Patents

Literature

71 results about "Hair spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hair spray (also hair lacquer or spritz) is a common cosmetic hairstyling product that is sprayed onto hair to protect against humidity and wind. Hair sprays typically consist of several components for the hair as well as a propellant.

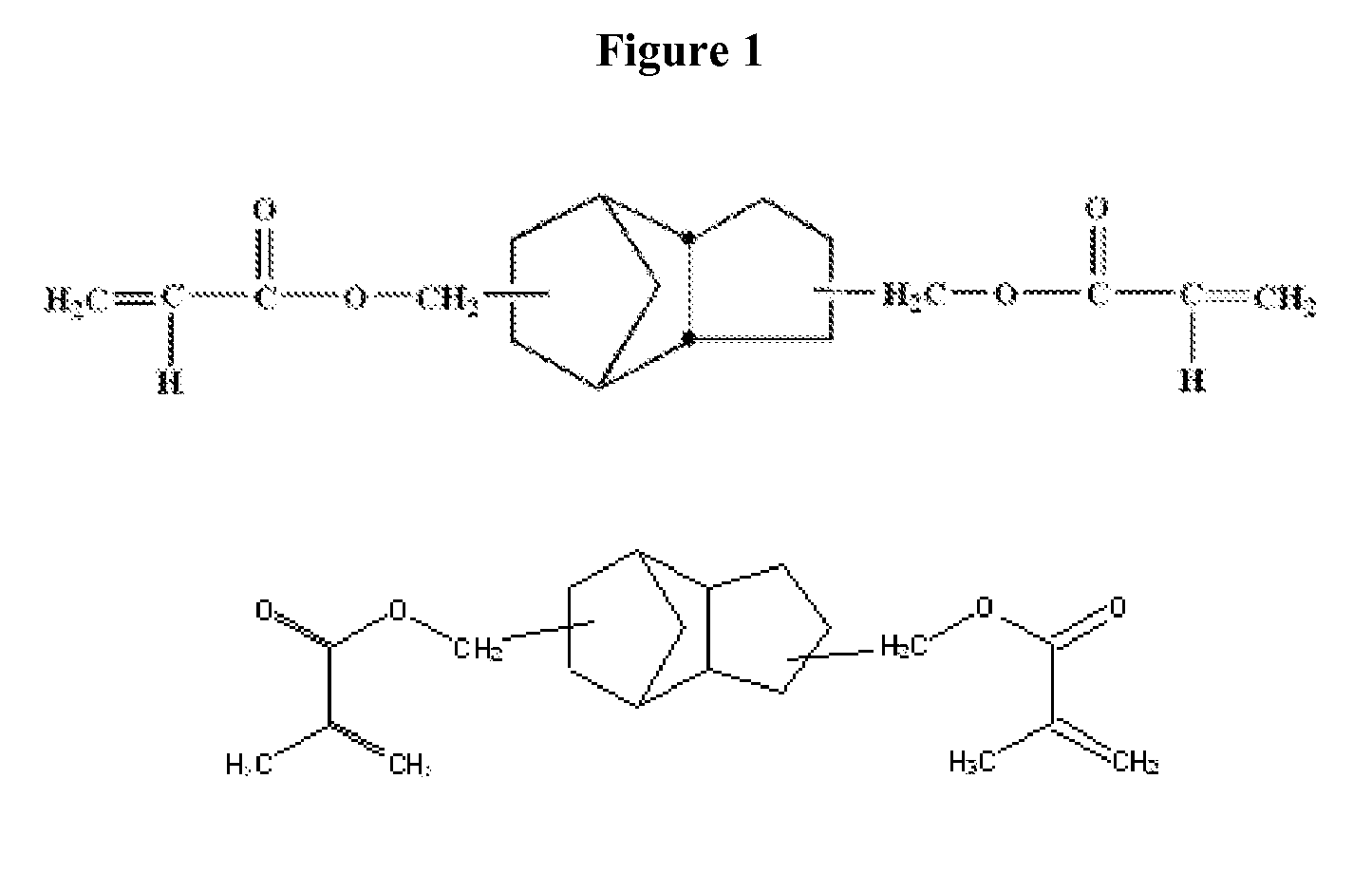

In situ polymerization for hair treatment

InactiveUS20080066773A1Effective for long period of timeImprove hair strengthCosmetic preparationsHair removalSolubilityIn situ polymerization

Hair care products represent a world-wide multi-billion dollar industry. Pre-formed polymers are commonly used in a variety of hair care products including shampoos, conditioners, gels, and hair sprays. The present invention provides technology for polymerizing monomers on hair in situ to produce desired hair characteristics. This eliminates the solubility and application issues found with some polymers. The polymerization of monomers on hair is typically initiated using a thermal or photoinitiatied free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the hair upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating hair with polymers.

Owner:LIVING PROOF INC

Aerosol Hairspray Composition

A hair spray composition comprising at least one hair setting polymer comprising pendant carboxyl groups, a solvent for the setting polymer and a neutraliser for the polymer wherein the level of neutraliser present is such that at least 170% of the total carboxyl groups on the polymer could be neutralised.

Owner:CONOPCO INC D B A UNILEVER

Hair Care and Nail Care Compositions Based on Ion-Pair Delivery System for Gender and Ethnic Selective Applications

InactiveUS20040241114A1Good synergyImprove bioavailabilityCosmetic preparationsHair removalElectron donorDelivery system

This invention relates to a novel ion-pair delivery system useful for gender and ethnic background selective hair care and nail care applications in which an electron donor composition and an electron acceptor composition, or a proton donor composition and a proton acceptor composition, or an anionic and a cationic composition, are combined synergistically. The bioavailability, deposition, functional performance, and consumer aesthetics of the compositions thus combined in such ion-pairs are enhanced synergistically. Hair care compositions, such as shampoo, conditioner, hair lotion, hair oil, hair gel, hair sheen, hair rinse, hair balm, hair wax, hair spray, and such, and nail care compositions, such as nail enamel, nail creams, nail serums, nail lacquers, nail spray, and nail polish, and such, can thus be obtained with synergistically enhanced performance.

Owner:GUPTA SHYAM K

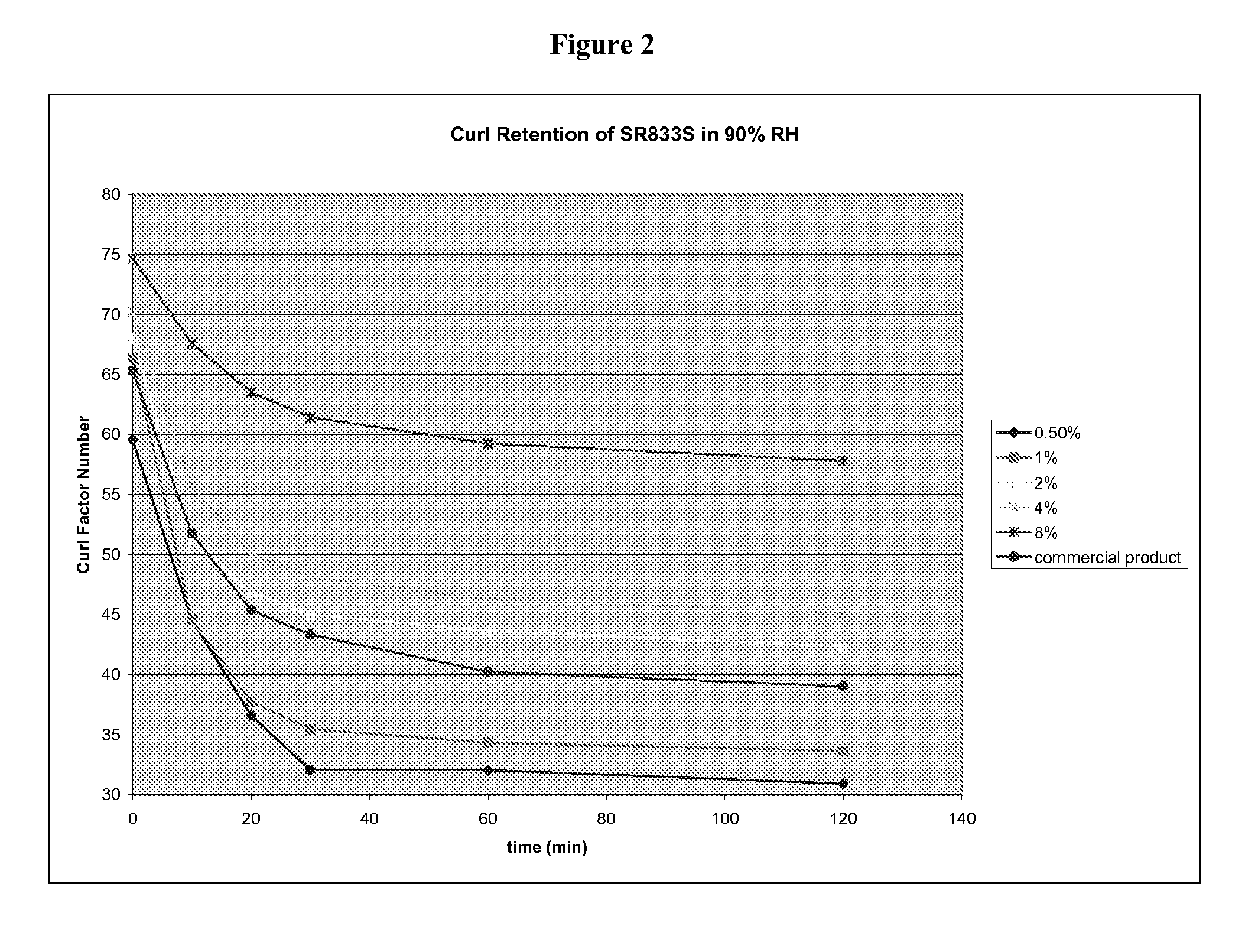

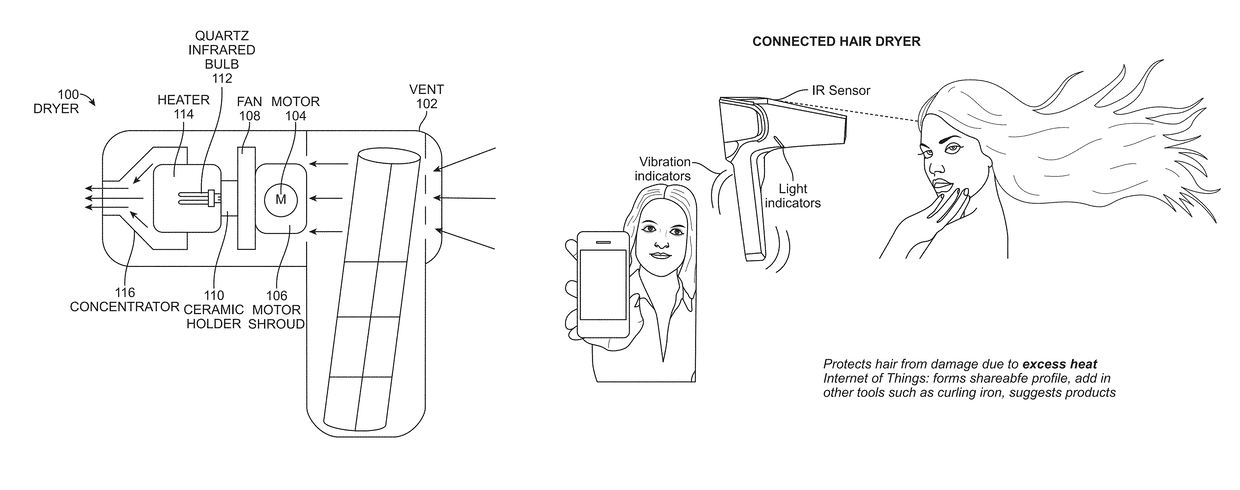

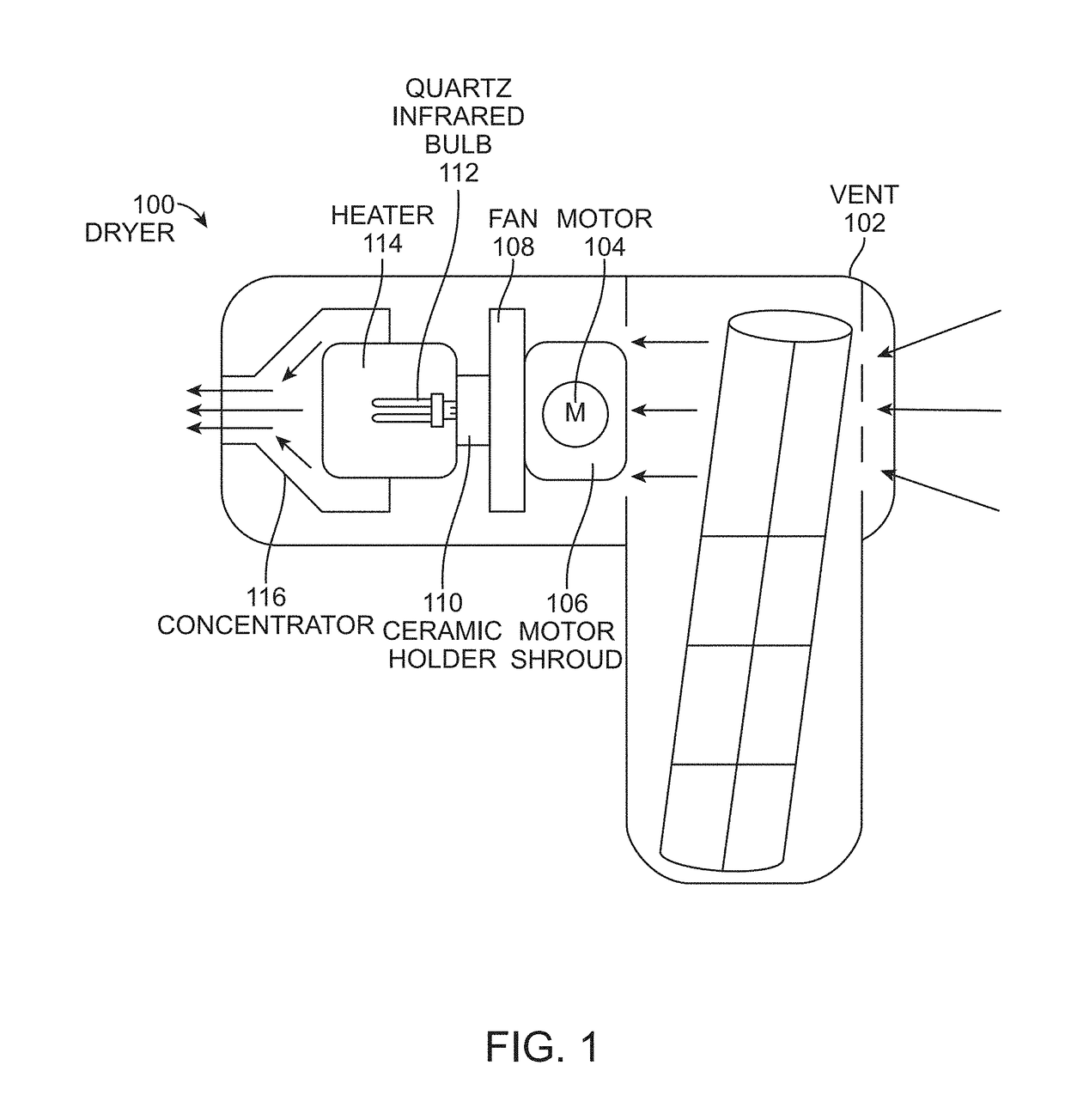

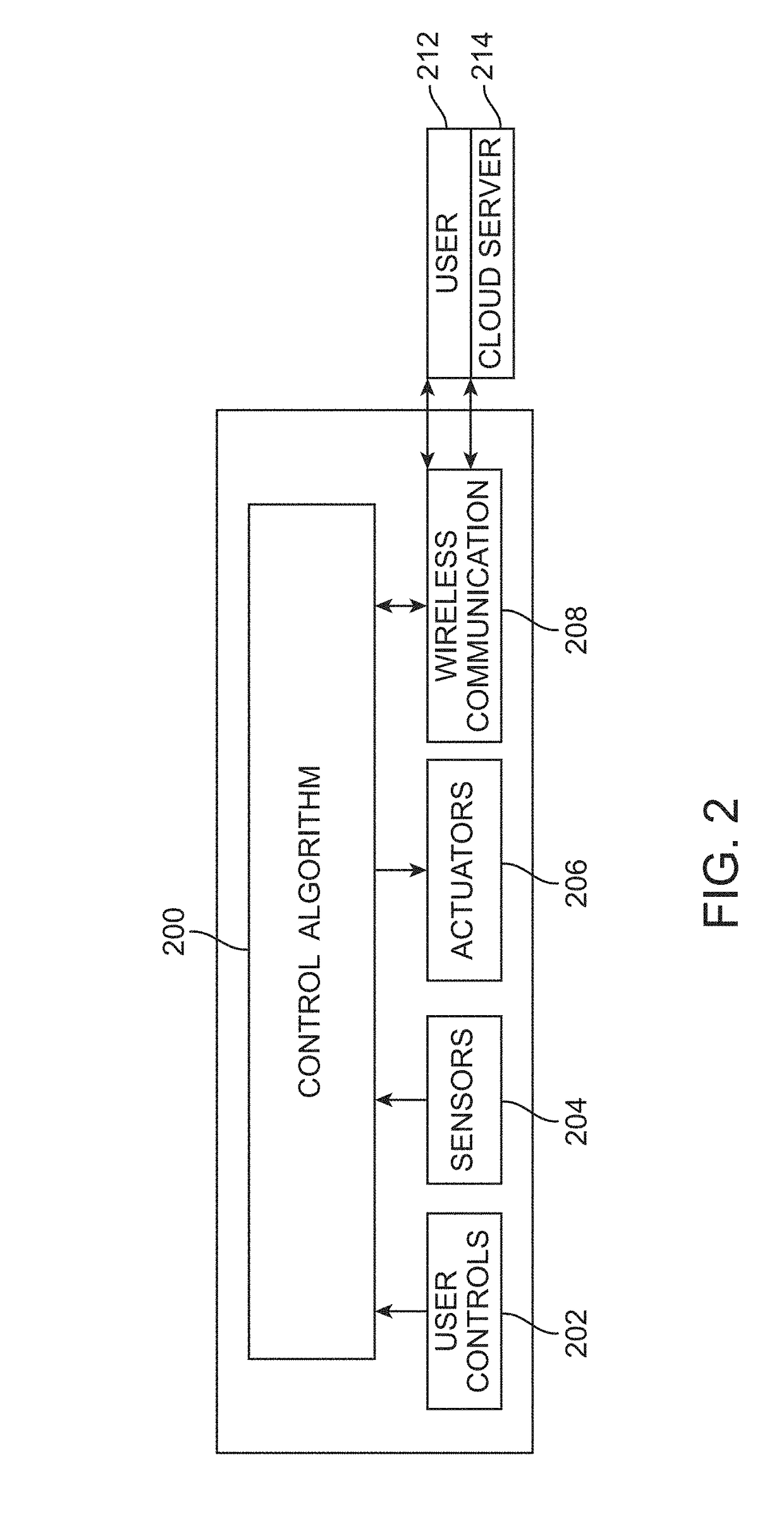

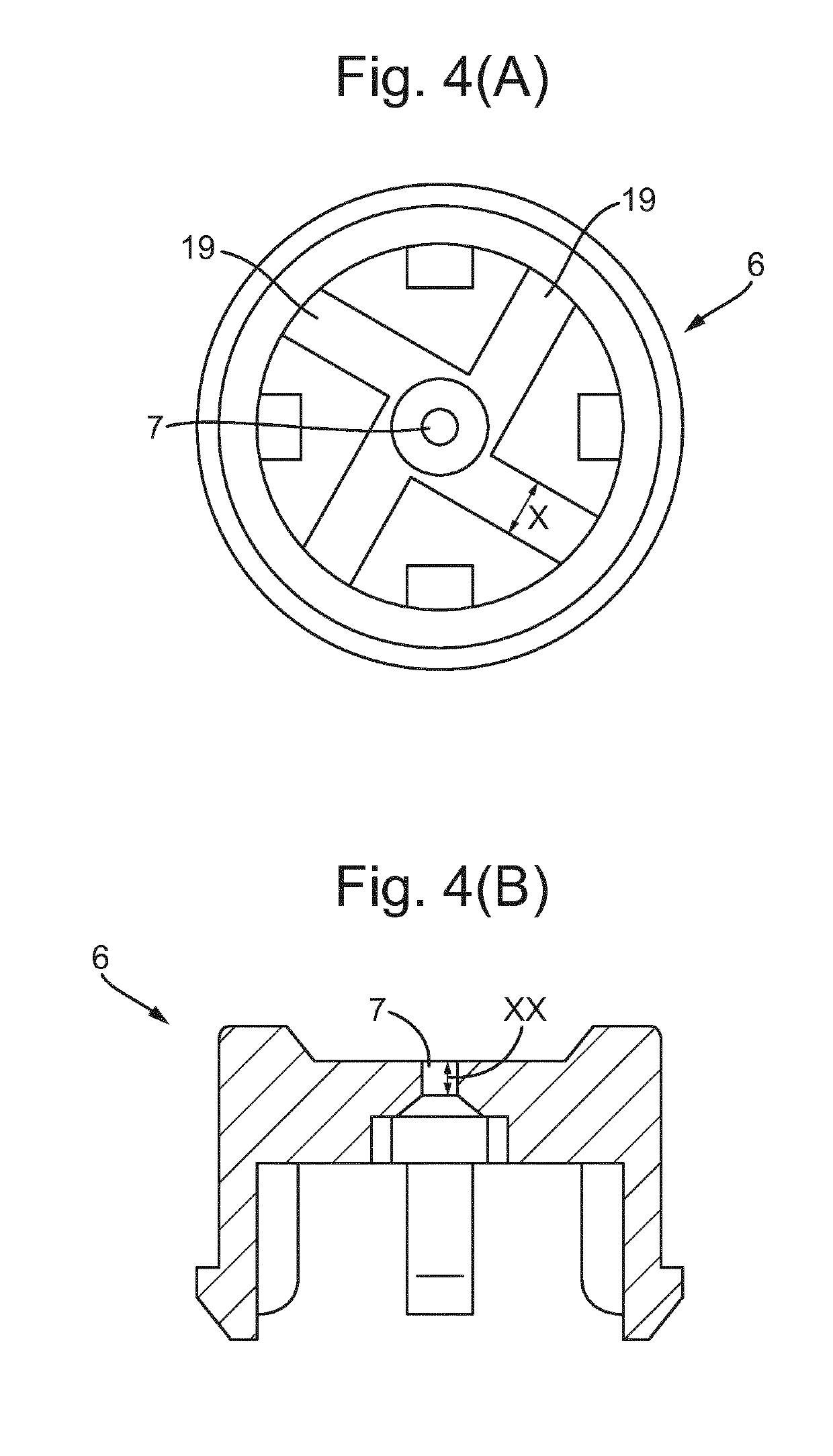

System and method for an enhanced hair dryer

ActiveUS10021952B2StructuredIncrease experienceDrying gas arrangementsHair dryingThe InternetEngineering

A system and method for an intelligent hair drying / styling apparatus with user information transmission and storage capabilities is herein provided. The hair drying / styling apparatus houses a control circuit board and an infrared or temperature sensor (or camera) in order detect an individual's hair condition moisture level to determine a user specific, customizable dryer setting. The information detected by the sensor is stored locally, on a proximal Internet-enabled device, or on a remote or cloud-based server and accessed by the hair drying / styling apparatus through a wireless local area network connectivity function. Accordingly, a user's hair temperature-drying profile may be stored and later recalled to provide optimal hair styling setting customized for that user. This innovation will enable any number of hair professionals and or end consumers to improve styling and dry time. Such a profile may contain a proprietary V-Factor calculation that will, among other applications, correspond to the use of a coordinated and optimized hair spray solution. According to the present invention, energy usage is reduced to enable a more efficient design.

Owner:SPUR CONCEPTS INC

Hair spray and hair mousse with natural ingredients

A naturally occurring film forming material for a hair spray or mousse, rather than a synthetic resin. A preferred naturally occurring film forming material is a polysaccharide, which is a sugar polymer with an INCI name of LEVAN. The film forming material may be mixed with any of a naturally occurring edible oil to add sheen to the hair, naturally occurring substances for antibacterial purposes and a naturally occurring fragrance and an emulsifier.

Owner:DIAMOND GEORGE B +1

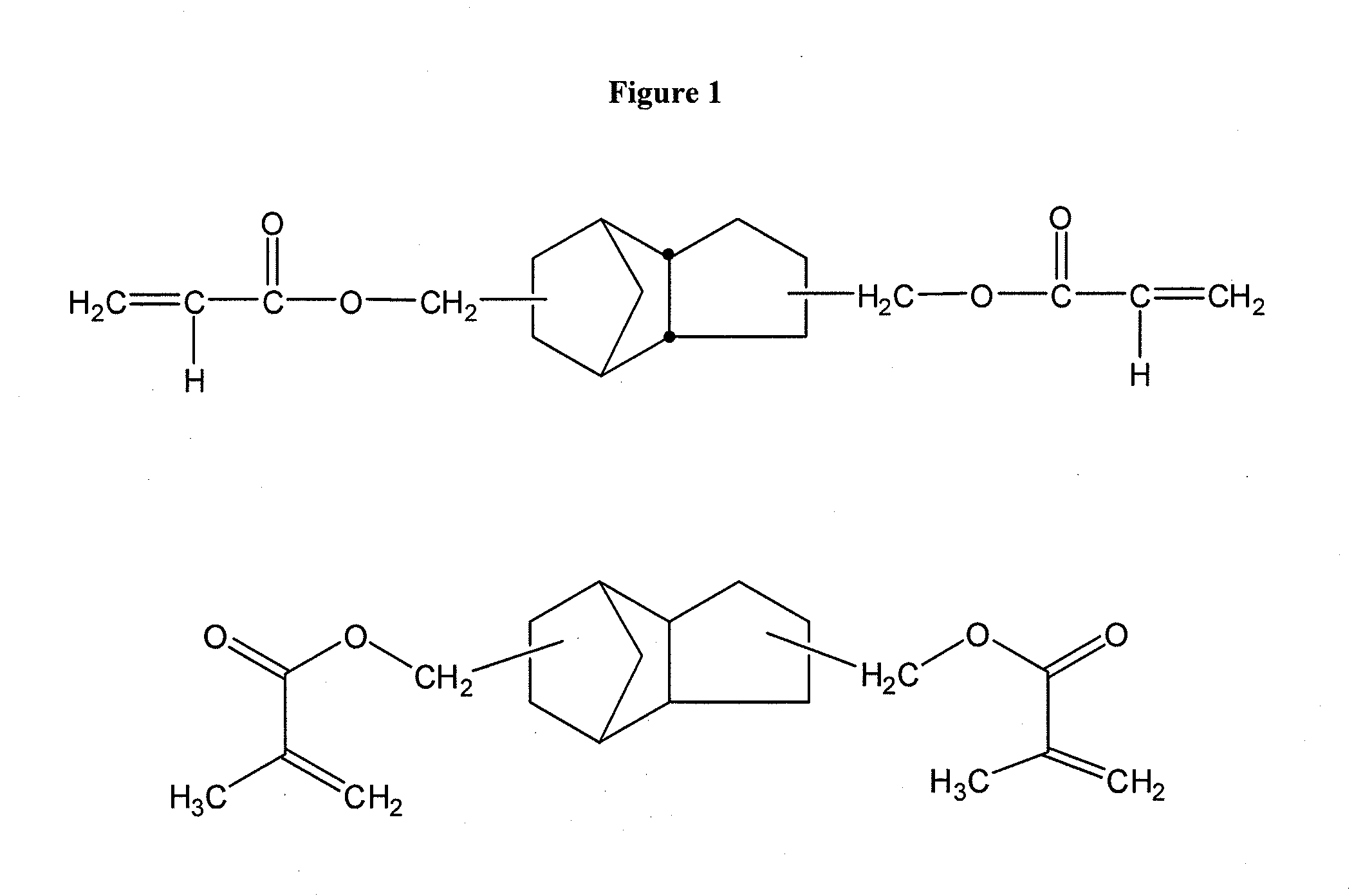

In Situ Polymerization For Hair Treatment

InactiveUS20110008265A1Long maintenance periodGood colorBiocideCosmetic preparationsSolubilityIn situ polymerization

Hair care products represent a world-wide multi-billion dollar industry. Pre-formed polymers are commonly used in a variety of hair care products including shampoos, conditioners, gels, and hair sprays. The present invention provides technology for polymerizing monomers on hair in situ to produce desired hair characteristics. This eliminates the solubility and application issues found with some polymers. The polymerization of monomers on hair is typically initiated using a thermal or photoinitiated free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the hair upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating hair with polymers.

Owner:LIVING PROOF INC

Method for inhibiting corrosion in an aqueous aerosol or foam hair styling composition

InactiveUS6368575B2Improve corrosion resistanceNegatively affecting performanceCosmetic preparationsHair removalEmulsionEmulsion polymerization

A method for improving the corrosion resistance of aerosol or foam hair spray formulations in metal containers is disclosed. In particular, the present invention involves the use of phosphate ester emulsifiers in the preparation of the emulsion polymer hair fixative resins to provide corrosion resistance of the hair styling composition in metal containers without negatively affecting the performance of the hair styling product itself. Use of the selected emulsifiers is particularly useful in non-corrosive aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

Ternary zwitterionic hair holding polymer for hair and preparation method thereof

The invention relates to a ternary zwitterionic hair holding polymer for hair and a preparation method thereof. The polymer is prepared from 40-70% of vinyl pyrrole subject reactive monomers, 15-30% of functional acrylic (salt) monomers providing negative ions, and 15-30% of nitrogen-containing reactive monomers by using a micromolecule polar compound containing hydroxyl as a reaction medium and azoisobutyronitrile or organic peroxides as a catalyst through the solution polymerization of free radicals and carrying out quaternization processing on the polymer. The polymer is colorless transparent sticky liquid with complete water solubility, and is suitable for various types of hair holding products, such as a gel type, a viscous liquid type, a spray gel type, an O\W emulsion type, a W\O emulsion type, a micro-emulsion type, spray type gel water, hair spray, and the like. Hair holding products, such as gel water and the like prepared by the polymer have the advantages of excellent hair holding, easy cleaning and smoothness, good affinity with hair, and good organization.

Owner:GUANGZHOU UNIVERSITY

Method of styling hair with aqueous based hair sprays

Cosmetic or personal care compositions comprise from 0.01% to 10% by weight of a hair styling polymer comprising one or more hydrophobic groups, from 0.001% to 10% by weight of an optionally substituted cyclodextrin and a cosmetically acceptable diluent or carrier. The cyclodextrin complexes with the hydrophobic groups to increase the solubility of the hair styling polymer in the composition. The cyclodextrin thus allows the formulation of compositions with relatively higher water contents.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

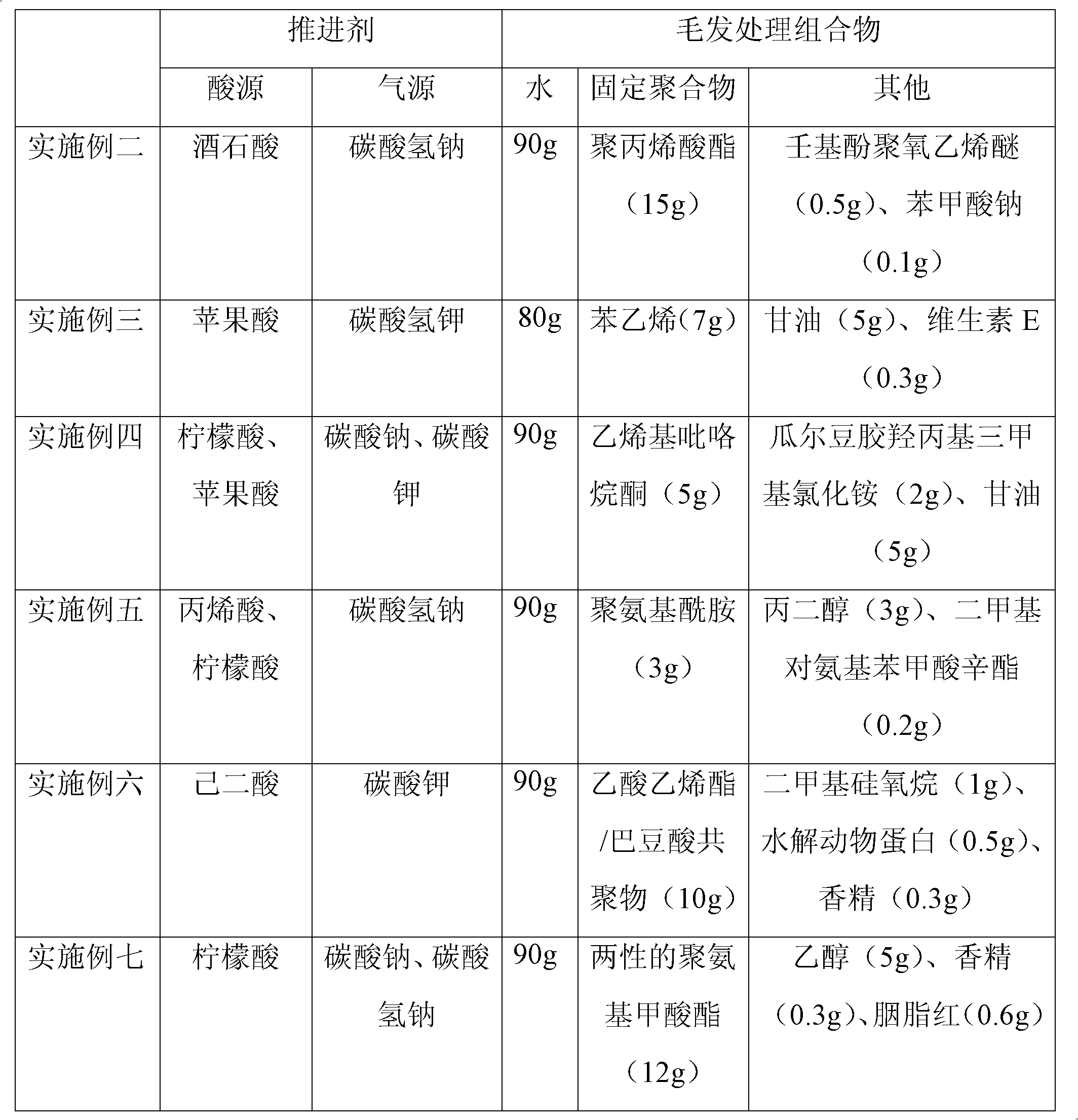

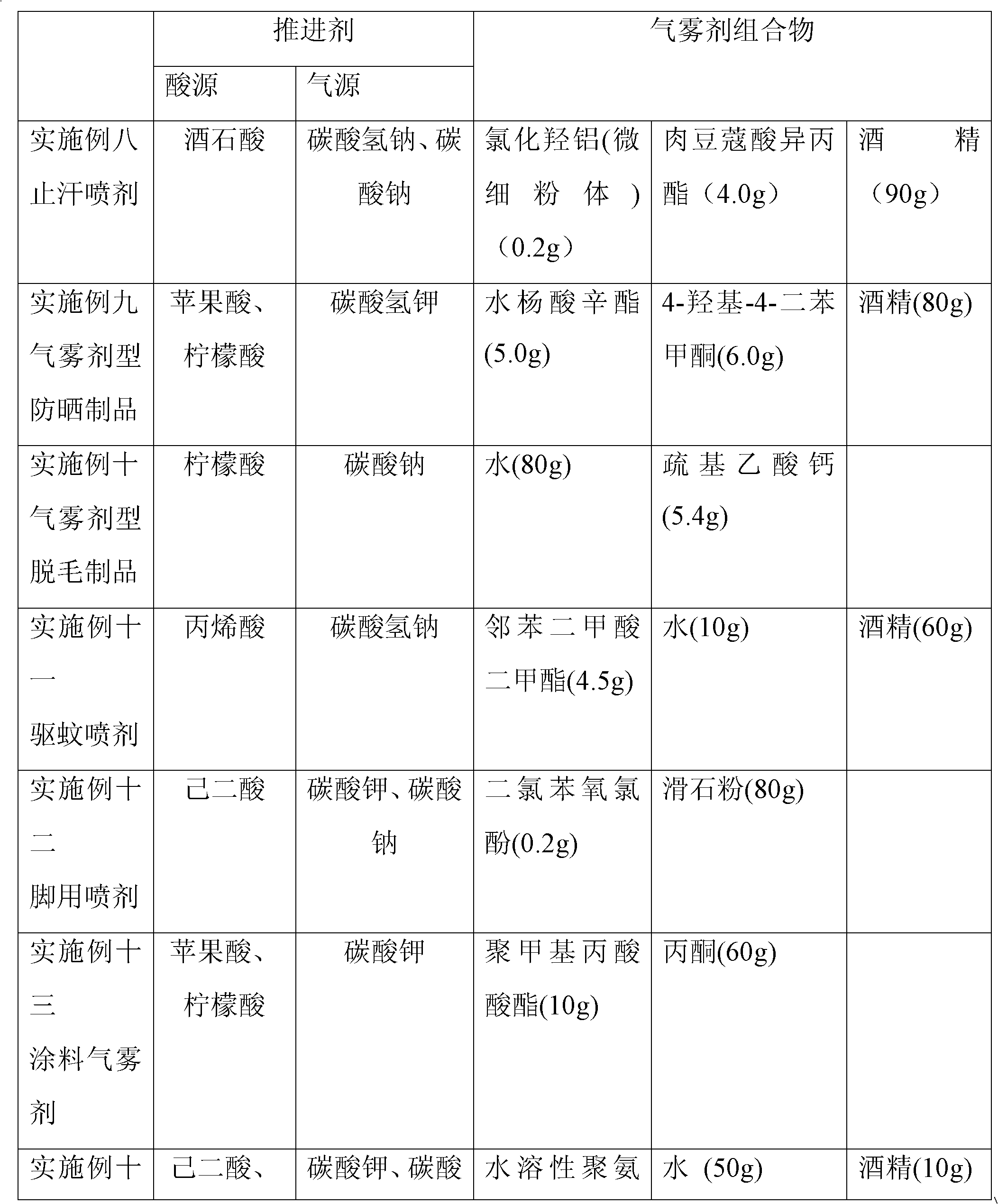

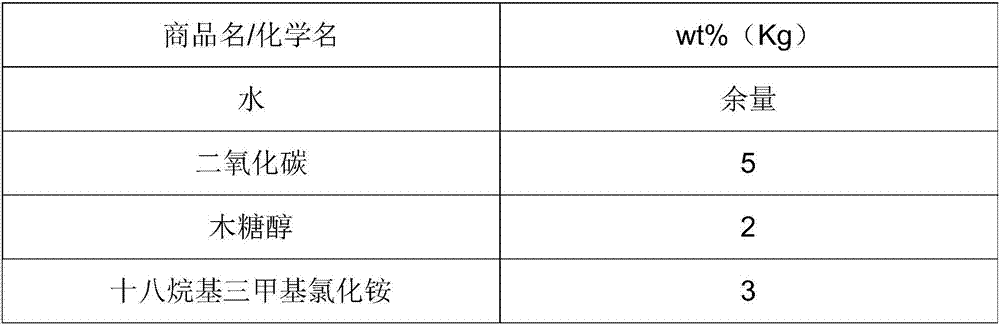

Low-pressure type propellant and application thereof

InactiveCN102058488AReduce energy consumptionReduce pollutionCosmetic preparationsHair removalSodium bicarbonateAdipic acid

The invention discloses a low-pressure type propellant which is formed by separated acid source and gas source, wherein the acid source is one or more of citric acid, crylic acid, tartaric acid, fumaric acid, adipic acid and malic acid, and the gas source is one or more of sodium carbonate, sodium bicarbonate, potassium bicarbonate and calcium carbonate. The application of the low-pressure type propellant can be used for daily chemicals comprising mousse, hair spray, unhairing articles, mosquitoes-dispelling articles, aerosol-type sunscreen articles, hidroschesis spray, aerosol-type shaving foam and foot spray. The invention also discloses a low-pressure mousse comprising a low-pressure type propellant and a hair processing composition. The invention broadens the service range and reduces the energy consumption of the aerosol-type product, reduces air pollution and improves the efficiency of the aerosol-type product.

Owner:广州好迪集团有限公司

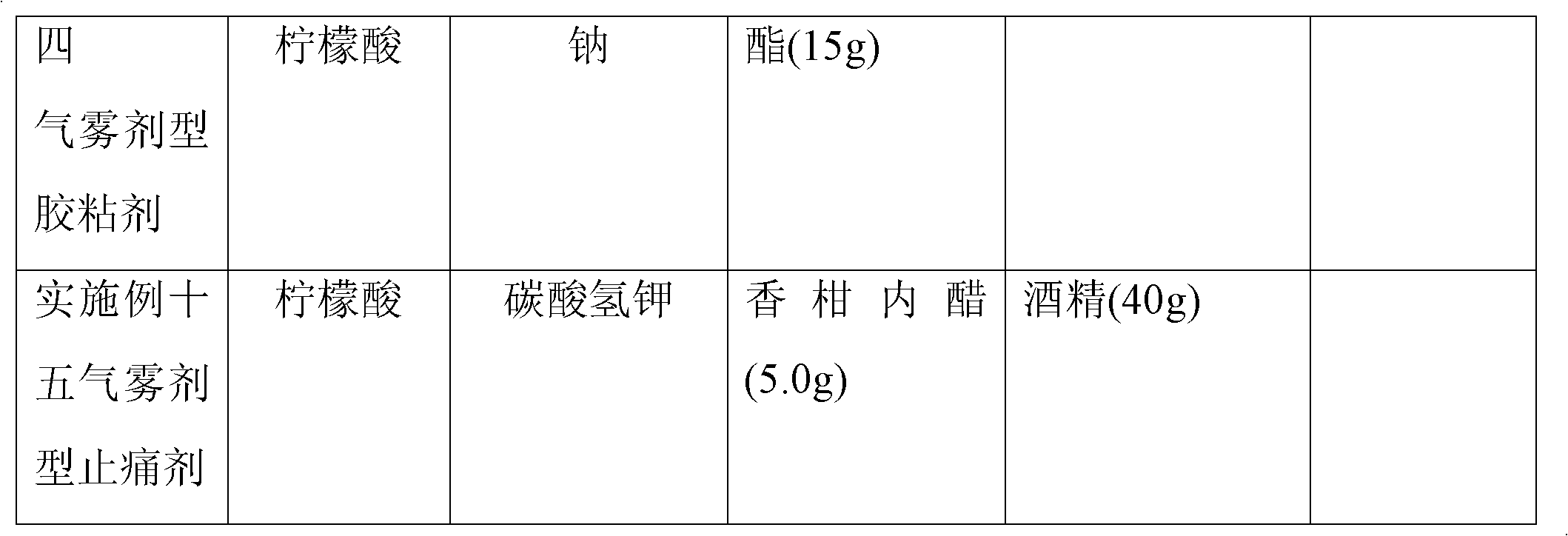

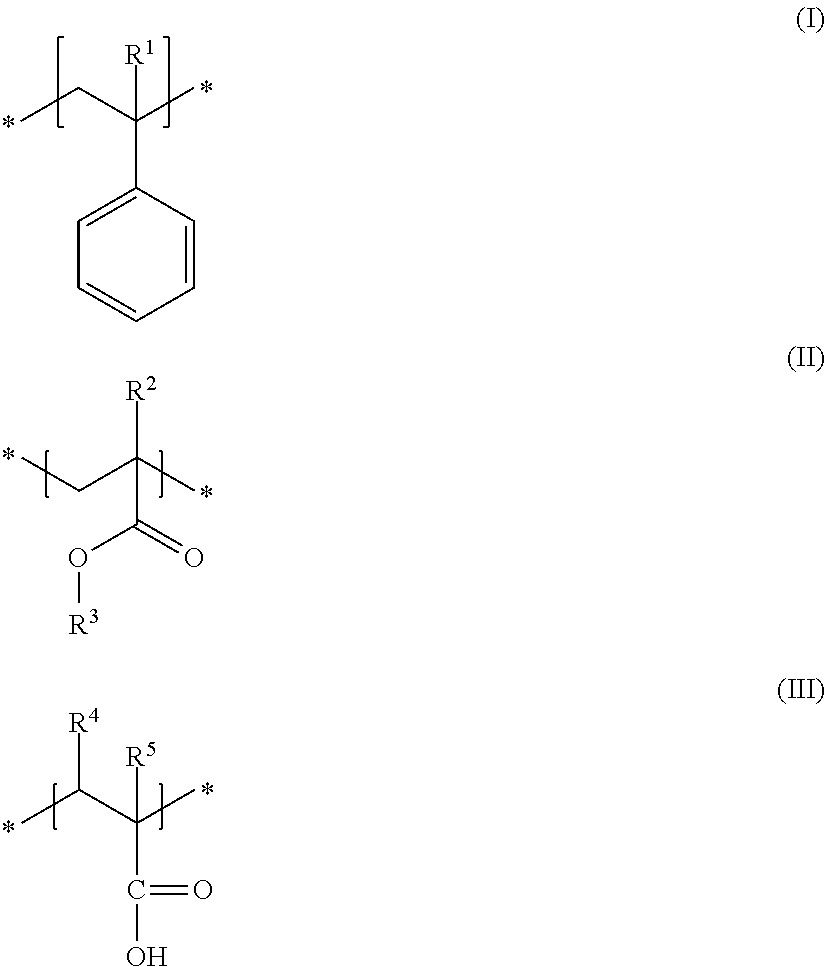

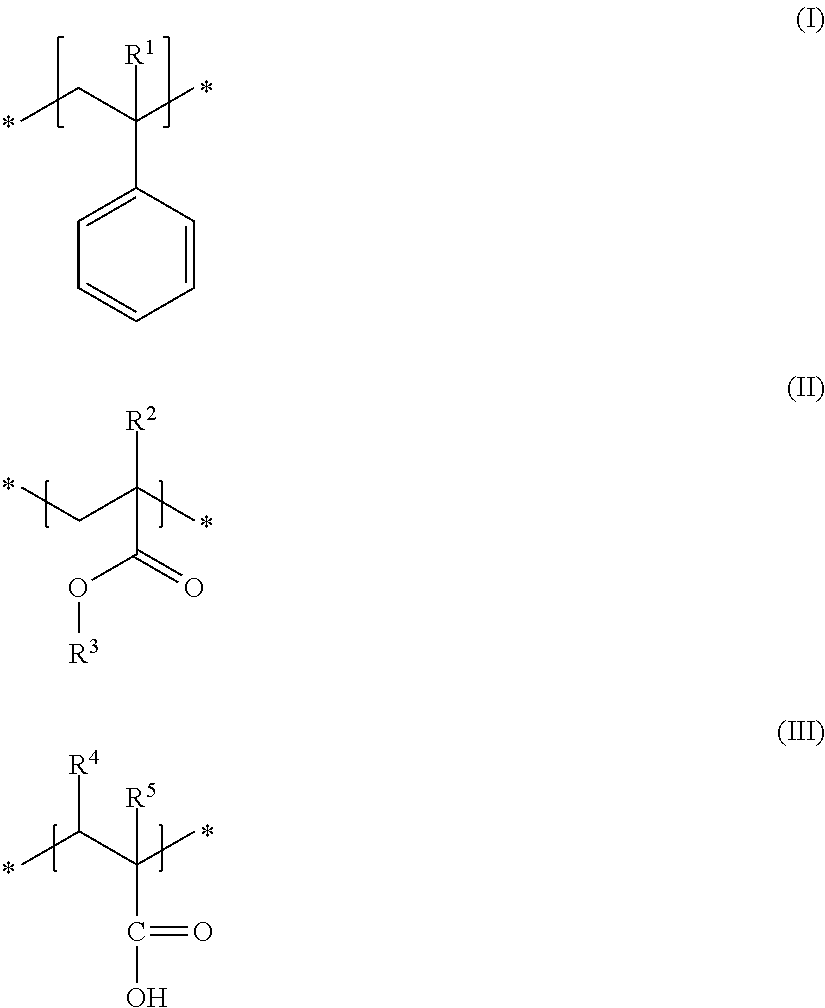

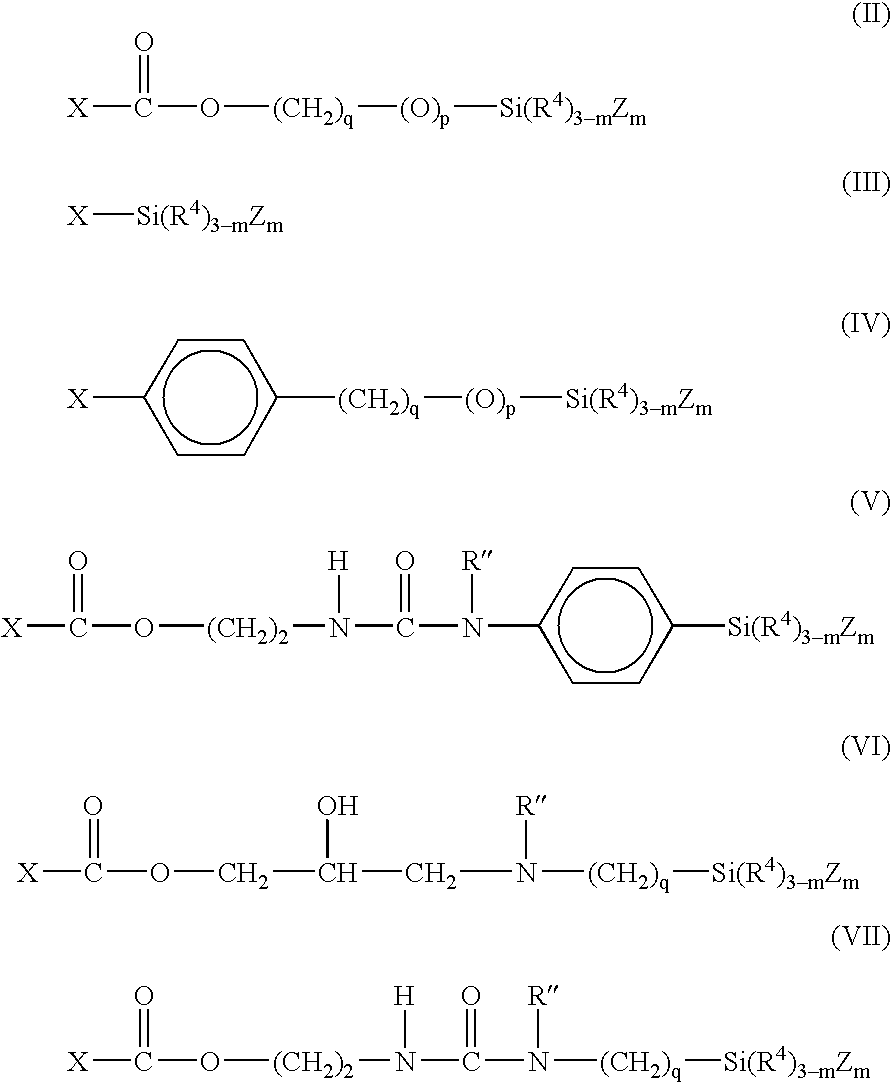

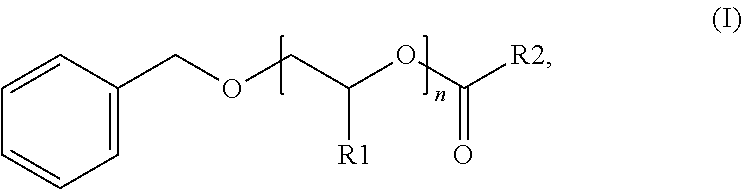

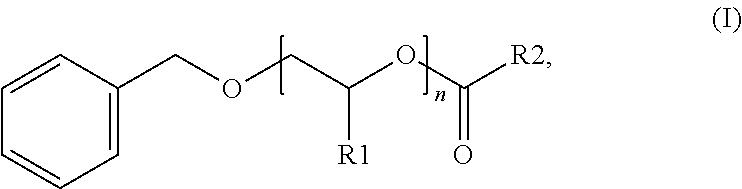

Shine-producing hair-styling product with a strong hold, providing hair with a pleasant feel

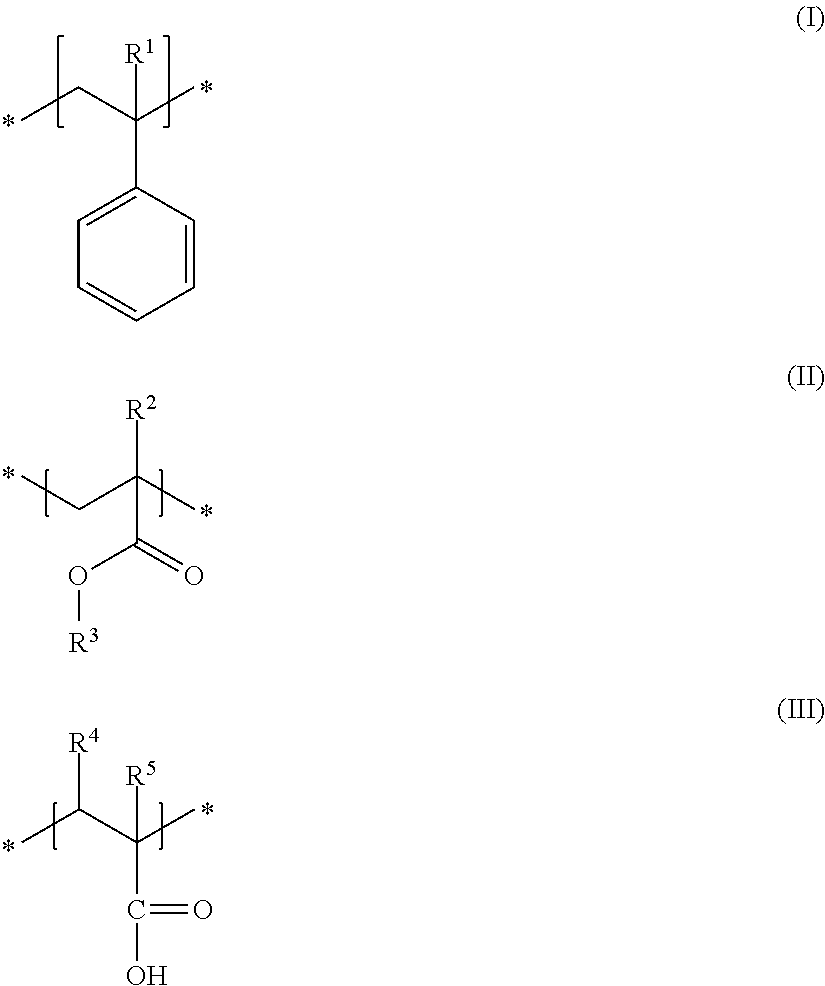

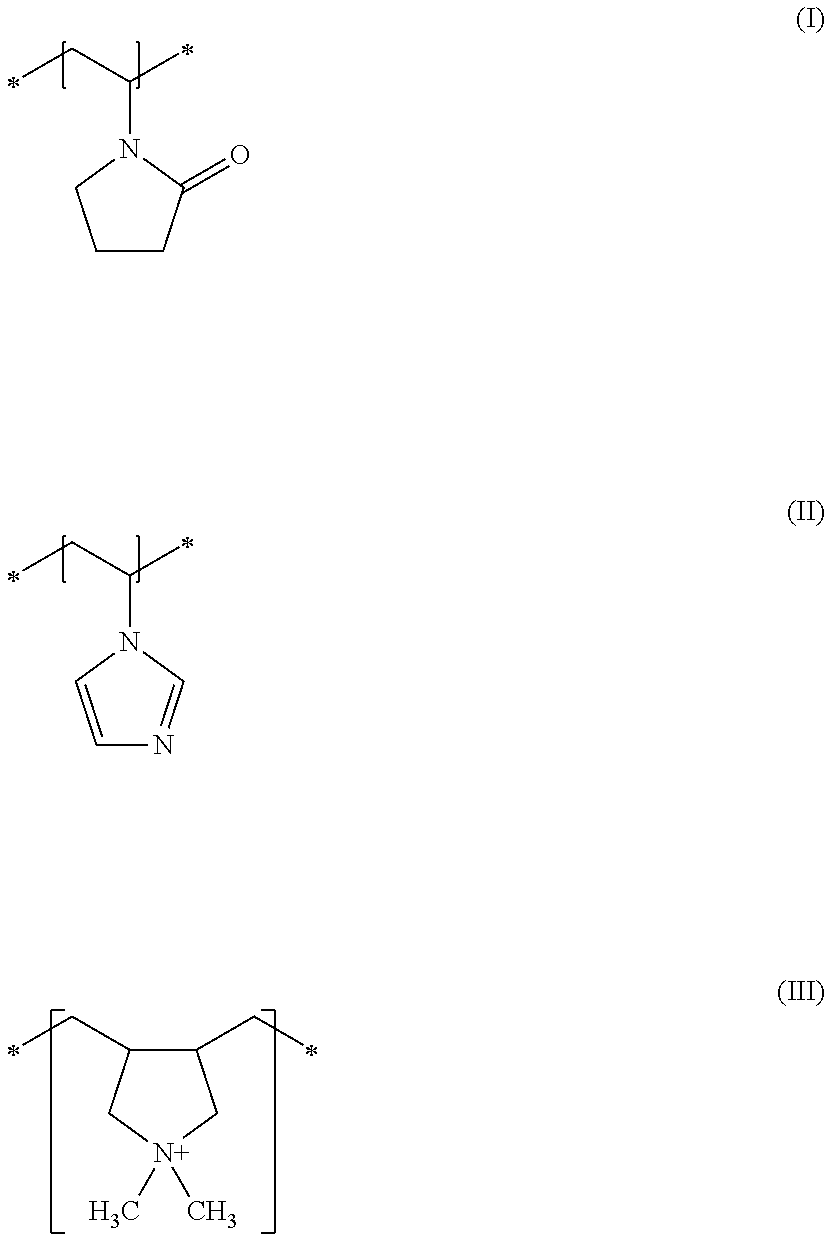

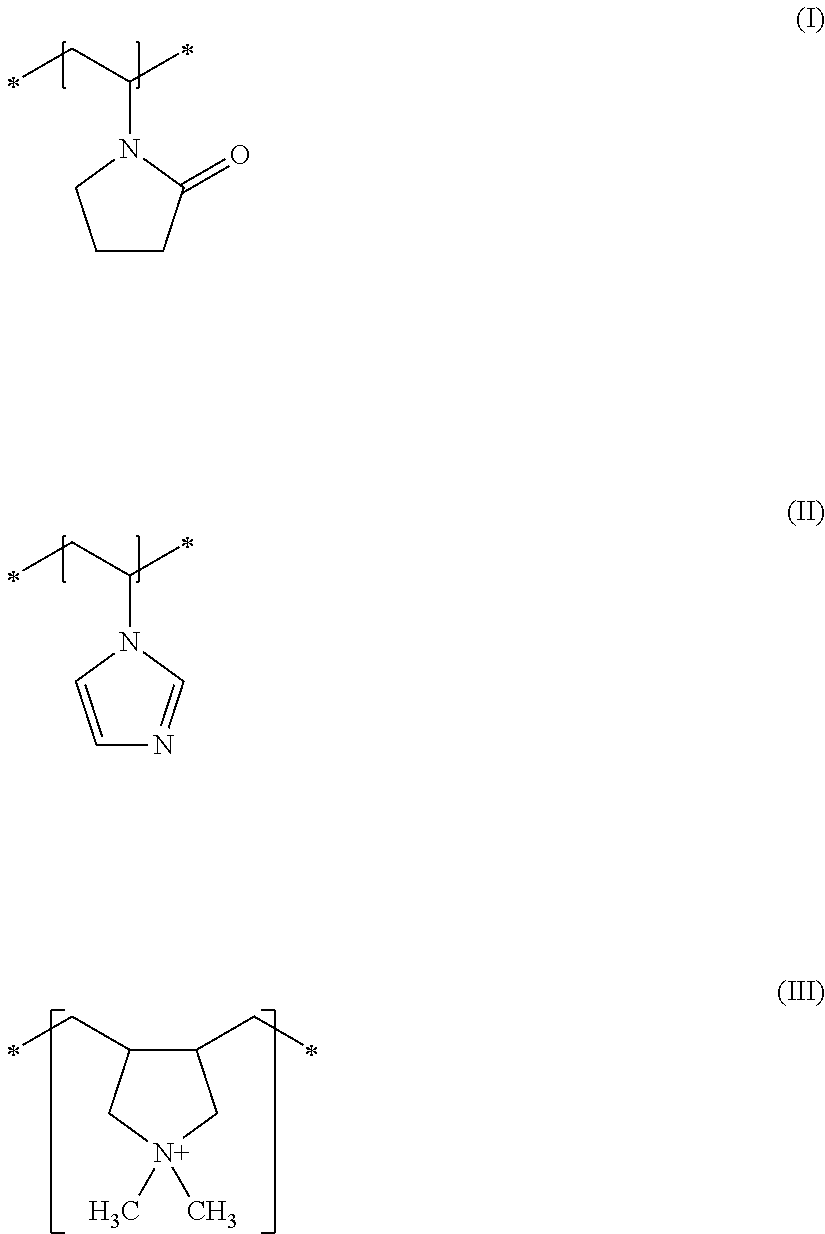

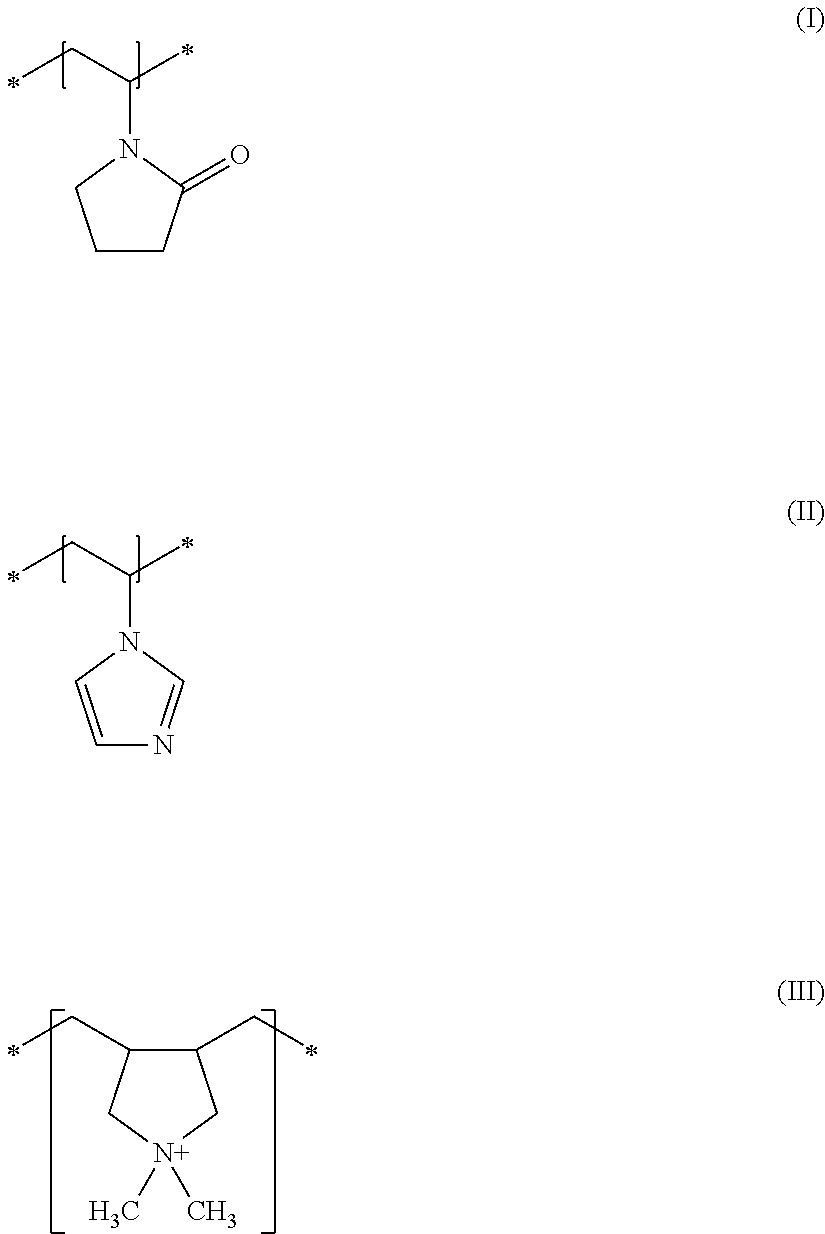

Agents for treating keratin-containing fibers, in particular human hair, containing, in a cosmetically acceptable carrier: at least one anionic setting copolymer encompassing at least one structural unit of formula (I) and at least one structural unit of formula (II) and at least one structural unit of formula (III), in which R1 denotes a hydrogen atom or a methyl group, R2 denotes a hydrogen atom or a methyl group, R3 denotes a branched (C1 to C20) alkyl group, a branched (C2 to C6) hydroxyalkyl group, or a *-(CH2CH2O)n—R6 group where R6=branched (C1 to C20) alkyl and n=1 to 30, R4 and R5 denote a hydrogen atom, or one of the two residues denotes a hydrogen atom and the other a methyl group, are suitable for temporary reshaping of hair and for imparting shine, in particular as an aerosol hair spray or aerosol hair foam.

Owner:HENKEL KGAA

Method for inhibiting corrosion in an aqueous aerosol or foam hair styling composition

InactiveUS20010003581A1Avoid corrosionImprove corrosion resistanceCosmetic preparationsHair removalEmulsionEmulsion polymerization

A method for improving the corrosion resistance of aerosol or foam hair spray formulations in metal containers is disclosed. In particular, the present invention involves the use of phosphate ester emulsifiers in the preparation of the emulsion polymer hair fixative resins to provide corrosion resistance of the hair styling composition in metal containers without negatively affecting the performance of the hair styling product itself. Use of the selected emulsifiers is particularly useful in non-corrosive aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

Washing-free hair spray and preparation method thereof

InactiveCN108524325ARestoring freshness and cleanlinessConserve waterCosmetic preparationsHair cosmeticsButaneChemistry

The invention relates to a washing-free hair spray. The washing-free hair spray is characterized by being prepared from the following components in percentage by weight: 65 to 85 percent of propyl butane, 10 to 25 percent of absolute ethanol, 10 to 20 percent of corn starch, 0.1 to 0.2 percent of cetrimonium chloride amine and 0.5 to 1.2 percent of perfume type essence. A preparation method of thewashing-free hair spray comprises the following steps: adding the absolute ethanol in a burdening kettle, and stirring at a speed of 500r / min; then respectively adding and dissolving the cetrimoniumchloride amine and the perfume type essence; adding the corn starch in the burdening kettle, and then stirring for 25 minutes; finally sealing in a white plastic barrel. The washing-free hair spray disclosed by the invention is capable of refreshing hairs immediately, fluffy hairs can feel clean and refresh, and the vitality of the hairs can be recovered; meanwhile, the problems of water conservation and environment protection are solved.

Owner:佛山市顺德区香江精细化工实业有限公司

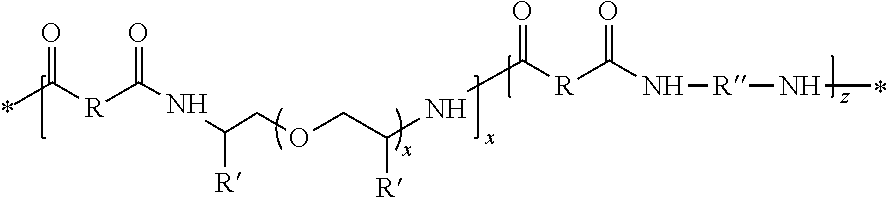

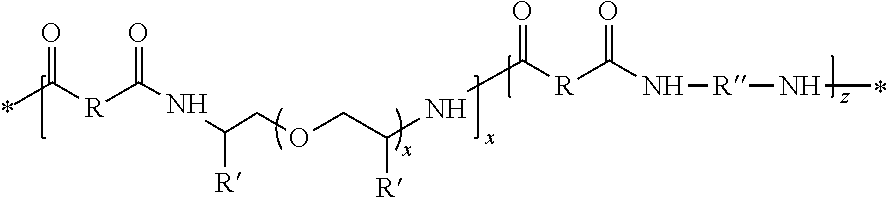

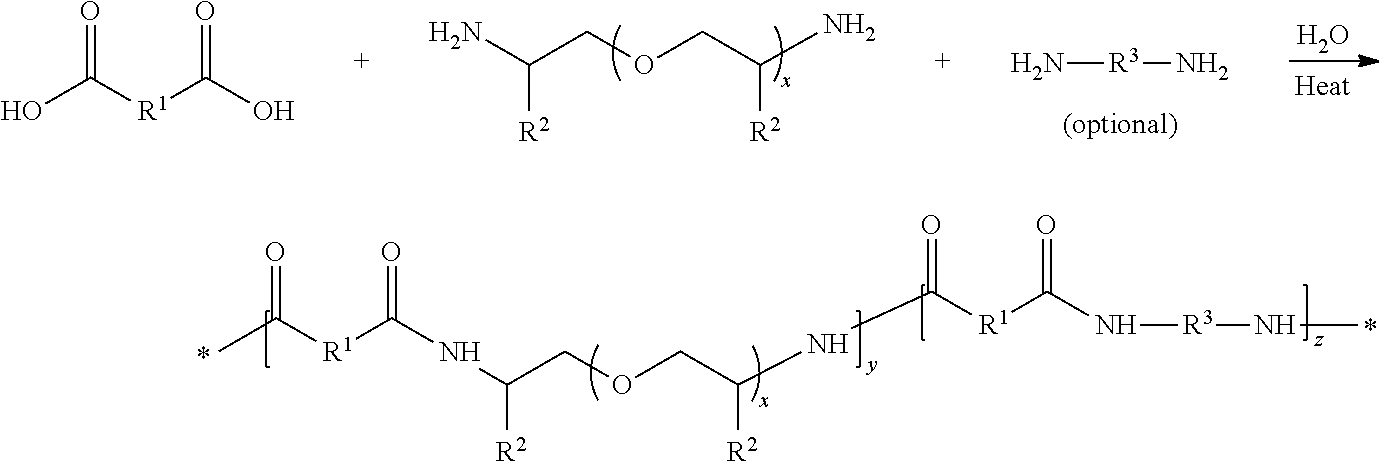

Polyetheramide compositions

InactiveUS20110136989A1Improve performanceAvoid poor resultsCosmetic preparationsHair cosmeticsPersonal carePolymer science

Ethanol soluble or dispersible polyetheramide polymers that have a percent elongation to break of less than 100%. The polymers are formed from a reaction mixture comprising at least one or more poly(alkyleneoxy) diamines and one or more diacids. The reaction mixture can optionally include one or more aliphatic diamines in addition to the one or more poly(alkyleneoxy) diamines. The polyetheramide polymers have application in personal care compositions such as hair fixative compositions, for example, hair spray formulations.

Owner:AKZO NOBEL NV

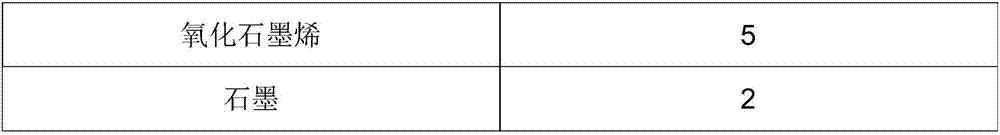

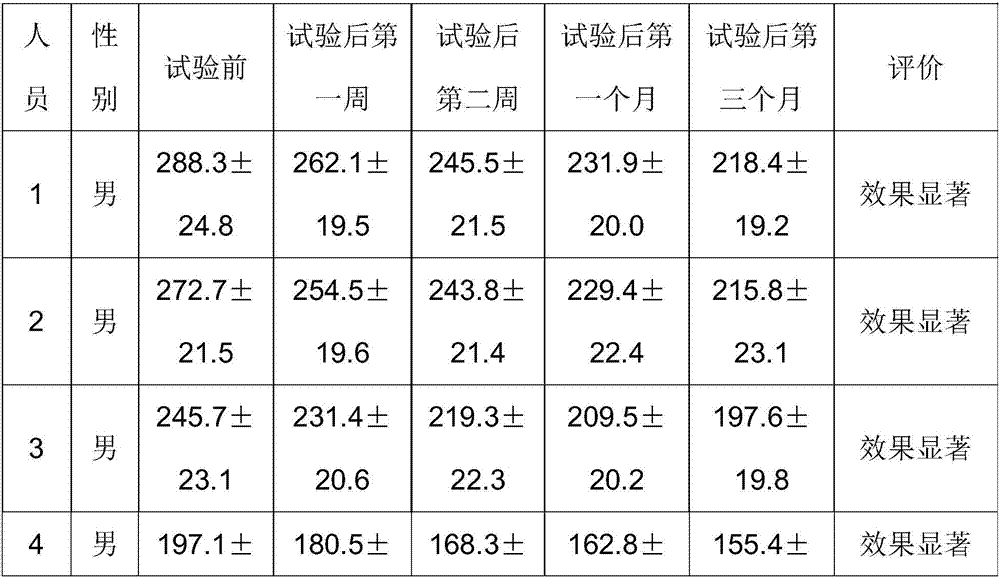

Graphene hair spray and preparation method thereof

InactiveCN107982074AReduce forksReduce drynessCosmetic preparationsHair cosmeticsPreservative freePreservative

The invention discloses graphene hair spray and a preparation method thereof. The graphene hair spray is mainly prepared from the following components in parts by weight: 60 to 96 parts of water, 1 to10 parts of essence, 1 to 10 parts of a spraying agent, 1 to 10 parts of a conditioner and 1 to 20 parts of graphene. Meanwhile, the invention further discloses the preparation method of the hair spray. By adopting the graphene hair spray disclosed by the invention, hairs can have proper hardness and elasticity and color and luster are kept for a long time; proper bulkiness and aroma are kept andthe hair spray is not sticky, does not easily fall off and is easy to wash off; meanwhile, the graphene is added so that hair splitting, falling and damages can be reduced, dandruff is removed and scalp oil is adsorbed. The graphene hair spray does not contain toxic and harmful substances including a preservative and the like, so that the graphene hair spray is green and environmentally friendlyand can ensure health of scalp, hair and body.

Owner:HANGZHOU GAOXI TECH CO LTD

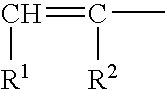

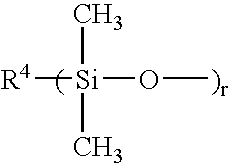

Aerosol hair spray compositions comprising combinations of silicone-grafted copolymers

Disclosed are aerosol hair spray compositions which comprise a first and a second silicone-grafted copolymer, wherein the copolymers exhibit a dichotomous viscosity behavior which results in superior hold and excellent hair feel benefits, and a method of styling hair comprising applying to the hair an effective amount of the above composition. The aerosol hair spray compositions comprise: (A) from about 0.1% to about 10% by weight of said composition, of a first silicone-grafted copolymer comprising a vinyl polymeric backbone and a polysiloxane macromer grafted to said vinyl polymeric backbone, (i) wherein said first silicone-grafted copolymer is formed from the copolymerization of randomly repeating hydrophilic monomer units, herein designated A, and hydrophobic monomer units, herein designated B, (a) wherein said vinyl polymeric backbone comprises from about 10% to about 50%, by weight of said first silicone-grafted copolymer, of copolymerizable hydrophilic A monomers, (b) wherein said vinyl polymeric backbone comprises from 0% to about 85%, by weight of said first silicone-grafted copolymer, of copolymerizable hydrophobic B monomers, (c) wherein said polysiloxane macromer comprises from about 5% to about 50%, by weight of said first silicone-grafted copolymer, of polysiloxane-containing monomer units, (ii) wherein said polysiloxane macromer has a weight average molecular weight from about 500 to about 50,000; and (iii) wherein said first silicone-grafted copolymer has a weight average molecular weight from about 10,000 to about 500,000; (B) from about 0.1% to about 5% by weight of said composition, of a second silicone-grafted copolymer, comprising a vinyl polymeric backbone and a polysiloxane macromer grafted to said vinyl polymeric backbone, (i) wherein said second silicone-grafted copolymer is formed from the copolymerization of randomly repeating hydrophobic monomer units, herein designated B, (ii) wherein said polysiloxane macromer comprises from about 10% to about 40%, by weight of said second silicone-grafted copolymer, of polysiloxane-containing monomer units, (iii) wherein said polysiloxane macromer has a weight average molecular weight from about 5,000 to about 50,000, (iv) wherein said second silicone-grafted copolymer has a weight average molecular weight from about 300,000 to about 5,000,000, and (v) wherein said first silicone-grafted copolymer is present, relative to said second silicone-grafted copolymer, by weight, in a ratio from about 2:1 to about 26:1; (C) a neutralizing system, (D) from about 20% to about 50%, by weight of said composition, of a propellant; and (E) the balance comprising a carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Longer-holding hairspray

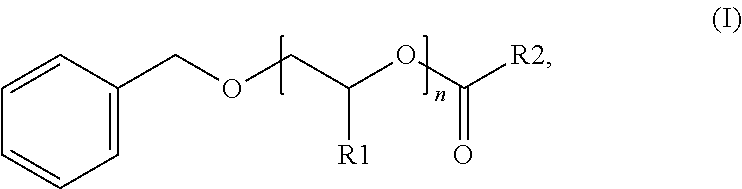

The invention relates to hair sprays comprising a pressurized container and an aerosol composition, located therein, which includes, based on its weight, 20 to 80% by weight of at least one propellant, 0.1 to 20% by weight of at least one fixing polymer, and 0.01 to 5% by weight of esters of the formula (I), in which R1 stands for —H or —CH3, R2 for a straight-chain or branched alkyl group having 7 to 15 carbon atoms, and n for an integer from the group comprising 1, 2, 3, 4, 5, 6, 7, 8; the hair sprays bring about an improved hair feel, improved lightness of the hairstyle, and improved hair texture, also with further improvement of the hold.

Owner:HENKEL KGAA

Products for keratin fibers, containing at least one special cationic polymer a having vinylimidazole structural units and at least one special alkoxylated cationic surfactant

Agents for treating keratin-containing fibers, particularly human hair, containing in a cosmetically acceptable carrier (a) at least one cationic polymer having at least one structural unit of formula (I), at least one structural unit of formula (II), and at least one structural unit of formula (III),and (b) at least one cationic surfactant of formula (IV),wherein x and y are independently an integer number greater than 0, R is a (C8 to C20) alkyl group or a (C8 to C20) alkenyl group, R′ is a *—(CH2CH2O)zH group wherein z is an integer number greater than 0, a (C8 to C20) alkyl group or a (C8 to C20) alkenyl group, and X− is a physiologically acceptable anion. The agents are gentle and can be used as hair care agents having outstanding styling properties, particularly in the form of an aerosol hair spray or aerosol hair foam.

Owner:MUELLER BURKHARD +1

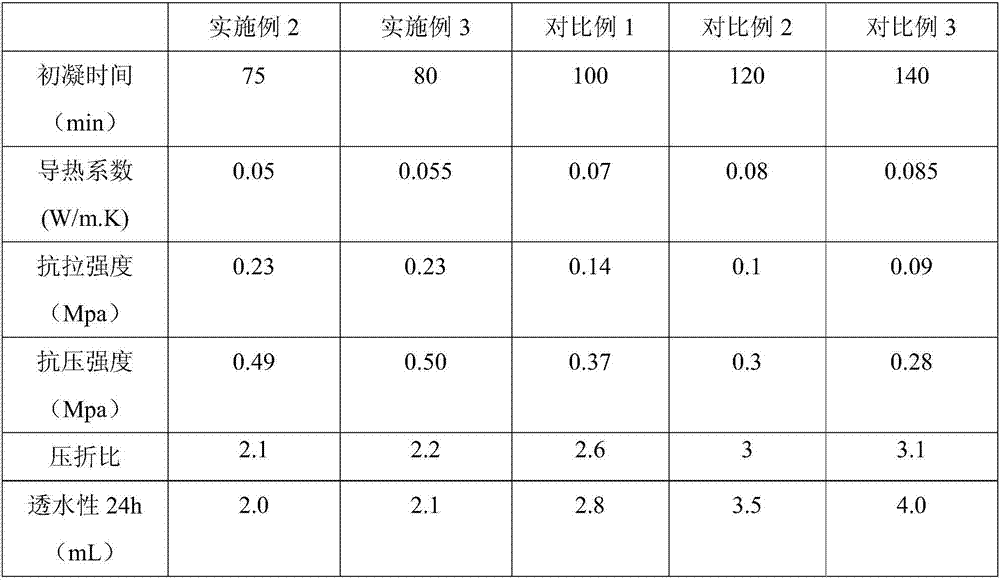

Construction technique for composite mortar

ActiveCN106906967AImprove workabilityGood early strength effectCovering/liningsFiberCarboxymethyl cellulose

The invention provides a construction technique for composite mortar and belongs to the technical field of buildings. The construction technique specifically comprises the following steps that a polished wall face is washed firstly, and the wall face is subjected to hair spraying treatment through a wall body interface agent, wherein the wall body interface agent is prepared by blending cement, sand, an additive and water, and the additive comprises carboxymethyl cellulose sodium, wood fibers, flexible rubber powder, a water-retaining agent, a water reducing agent and a water repellent; then the wall body surface is subjected to anchoring; and finally the wall face is subjected to composite mortar layered spraying through a dedicated mortar spray gun, and water spraying maintenance is noticed, wherein the composite mortar comprises cement, mineral sand, prefabricated coal powder ash, glazed hollow beads and an additive. According to the construction technique for the composite mortar, the anti-cracking and waterproof effects of the composite mortar can be improved, the used composite mortar has the advantages of being safe and innoxious and has the characteristics of being good in workability and capable of achieving the anti-cracking, heat-insulation, heat-preservation, waterproof, high-strength and corrosion-resistance effects, and building cost can further be reduced.

Owner:广西绿地涂装工程有限公司

Styling hair spray and preparation method thereof

InactiveCN106806253AImprove uniformityImprove bindingCosmetic preparationsHair cosmeticsSolubilityFilm-forming agent

The invention discloses a styling hair spray and a preparation method thereof. The invention relates to a styling hairdressing product and particularly relates to a styling hair spray which contains the following substances in parts by weight: 1-3 parts of grease, 1-3 parts of emulsifier, 0.2-1 part of stabilizer, 3-12 parts of film forming agent, 15-20 parts of conditioner and 5-15 parts of moisturizer. Appropriate xanthan gum mixed with metal ions is added into the hair spray to replace waxy substances in pomade, and the water solubility enables the xanthan gum to be easily cleared in a cleaning process; the xanthan gum has a good bonding effect with the film forming substance in the hair spray; by adding the emulsifier, a good emulsifying effect can be realized at relatively low stirring speed, and the storage time is relatively long; and the substances in the hair spray are of high homogeneity, and the viscosity can reach 6,000-8,000cp to realize a satisfactory styling effect.

Owner:田鹏新

Hair compositions and methods of use thereof

ActiveUS10987286B2Increase hair volumeLow densityCosmetic preparationsHair cosmeticsPolymer scienceMicrosphere

Owner:LIVING PROOF INC

Hair compositions and methods of use thereof

ActiveUS20180000699A1Increase hair volumeLow densityCosmetic preparationsHair cosmeticsPolymer chemistryPolymer

Hair spray compositions comprising a liquid carrier, hollow, fluid-filled micropspheres, a polymer fixative, and propellant are provided.

Owner:LIVING PROOF INC

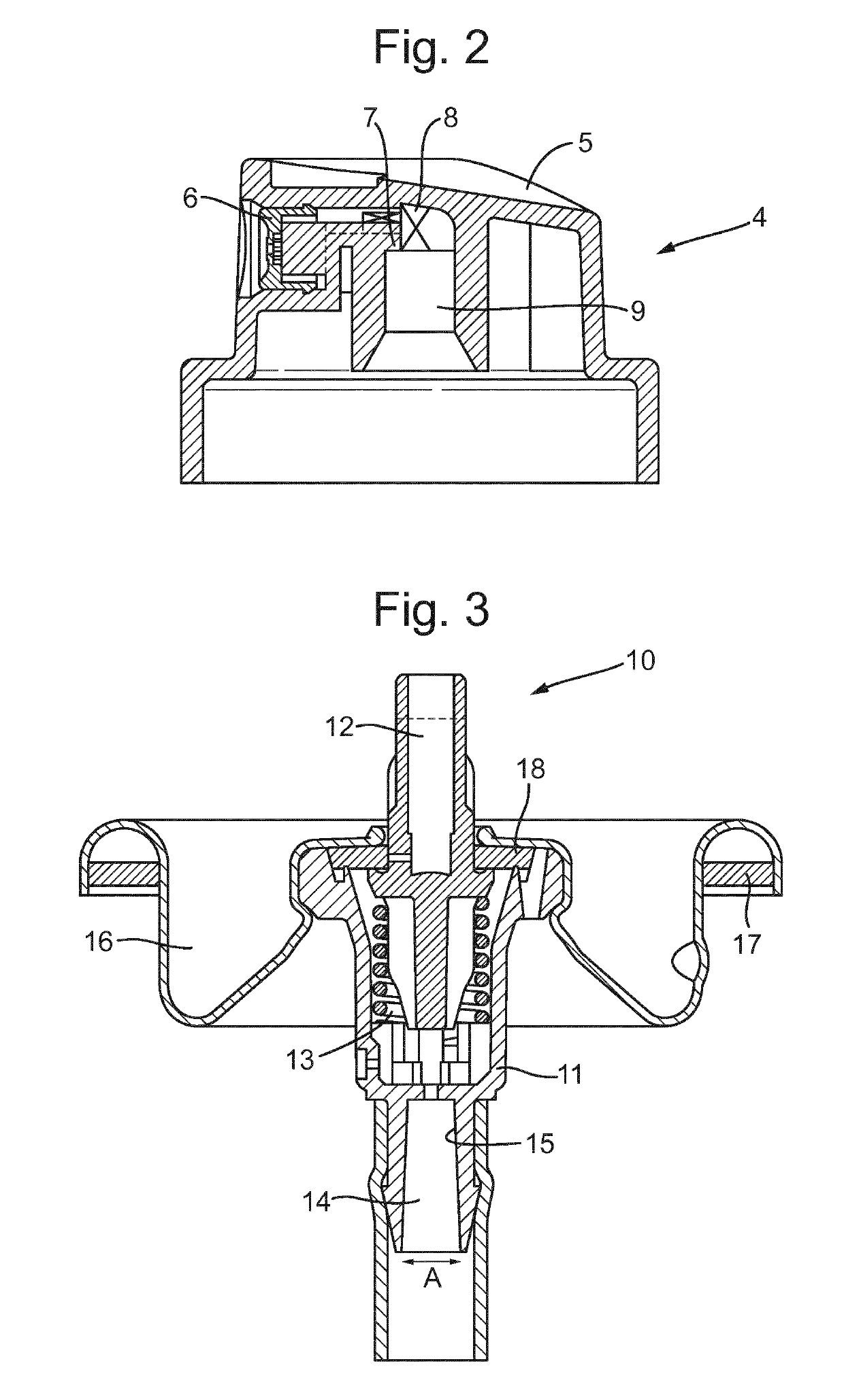

Compressed hair spray

An aerosol hairspray product includes a pressurisable container having a propellant and a container wall which encloses a reservoir, a hairstyling formulation having from 20 wt % to 75 wt % water, by total weight of the hairstyling formulation and propellant and from 1.0 wt % to 15 wt % hairstyling polymer, by total weight of the hairstyling formulation and propellant, and a spraying device attached to the pressurisable container and having a valve and an actuator. The reservoir is configured to store the hairstyling formulation. The valve has a spring means, a valve body having a stem, a restricted tail piece (RTP) having a first diameter of from 0.1 mm to 2.5 mm, and a vapour phase tap (VPT) having a second diameter of from 0.1 mm to 1.5 mm. The actuator has a main spray channel and communicates with an insert.

Owner:CONOPCO INC D B A UNILEVER

Ethanol-free washing-free hair spray

PendingCN113116752AGood conditioning effectGood dispersionCosmetic preparationsHair cosmeticsSolvent freeSilicone oil

The invention relates to the field of washing-free hair spray, and discloses ethanol-free washing-free hair spray which comprises a propellant, dipolysiloxane and starch, the weight ratio of the dipolysiloxane to the starch is (10-20): (80-90). The spray adopts a solvent-free formula, most ethanol allergy can be avoided due to the absence of ethanol, and meanwhile, we surprisingly find that the solvent-free formula has an obvious promoting effect on the performance of the silicone oil.

Owner:清远市立道精细化工有限公司

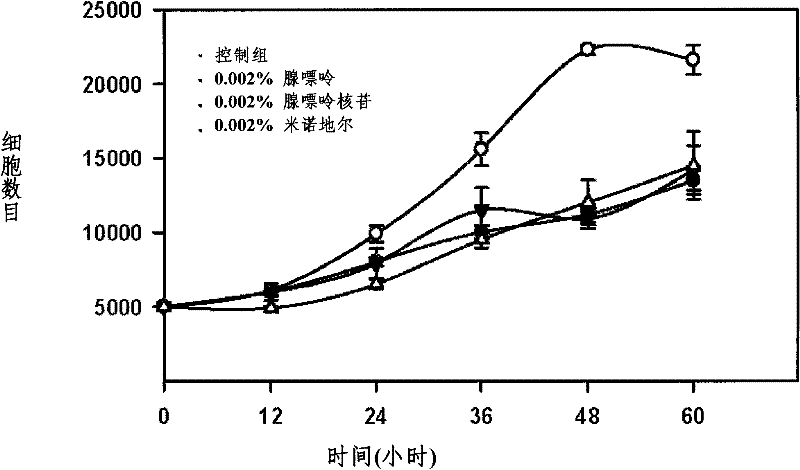

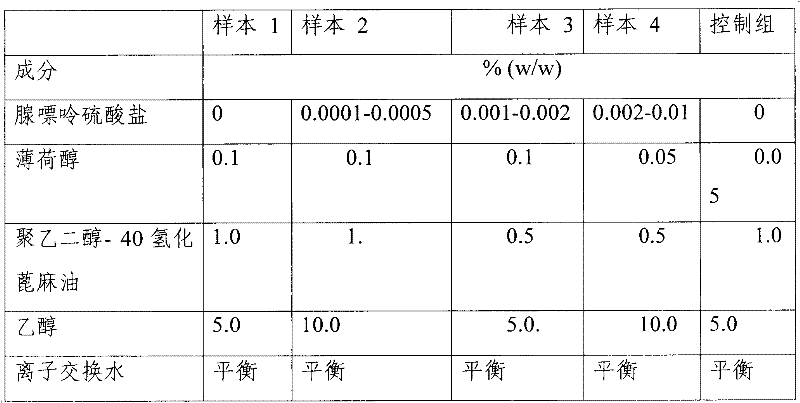

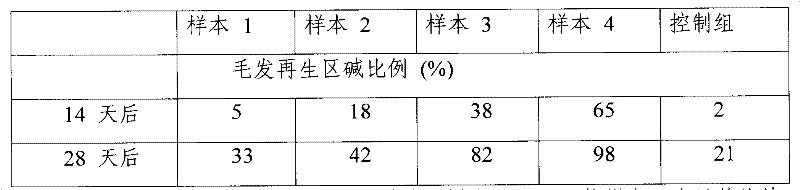

Hair growth promoter

InactiveCN102475633APromote growthPrevent hair lossCosmetic preparationsHair cosmeticsEyelashCosmetic vehicle

The invention relates to a hair growth promoter, mainly comprising adenine or adenine salts as active substances, and a cosmetic carrier, wherein the active substances account for more than 0.0001% (by weight) of the composition, and the cosmetic carrier is lubricant, solvent, humectant or thickener. The hair growth promoter of the invention can be applied in hair lotion, hair cleaning lotion, hair conditioning lotion, hair care gel, hair spray, shampoo or other related products. The hair growth promoter not only has the effect of promoting hair growth, but also has the effects of preventing alopecia, and promoting growth of eyelashes and eyebrows.

Owner:ENERGENESIS BIOMEDICAL

Aerosol hair spray compositions comprising combinations of silicone-grafted copolymers

InactiveCN1349399AEasy to shapeHigh viscosity propertiesCosmetic preparationsHair cosmeticsViscosityPolymer chemistry

Owner:THE PROCTER & GAMBLE COMPANY

Style-fixing hair spray made from composite plant gum

The invention provides a style-fixing hair spray made from composite plant gum and relates to the field of hair care, in particular to a style-fixing hair spray manufacturing technology. The style-fixing hair spray is characterized by being prepared from the algal polysaccharide composite plant gum, pelvetia silquosa, bacillus licheniformis, guar bean gum, blubber alcohol, a dalbergia greveana extract, sodium alginate, ramie fibers, locust bean gum and fructose. The adopted composite plant gum makes a fixed shape not be rigid, is free of residues, mild, non-irritant and has antibacterial, health-care and strong-scurf-removing functions.

Owner:黄剑忠

Horizontal apparatus for processing printed circuit boards and method for processing printed circuit boards

InactiveCN102264192AReduce water consumptionReduce environmental costsConductive pattern polishing/cleaningEngineeringPrinted circuit board

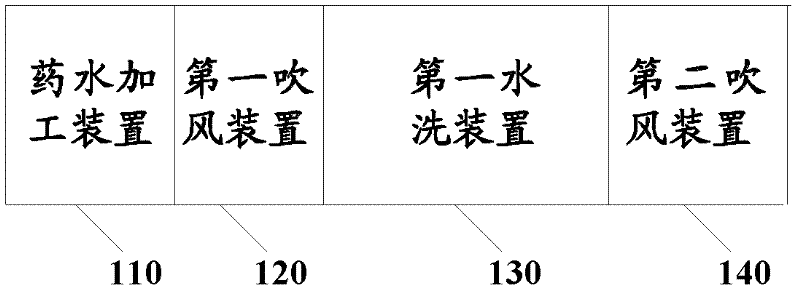

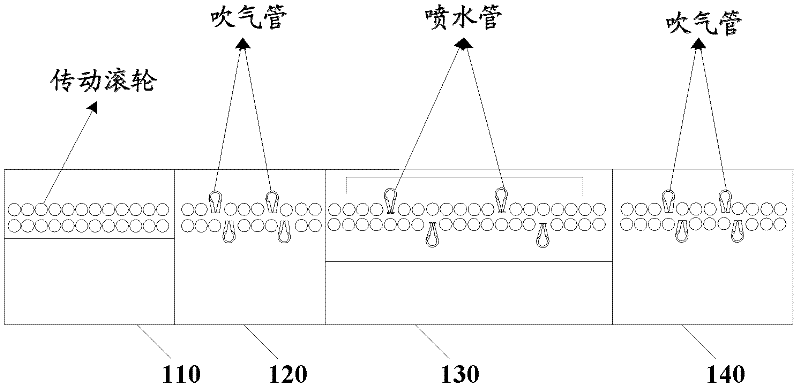

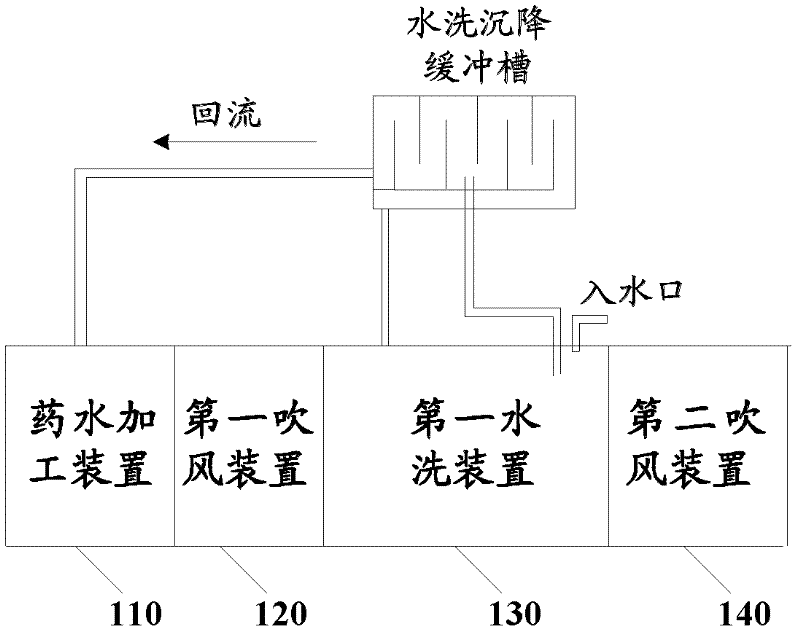

The embodiment of the invention discloses a horizontal device for processing printed circuit boards and a method for processing printed circuit boards. Among them, a horizontal equipment for processing printed circuit boards, including: a liquid medicine processing device, a first blowing device, a first washing device and a second blowing device; wherein, the first blowing device is used to process the liquid medicine through the liquid medicine processing device The board surface of the printed circuit board is blown; the first water washing device is used to spray water to the printed circuit board processed by the first blowing device; the second blowing device is used to wash the printed circuit board through the first water washing device Blow air on the surface of the printed circuit board. The solutions provided by the embodiments of the present invention are beneficial to reduce the water consumption for cleaning PCB attachment chemicals and reduce environmental protection costs.

Owner:SHENNAN CIRCUITS

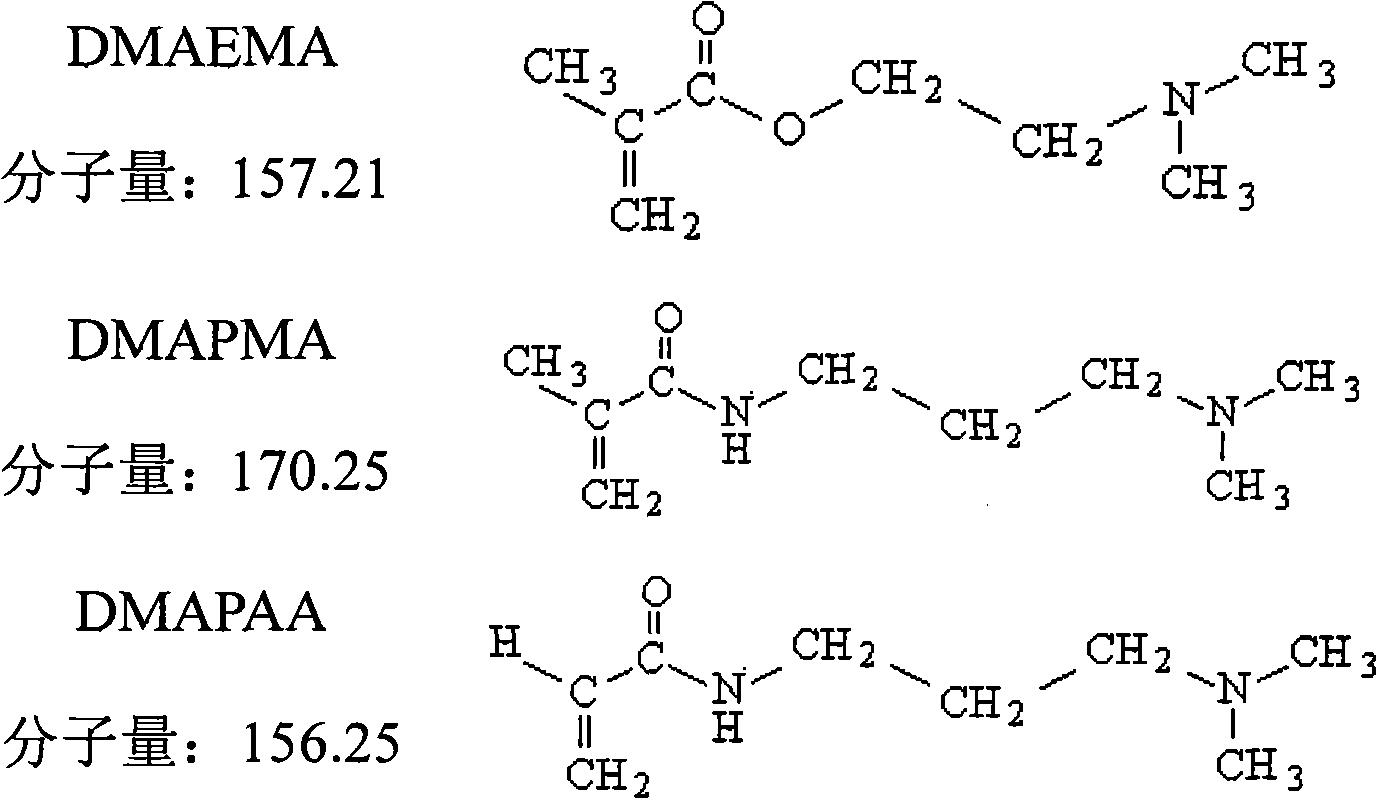

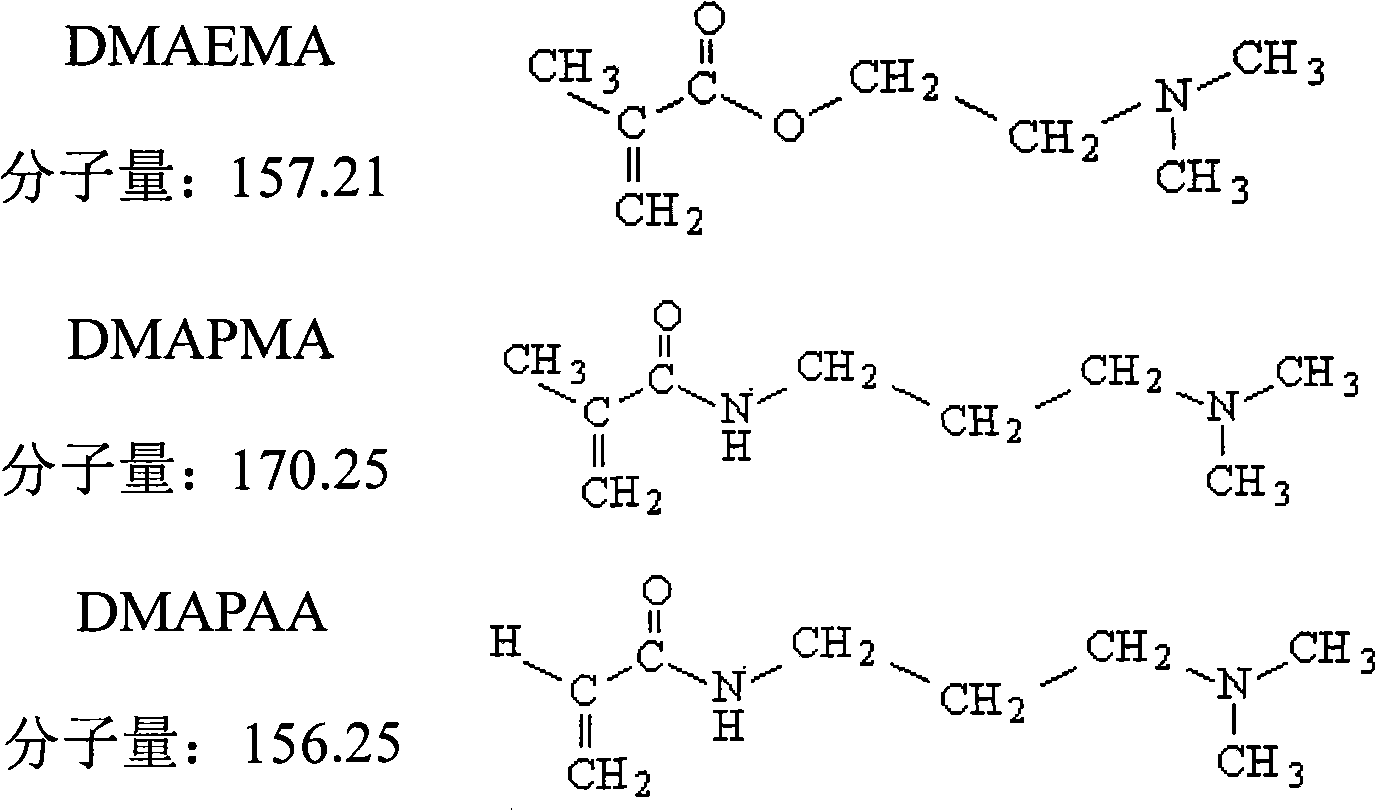

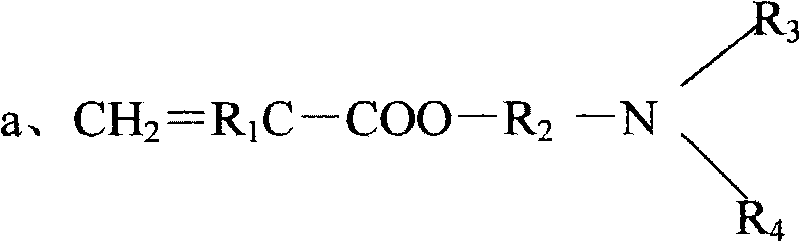

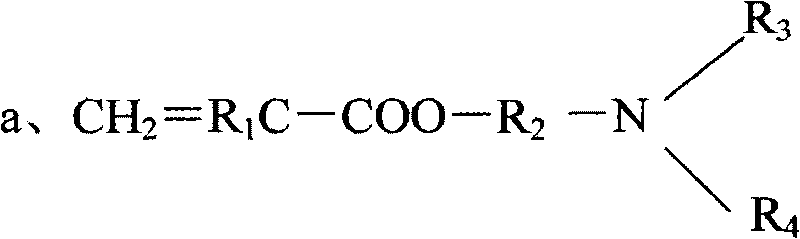

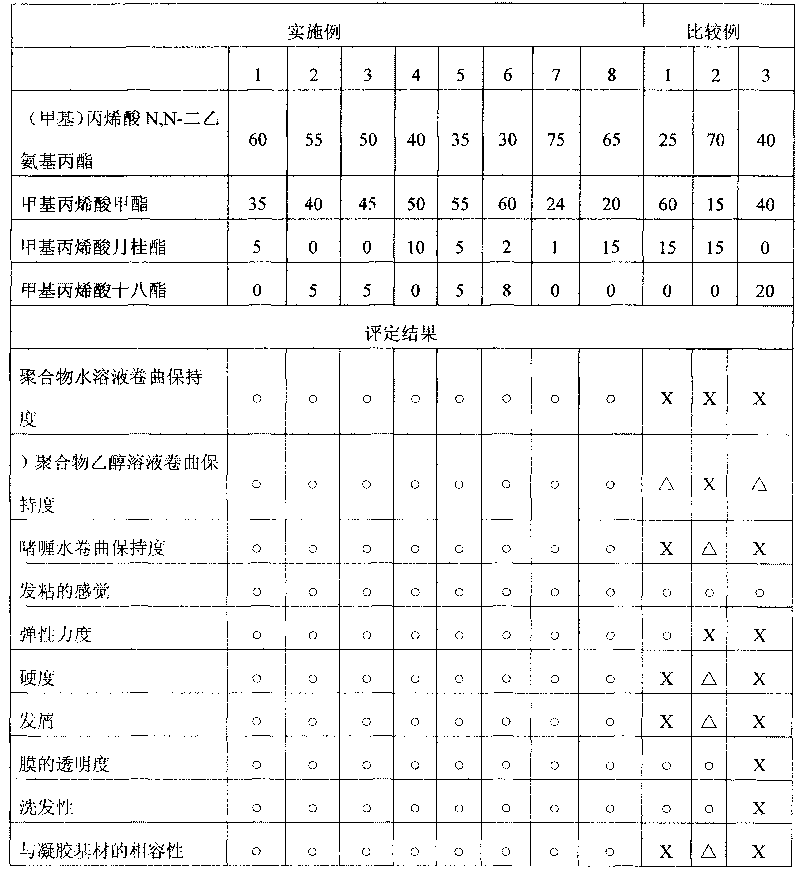

Forming polymer for amine oxide type amphoteric hair and application thereof

ActiveCN101735382AFeel goodHigh transparencyCosmetic preparationsHair cosmeticsCompatibilizationPolymer chemistry

The invention relates to a forming polymer for amine oxide type amphoteric hair and application thereof, in particular to a water-soluble polymer of an amphoteric ionic polymer. The forming polymer for the amine oxide type amphoteric hair has a thin film with stronger hardness and favorable hand feel, and has excellent forming force, hair care property and hair washing property, and favorable compatibility with various base materials. The polymer is prepared by raising temperature of three polymer monomers and adding an initiator for polymerization in batches, adding an appropriate amount of oxidant and catalyst and carrying out amphotericity, and can be used in the aspects, such as gel water, gel paste or hair spray, and the like. The invention provides the forming polymer for amine oxide type amphoteric hair which can form a thin film with stronger hardness and favorable hand feel, and has excellent forming force, hair care property and hair washing property, and favorable compatibility with various base materials, a preparation method and the application thereof.

Owner:GUANGZHOU TINCI MATERIALS TECH

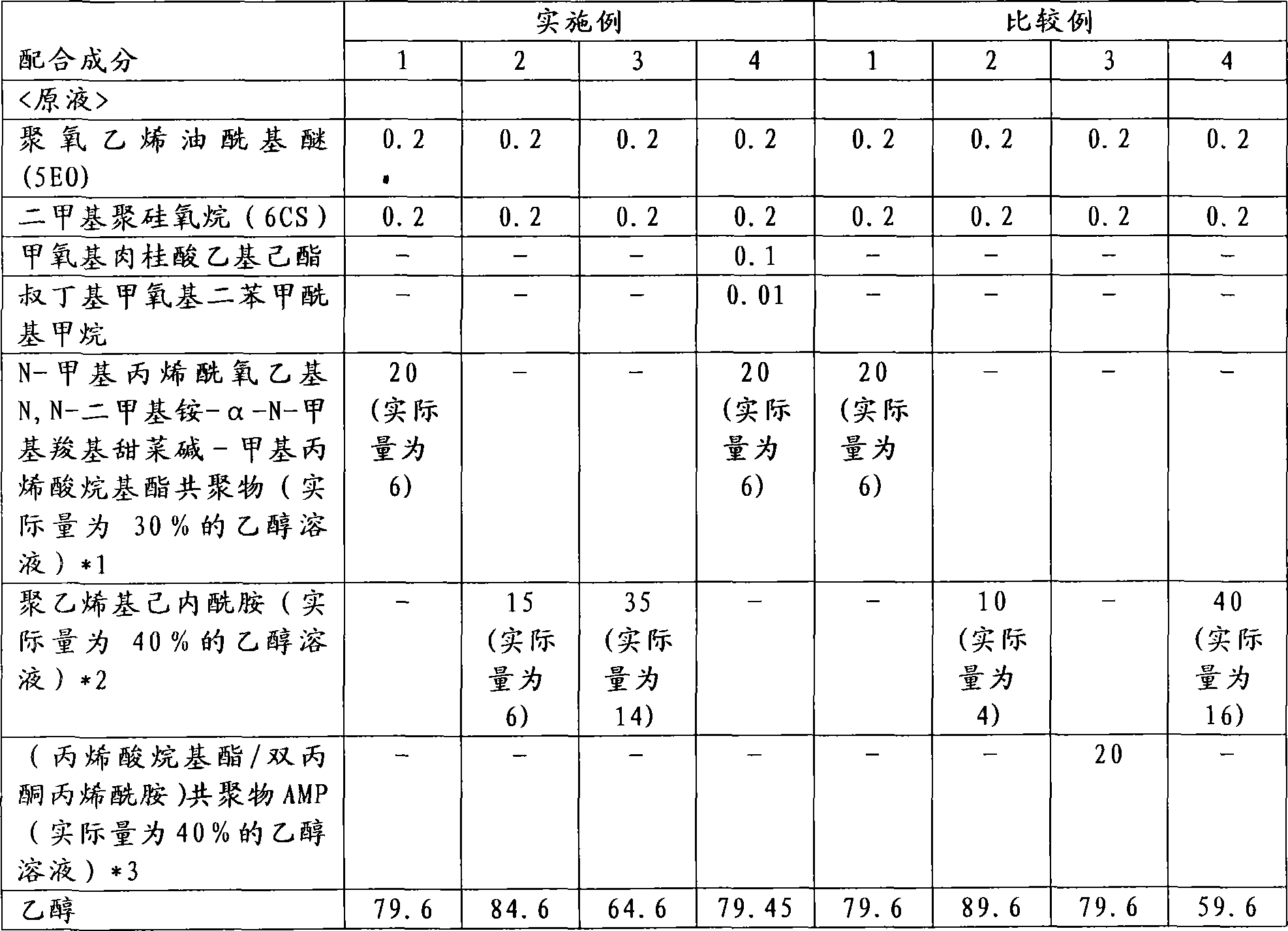

Aerosol type cosmetic hair preparations

InactiveCN101472549AEasy to useNo cloggingCosmetic preparationsHair cosmeticsPolymer chemistryCopolymer

An aerosol type cosmetic hair preparation characterized in that a raw ethanol solution containing 0.1-15 mass% N-methacryloyloxyethyl-N,N-dimethylammonium a-N-methylcarboxybetaine / alkyl methacrylate copolymer and an aerosol propellant comprising a liquefied petroleum gas having an initial internal pressure as measured at 20 DEG C of 0.15-0.2 MPa have been packed in such a mixing proportion that the raw ethanol solution / aerosol propellant ratio by mass is in the range of 40 / 60 to 50 / 50. Also provided is an aerosol type cosmetic hair preparation characterized in that a raw ethanol solution containing 0.1-15 mass% polyvinylcaprolactam and an aerosol propellant comprising a liquefied petroleum gas having an initial internal pressure as measured at 20 DEG C of 0.15- 0.2 MPa have been packed in such a mixing proportion that the raw ethanol solution / aerosol propellant ratio by mass is in the range of 40 / 60 to 50 / 50. Based on the results of a detailed investigation made again on behaviors of hair-spray users, the hair sprays which can be comfortably used are provided.

Owner:SHISEIDO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com