Ternary zwitterionic hair holding polymer for hair and preparation method thereof

A technology for hair styling and amphoteric ions, which is applied in cosmetic preparations, hair care, pharmaceutical formulations, etc. It can solve the problems of anionic resin compatibility limitations, insufficient polymer softness, poor transparency and water solubility, etc., and achieve hand feeling Good, easy to comb, good affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 300kg of 95% ethanol to a 1000L stainless steel reactor equipped with a reflux condenser, flow-controllable high-level metering mixing tank, thermometer and stirring, turn on the reflux condenser and stir, heat up to 60°C for use;

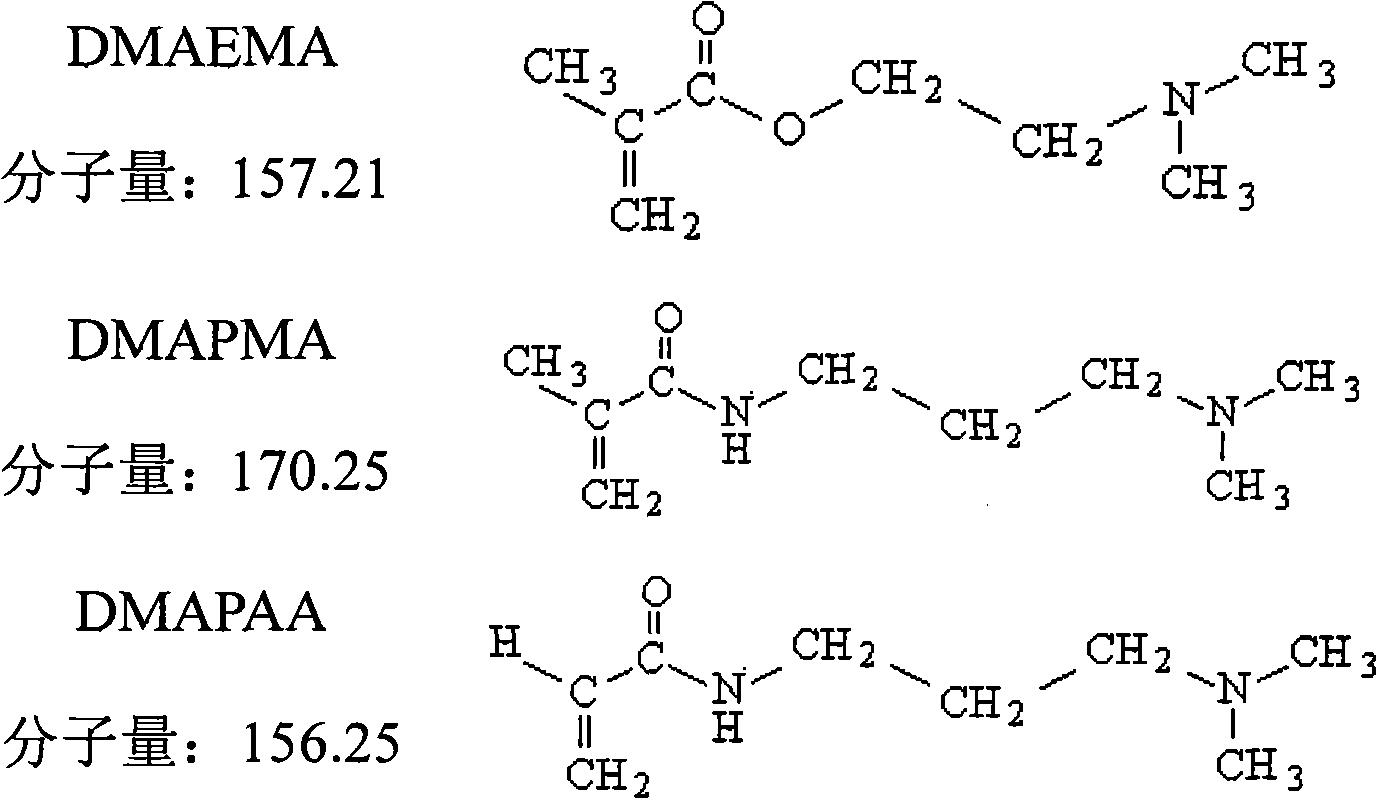

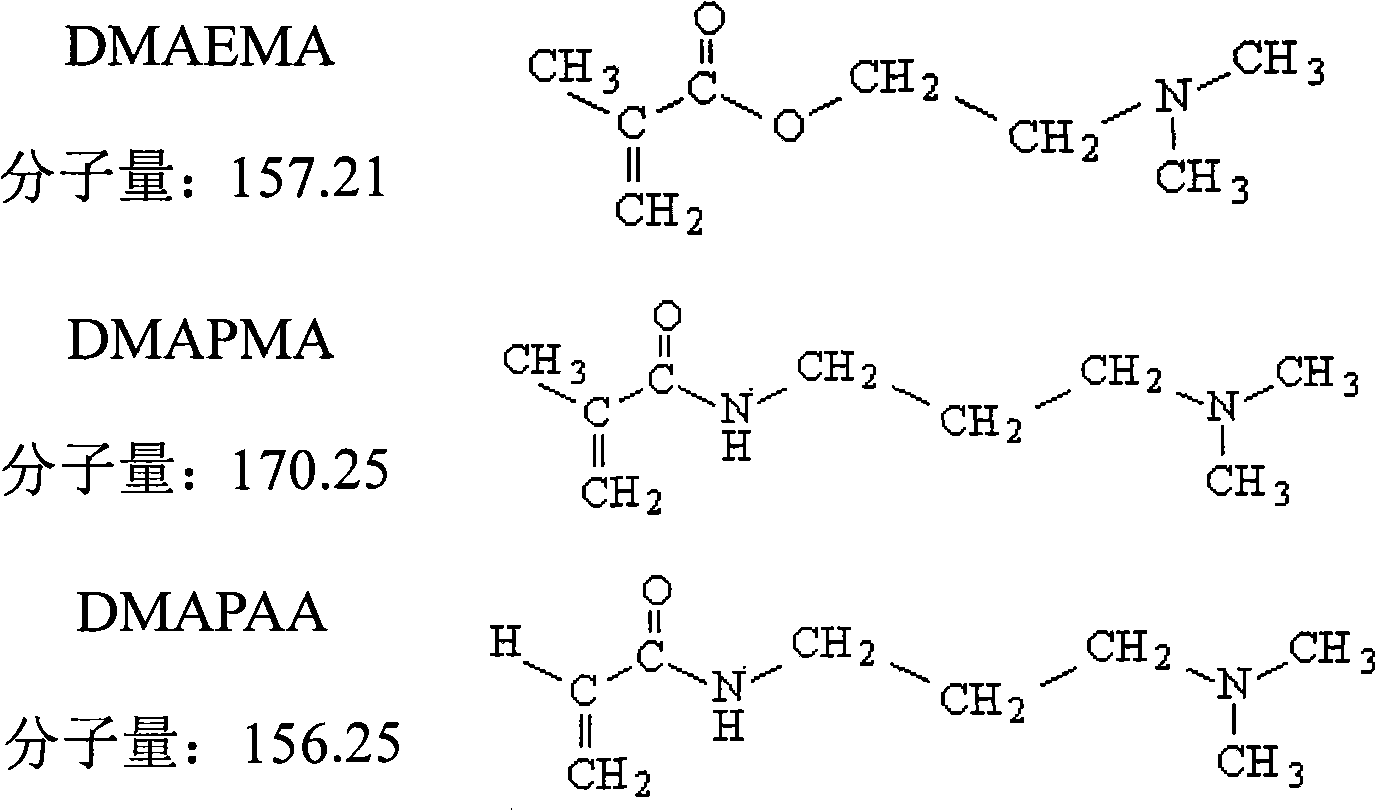

[0024] Add 140kg of vinylpyrrolidone, 30kg of acrylic acid, 30kg of DMAEMA (dimethylaminoethyl methacrylate) and 1.5kg of phthaloyl peroxide into a stainless steel high-level metering mixing tank, mix well and set aside;

[0025] Under the condition of stirring, add the mixed reactive monomer mixed with phthalyl peroxide catalyst into the reaction kettle at a constant speed for 3 hours. Since the polymerization process is an exothermic reaction, the reaction temperature of the reaction system is strictly controlled within the range of 70±5°C;

[0026] After the feeding of the mixed reactive monomer is completed, dissolve 0.5kg of phthaloyl peroxide with 3kg of ethanol, add it to the reaction system at one time, and keep it warm for 1.5 h...

Embodiment 2

[0029] 400 kg of methanol was added to the 1000 L stainless steel reaction kettle in Example 1, and after the temperature was raised to 63° C., under stirring conditions, the reaction temperature was controlled at 70 ± 5° C., and 100 kg of vinylpyrrolidone, 50 kg of methacrylic acid, DMAPMA (N, The mixed monomer composed of N-dimethylaminopropyl methacrylamide) 50kg and 0.75kg azobisisobutyronitrile was added within 3 hours. After the addition was completed, 0.25kg azobisisobutyronitrile was used Dissolve 2kg of methanol, add it to the reaction system at one time, and keep it warm for 1.5 hours under the condition of stirring and 70±5°C; weigh 21kg of sodium chloroacetate, add it to the reaction kettle at one time, and keep it at 70±5°C Continue to stir and keep warm for 1 hour under the same conditions; measure the pH value of the reaction product with precision pH test paper, and neutralize the pH value of the reaction product to 6.6 with 30% NaOH. After the reaction was com...

Embodiment 3

[0031] In Example 1, 200 kg of industrial water was added to the 1000L stainless steel reactor. After the temperature was raised to 65° C., 120 kg of vinylpyrrolidone, 50 kg of sodium acrylate, DMAPAA (N, N-dimethylaminopropyl methacrylamide) were prepared in 3 hours. ) 30kg and 1.00kg tert-butyl hydroperoxide mixed monomer after adding, after the addition is completed, 0.33kg tert-butyl hydroperoxide is dissolved with 2kg methanol, and added to the reaction system in one go, stirring and Under the condition of 70±5℃, keep warm for 1.5 hours; add 13.5kg of chloroethanol into the reaction kettle at one time, and continue stirring for quaternization under the condition of 70±5℃ for 1 hour; measure the pH value of the reaction product with precision pH test paper , and neutralize the pH of the reaction product to 6.5 with 20% NaOH. The reaction yielded 420 kg of hair styling polymer with a solid content of 52.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com