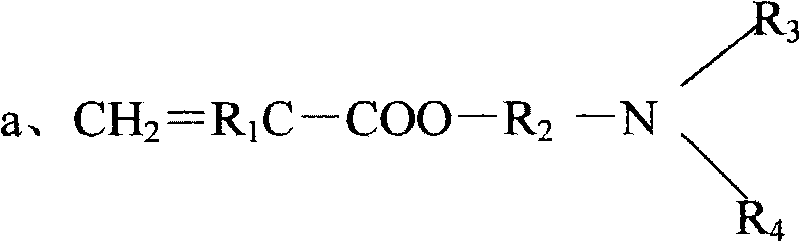

Forming polymer for amine oxide type amphoteric hair and application thereof

An amphoteric polymer, hair styling technology, applied in cosmetics, hair care, cosmetic preparations, etc., can solve problems such as poor compatibility, insufficient compatibility, and low film hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

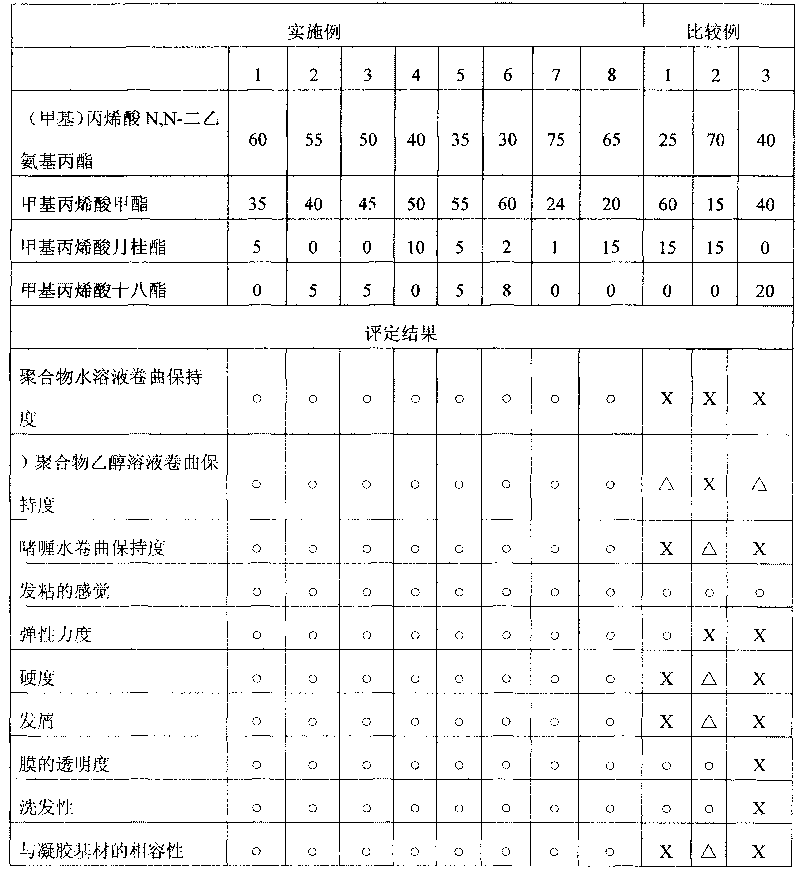

Examples

Embodiment 1

[0058] A, add (meth)acrylic acid N in the reactor with reflux cooler, dropping funnel, thermometer, nitrogen inlet pipe and stirring device, 60 parts by weight of N-diethylaminopropyl ester, 35 parts by weight of methyl methacrylate Parts by weight, 5 parts by weight of lauryl methacrylate, 160 parts by weight of absolute ethanol, nitrogen gas, stirring and mixing while raising the temperature, when the temperature reaches 70 ° C, slowly dropwise add 37.5% of azobisisoheptanonitrile within 2 hours (weight parts) ethanol solution 15 weight parts, insulation reaction 1 hour;

[0059] B. Then when the temperature of the reaction system was raised to 72° C., slowly dropwise added 15 parts by weight of ethanol solution containing 50% (parts by weight) of azobisisoheptanonitrile within 2 hours, and kept the reaction for 1 hour;

[0060] C, when the temperature of the reaction system is raised to 75° C., slowly dropwise add 15 parts by weight of ethanol solution of 62.5% (parts by we...

Embodiment 2

[0065] The synthesis method and steps of P-2 are basically the same as those of P-1, except that 55 parts by weight of N,N-diethylaminopropyl (meth)acrylate, 40 parts by weight of methyl methacrylate, stearyl methacrylate 5 parts by weight, and in step A, slowly add azobisisobutyronitrile dropwise within 1 hour and raise the temperature to 70°C for 2 hours, and in step B, raise the temperature to 75°C and slowly add azobisisobutyronitrile dropwise within 1 hour Nitrile is kept warm for 2 hours, step C is heated to 80°C, and azobisisobutyronitrile is slowly added dropwise within 1 hour and kept warm for 3 hours. In step D, add 0.1 parts by weight of citric acid and disodium EDTA to the system at one time , Then will account for (meth)acrylic acid N, the 25% aqueous solution of the ammonium persulfate of 1.5 mole times of N-diethylaminopropyl ester is added dropwise in the polymerization solution within 5 hours with a dropper, and then continue to stir for 12 hours.

[0066] The...

Embodiment 3

[0068] The synthetic method and steps of P-3 are the same as those of P-1, adding 50 parts by weight of N,N-diethylaminopropyl (meth)acrylate, 45 parts by weight of methyl methacrylate, and 5 parts by weight of stearyl methacrylate. Parts by weight, in addition, in step A, azobisisobutyronitrile was slowly added dropwise within 1.5 hours and the temperature was raised to 62°C for 2 hours, and in step B, the temperature was raised to 65°C and azobisisobutyronitrile was slowly added dropwise within 1.5 hours Insulate for 1.5 hours, in step C, raise the temperature to 75°C, slowly add azobisisobutyronitrile dropwise within 1.5 hours and keep warm for 2.5 hours, in step D, add 0.05 parts by weight of citric acid and disodium EDTA to the system at one time, Then, a 55% aqueous solution of peracetic acid, which accounts for 0.5 mole times of (meth)acrylic acid N, N-diethylaminopropyl ester, was added dropwise to the polymerization solution within 2 hours through a dropper, and the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com