Stream setting machine

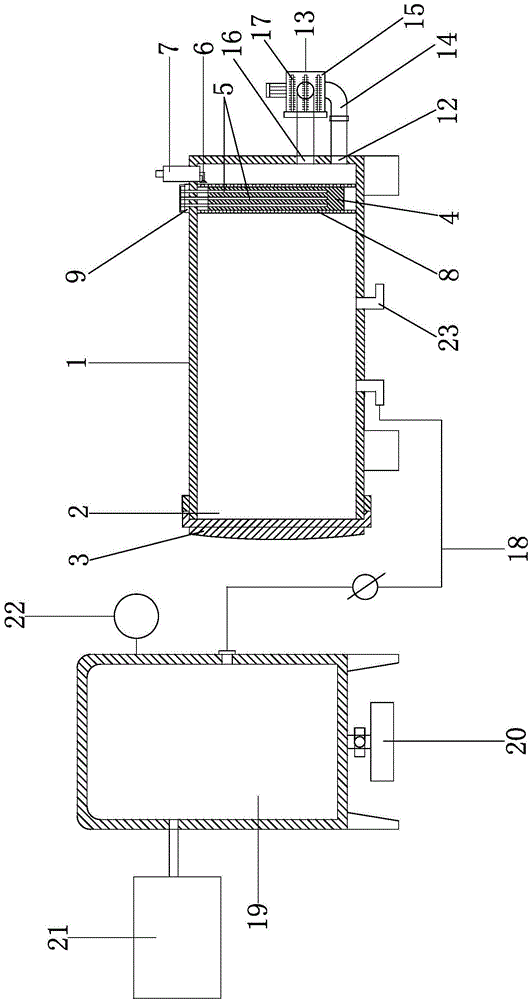

A technology of setting machine and steam, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve problems such as imminent technological innovation of setting equipment, ineffective control of evaporation, inconvenient control of cylinder temperature, etc. Achieve comprehensive styling effects, shorten drying time, and improve styling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

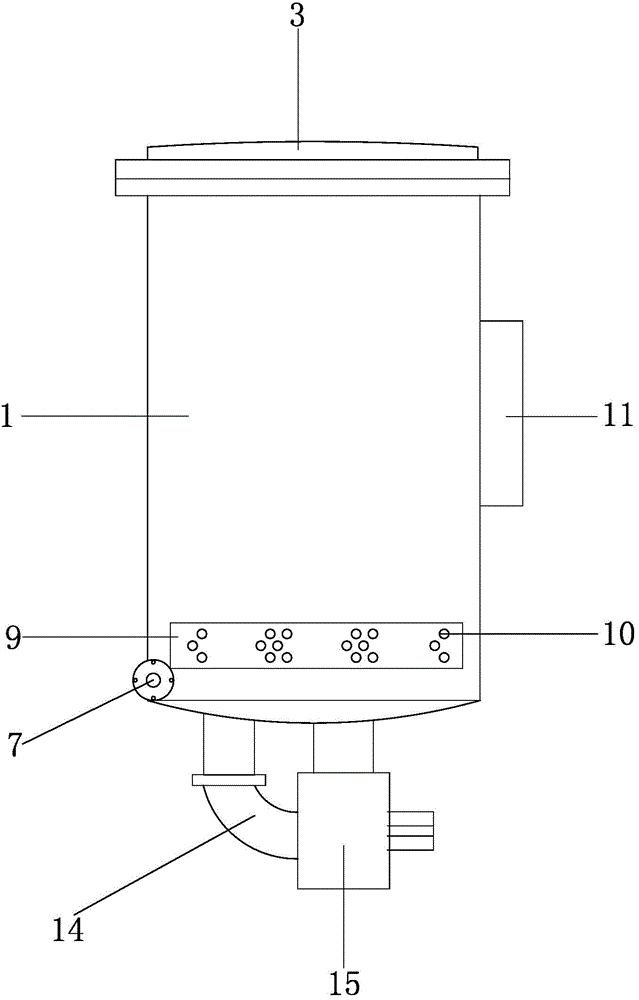

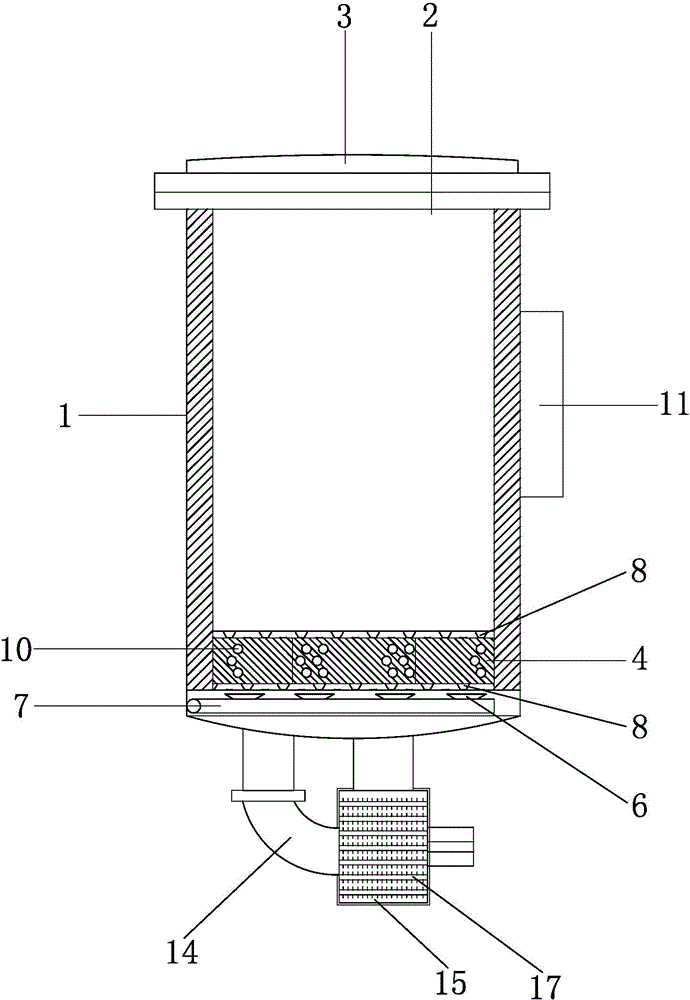

[0041] Another specific embodiment of the present invention: see Figure 4 ,

[0042] The tank body 1 is symmetrically provided with a left partition 24 and a right partition 25,

[0043] A molding cavity 26 is formed between the left side dividing plate and the right side dividing plate,

[0044] A heating chamber 28 is formed between the left dividing plate and the tank body and between the right dividing plate and the tank,

[0045] There is an overflow gap 27 between the lower ends of the left side partition and the right side partition and the tank body,

[0046] The high-temperature heat storage plate, spray head and finned heating tube are installed in the heating chamber,

[0047] An air outlet 12 connected to an exhaust fan is provided on the top of the shaping chamber or on the rear end of the shaping chamber.

[0048] The top of the heating chamber or the upper side of the rear end of the heating chamber is provided with an air inlet 16 connected to the air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com