Shaping box for sock production

A technology for socks and boxes, applied in the direction of shaping/stretching ring fabrics, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of steam contact, insufficient socks, poor shaping effect, etc., to achieve the guaranteed effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

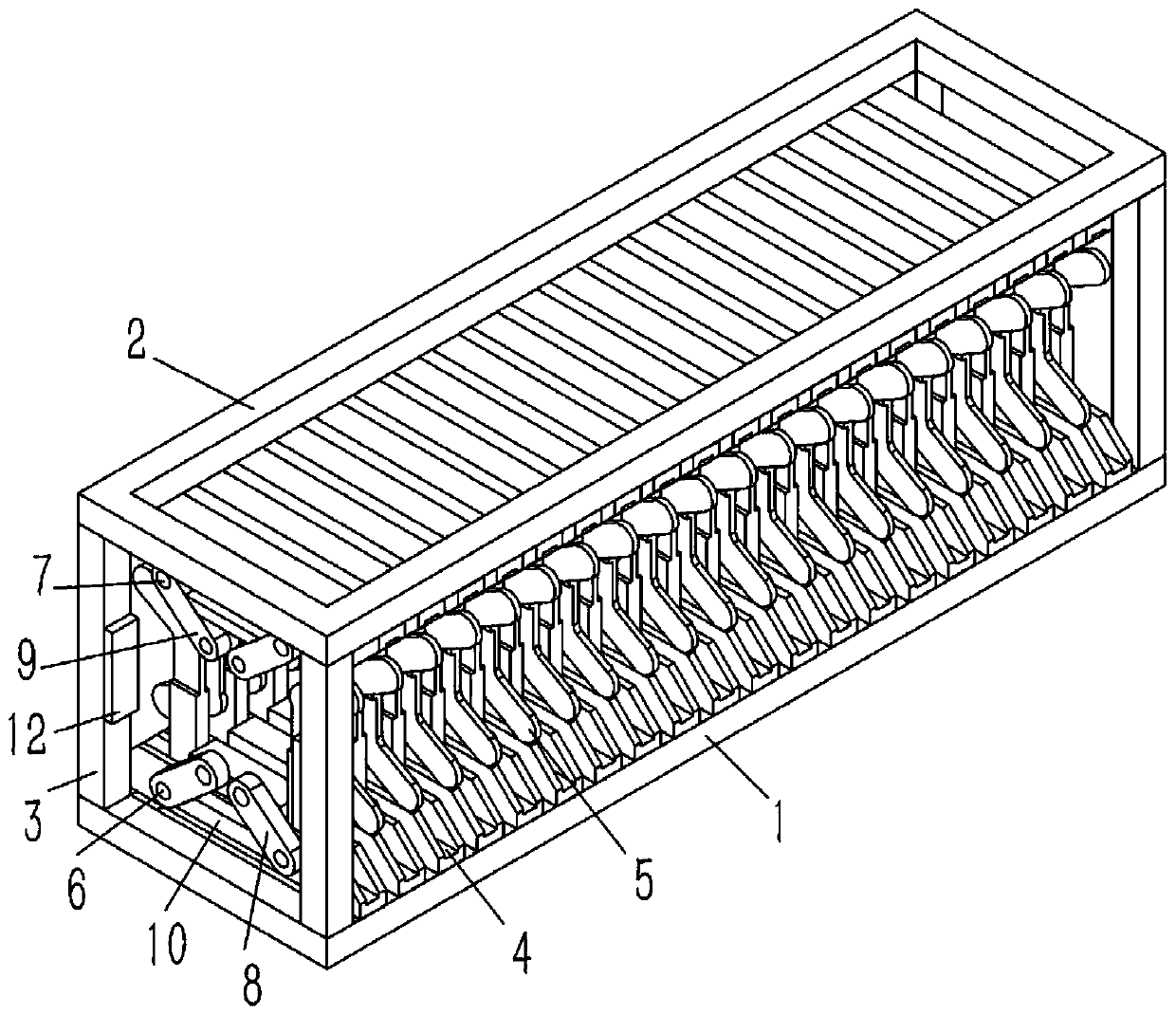

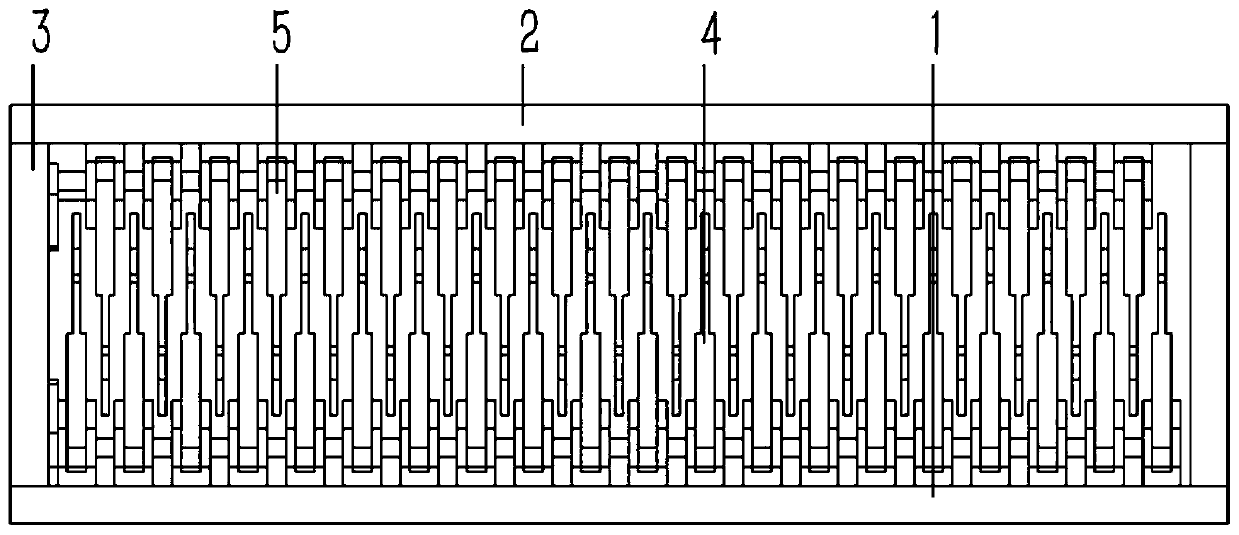

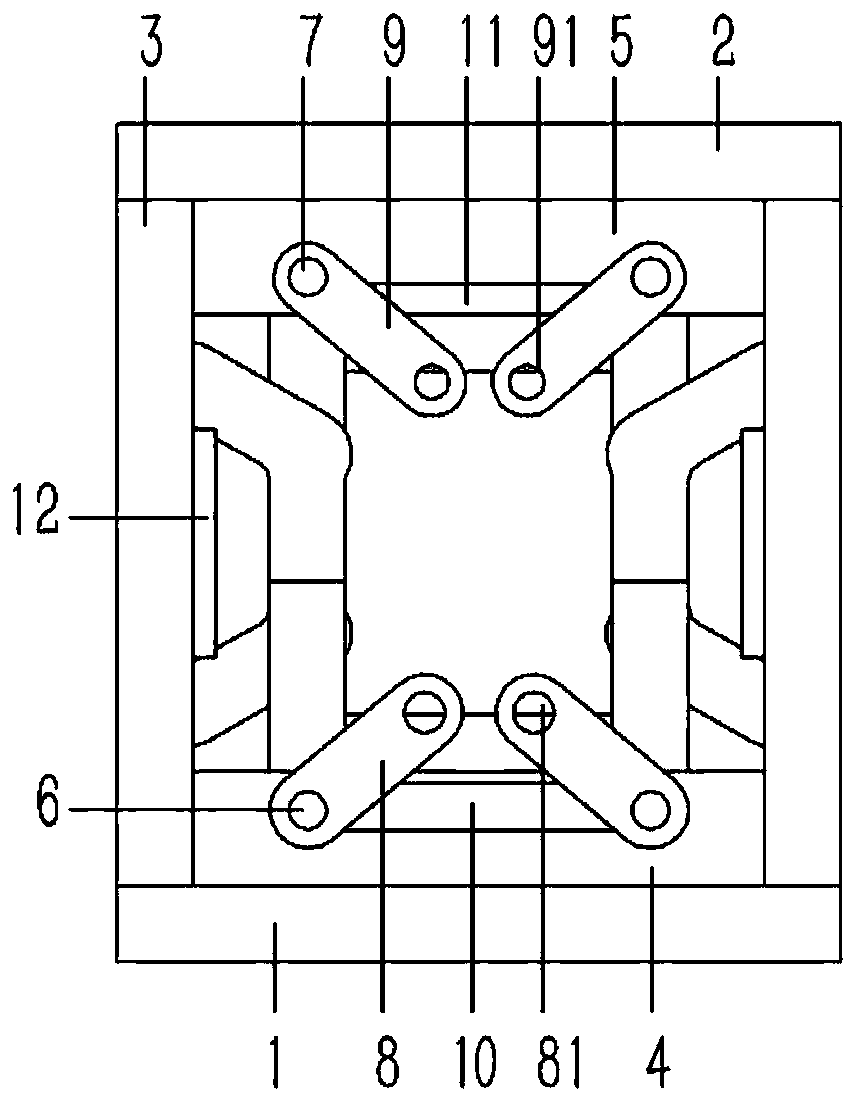

[0019] Example: see Figures 1 to 4 As shown, a stereotyped box for socks production includes a box body, and the box body is composed of a rectangular bottom frame 1, a rectangular top frame 2 and a plurality of columns 3, the lower ends of the columns 3 are fixed on the four corners of the bottom frame 1, and the bottom frames of the columns 3 The top is fixed on the four corners of the top frame 2; the lower end surface of the top frame 2 and the upper end surface of the bottom frame 1 are respectively fixed with several upper sizing frames 5 and lower sizing frames 4, and the lower sizing frames 4 are inserted in the adjacent upper sizing frame. Between the frames 5, the upper sizing frame 5 and the lower sizing frame 4 are both composed of a "凵" shaped channel a and a turning plate b distributed at both ends of the channel a, the upper end of the turning plate b is formed with a sock cover c, the lower end of the turnover plate b is inserted into the channel a, the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com