Horizontal apparatus for processing printed circuit boards and method for processing printed circuit boards

A technology for printed circuit boards and equipment, which is applied in the field of horizontal equipment to achieve the effect of reducing water consumption and environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

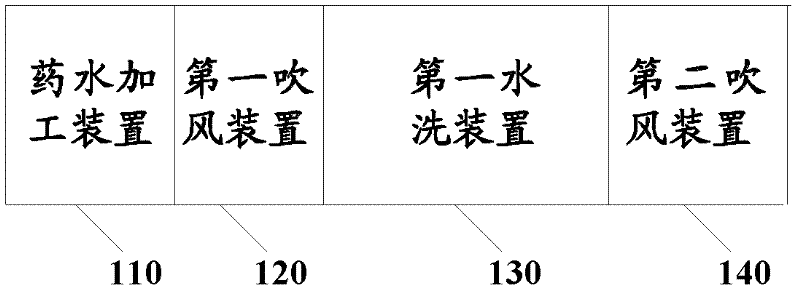

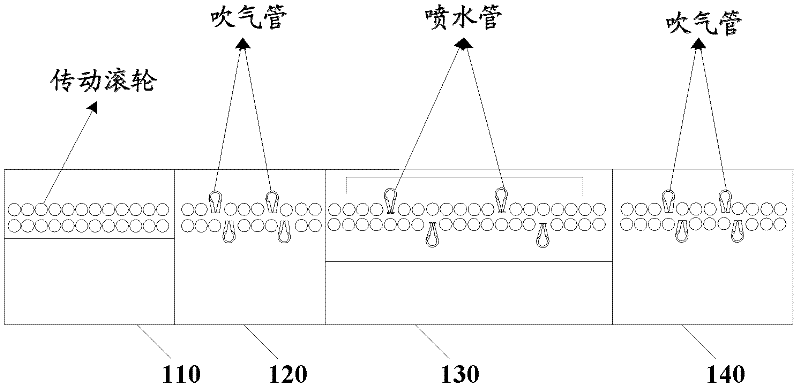

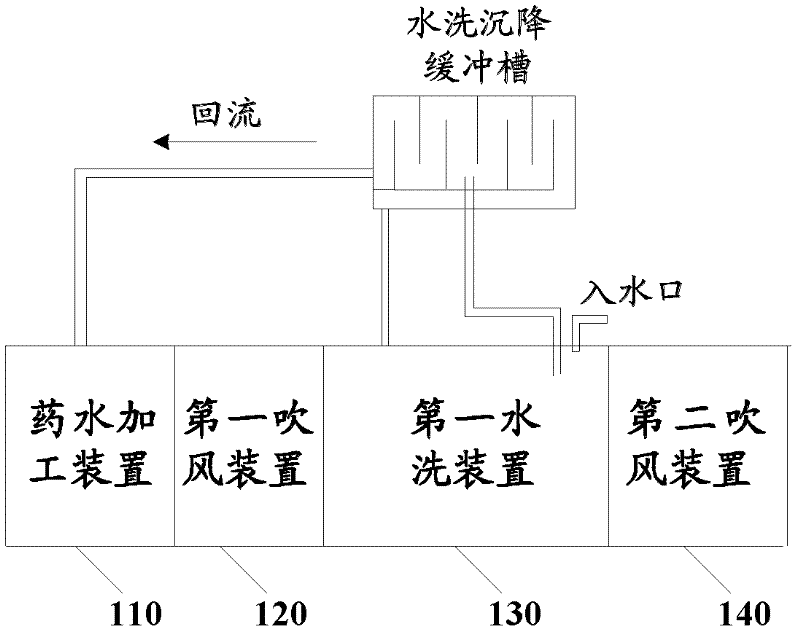

[0033] see Figure 1-a , a horizontal equipment for processing printed circuit boards provided by an embodiment of the present invention may include: a liquid medicine processing device 110 , a first blowing device 120 , a first water washing device 130 and a second blowing device 140 .

[0034] Wherein, the liquid processing device 110 is used for processing the printed circuit board with liquid.

[0035] For example, the potion processing device 110 may include a potion tank for holding the potion, and the potion processing device 110 uses the corresponding potion contained in the potion tank to etch, clean or desmear the printed circuit board. Of course, the potion processing device 110 may also use the corresponding chemical solution to perform other processing on the printed circuit board, and no more examples will be given here.

[0036] In practical application, the discharge port of the liquid medicine processing device 110 is connected with the feed port of the first ...

Embodiment 2

[0061] see image 3 1. A method for processing a printed circuit board provided by an embodiment of the present invention may include:

[0062] 301. Using the liquid medicine processing device to process the printed circuit board with liquid medicine;

[0063] 302. Use the first air blowing device to blow air on the surface of the printed circuit board that has been processed by the liquid medicine processing device;

[0064] 303. Use the first water washing device to perform water spray washing treatment on the above-mentioned printed circuit board that has been blown by the first blowing device;

[0065] 304. Use the second air blowing device to blow air on the surface of the printed circuit board that has been sprayed and rinsed by the first water washing device.

[0066] Further, the method may further include: using the second water washing device to spray water on the printed circuit board that has been blown by the second blowing device; The surface of the printed ci...

Embodiment 3

[0070] see Figure 4-a Another horizontal equipment for processing printed circuit boards provided by an embodiment of the present invention may include: a liquid medicine processing device 110, a first blowing device 120, a first water washing device 130, a second blowing device 140, and a residual liquid medicine detection device 450;

[0071] Wherein, the liquid medicine processing device 110 is used to process the liquid medicine on the printed circuit board;

[0072] The first blowing device 120 is used to blow air to the surface of the printed circuit board processed by the liquid medicine processing device 110;

[0073] The first water washing device 130 is used for spraying and rinsing the printed circuit board processed by the first blowing device 120;

[0074] The second blowing device 140 is used to blow air to the surface of the printed circuit board rinsed by the first water washing device 130 .

[0075] In practical application, the discharge port of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com