Fabric thermosetting intelligent control method and setting machine adopting same

A technology of intelligent control and heat setting, applied in the direction of fabric surface trimming, heating/cooling fabric, non-electric variable control, etc., can solve the problem of fabric dimensional stability, poor dyeability, failure to guarantee the temperature required for setting, and failure to meet Energy saving and environmental protection requirements and other issues, to achieve the effect of meeting energy saving and environmental protection requirements, optimizing the shaping effect, and better shaping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

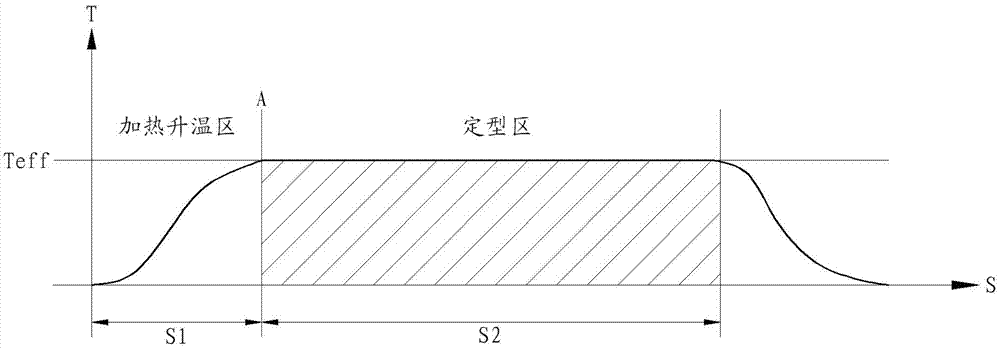

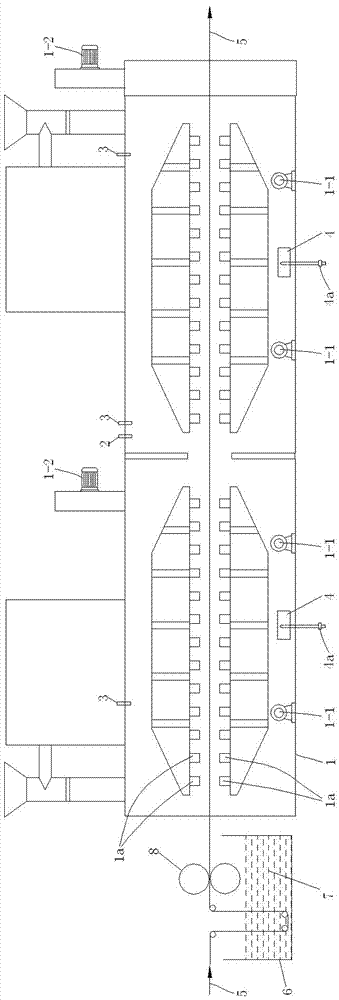

[0022] In order to accurately control the setting temperature and setting time, the present invention adopts such as figure 1 , figure 2 The shown intelligent control method for fabric heat setting and the setting machine adopting the method. The intelligent control method for fabric heat setting includes a step of heating the fabric 5 impregnated with the process liquid 7 in the oven 1 of the setting machine and a step of heat setting the fabric after heating, the heating step It refers to heating and heating the fabric in the heating and heating zone of the oven within the heating and heating time S1 required by the process. After the fabric is heat-set, the intelligent control method also includes the step of setting the running speed of the fabric according to the setting temperature Teff and setting time S2 required by the process before the heating step, and during the heat setting step, according to the online monitoring of the starting point of the setting area The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com