Artificial leather for leather carving and manufacturing method thereof

A manufacturing method and a technology for artificial leather, applied in the field of artificial leather, can solve the problems of low radial elongation of artificial leather, and achieve the effect of ensuring shapeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

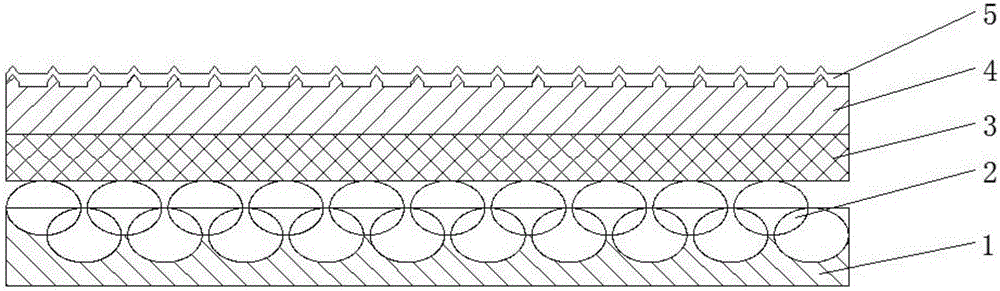

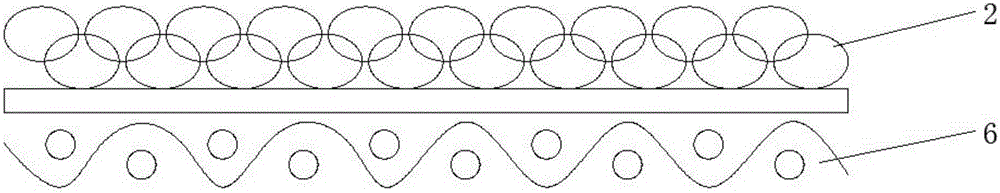

[0021] see figure 1 , is a kind of artificial leather for leather carving as the best embodiment of the present invention, including wipeable layer 1, protective layer 2, PU foam layer 3, four-way elastic knitted cloth layer 4 and shaping Layer 5. The outer surface of the protective layer 2 has patterns. The wipeable layer is formed by coating the outer surface of the protective layer 2 with a paint mixed with nitrocellulose, wax powder and organic solvent, and finally wiped to achieve an antique effect, and is mainly used for leather carving products with an antique effect. like figure 2 To make the four-way stretch knitted fabric layer 4, the four-way stretch knitted fabric and the woven fabric 6 need to be compounded to form a composite cloth.

[0022] The specific manufacturing steps are as follows:

[0023] 1. Combining four-way stretch knitted fabric and woven fabric to form a composite fabric;

[0024] 2. Using the above-mentioned composite cloth as the base cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com