTAI COUNTY MINGTONG MACHINERY

Artificial leather for leather carving and manufacturing method thereof

The invention provides artificial leather for leather carving and a manufacturing method thereof. The artificial leather for the leather carving comprises a layer capable of being wiped, a protective layer, a PU foamed layer, a side stretch knitted fabric layer and a setting layer which are sequentially fit from outside to inside. Decorative patterns are formed on the outer surface of the protective layer. The layer capable of being wiped is mainly used for a leather carving product with an antiquing effect. The artificial leather for the leather carving has the advantages that the side stretch knitted fabric is adopted as a base, so that the artificial leather has extensibility in radial direction and weft direction and is applicable to a leather carving product with strong concavo-convex sense; and the setting layer is added on the back, so that setting property of the leather carving can be guaranteed.

Owner:DADI FUJIAN TECH

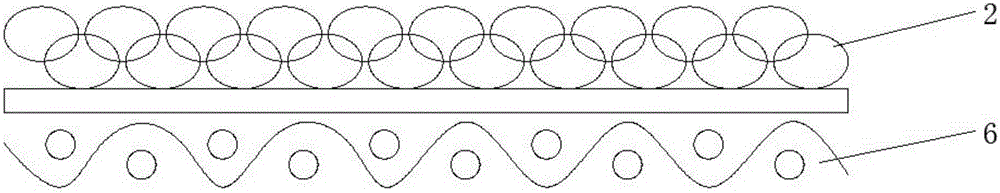

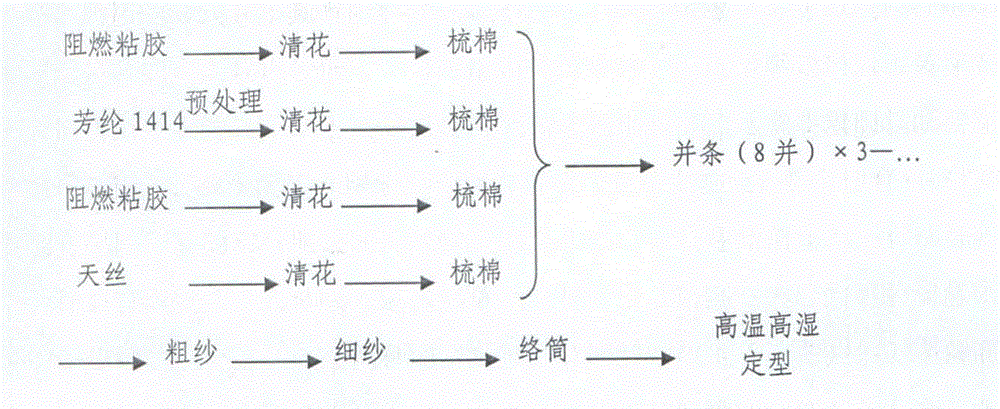

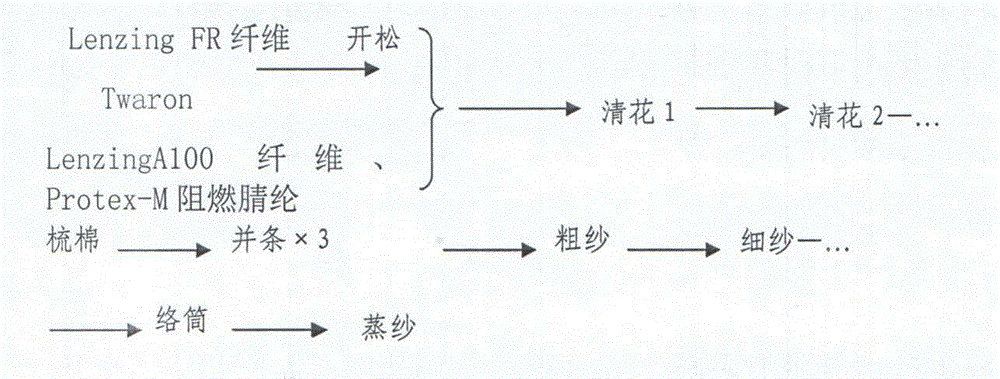

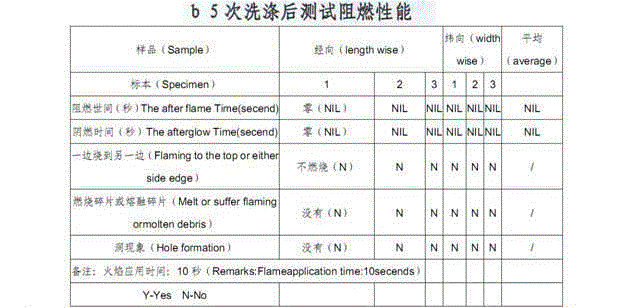

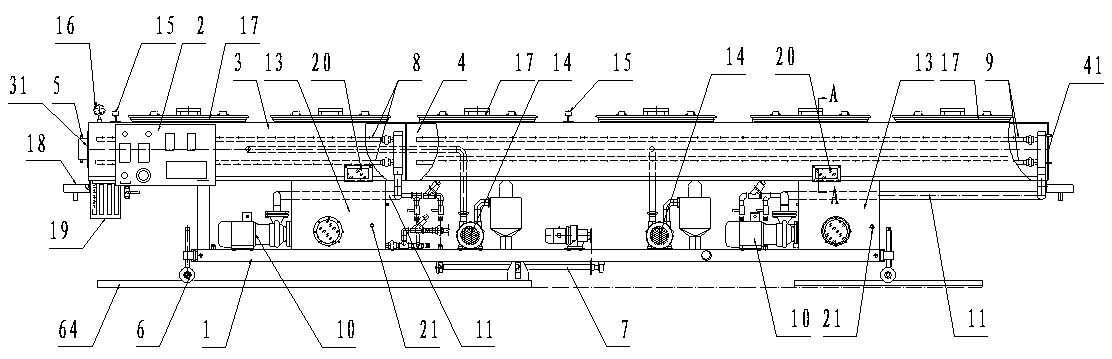

Fire resistant fiber blended yarn and production method thereof

InactiveCN104611796AWith flame retardant functionPermanent flame retardant functionYarnYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a fire resistant fiber blended yarn and a production method thereof. The fire resistant fiber blended yarn comprises, by weight, 30-45% of Lenzing FR fibers, 30-40% of Protex-M fire-resistant acrylic, 15-20% of Lenzing A100 fibers, and 5-10% of Twaron. The production method sequentially comprises the following steps of 1, conducting pretreatment on the Lenzing FR fibers and the Twaron, 2, conducting blowing for the first time, 3, conducting blowing for the second time, 4, conducting cotton carding, 5, conducting drawing, 6, conducting roving, 7, conducting spinning, 8, conducting spooling and 9, conducting yarn steaming. A garment manufactured by the yarn has the permanent fire resistant function, the adopted yarn is safe and environmentally friendly, and no poisonous gas is released; the garment manufactured by the yarn is soft in touch, a user wears the garment comfortably, and the moisture absorption and breathable performance is good; the yarn is formed by evenly mixing the fibers, and the thermal protection and comfort differences caused when the fibers are unevenly mixed at different places of a shell fabric are avoided.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Efficient environmental protection casting device facilitating demoulding

InactiveCN106734971AHighly integratedLow costMoulding machinesMould handling equipmentsEngineeringCooling efficiency

The invention discloses an efficient environmental protection casting device facilitating demoulding. The efficient environmental protection casting device comprises a cope flask, a drag flask, a cope flask fixing bracket and a drag flask supporting platform; the cope flask fixing bracket comprises four upright columns arranged symmetrically; the middle part of each upright column is provided with a hydraulic lifting sliding block; each hydraulic lifting sliding block is connected with a cross arm; one end of one cross arm is hinged to one hydraulic lifting sliding block through a hinge correspondingly; the other ends of the cross arms are hinged to the cope flask through hinges; a hydraulic compacting machine is arranged at the tops of the upright columns; the four corners of the bottom of the drag flask supporting platform are each connected with a lifting supporting rod through a hinge; the drag flask is placed on the drag flask supporting platform; baffles are arranged among the upright columns; an operation door is formed in one of the baffles; a top plate is arranged at the tops of the upright columns; the baffles and the top plate form sealed space; an exhaust fan is arranged on the top plate; and the internal surfaces of the cope flask and the drag flask are coated with surfactants. The efficient environmental protection casting device is high in integration level, convenient to use, low in manufacturing cost, good in shaping quality, and high in efficiency, cooling efficiency and casting precision, and facilitates flask demoulding.

Owner:成都嘉新特种精密铸造有限公司

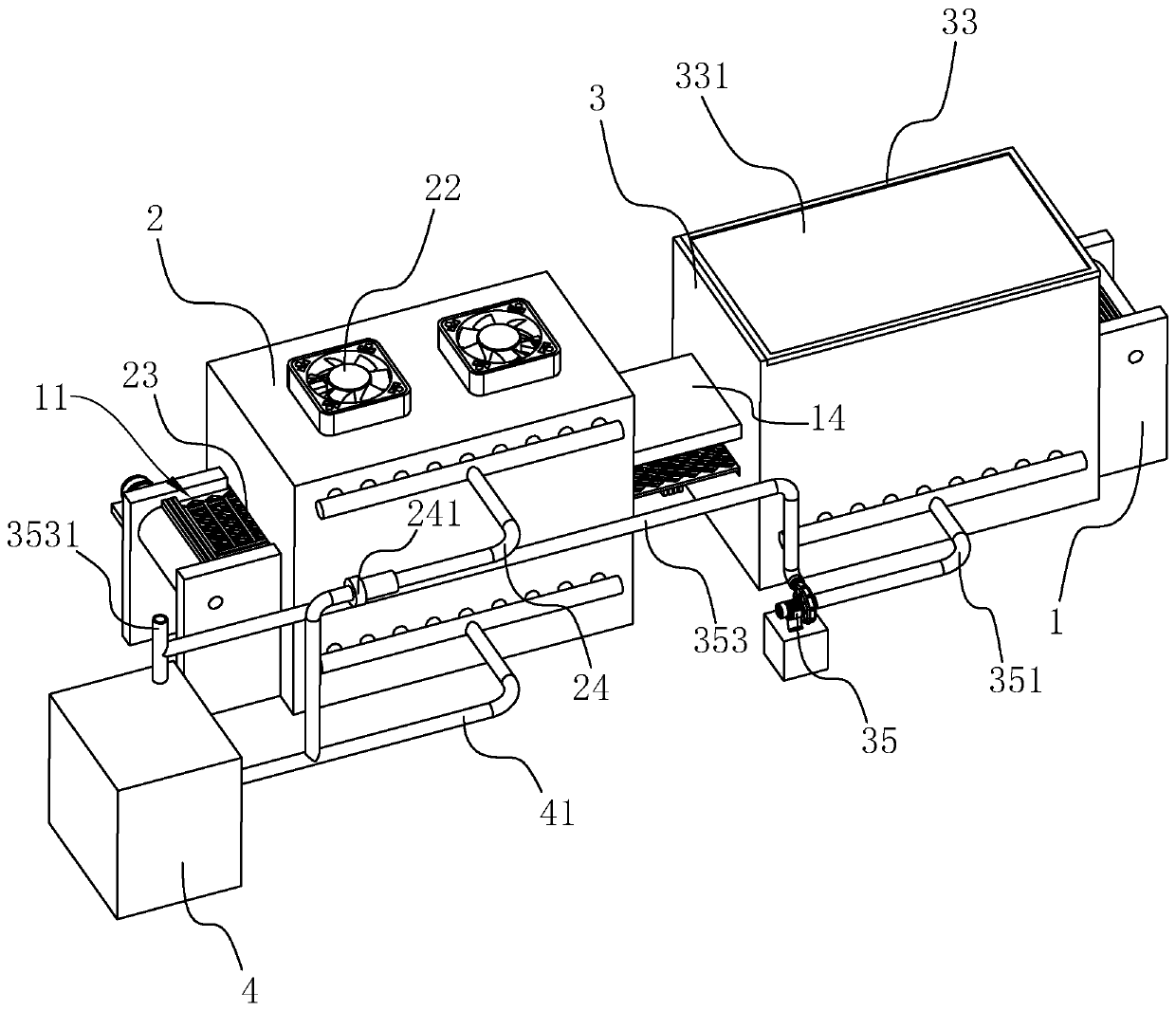

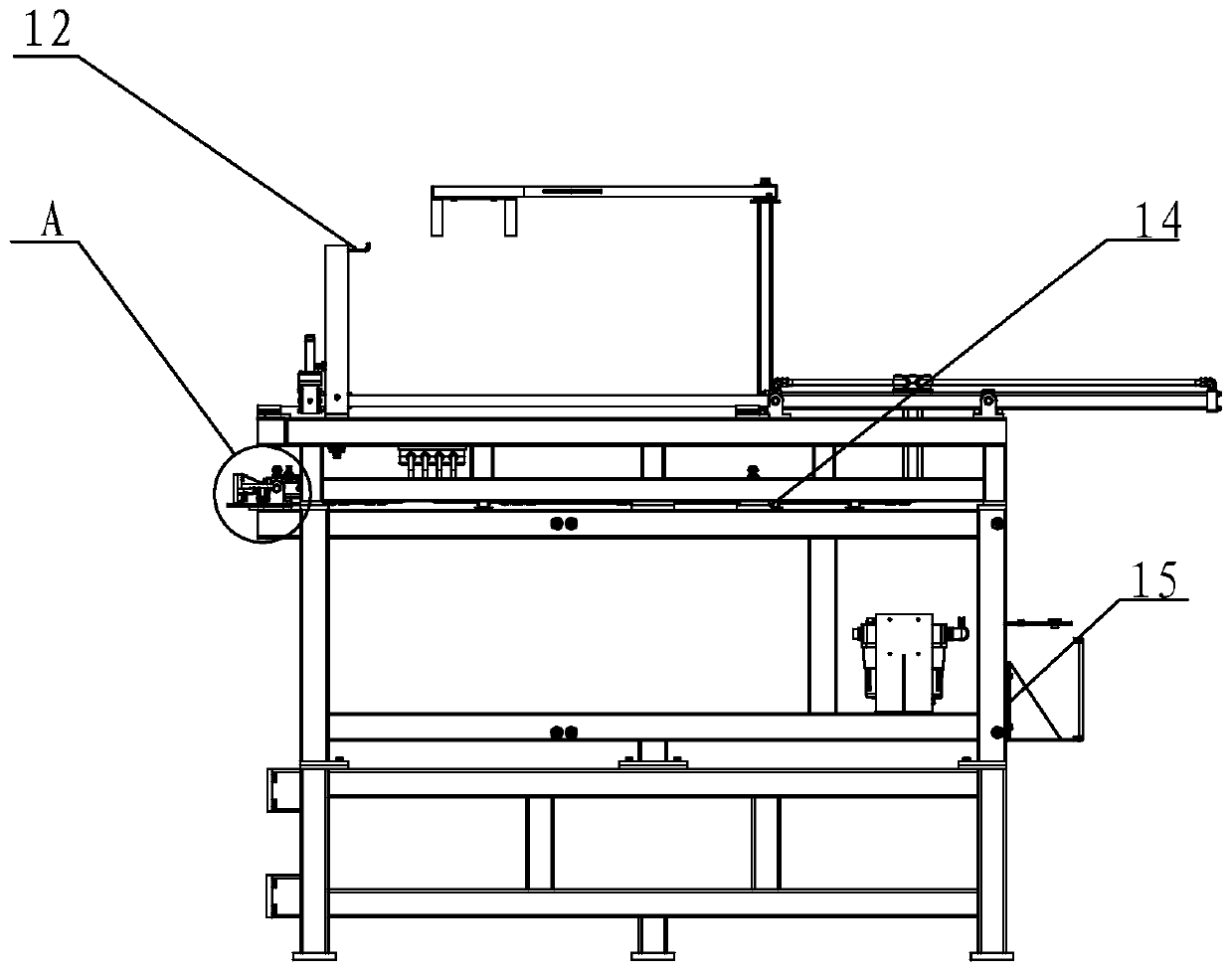

Fabric steaming and sizing device

ActiveCN109944004AGuaranteed temperature differenceEnough temperature differenceTextile treatment machine arrangementsTextile treatment carriersTemperature controlTemperature difference

The invention discloses a fabric steaming and sizing device, and belongs to the field of fabric steaming devices. The fabric steaming and sizing device comprises a machine frame and a conveying belt connected to the machine frame. The conveying belt comprises a mesh-shaped belt. A heating box and a cooling box are fixedly connected with the position, corresponding to the conveying belt, of the machine frame. The end, close to the cooling box, of the heating box is fixedly connected with a channel. The other end of the channel is fixedly connected to the bottom of the cooling box. The conveyingbelt penetrates through the heating box, the channel and the cooling box. An electric heating plate is fixedly connected into the heating box. A refrigerator is fixedly connected into the cooling box. The electric heating plate and the refrigerator are connected with a control circuit. The control circuit comprises a first temperature collecting module, a second temperature collecting module, a high-temperature control module and a temperature difference control module. The control circuit controls the electric heating plate and the refrigerator according to the temperatures in the heating box and the cooling box. The fabric steaming and sizing device has the advantages that the temperatures in the heating box and the cooling box can be accurately controlled, residual moisture in fabricscan be taken away during refrigeration of an exhaust fan, and the quality of the finished fabrics is ensured.

Owner:北京君杰一鸣企业服装发展有限公司

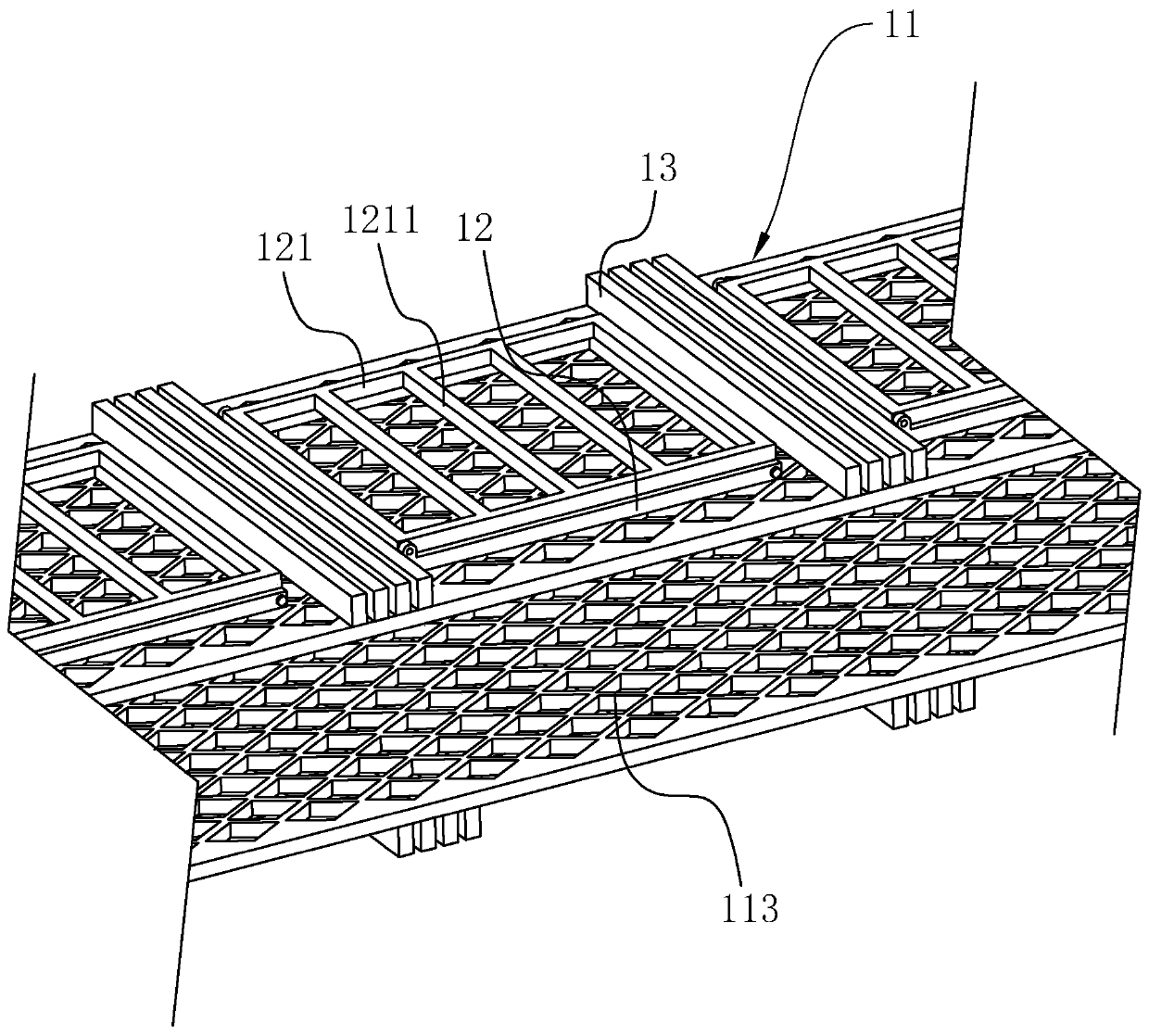

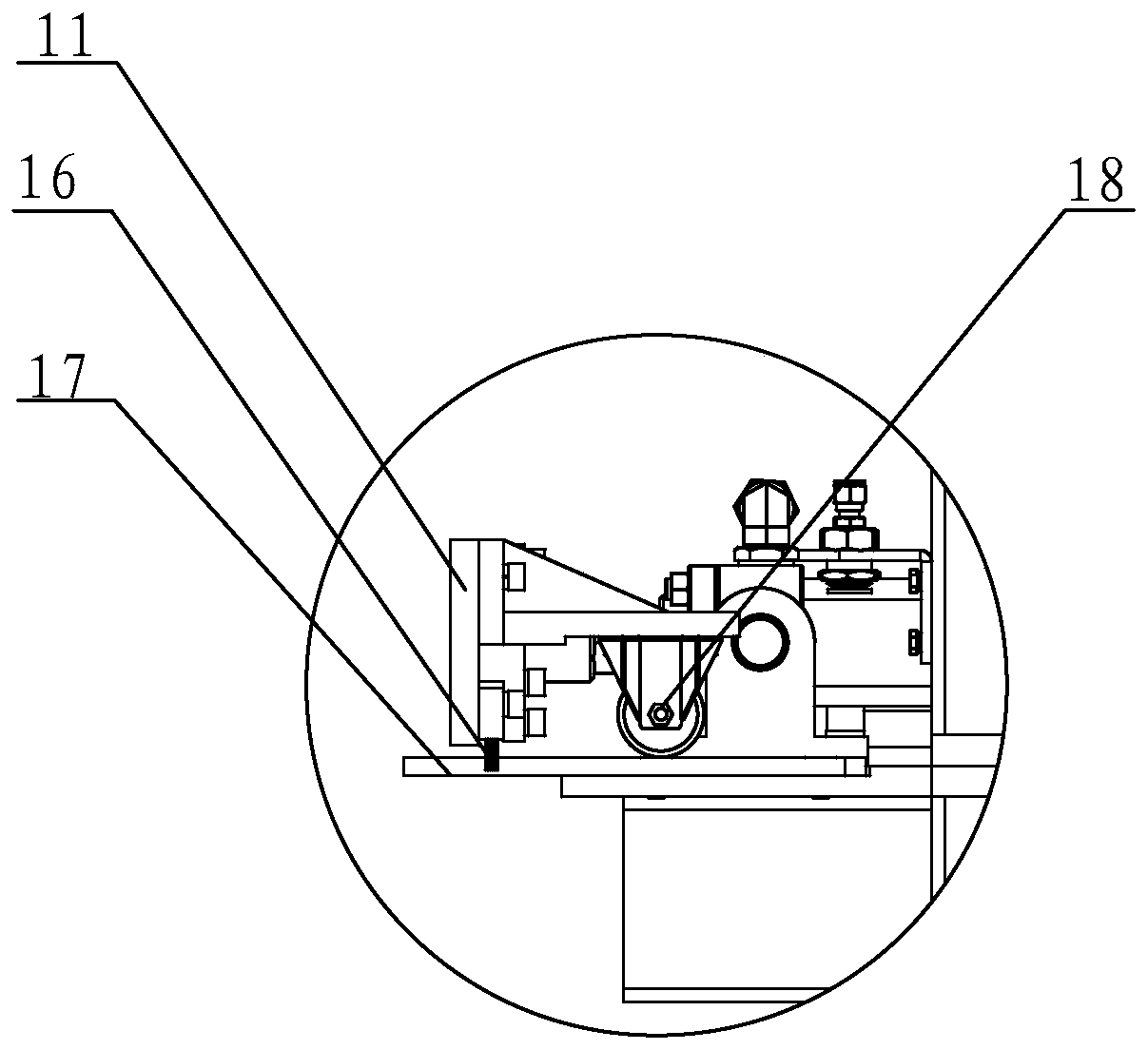

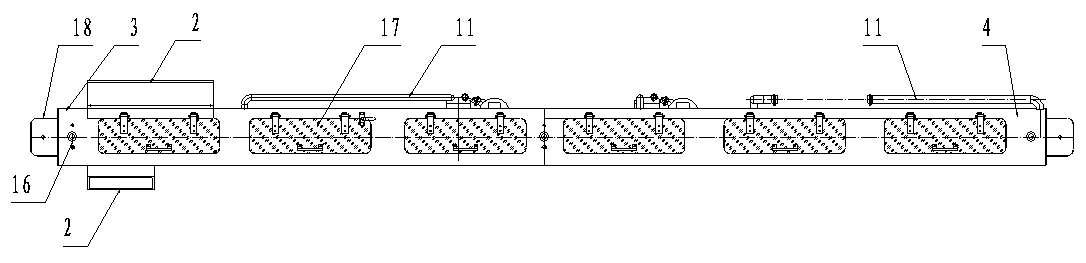

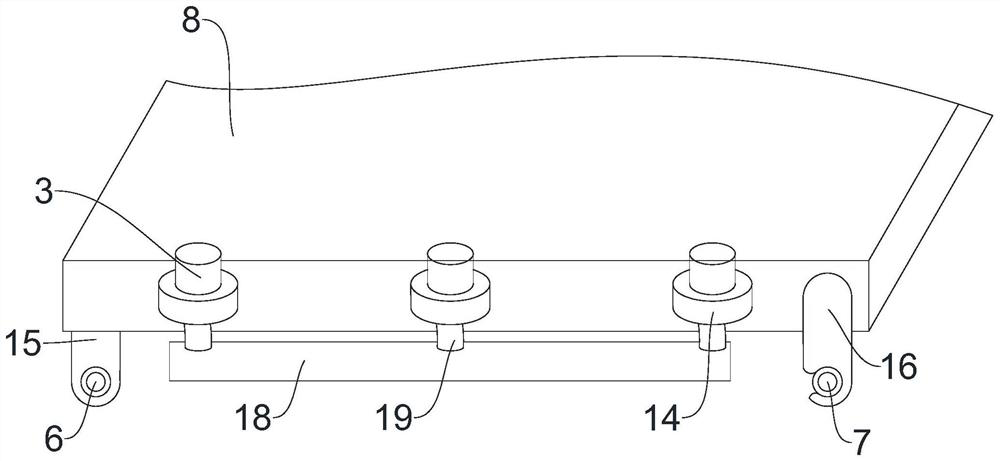

Sand mold molding machine conveying device

PendingCN110252965AReduce volumeSmall footprintMoulding machine componentsMolding machineEngineering

The invention discloses a sand mold molding machine conveying device. The sand mold molding machine conveying device comprises an upper rack, a lower rack fixedly connected with the upper rack, a mold conveying device arranged on the upper rack and a sand mold conveying device arranged on the lower rack. The side ends of the upper rack and the lower rack are both provided with bolt fastening plates connected with external shot blasting equipment. The mold conveying device comprises two horizontal guide rails fixed to the upper rack, a sliding plate slidably connected with the guide rails, a shaping plate trolley fixed to the sliding plate and a shaping plate oil cylinder suede for driving the sliding plate. The sand mold molding machine conveying device integrates the mold conveying function and the sand mold ejection function, is high in automation degree and greatly simplifies the processing flow.

Owner:盐城市东云自动化科技有限公司

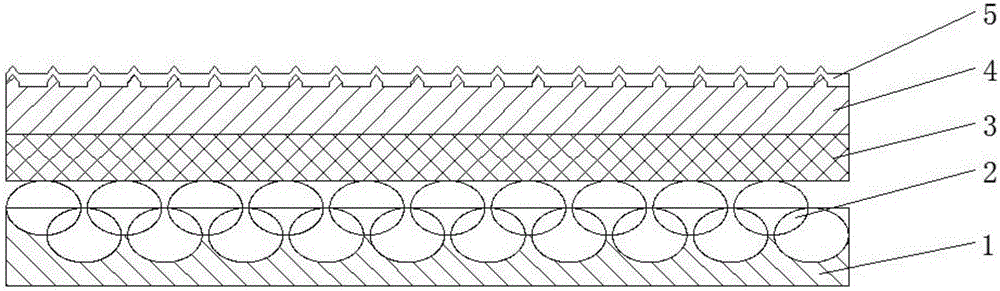

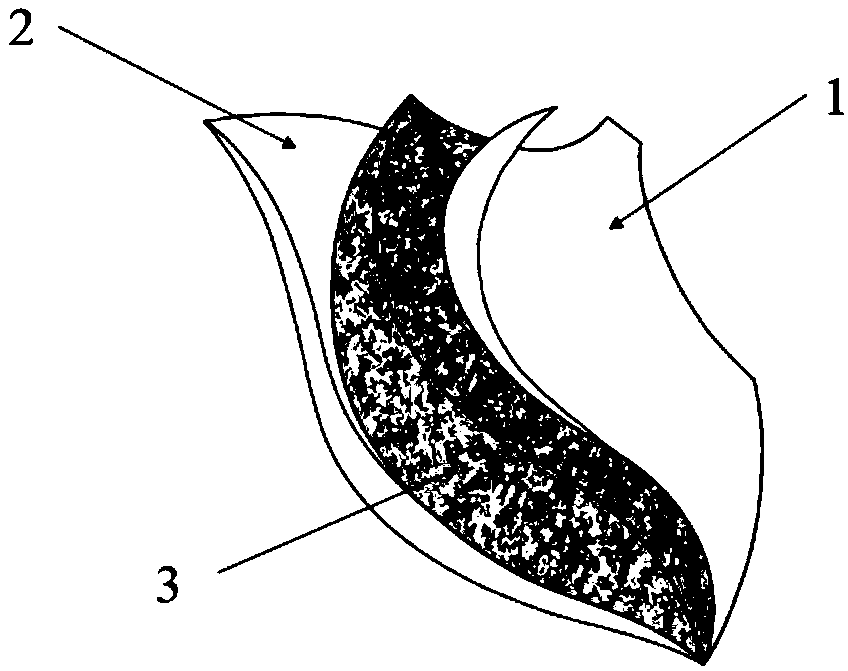

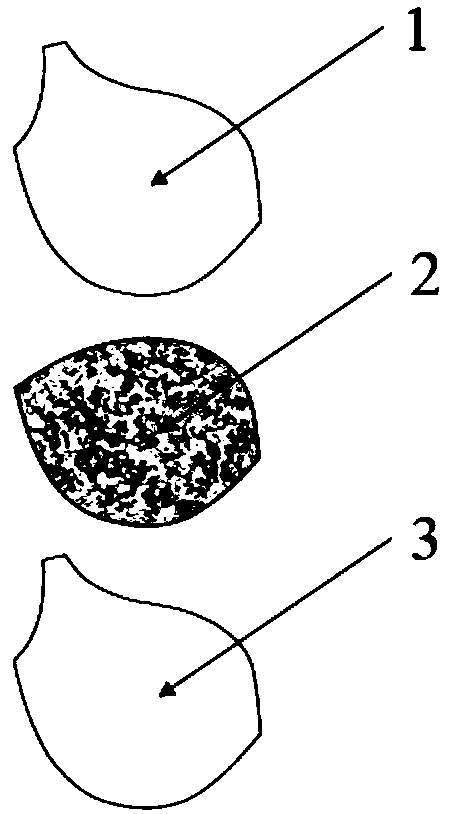

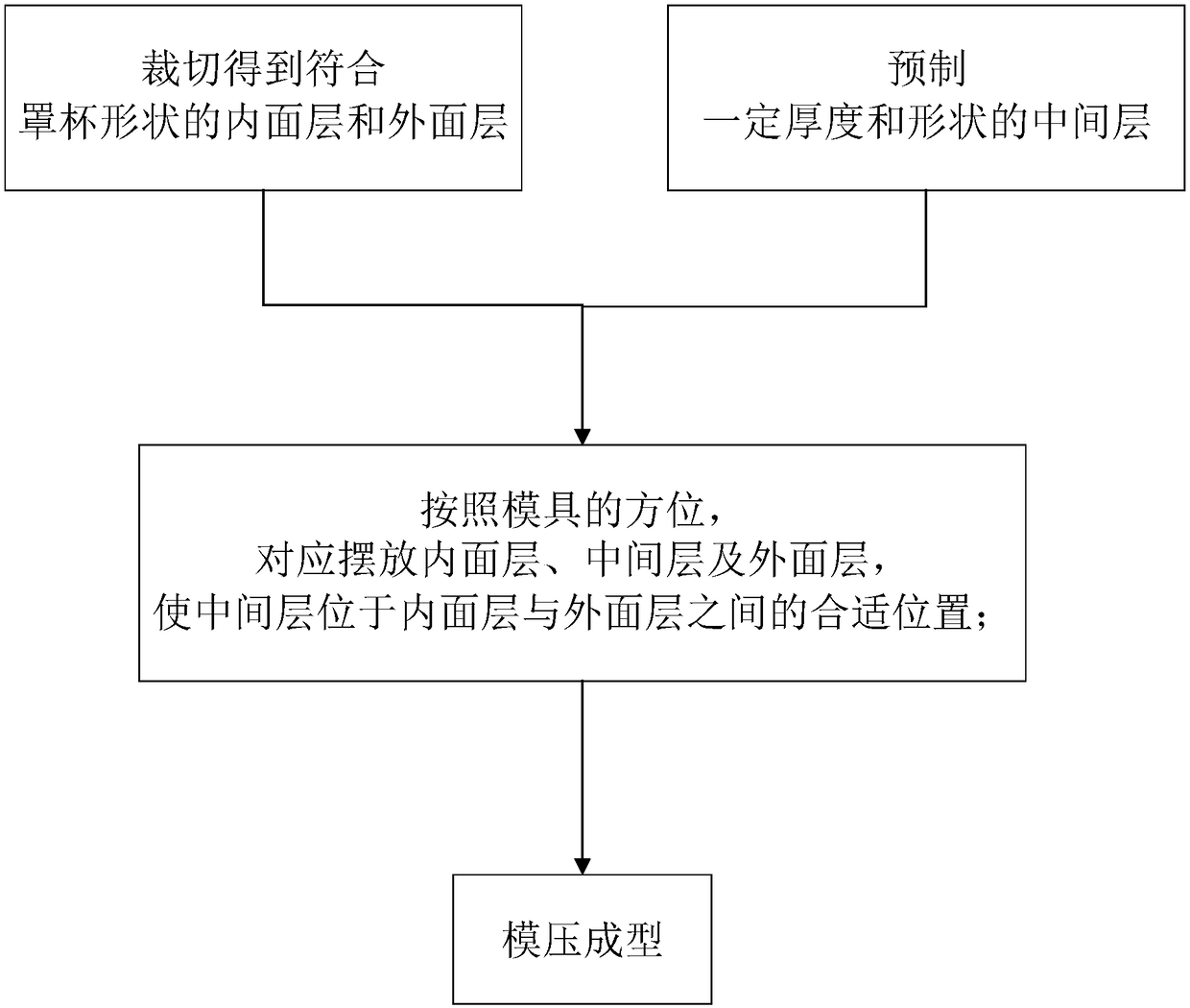

Highly-elastic ultra-light-soft bra cup preparation method

The invention discloses a highly-elastic ultra-light-soft bra cup preparation method, wherein the bra cup comprises a middle layer (2), one side of the middle layer (2) is provided with an inner surface layer (1), and the other side of the middle layer (2) is provided with an outer surface layer (3). The preparation method comprises: (a) cutting to obtain an inner surface layer (1) and an outer surface layer (3), and prefabricating a middle layer (2); (b) according to the orientation of a mold, correspondingly placing the inner surface layer (1), the middle layer (2) and the outer surface layer (3); and carrying out pressing molding. According to the present invention, the highly-elastic ultra-light-soft bra cup is prepared by combining the beneficial effects of the silk-cotton material and the existing molding pressing technology and optimizing and improving the processing method; the bra cup is prepared by using the middle filling prefabricating method, and the preparation of the cotton pad shape with the special device is not required, such that the preparation method is simple, and the cost is cost; and the inner-outer layer sponges and the prefabricated cotton pad middle layerdo not require any glue bonding, such that the odor of the adhesive after the high temperature molding pressing can be avoided so as to reduce the damage to the human body.

Owner:EMBRY CHINA GARMENTS

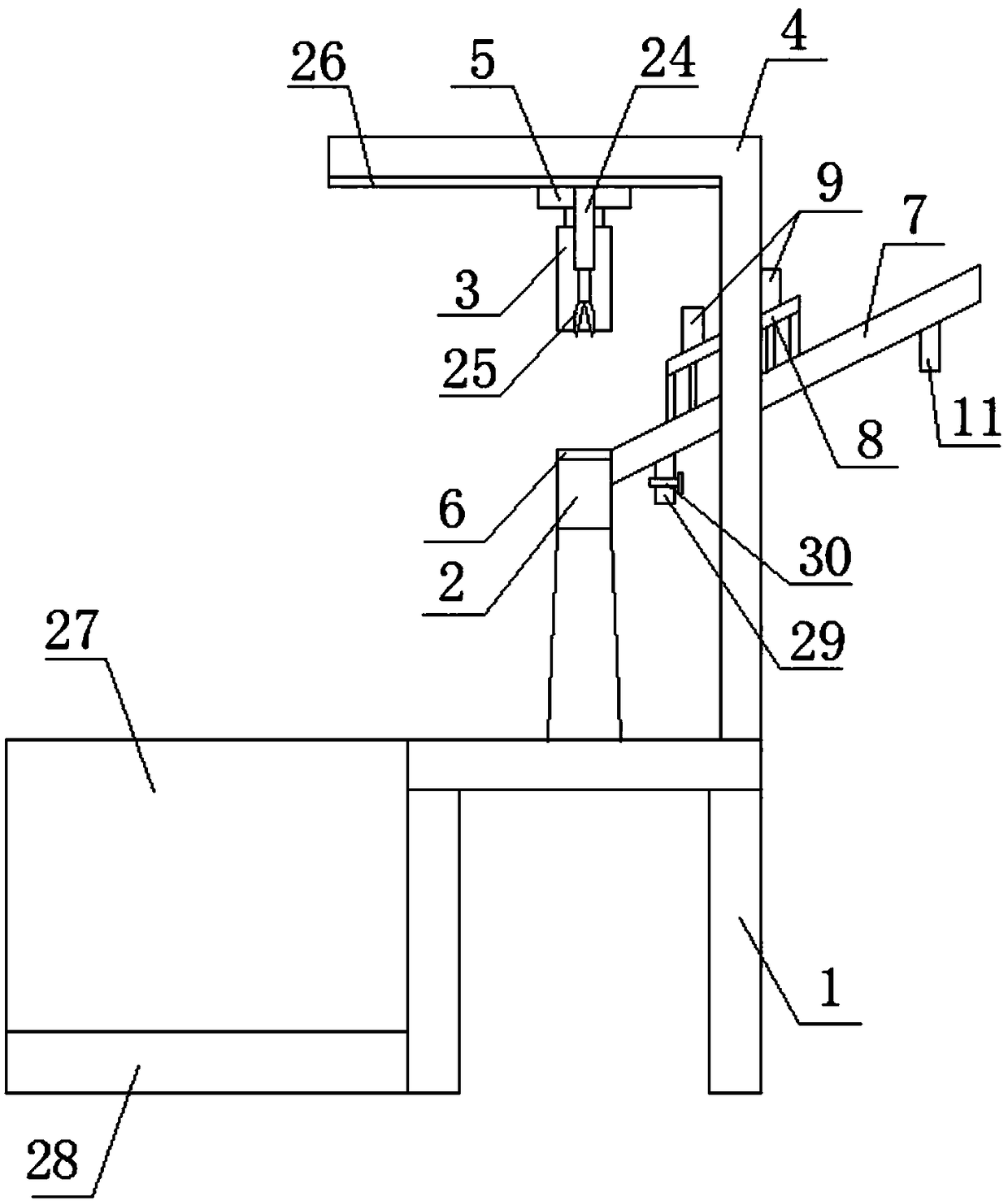

Heat setting processing equipment for fiber fabric for garment production and use method of heat setting processing equipment

InactiveCN113529323AAutomate stylingImprove work efficiencyHeating/cooling textile fabricsTextile treatment by spraying/projectingProcess engineeringTextile production

The invention discloses heat setting processing equipment for fiber fabric for garment production and a use method of the setting processing equipment, and particularly relates to the field of textile production. The heat setting processing equipment comprises a setting treatment box, material passing holes are formed in the two sides of the setting treatment box, and a setting pressing plate mechanism is fixedly installed on the bottom face of an inner cavity of the setting treatment box. A steam setting mechanism is fixedly mounted in the setting treatment box, a guide roller and a hot tentering transmission roller are rotatably mounted in the setting treatment box, a fan is fixedly mounted on the top surface of an inner cavity in the setting treatment box, and the air inlet end of the fan is fixedly connected with an air guide cover. According to the scheme, the heat setting treatment equipment adopts the steam injection structure, high-pressure airflow is generated by a compression tank and a high-pressure air pump, and the high-pressure airflow is mixed with high-heat steam to inject fabric, so that the steam can penetrate through the surface of the fabric to humidify and heat the two sides of the fabric; and the fabric is shaped by abutting against the setting pressing plate mechanism, so that the setting effect is improved.

Owner:嘉兴鼎澳纺织科技有限公司

Efficient casting equipment easily achieving demoulding

InactiveCN106735131AHighly integratedLow costMoulding machinesMould handling equipmentsFixed frameSurface-active agents

The invention relates to the technical field of casting and discloses efficient casting equipment easily achieving demoulding. The casting equipment comprises an upper sand box, a lower sand box, an upper sand box fixing frame and a lower sand box supporting platform. The upper sand box fixing frame comprises four symmetrically-arranged vertical pillars. Hydraulic lifting sliding blocks are installed in the middles of the vertical pillars, a transverse arm is connected to each hydraulic lifting sliding block, one end of each transverse arm is hinged to the corresponding hydraulic lifting sliding block through a hinge, and the other end of each transverse arm is hinged to the upper sand box through a hinge. A hydraulic compactor is installed at the tops of the vertical pillars, the four corners of the bottom of the lower sand box supporting platform are all provided with lifting supporting rods for supporting the lower sand box supporting platform, and the lifting supporting rods are hinged to the lower sand box supporting platform through hinges. The lower sand box is stored on the lower sand box supporting platform, the hydraulic compactor, the upper sand box and the lower sand box are vertically arranged on the same axis from top to bottom, and the inner surfaces of the upper sand box and the lower sand box are both coated with surface active agents. The efficient casting equipment easily achieving demoulding is high in integration level, convenient to use, low in manufacturing cost, good in molding quality and high in efficiency and casting efficiency, and demouding of the sand boxes is easy.

Owner:成都嘉新特种精密铸造有限公司

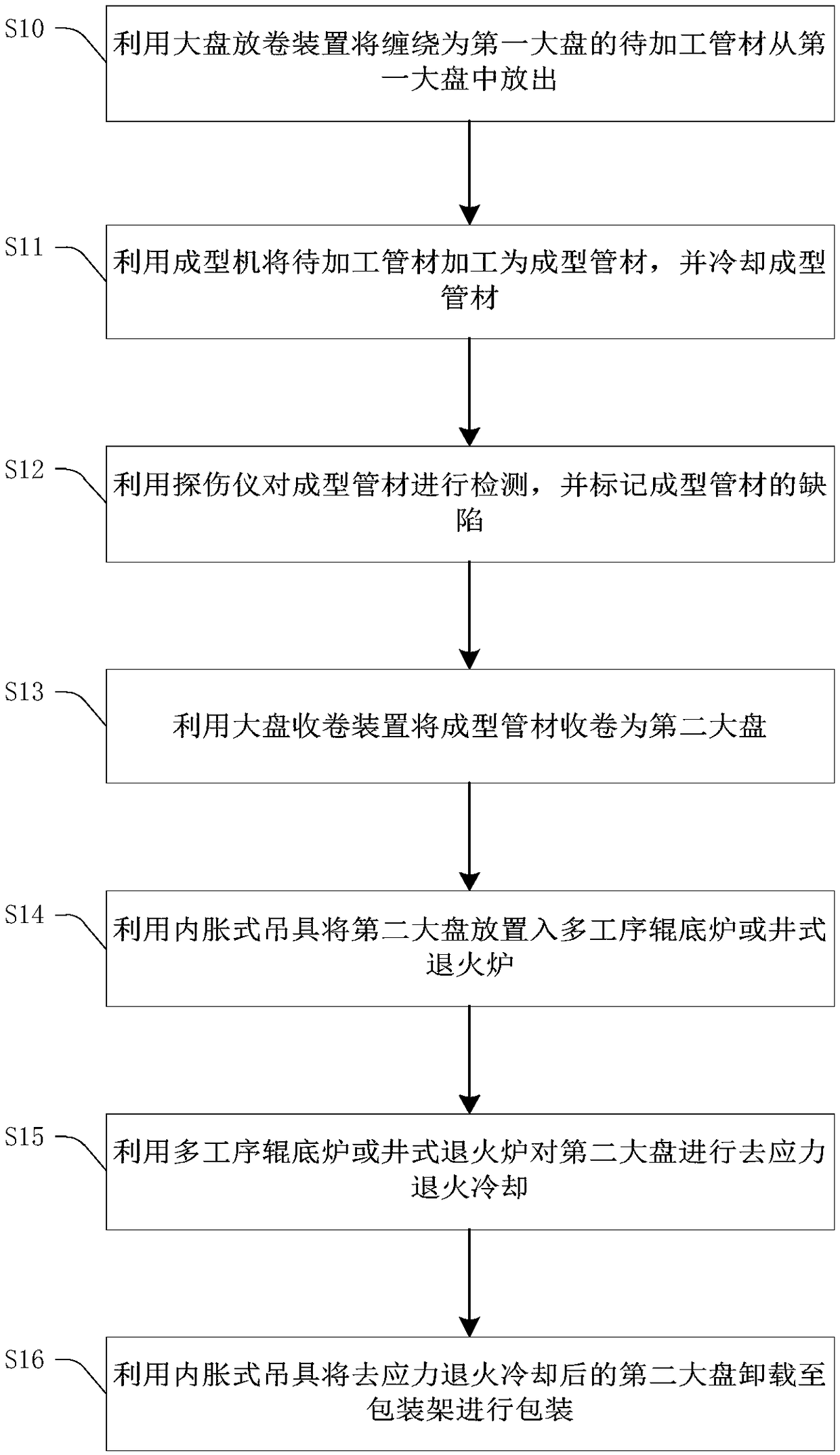

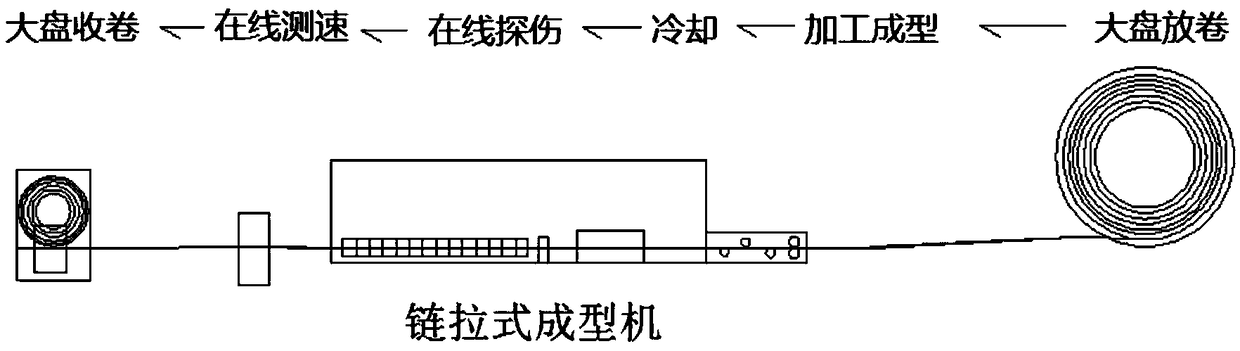

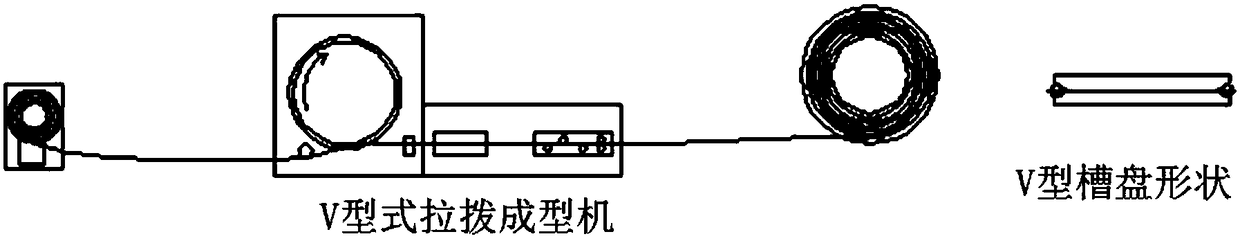

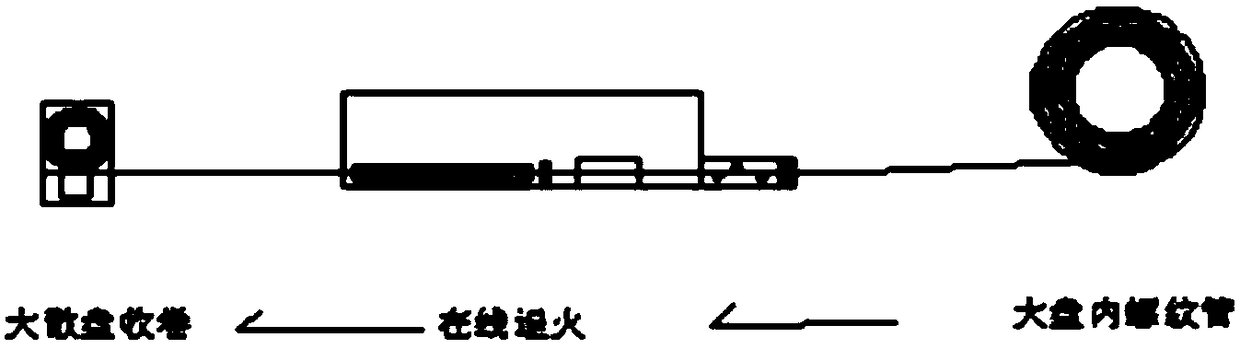

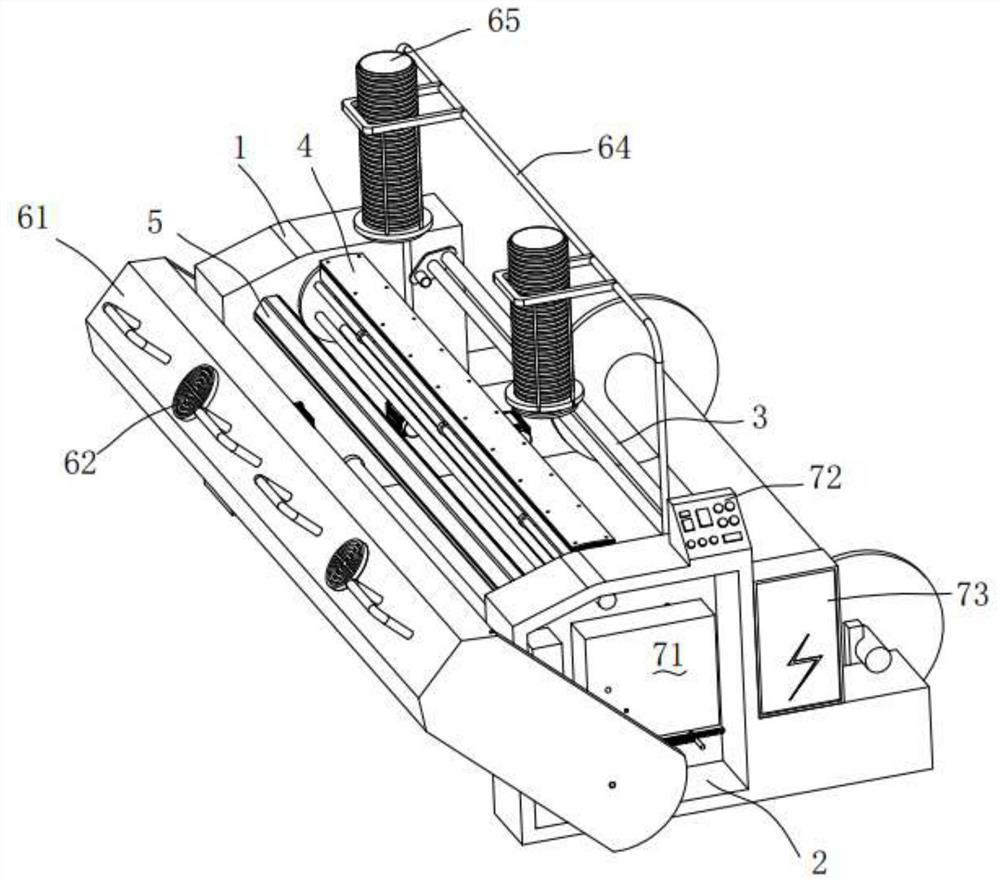

Mosquito-repellent incense type large scattered plate production method and system

The invention relates to the technical field of machining, and provides a mosquito-repellent incense type large scattered plate production method and system. The method comprises the following steps:discharging to-be-machined tubes from a first large plate by a large plate unreeling device; machining the to-be-machined tubes into formed tubes by using a forming machine and cooling the formed tubes; detecting the formed tubes by using a flaw detector and marking flaws; reeling the formed tubes into a second large plate by using a large reeling device, controlling the reeling speed of the largereeling device and the unreeling speed of the large unreeling device to be synchronous by using an encoder in a reeling process; placing the second large plate in a multi-procedure roller hearth furnace or a well annealing furnace by using an internal expansion type hoist; carrying out stress relief annealing and cooling on the second large plate by using the multi-procedure roller hearth furnaceor the well annealing furnace; and unloading the second large plate to a packing pack after stress relief annealing and cooling by using the internal expansion type hoist and packing the second largeplate. The method is simple in production process and high in degree of automation, and the machined mosquito-repellent incense type large scattered plate is uniform in hardness, high in reeling density and convenient to stack and transport.

Owner:冯境铭

Bismaleimide resin LCM (Liquid Composite Molding) composite material preform setting agent and preparation method thereof

InactiveCN107163575ASimple preparation processThe reaction conditions are mild and controllableEnergy consumptionPolyresin

The invention relates to a bismaleimide resin LCM (Liquid Composite Molding) composite material preform setting agent and a preparation method thereof. The setting agent is prepared from a bismaleimide resin, an epoxy resin, an allyl process modifier, a thickening agent and a toughening modifier. The setting agent disclosed by the invention is simple in preparation process, the reaction conditions are mild and controllable, and the production cost of the setting agent powder is reduced. The setting agent is low in setting temperature and low in time, the equipment energy consumption is reduced, the processing cycle of the preform is shortened, and the manufacturing cost of a large preform part of a complicated structure is effectively reduced. Meanwhile, a high-temperature-resistant flexibilizer and an inorganic particle thickening agent contained in the system can achieve the effects of improving Tg, preventing the setting agent from being hardened in the storage process and improving the scouring resistance of the setting agent, the setting agent is guaranteed, the effective usage amount is reduced to be 3-5% of the density of a fabric surface, the permeability of the preform is improved, flow resistance of the resin during infiltration is reduced, and the problem that the glass transition temperature of the system is reduced due to excessive setting agent is solved.

Owner:HENGSHEN

Novel efficient casting device capable of achieving easy demoulding

InactiveCN106735130AHighly integratedLow costMoulding machinesMould handling equipmentsFixed frameConfined space

The invention discloses a novel efficient casting device capable of achieving easy demoulding. The novel efficient casting device capable of achieving easy demoulding comprises an upper sand box, a lower sand box, an upper sand box fixing frame and a lower sand box supporting platform. The upper sand box fixing frame comprises four symmetrically arranged stand columns. Hydraulic lifting sliding blocks are installed in the middles of the stand columns and connected with cross arms. One ends of the cross arms are hinged to the hydraulic lifting sliding blocks through hinges, and the other ends of the cross arms are hinged to the upper sand box through hinges. A hydraulic compactor is installed at the tops of the stand columns. The four corners of the bottom of the lower sand box supporting platform are hinged to lifting supporting rods through hinges. Baffles are installed between the stand columns, and one of the baffles is provided with an operation door. A top plate is installed at the tops of the stand columns, and a confined space is formed by the baffles and the top plate. A water mist spraying pipe is installed on the lower surface of the top plate. The inner surfaces of the upper sand box and the lower sand box are both coated with surface active agents. The novel efficient casting device capable of achieving easy demoulding is high in integration degree, convenient to use, low in manufacturing cost, good in moulding quality, high in efficiency, high in casting efficiency and free of environment pollution, and demoulding of the sand boxes is easy.

Owner:成都嘉新特种精密铸造有限公司

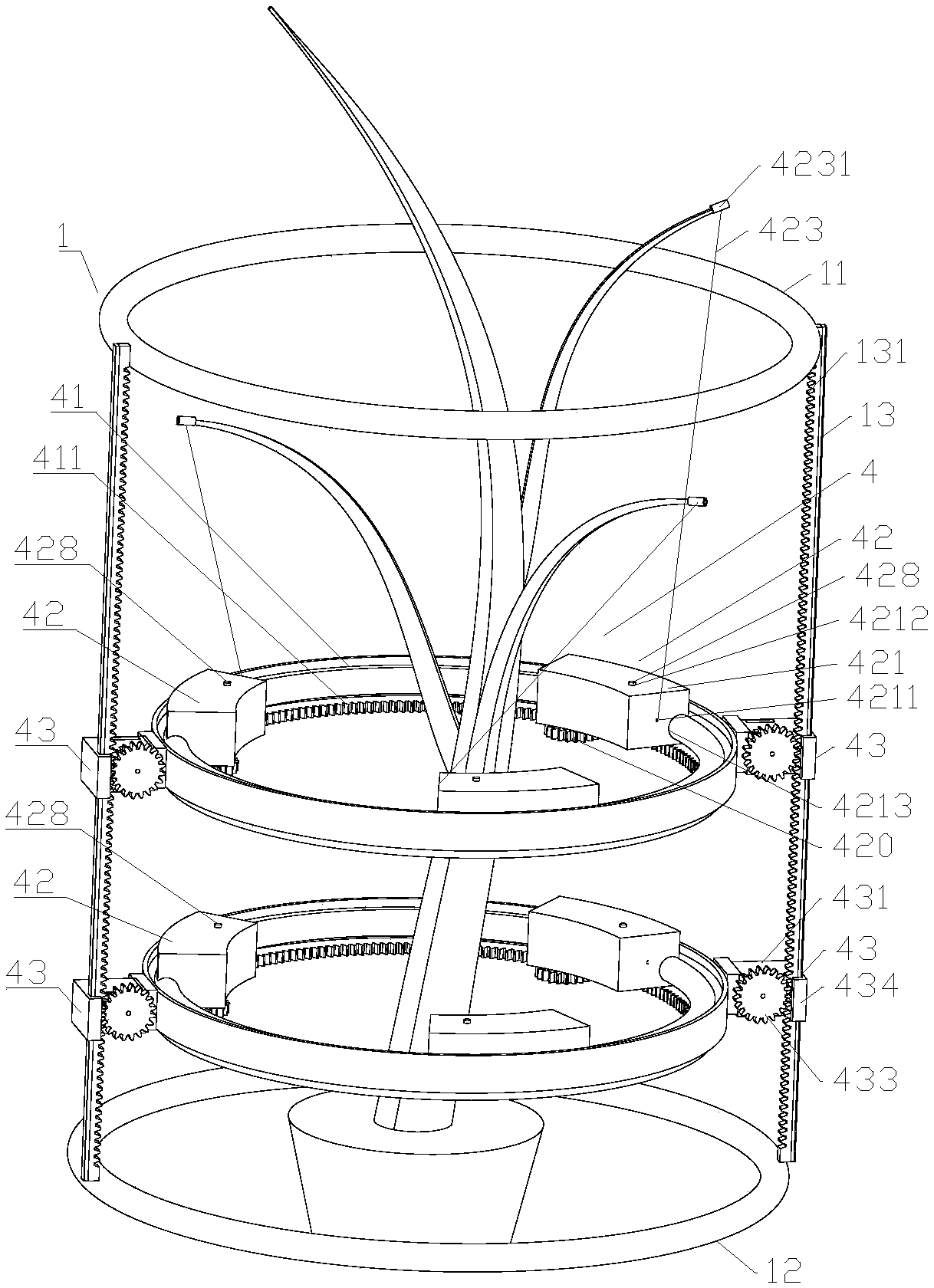

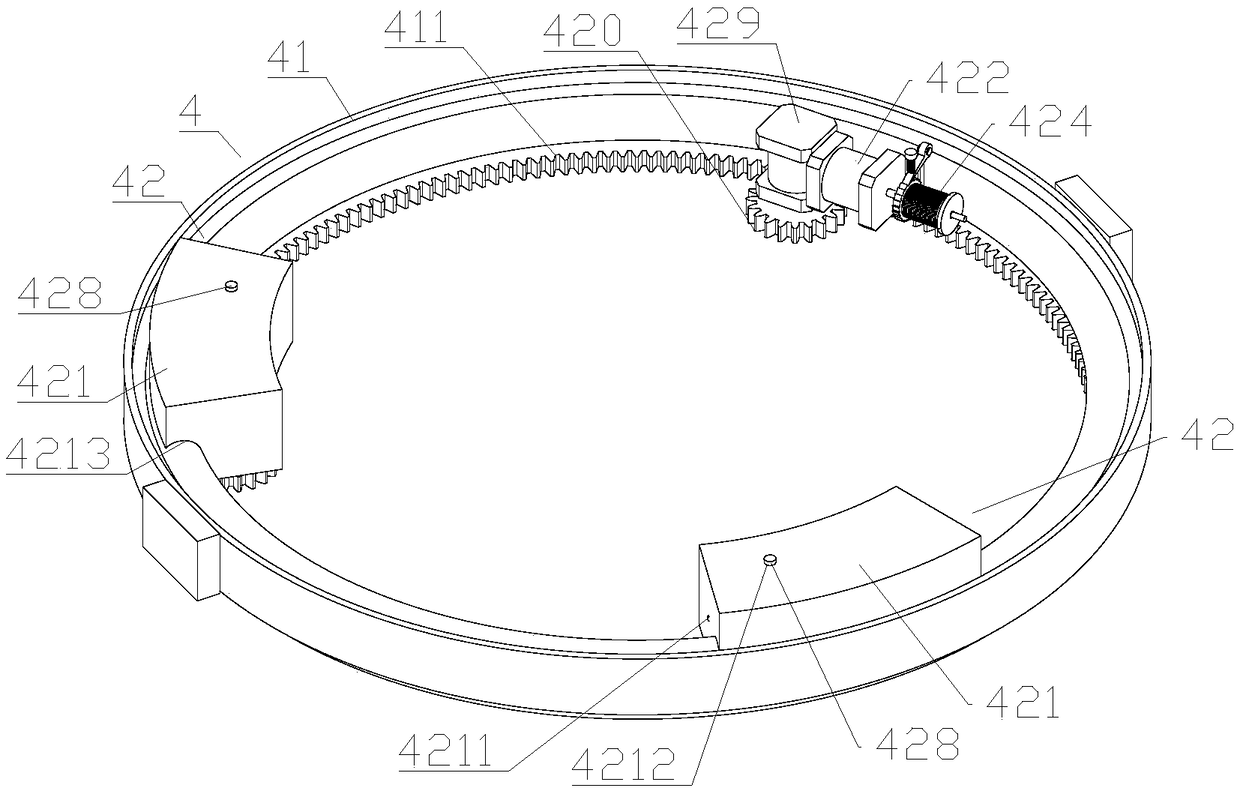

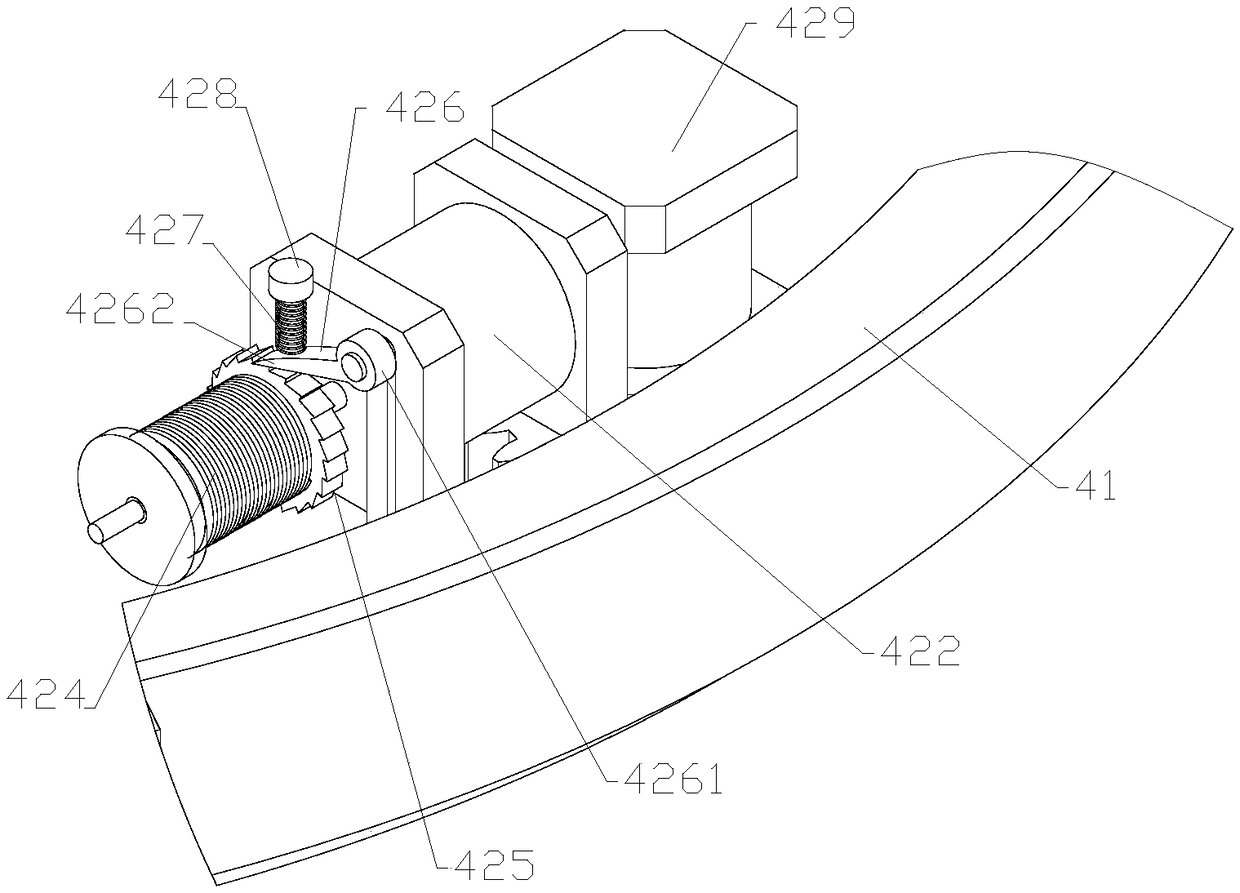

Bonsai modelling device

InactiveCN109089819ARealize intelligent traction and shapingGood shaping effectFlowers cultivationHorticulture methodsElectricityEngineering

The invention relates to a bonsai modeling device. The device comprises a support frame, a 3D camera, a sever and multiple traction mechanism, and the 3D camera is fixed to the support frame; each traction mechanism comprises a circular rail and multiple traction pieces arranged on the circular rail, and the circular rail is arranged in the support frame; each traction piece comprises a first fixing base, a first motor, a traction wire and a winding reel, wherein the first fixing base is sleeved with the inner side of the circular rail; each fixing base is hollow inside, the first motors and the winding reels are arranged in the first fixing bases, and the winding reels sleeve output shafts of the first motors respectively; one end of each traction wire is fixed to the corresponding winding reel, and the other end of each traction wire winds around the corresponding winding reel and then penetrates through a first through hole formed in the corresponding first fixing base and is connected with branches of bonsai, so that the branches of the bonsai are subjected to traction and shaping; the 3D camera and the first motors are electrically connected with the server. Accordingly, the traction mechanism is electrically connected with the server, and the intelligent traction and shaping of the branches of the bonsai can be achieved.

Owner:WUHAN BAIQI TECH CO LTD

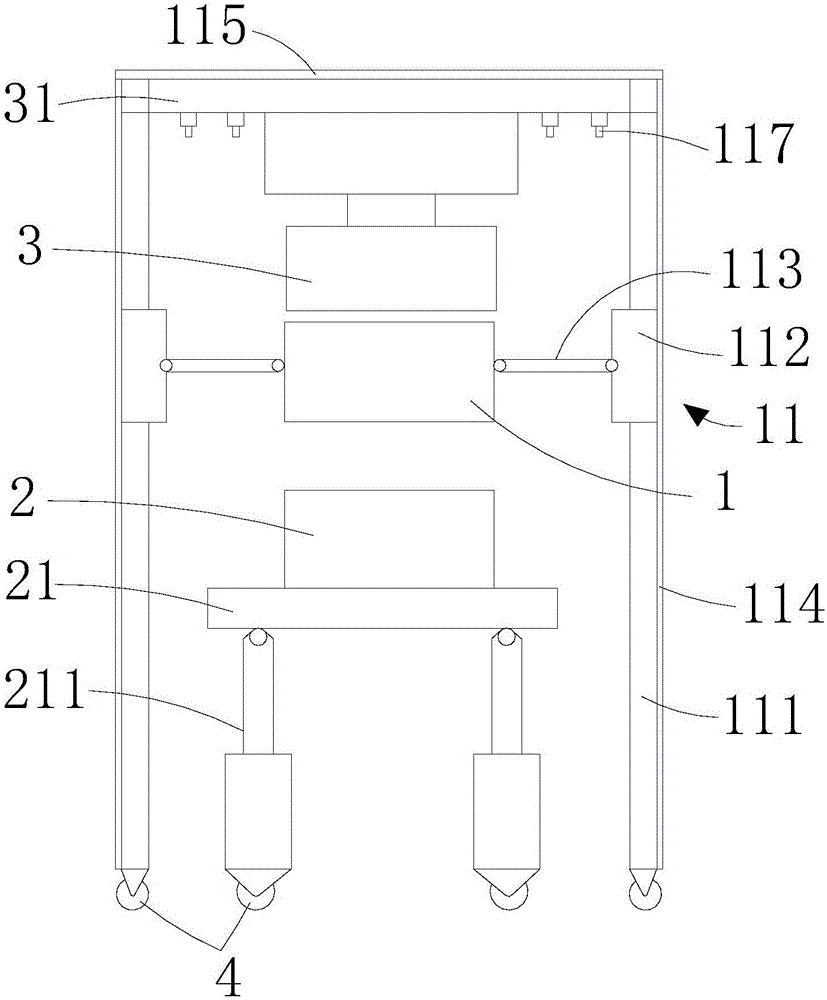

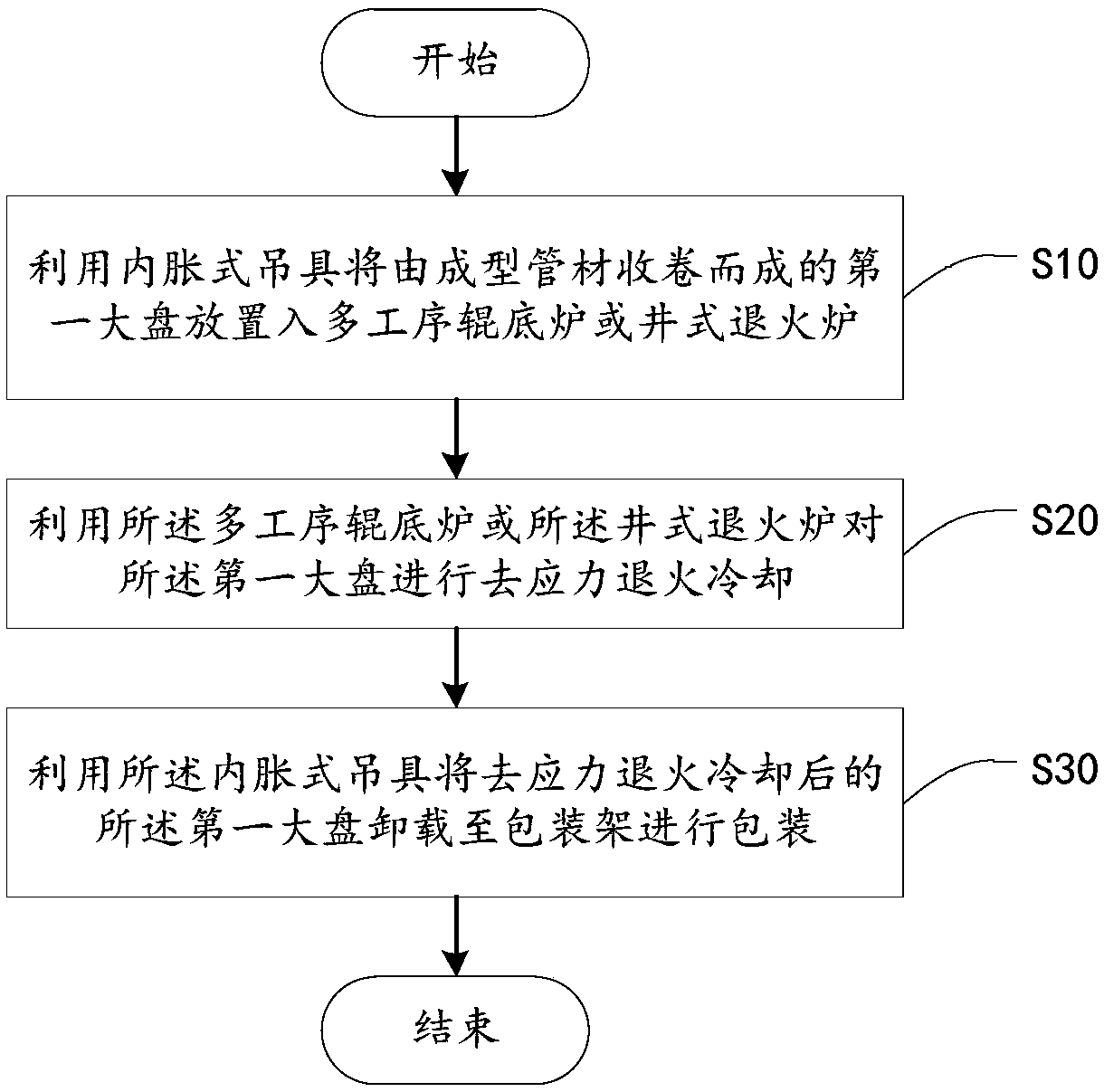

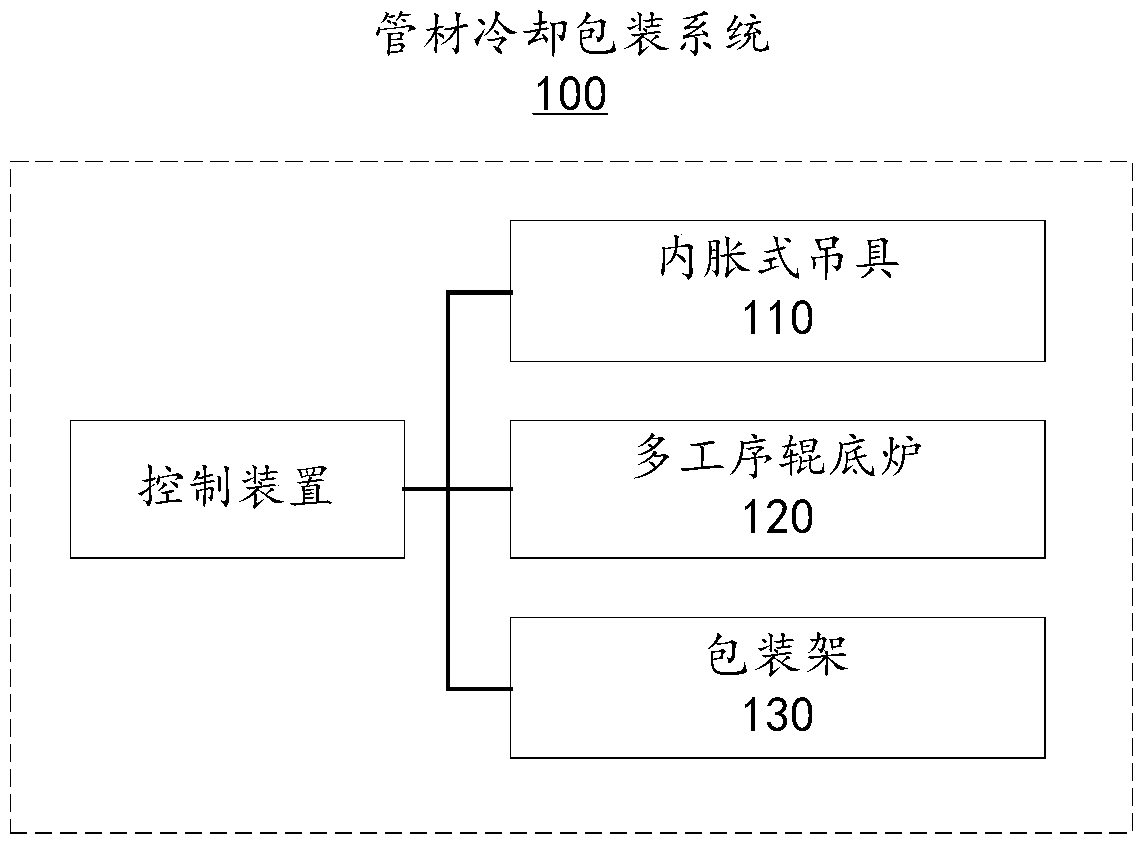

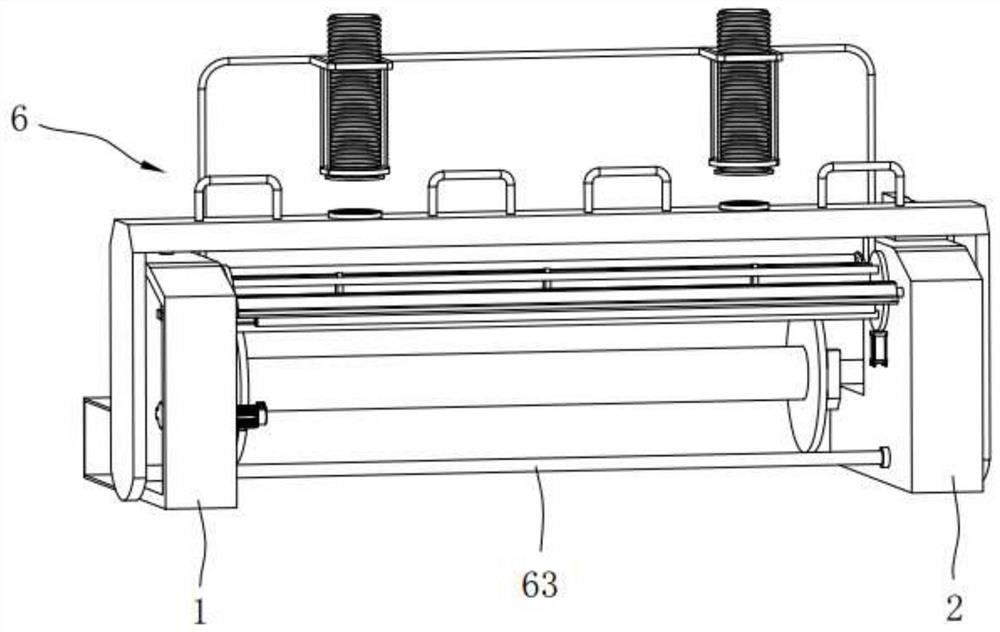

Annealing, cooling and packaging method and system for mosquito-repellent incense type large scattering disc

InactiveCN108950165AImprove packaging qualityImprove packaging efficiencyFurnace typesPackagingEngineeringHardness

The invention provides an annealing, cooling and packaging method and system for a mosquito-repellent incense type large scattering disc, and relates to the technical field of machine machining. The annealing, cooling and packaging method of the mosquito-repellent incense type large scattering disc comprises the steps that an internal expanding type lifting tool is used for placing a first large disc formed through winding of formed pipes into a multi-procedure roller bottom furnace or well type annealing furnace; the multi-procedure roller bottom furnace or well type annealing furnace is usedfor carrying out destressing annealing and cooling on the first large disc; the internal expanding type lifting tool is used for unloading the first large disc obtained after destressing annealing and cooling to a packaging frame to be packaged. The annealing, cooling and packaging method and system for the mosquito-repellent incense type large scattering disc is matched with the internal expanding type lifting tool, the multi-procedure roller bottom furnace or well type annealing furnace and the packaging frame provided by the mosquito-repellent incense type large scattering disc annealing,cooling and packaging system for destressing annealing and cooling on the pipe large disc to obtain the pipe scattering disc with the uniform hardness and the large coiling density, the pipe scattering disc can be subject to stacked transport, the transportation cost is reduced, and meanwhile, the inner cleaning degree of the large scattering disc copper pipe is improved.

Owner:冯境铭

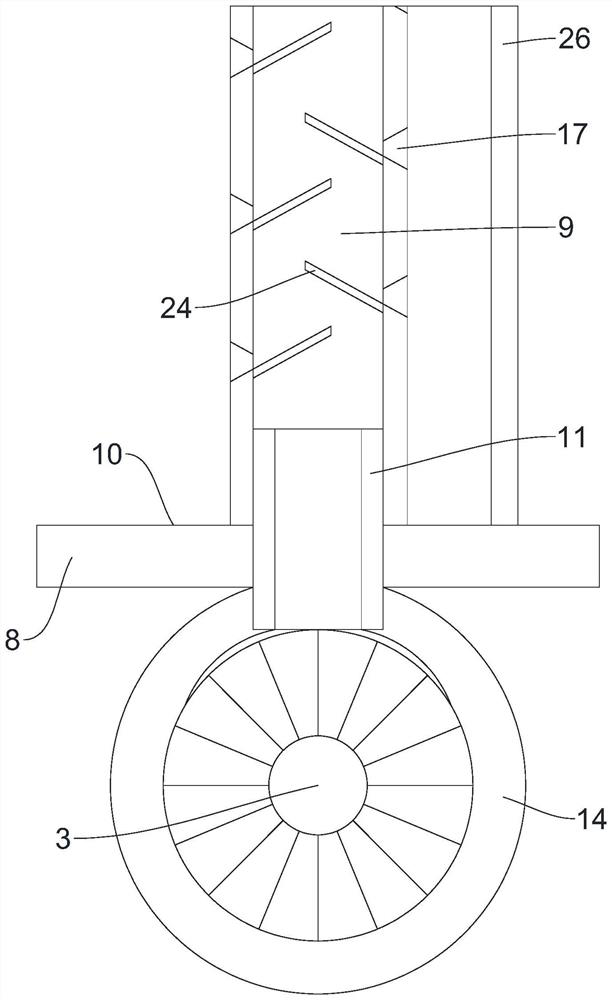

Spandex setting machine

ActiveCN112831885AGuaranteed tensionIncrease productivityLiquid/gas/vapor removalTextile treatment carriersSupport planeAutonomation

The invention discloses a spandex setting machine. The spandex setting machine comprises a left supporting frame and a right supporting frame which are symmetrically arranged, mounting grooves are formed in the left supporting frame and the right supporting frame, a tension warp beam assembly, a tension frame, an ironing plate assembly and a winding assembly are sequentially mounted between the left supporting frame and the right supporting frame from left to right, protection assemblies are further mounted on the left supporting frame and the right supporting frame, and the protection assemblies are located above the ironing plate assembly. Spandex penetrates through the space between a rotating rod and a tension roller and then passes through the upper surface of an ironing device to be ironed and shaped, and the tension of the spandex in the ironing process is further kept through a winding assembly; and meanwhile, the spandex is wound and recycled, automatic shaping and recycling of spandex are achieved, the production efficiency is greatly improved, the production cost is reduced, and the automation degree of equipment is high.

Owner:吴江市晟鼎机械制造有限公司

Ship T-shaped profile welding deformation correcting method

InactiveCN112008273AGuaranteed deformabilitySimplify the corrective stepsWelding/cutting auxillary devicesAuxillary welding devicesCold airEngineering

The invention belongs to the field of shipbuilding, and particularly discloses a ship T-shaped profile welding deformation correcting method. The ship T-shaped profile welding deformation correcting method comprises the steps that a T-shaped profile panel is flatly placed on a correcting machining table, a laser heater is used for heating the welding position, a pushing mechanism pushes a push plate, the push plate and a standard vertical plate are kept in the state for clamping a T-shaped profile web, and cold air is used for cooling. According to the method, the T-shaped profile panel is kept in a straight state, the T-shaped profile web is corrected, and the correction steps are simplified; through assistance of the standard vertical plate and the push plate, the assembly welding position of the T-shaped profile panel and the T-shaped profile web is heated through the laser heater, the deformation effect of the end portion of the T-shaped profile web is guaranteed, and correction isfacilitated; the T-shaped profile web is restored to the vertical state by pushing of the push plate and is matched with the standard vertical plate to be clamped, so that the surface of the T-shapedprofile web is straightened and shaped conveniently; the cold air is used for cooling the assembly welding position at the bottom of the T-shaped profile web, the shaping effect after correction is guaranteed, and the correction efficiency is high.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

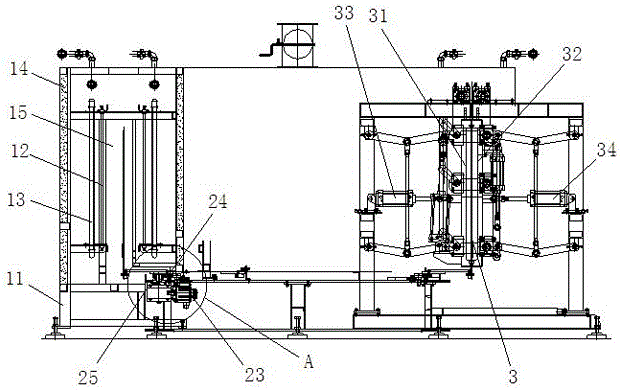

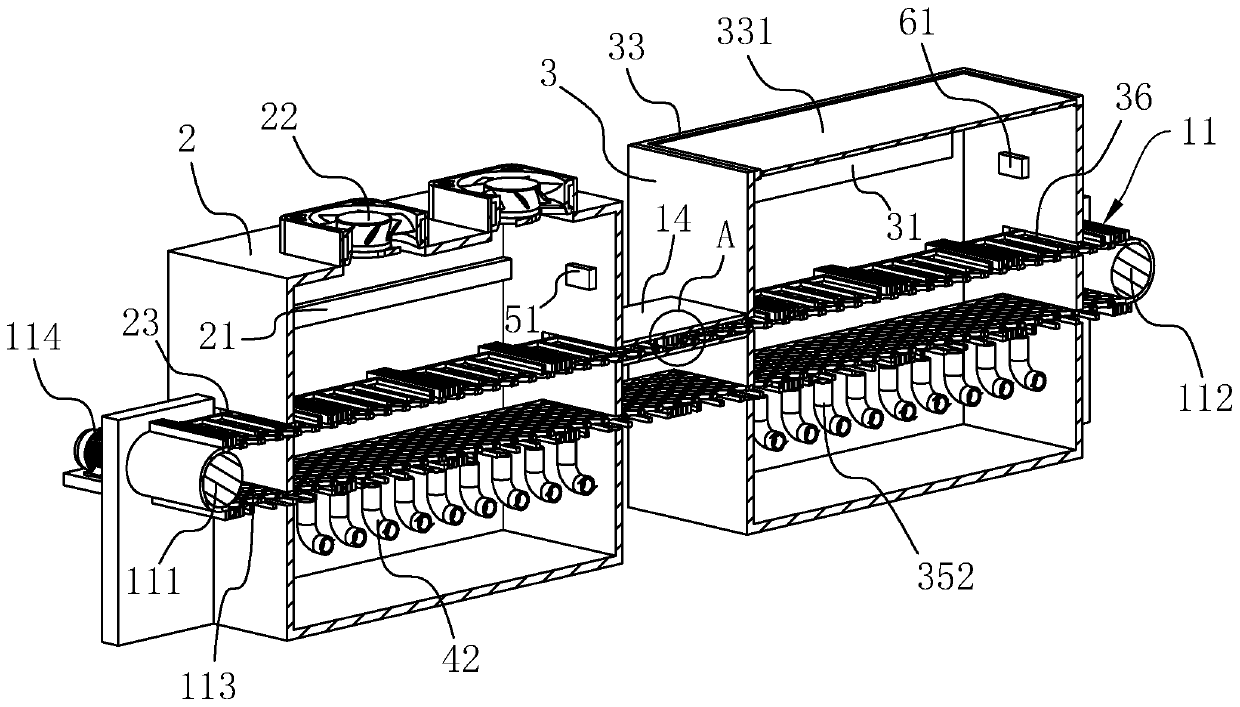

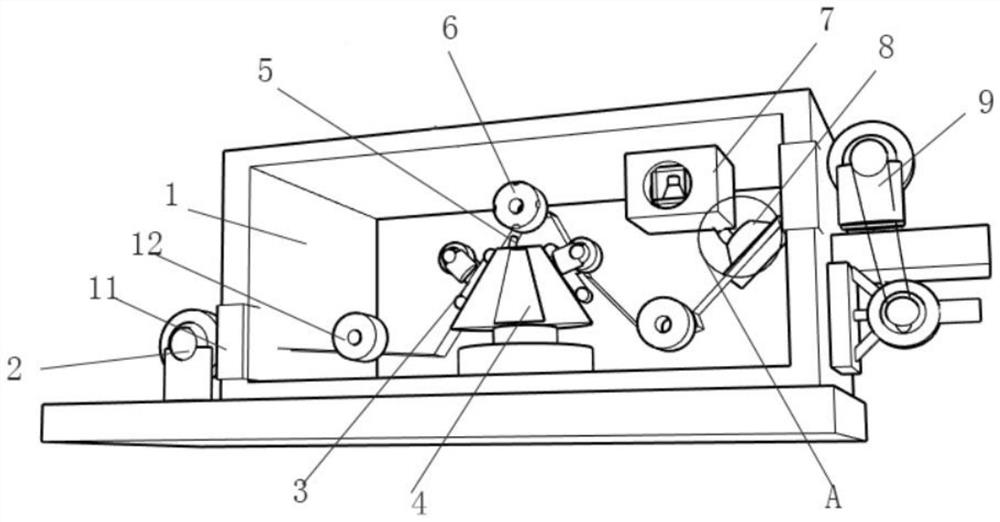

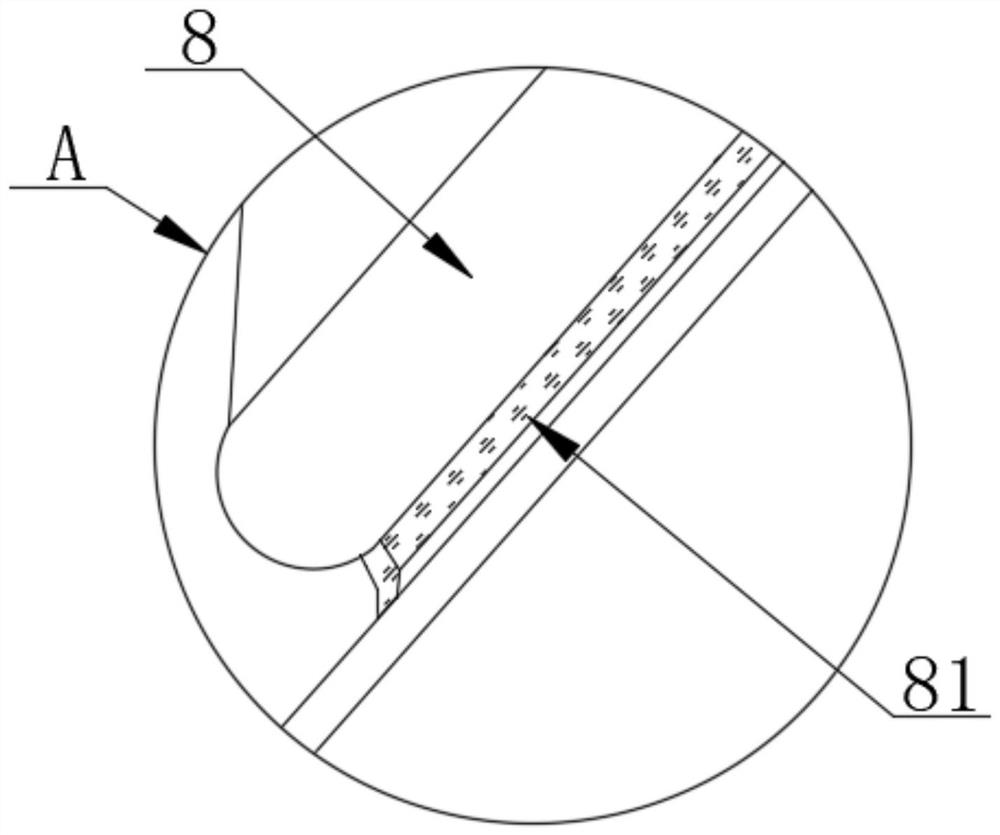

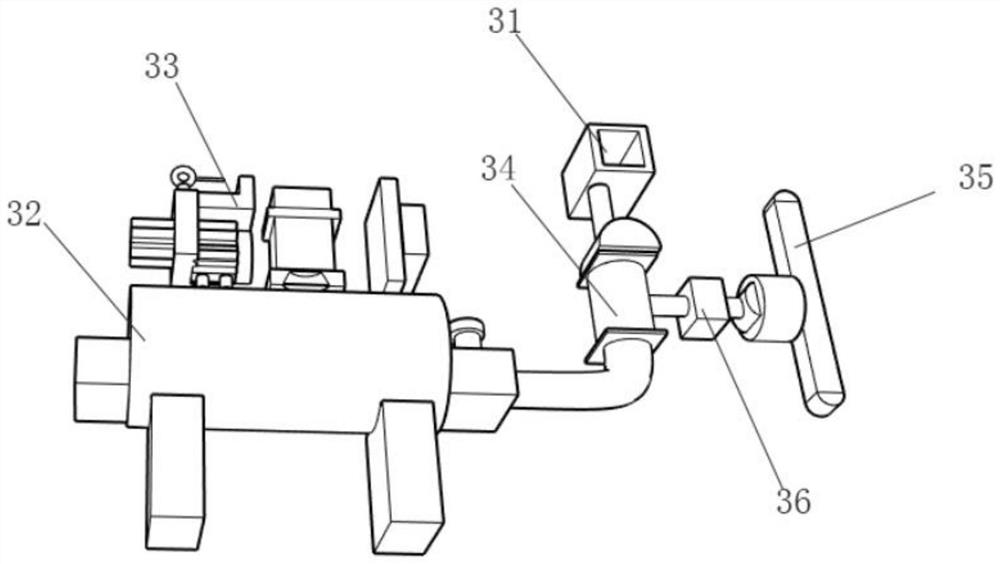

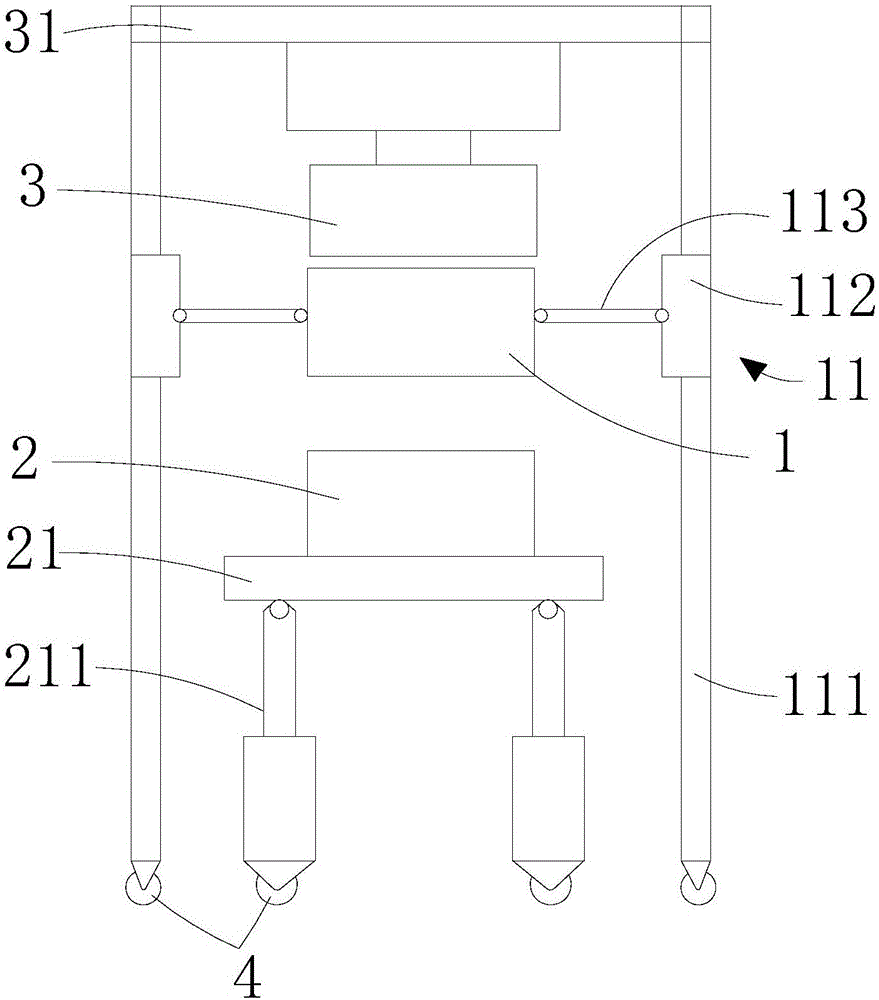

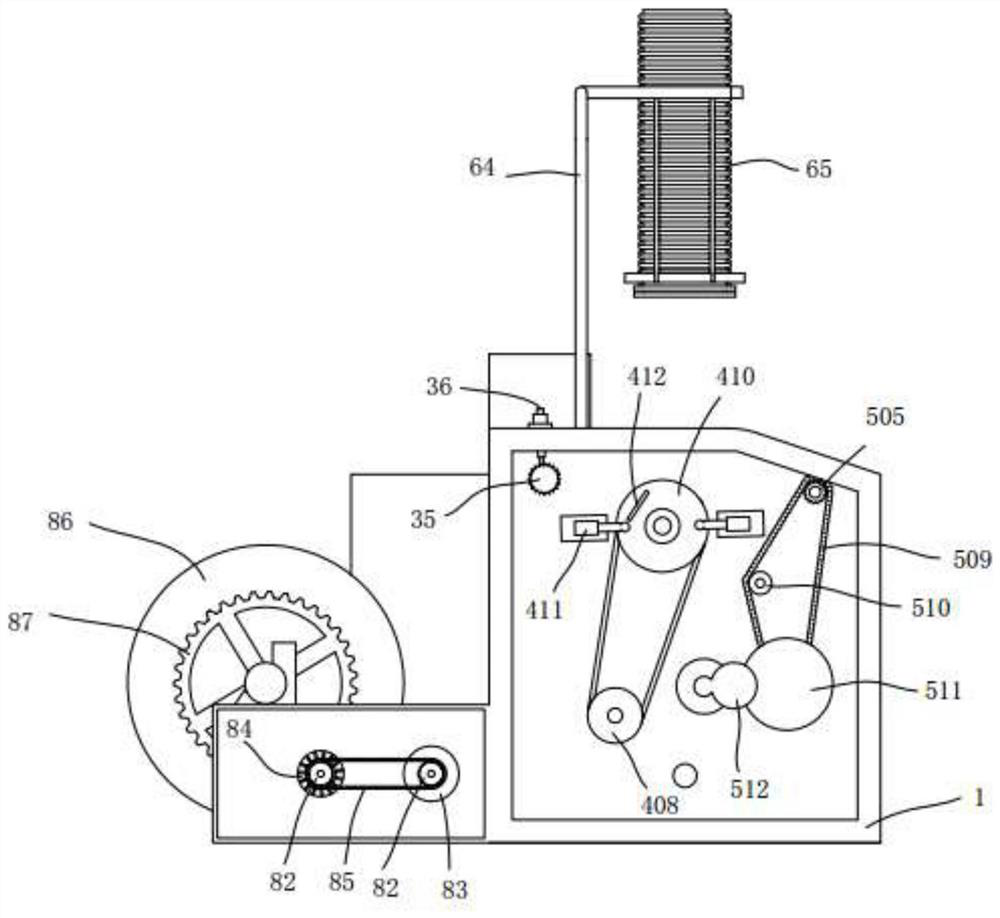

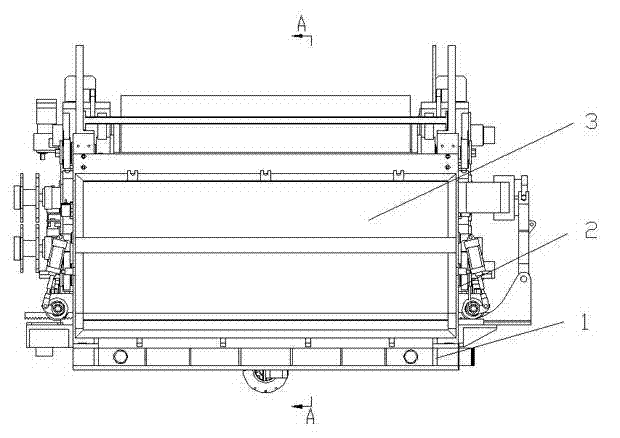

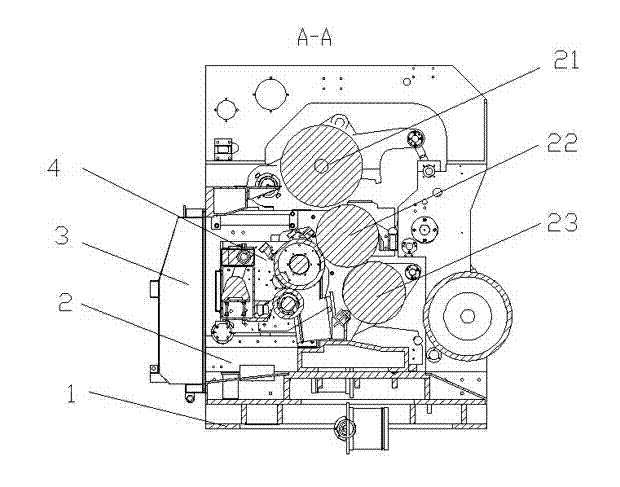

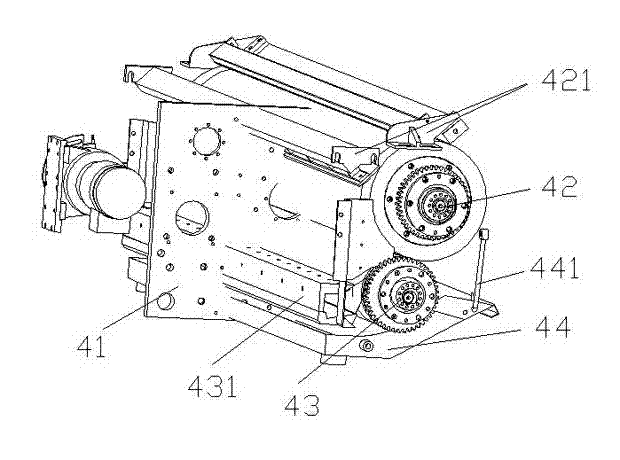

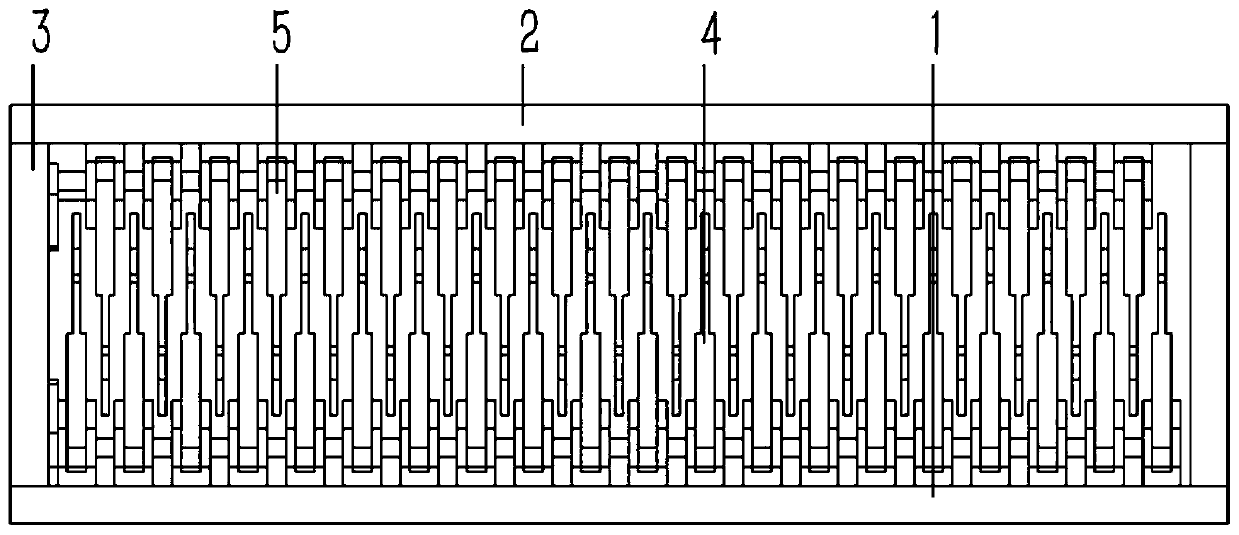

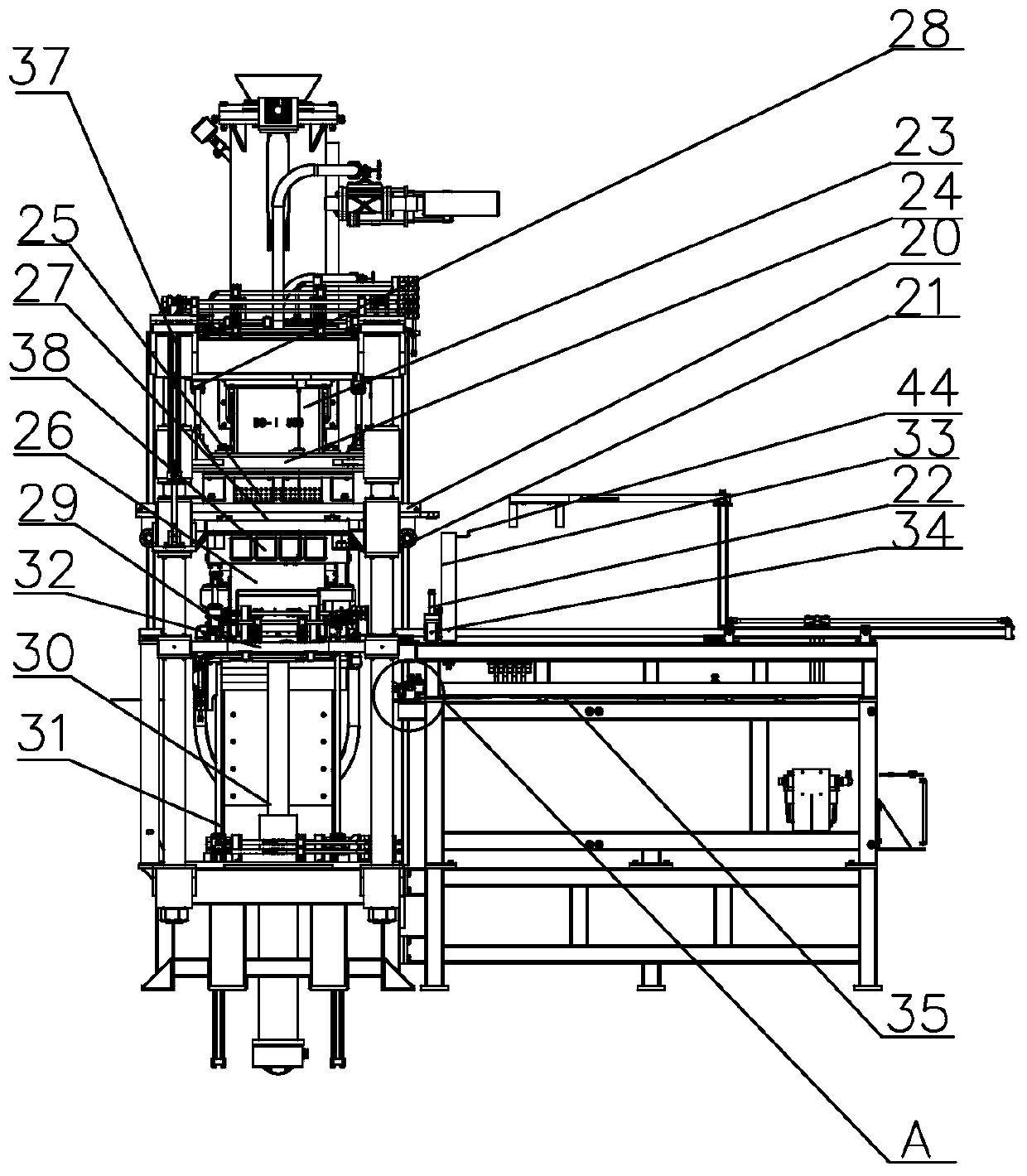

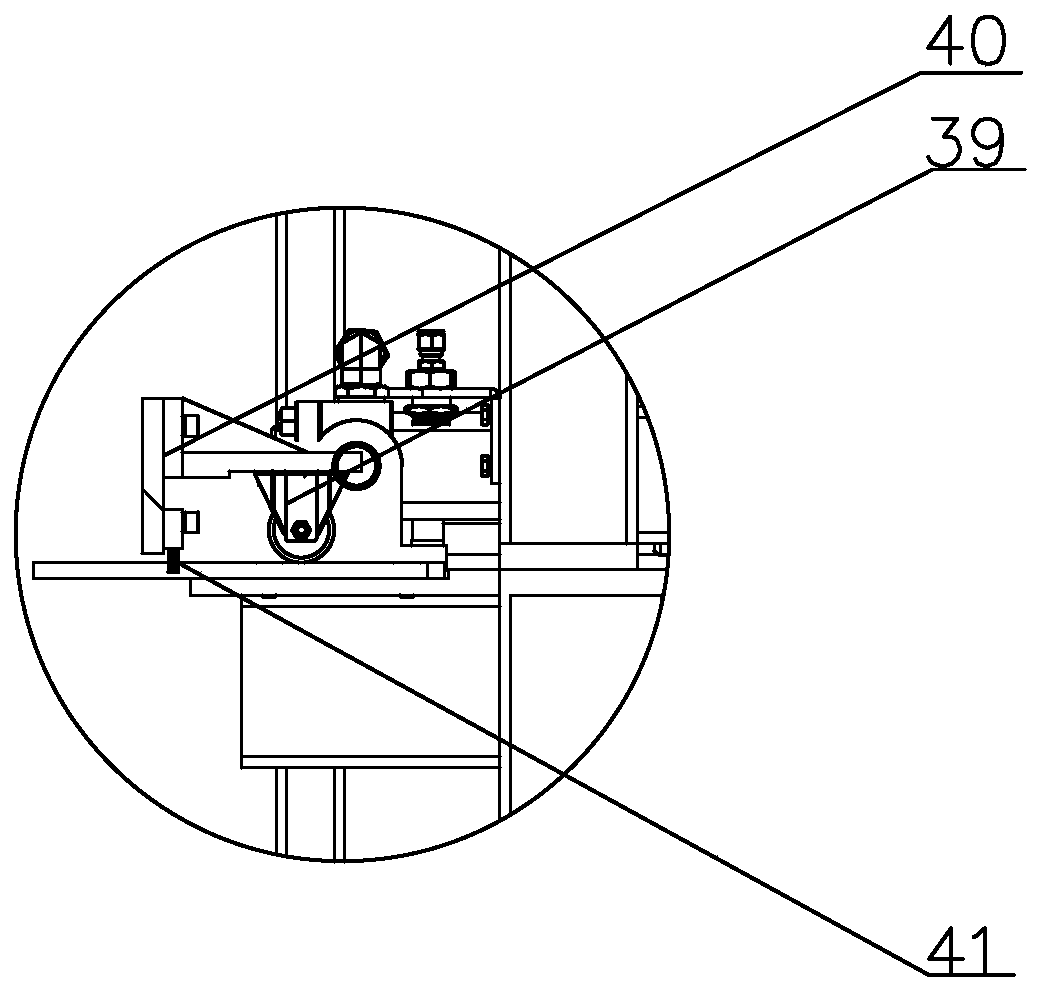

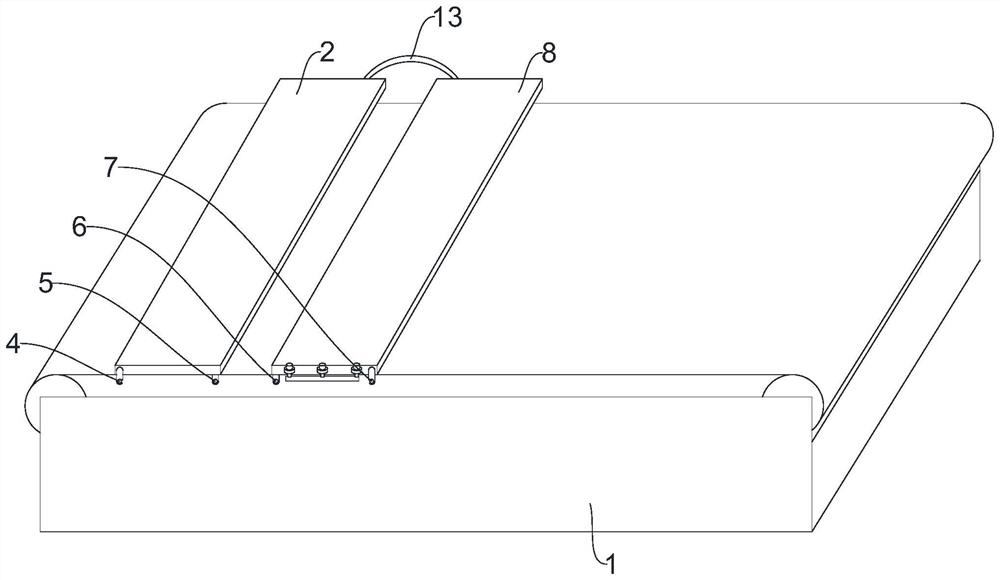

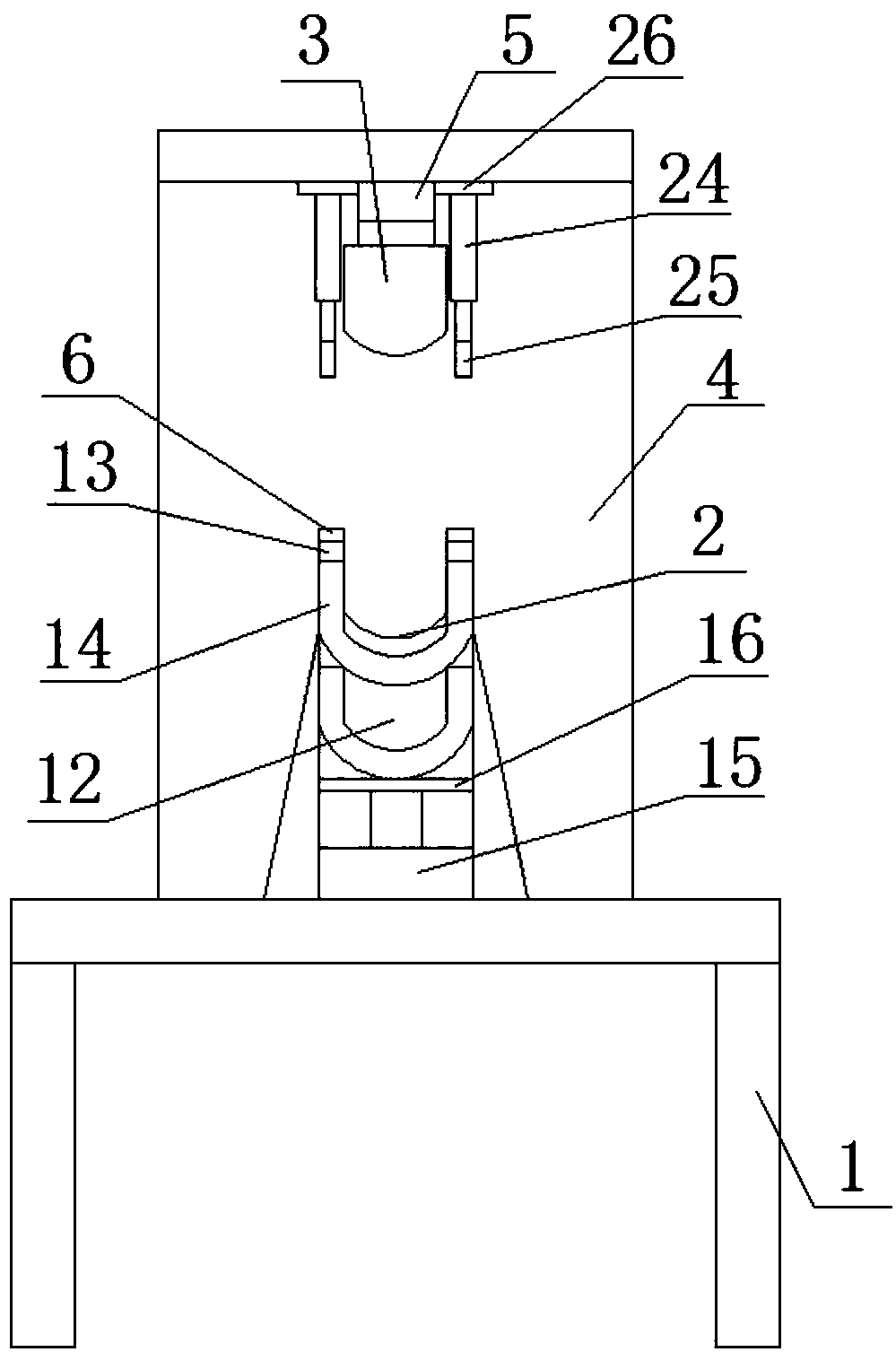

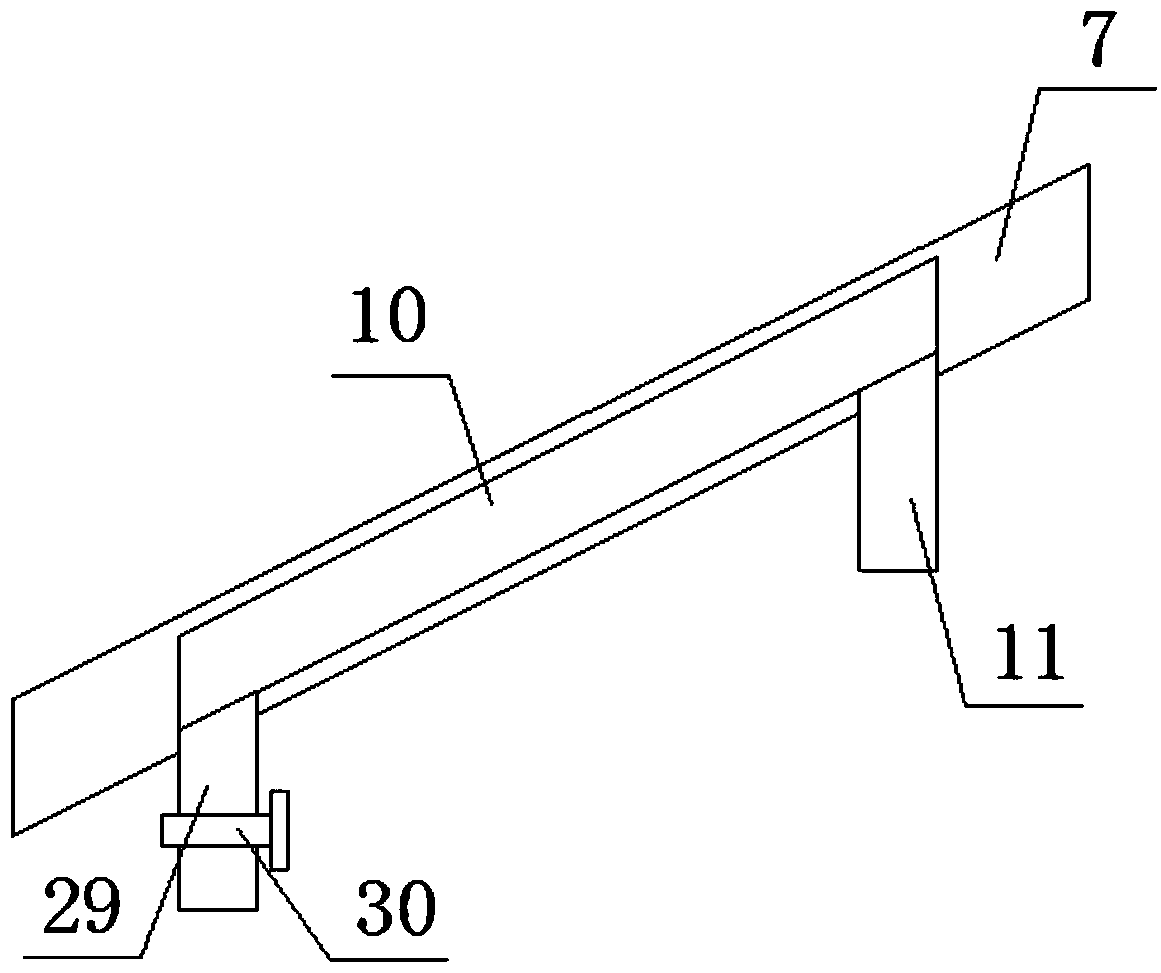

Single-face machine with paste coating system

ActiveCN102774036AImprove adhesionGuaranteed styling effectMechanical working/deformationCoating systemPulp and paper industry

The invention relates to a production device of corrugated boards and discloses a single-face machine with a paste coating system. The single-face machine with the paste coating system comprises an upper corrugated roller (22), a lower corrugated roller (23), the paste coating system (4), a base (1) and a wallboard (2). A non-metal roller (21), the upper corrugated roller (22) and the lower corrugated roller (23) are matched sequentially from the top to the bottom and arranged on the wallboard. The paste coating system (4) comprises a paste roller (42), a paste scraping roller (43), a slurry scraping mechanism and a paste basin (44). The diameter of the upper corrugated roller (22) is 666 mm, and the diameter of the lower corrugated roller (23) is 320 mm. By means of the technical scheme, the paste roller and the paste scraping roller are in external circle transmission, precise gap data is provided for gap adjustment between the paste roller and the paste scraping roller, different glue amount is provided, and the corrugated boards with good bonding effect are manufactured. Due to the diameter design of the upper corrugated roller and the lower corrugated roller, certain corrugation peaks are formed, and shape setting effect of the corrugated boards is guaranteed.

Owner:绍兴誉虎智能机械有限公司

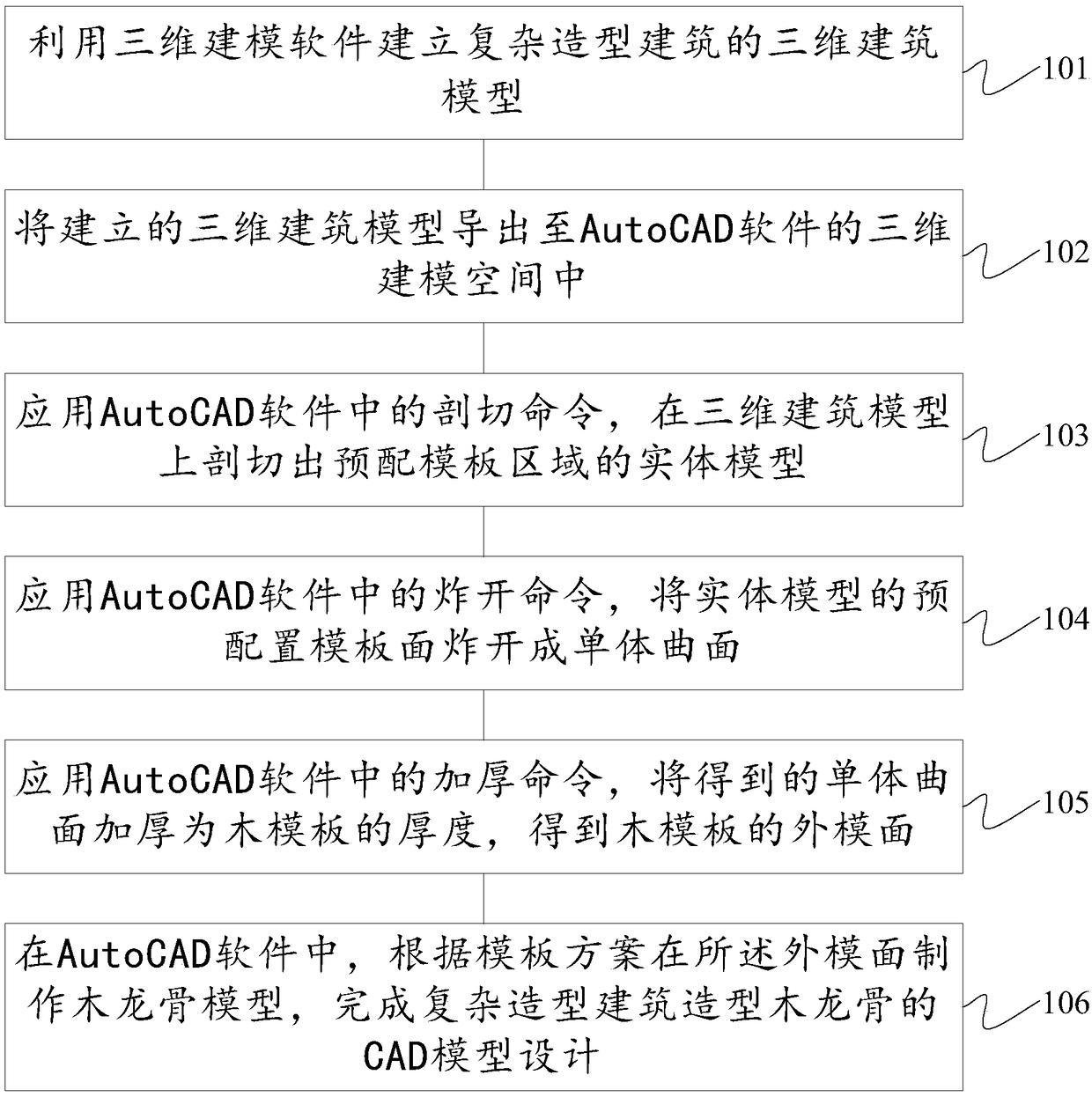

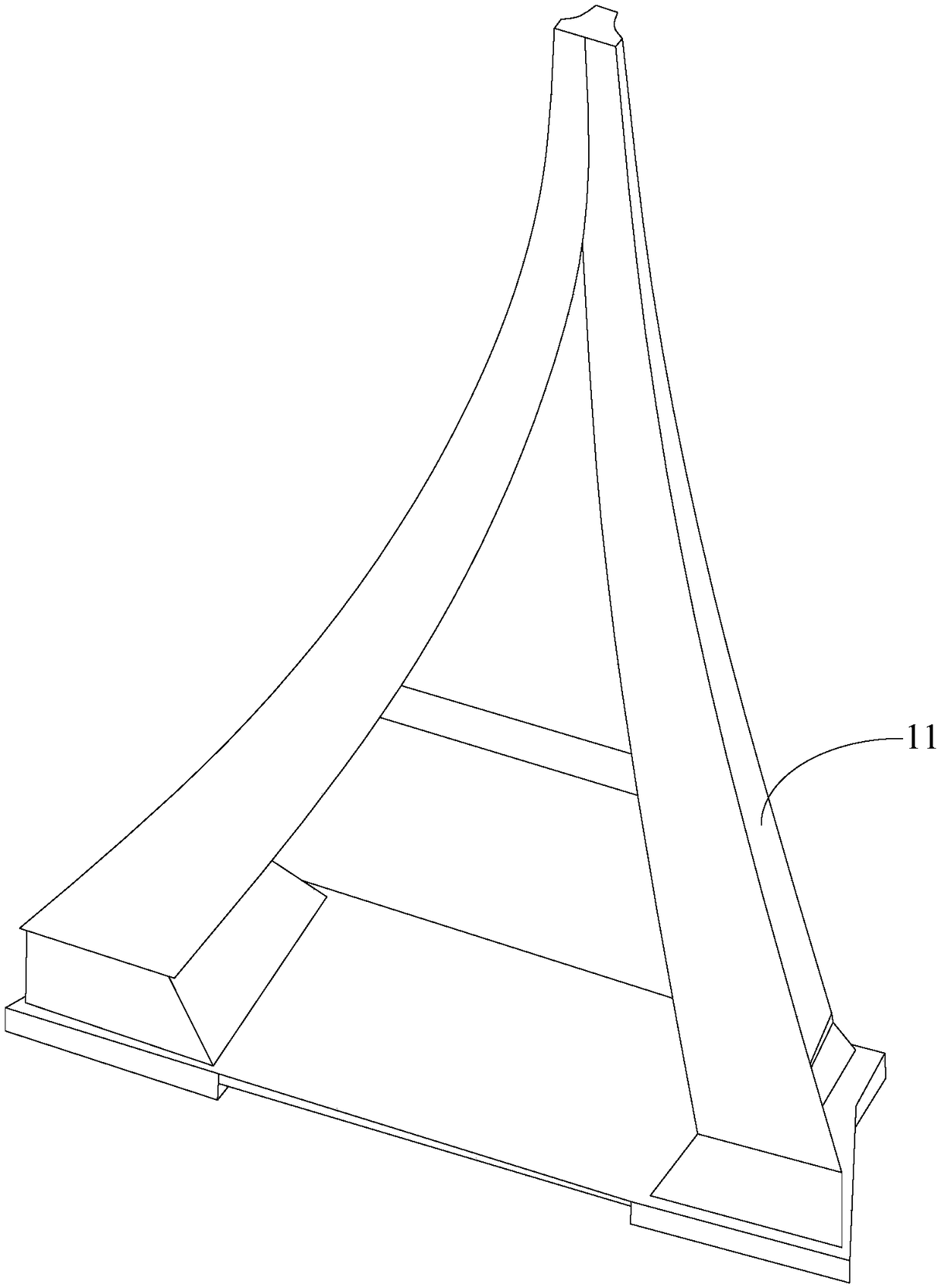

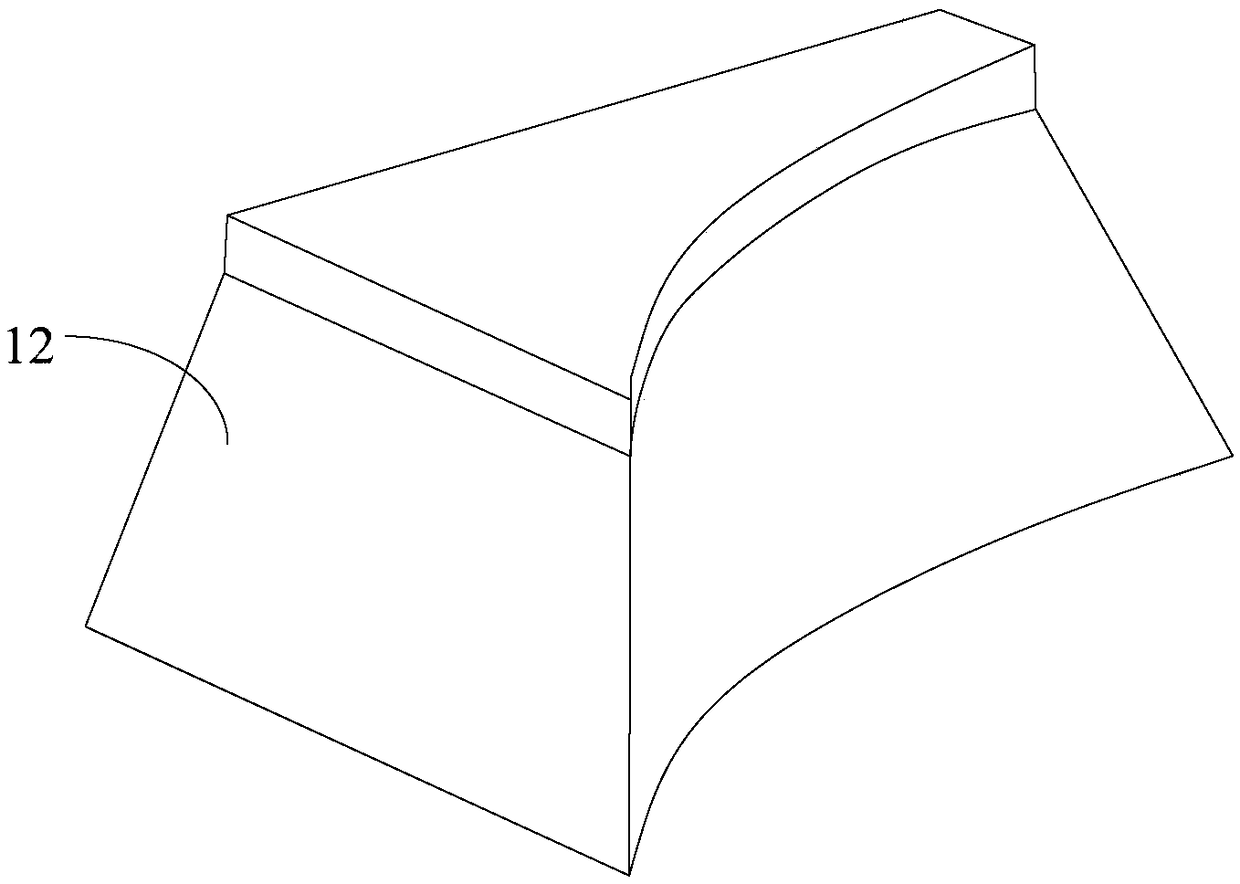

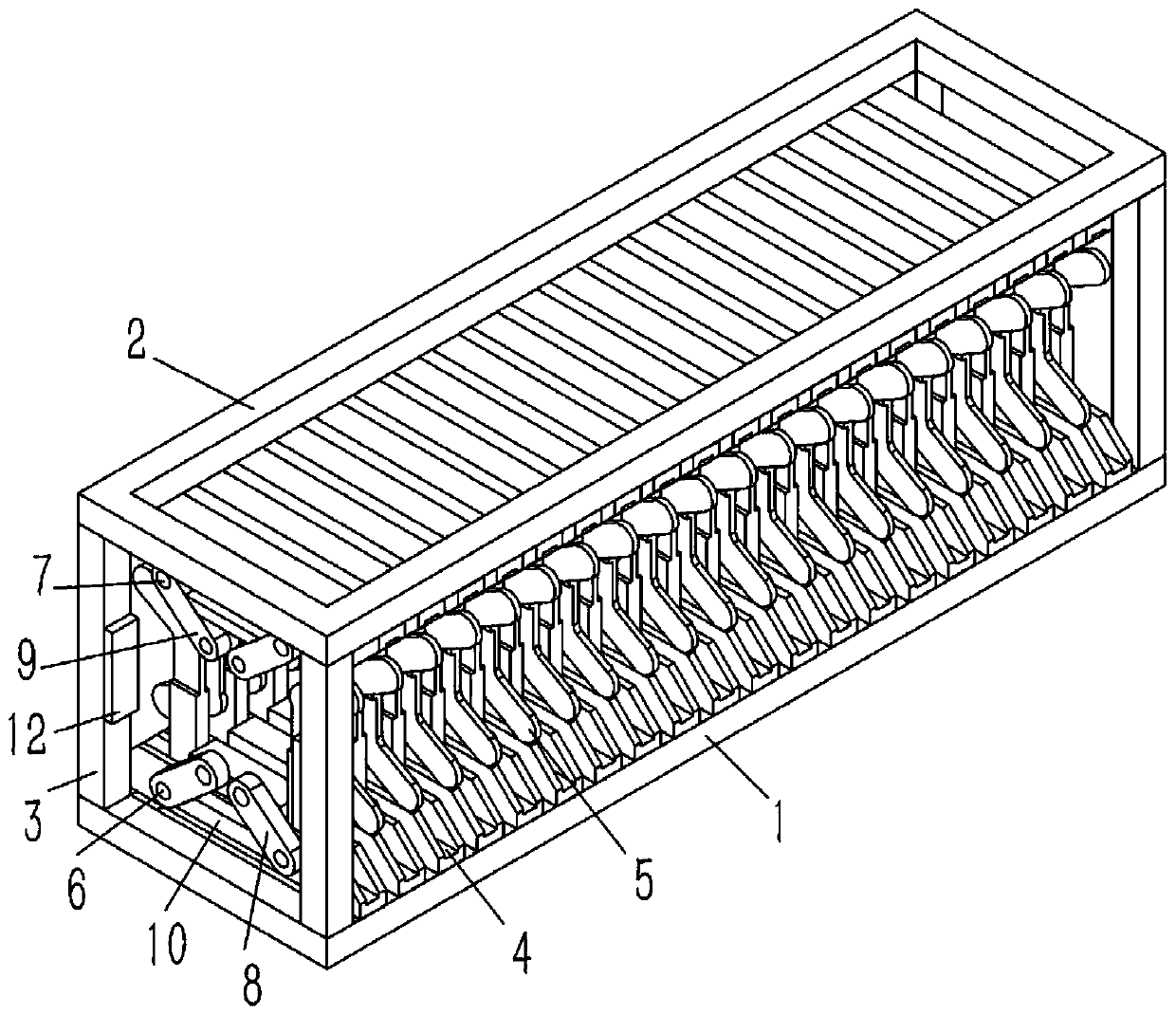

CAD design and manufacture method of wooden keel for complex modelling building modelling

ActiveCN109344466AGuaranteed styling effectGeometric CADDesign optimisation/simulationKeelEngineering

The invention discloses a CAD design and manufacture method of a wooden keel plate of a complex modelling building, which comprises the following steps: a three-dimensional building model of the complex modelling building is established by using a three-dimensional modeling software; The three-dimensional building model is exported to the three-dimensional modeling space of AutoCAD software. The solid model of the pre-matched formwork area is cut on the three-dimensional building model by using the cutting command. The pre-configured template surface of the solid model is exploded into a single curved surface by using the explosion command. By using the thickening command, the obtained single curved surface is thickened to the thickness of the wood template, and the outer mould surface ofthe wood template is obtained. According to the template scheme, the wooden keel model is made on the outer mould surface, and the CAD model design of the complex modelling building wooden template iscompleted. 3-D model is use for modeling, and that 3-D model of the mol wood is produced in cooperation with CAD 3d related functions, and the 3-D model is reduce in dimension and exported to 2-D drawings to directly guide on-site processing.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

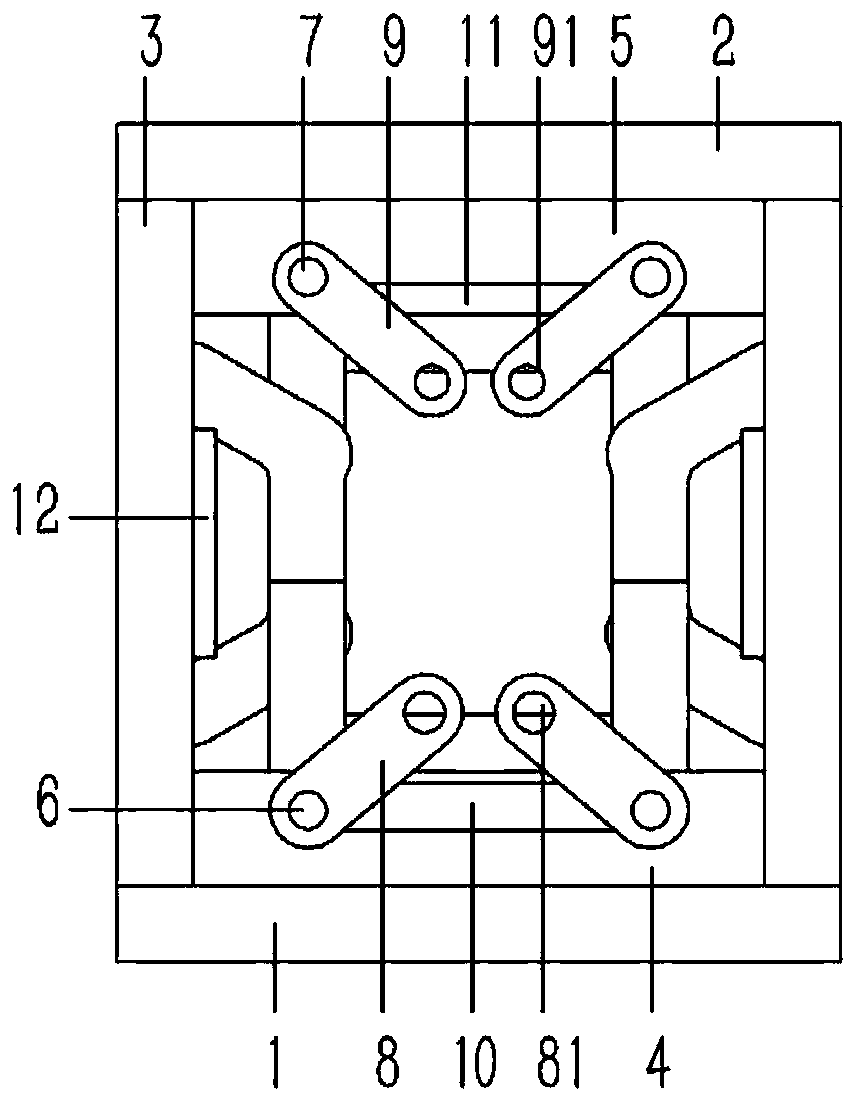

Shaping box for sock production

InactiveCN111254620AFully contactedGuaranteed styling effectHeating/cooling textile fabricsShaping/stretching tubular fabricsStructural engineeringMechanical engineering

Owner:徐日光

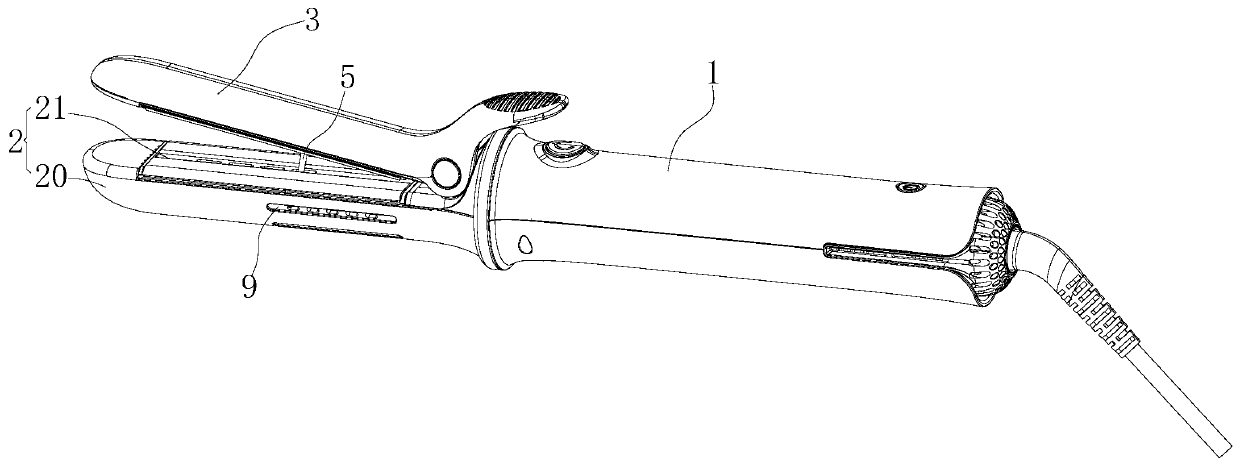

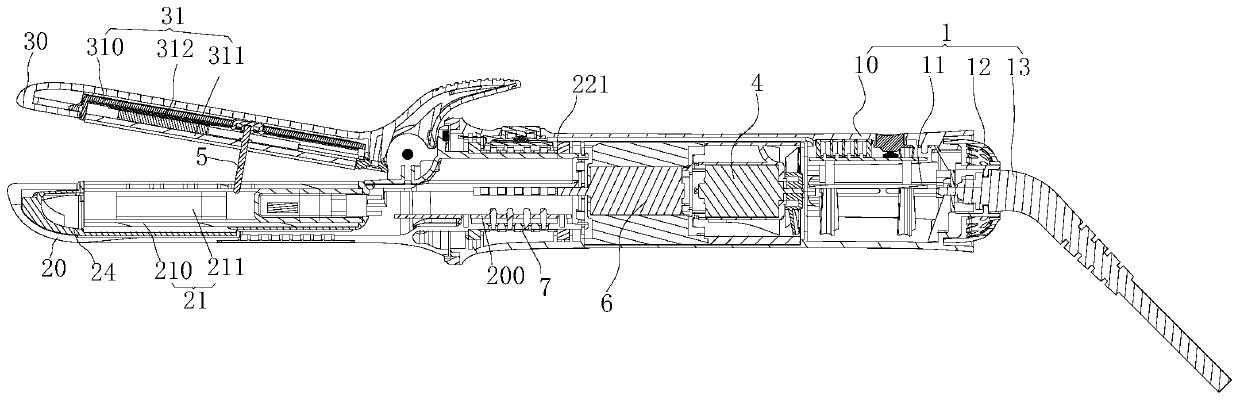

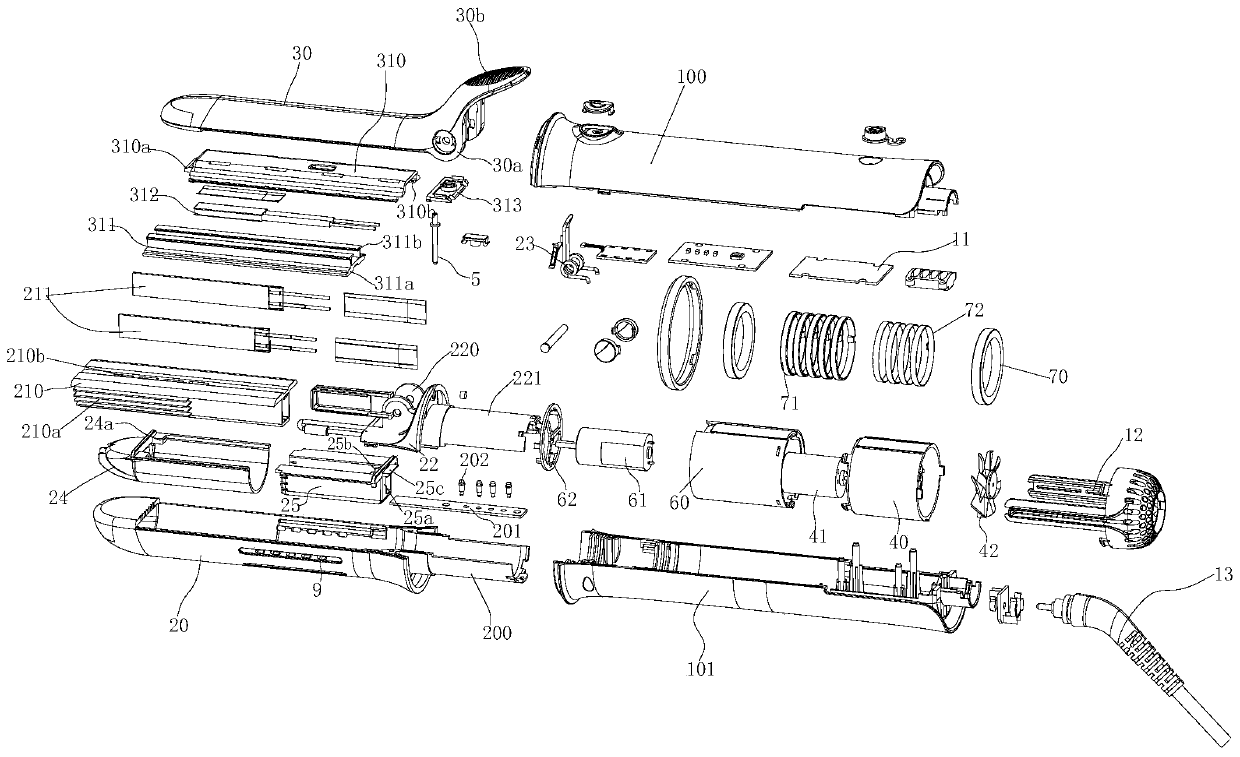

Curl Cooling and Styling All-In-One Curling Iron

ActiveCN108634527BRapid cooling and settingAvoid deformationCurling devicesCold airMechanical engineering

The invention discloses a hair curling cooling and shaping integrated hair curler, which comprises a handle mechanism, wherein one end of the handle mechanism is provided with an upper clamping mechanism which is clamped by a lower clamping mechanism and an upper clamping mechanism; the upper clamping mechanism comprises an upper clamping body and a first heating unit arranged in the upper clamping body; the lower clamping mechanism comprises a lower clamping body and a second heating unit arranged in the lower clamping body; a cold air hole is formed on the lower clamp main body; after the upper clamping mechanism and the lower clamping mechanism clamp the hair tightly, the hair is wound on the upper clamping mechanism and the lower clamping mechanism, the first heating unit and the second heating unit are electrified and the hair is heated, the hair curling cooling and shaping integrated curler is gradually pulled towards the direction of the hairpins, and the heated hair is deformedwhen the hair passes through the outer side of the upper clamping mechanism and the lower clamping mechanism, the air supply mechanism arranged in the handle mechanism is set up so that the air convection formed by the cold air hole can cool and shape the heated hair.

Owner:DONGGUAN BIDISCO ELECTRIC

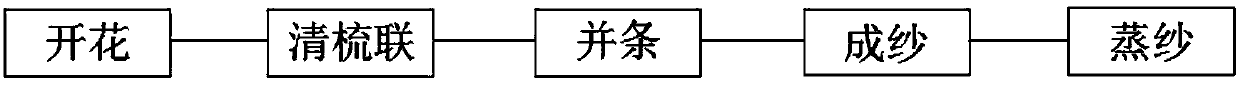

Processing technology for cotton yarn

InactiveCN109518323AQuality improvementEfficient removalYarnLiquid/gas/vapor yarns/filaments treatmentYarnTextile technology

The invention relates to a processing technology for cotton yarn, and belongs to the technical field of spinning. The processing technology for the cotton yarn includes the steps of opening, blowing-carding, drawing, yarn forming and yarn steaming. The processing technology for the cotton yarn is simple, impurities in raw materials are effectively removed, full mixing is achieved, the cotton yarncan be treated in a more detailed manner, and the processing quality of the cotton yarn is greatly improved.

Owner:湖北德永盛纺织有限公司

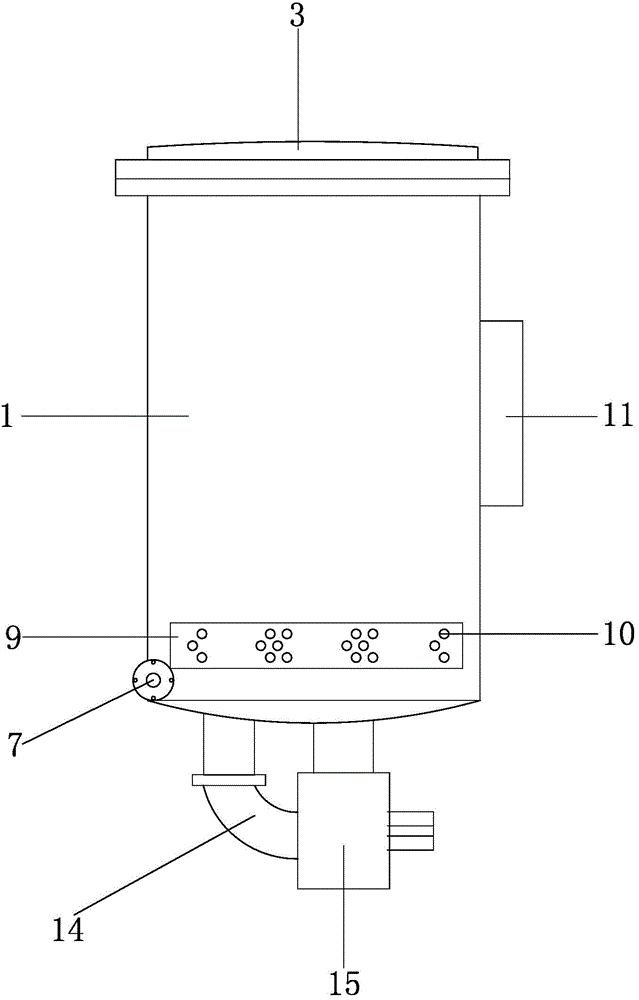

Vacuum pipe shaping machine with adjusting function

The invention discloses a vacuum pipe shaping machine with an adjusting function. The vacuum pipe shaping machine with the adjusting function comprises a machine frame, a control cabinet, and a left vacuum chamber, a right vacuum chamber, a diameter sizing sleeve, a longitudinal and height adjustment component, a transverse adjustment component, a front chamber spraying pipe, a rear chamber spraying pipe, a cooling water pump, a cooling water pipeline and a spraying nozzle mounted on the machine frame; a pipe to be shaped enters, from an inlet in the left end of the left vacuum chamber throughthe diameter sizing sleeve, the vacuum chamber for adjusting, shaping and cooling, and exits from an outlet of the right end of the right vacuum chamber after being shaped; and the longitudinal and transverse distance and the height of the shaping machine are adjusted by means of the longitudinal and height adjustment component and the transverse adjustment component. The technical scheme disclosed by the invention is convenient to adjust and can adjust from transverse direction, longitudinal direction and height; the speed is high; and the shaping effect of the pipe is ensured.

Owner:安徽巴瑞挤出设备有限公司

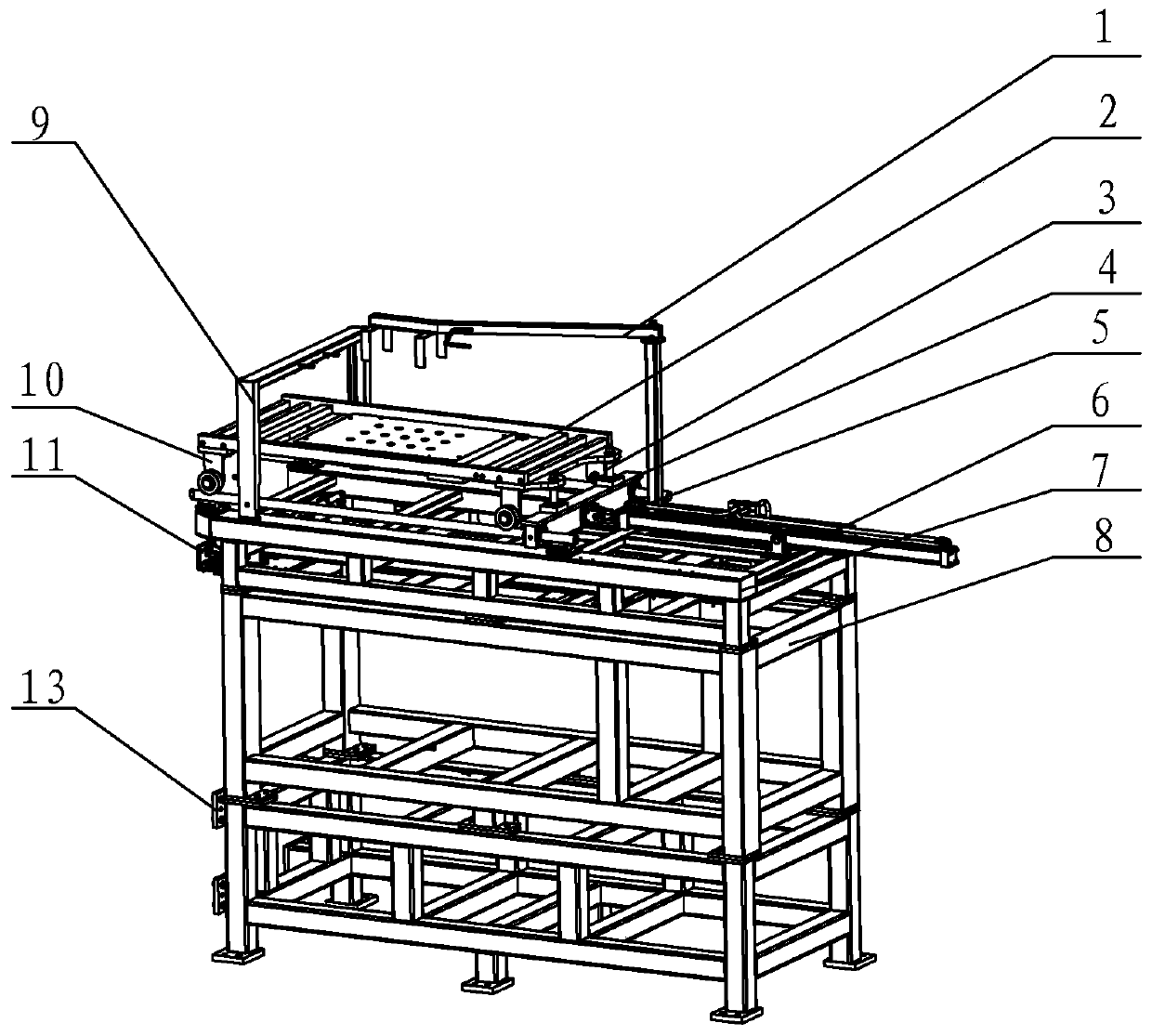

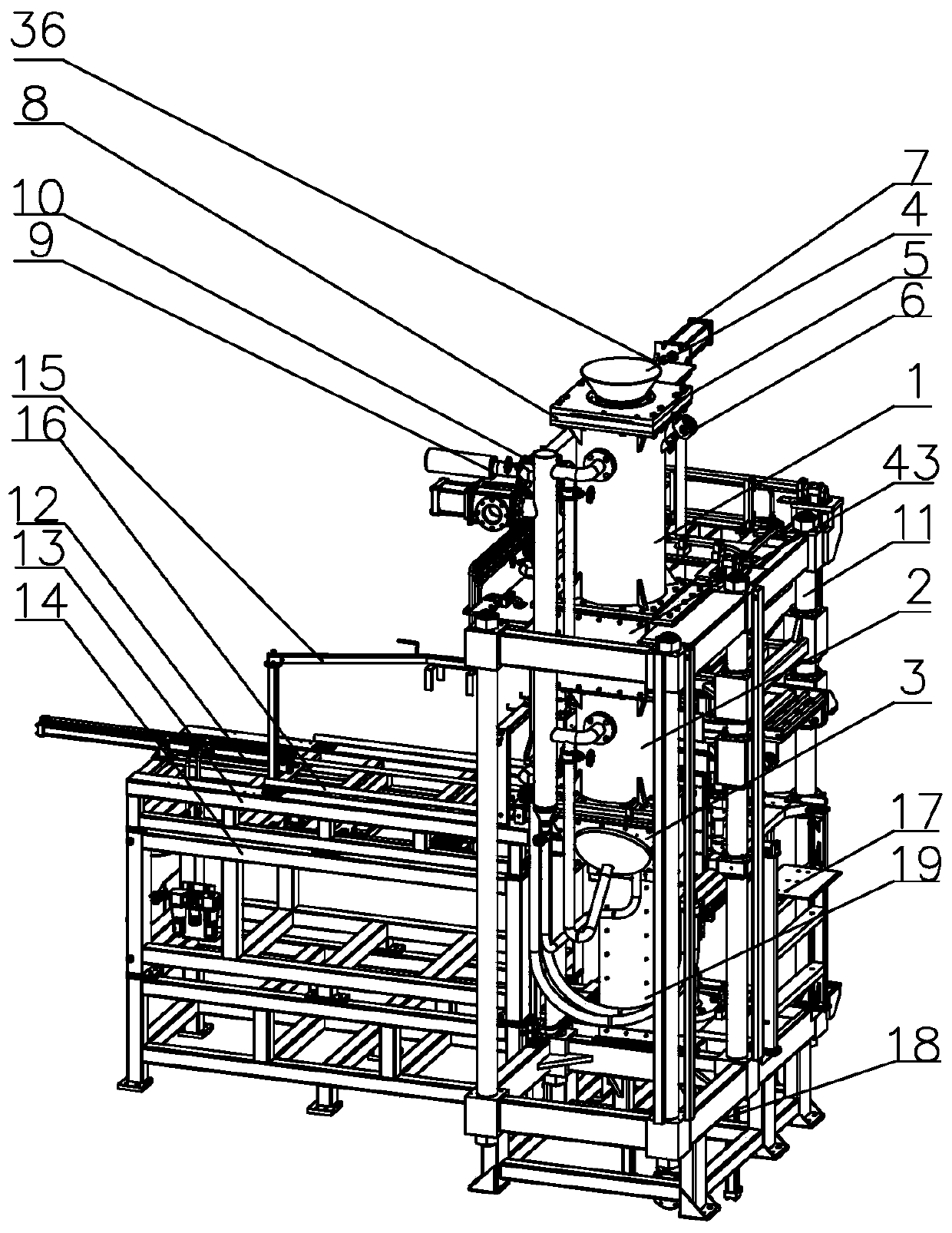

Full-automatic sand casting molding machine for clay sand

PendingCN110586878AGuaranteed styling effectReduce difficultyMoulding machinesSurface cleaningMolding machine

The invention discloses a full-automatic sand casting molding machine for clay sand. A traditional integrated design is improved, an equipment support is designed as a separated rack and a mounting rack, machining and transportation are facilitated, sand pushing operation is combined with surface cleaning, a sand pushing brush is arranged on the back of a sand pushing flat plate, air blowing openings are formed in the rack and the mounting rack, and surface cleaning of equipment is facilitated.

Owner:盐城市东云自动化科技有限公司

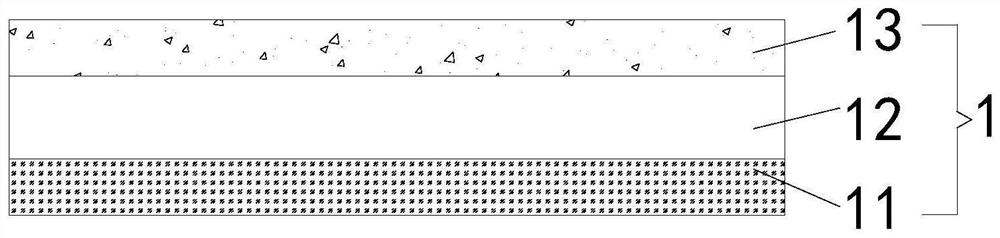

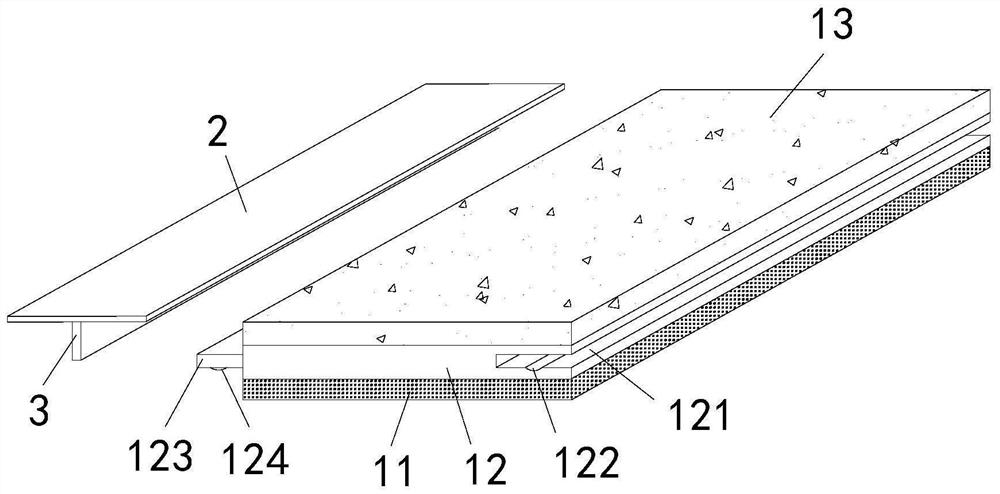

Self-adhesive waterproof roll structure

ActiveCN113715423APlay multiple protective effectsExcellent waterproof and impermeabilityNon-macromolecular adhesive additivesSynthetic resin layered productsInsulation layerEngineering

The invention discloses a self-adhesive waterproof roll structure which comprises a waterproof roll body and a waterproof cover layer, the waterproof roll body is formed by sequentially attaching a base layer, a composite waterproof layer and a bonding layer from bottom to top, an inserting piece layer is arranged on one side of the composite waterproof layer, and a protruding strip is arranged at the bottom of the inserting piece layer; the other side of the composite waterproof layer is provided with an installation clamping groove corresponding to the inserting piece layer, and the bottom of the installation clamping groove is provided with a concave groove corresponding to the protruding strip. Sealing rubber strips are arranged in the middle of the lower end of the waterproof cover layer; the base layer is of a three-layer structure, the upper layer and the lower layer are composite wear-resistant layers, and the middle layer is a heat preservation layer. According to the structure, the defects in the prior art are overcome, the design is reasonable, the self-adhesion is high, the waterproof and anti-seepage performance of the two coiled materials is improved through the arrangement of the sealing rubber strips, the long-term protection effect on a building structure can be achieved, and high social use value and application prospects are achieved.

Owner:安徽大禹防水科技发展有限公司

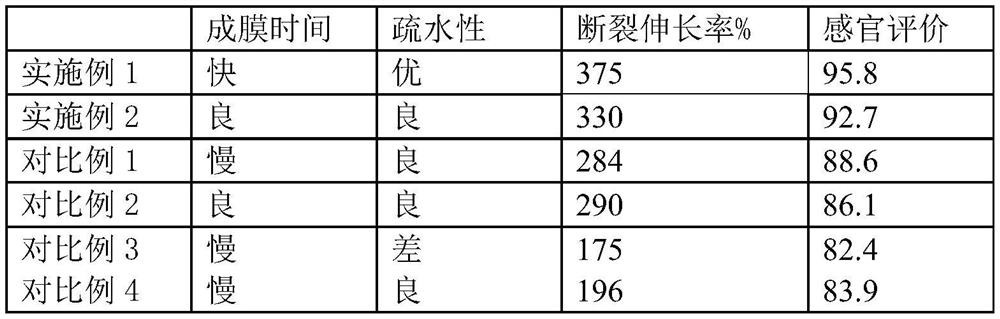

Hair spray slurry containing modified organosilicone and production method of hair spray slurry containing modified organosilicone

ActiveCN111991244ASolve hydrophobicitySolve the problem of poor flexibilityCosmetic preparationsHair cosmeticsAlcoholEthanolamines

The invention relates to the field of hair cosmetics, in particular to a hair spray slurry containing modified organosilicone and a production method of the hair spray slurry containing the modified organosilicone. The hair spray slurry containing the modified organosilicone comprises the following raw materials in percentage by mass: 10-15% of a film-forming agent, 0.05-0.2% of ethanolamine, 65-75% of ethyl alcohol and 10-25% of a propellant. The hair spray slurry produced according to the method has the advantages of fast film formation and strong styling; the hair spray slurry containing the modified organosilicone can make hair bands soft, smooth and not liable to be snarled; the hydrophobicity of the hair spray slurry is high after the hair spray slurry is cured to form films, hair does not adhere even on rainy days or after exercise, and persistent styling can be achieved; and the hair spray slurry does not contain methyl alcohol, is environmentally friendly, does not have pungent smells, has functions of conditioning and styling at the same time, can improve the brightness and the anti-static capability of the hair bands, and has wide application prospects.

Owner:广州市白云区金利工艺用品厂

Heat exchange device for weaving setting machine

PendingCN114164596AImprove structural firmness and stabilityGuaranteed styling effectMechanical cleaningPressure cleaningWoven fabricCentrifugal fan

The invention relates to the technical field of textile machinery, in particular to a heat exchange device for a weaving setting machine, which comprises an external main frame, an electric conveying belt module, a turnover upper setting extrusion plate and an electric centrifugal fan. The heat exchange device for the woven fabric setting machine is composed of an overturning type upper setting extrusion plate and an overturning type upper heat recovery plate which are movably installed on an external main rack, and the overturning type upper setting extrusion plate and the overturning type upper heat recovery plate are matched with overturning type limiting hooks on the side walls of the front end and the rear end to fix the heat exchange device, so that the structural firmness and stability of the woven fabric setting machine are improved; the shaping effect of woven cloth is ensured, so that adjustment operation is convenient; a rolling type heat exchange pipe communicating with an air outlet of an electric centrifugal fan is installed in a bottom heat exchange groove in the lower end of the overturning type upper heat recovery plate, an outer side air conveying hose communicates with a snake-shaped structure heating copper pipe, the heat exchange effect is greatly improved, and waste caused by heat energy leakage is avoided.

Owner:JIANGSU RUNYUN TEXTILE TECH CO LTD

Bamboo stick bending shaping device

InactiveCN108297215AGuaranteed continuous bending timeGuaranteed styling effectWood compressionCane mechanical workingHydraulic cylinderEngineering

The invention discloses a bamboo stick bending shaping device. The device comprises a rack, a u-shaped fixed mold is connected to the rack, a movable mold corresponding to the fixed mold is arranged above the fixed mold, a connecting frame is arranged above the movable mold, a hydraulic cylinder A is connected between the connecting frame and the movable mold, a clamping groove is formed in the top end of the fixed mold, one side of the clamping groove is connected with an inclined guide groove, a limiting plate is connected to the guide groove, two sets of hydraulic cylinders B distributed inthe direction of the guide groove are connected to the limiting plate, a steam cavity is formed in the guide groove, a steam pipe is connected to the steam cavity, a guide cavity is arranged in the fixed mold, an electromagnetic gate is arranged at the position, corresponding to the top end of the guide cavity, of the fixed mold, a clamp is arranged in the guide cavity, a hydraulic cylinder is arranged at the bottom end of the guide cavity, the top end of the hydraulic cylinder C is connected with a push plate, and the push plate is arranged in the guide cavity. Operation is facilitated, andthe beneficial effects that the shaping effect is good, and work efficiency is high are achieved.

Owner:杨文祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com