Construction technique for composite mortar

A composite mortar and construction technology technology, which is applied in construction, building structure, covering/lining, etc., can solve the problems of unstable quality and low early strength, and achieve the effect of reducing thermal conductivity, reducing usage, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

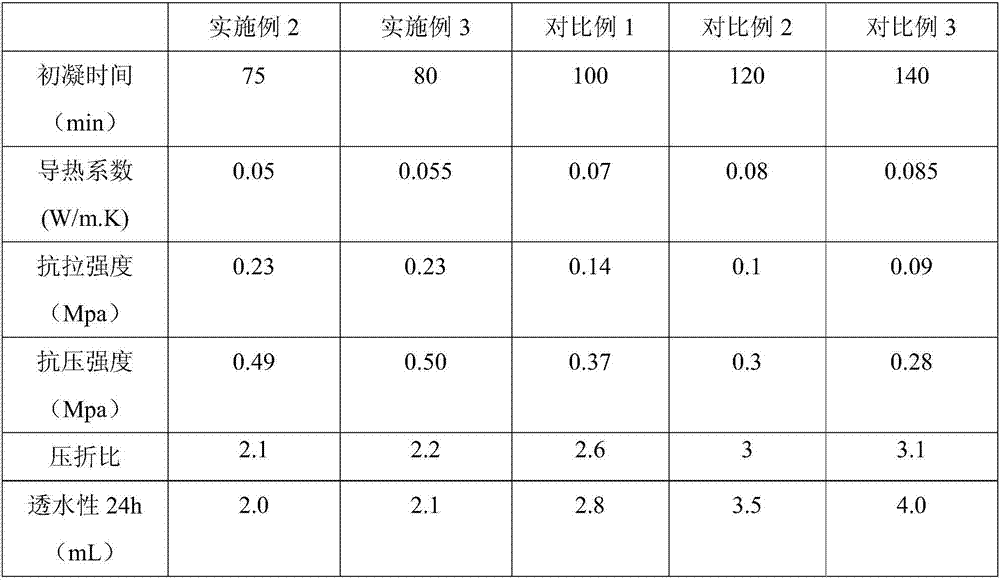

Examples

Embodiment 1

[0042] A construction technology of composite mortar, the construction technology comprises the following steps:

[0043] (1) Wall surface treatment: clean and polish the wall surface, use high-pressure cleaning to clean the wall surface, and then seal the gap between the masonry with a caulking agent; wherein the caulking agent is organic silica gel;

[0044] (2) hair spraying treatment: the wall surface is sprayed with a wall interface agent, wherein the wall interface agent is prepared from cement, sand, admixture, and water; the sand passes through 60-80 mesh Sieve, the admixture is made by mixing sodium hydroxymethyl cellulose, wood fiber, flexible rubber powder, water retaining agent, water reducing agent and water repellent according to the mass ratio of 2.8:1.3:0.5:0.25:0.28:0.29 ;

[0045] Wherein, the flexible rubber powder is made by mixing polyvinyl alcohol, vinyl acetate-ethylene copolymer, urea-formaldehyde resin and starch ether according to the mass ratio of 1...

Embodiment 2

[0057] A construction technology of composite mortar, the construction technology comprises the following steps:

[0058] (1) Wall surface treatment: clean and polish the wall surface, use high-pressure cleaning to clean the wall surface, and then seal the gap between the masonry with a caulking agent; wherein the caulking agent is organic silica gel;

[0059] (2) hair spraying treatment: the wall surface is sprayed with a wall interface agent, wherein the wall interface agent is prepared from cement, sand, admixture, and water; the sand passes through 60-80 mesh Sieve, the admixture is made by mixing sodium hydroxymethyl cellulose, wood fiber, flexible rubber powder, water retaining agent, water reducing agent and water repellent according to the mass ratio of 3.1:1.6:0.7:0.31:0.32:0.32 ;

[0060] Wherein, the flexible rubber powder is made by mixing polyvinyl alcohol, vinyl acetate-ethylene copolymer, urea-formaldehyde resin and starch ether according to the mass ratio of 1...

Embodiment 3

[0072] A construction technology of composite mortar, the construction technology comprises the following steps:

[0073] (1) Wall surface treatment: clean and polish the wall surface, use high-pressure cleaning to clean the wall surface, and then seal the gap between the masonry with a caulking agent; wherein the caulking agent is organic silica gel;

[0074] (2) hair spraying treatment: the wall surface is sprayed with a wall interface agent, wherein the wall interface agent is prepared from cement, sand, admixture, and water; the sand passes through 60-80 mesh Sieve, the admixture is made by mixing sodium hydroxymethyl cellulose, wood fiber, flexible rubber powder, water retaining agent, water reducing agent and water repellent according to the mass ratio of 2.9:1.4:0.6:0.28:0.3:0.31 ;

[0075] Wherein, the flexible rubber powder is made by mixing polyvinyl alcohol, vinyl acetate-ethylene copolymer, urea-formaldehyde resin and starch ether according to the mass ratio of 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com