Fire resistant fiber blended yarn and production method thereof

A technology of blended yarn and flame-retardant fiber, which is applied in the field of flame-retardant blended yarn and its production, can solve the problems of easy burn skin, poor wearing comfort of clothing fabrics, unsafe and environmentally friendly yarn, etc., and achieve good moisture absorption and breathability, Dimensional stability, effects of avoiding differences in thermal protection and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

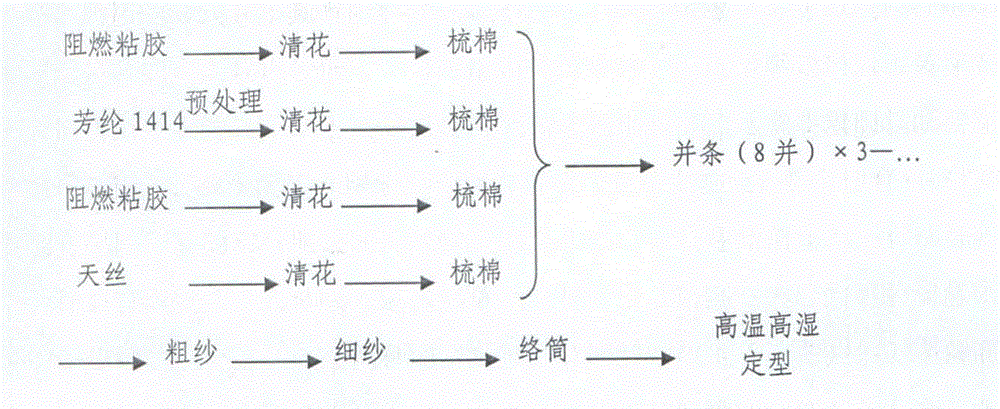

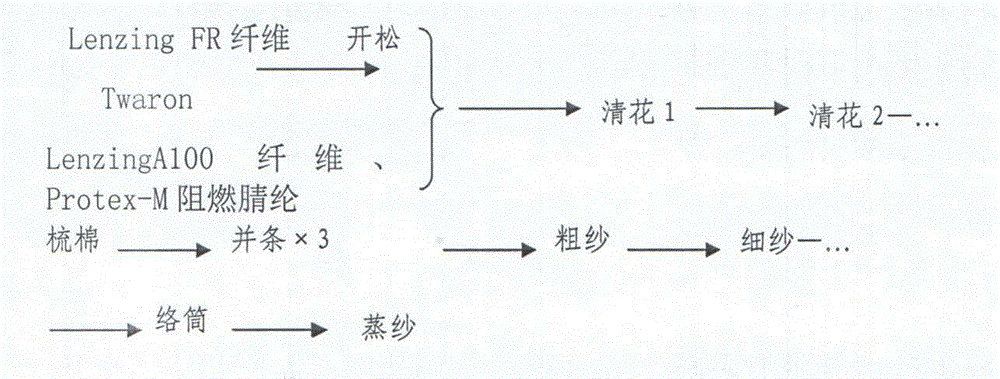

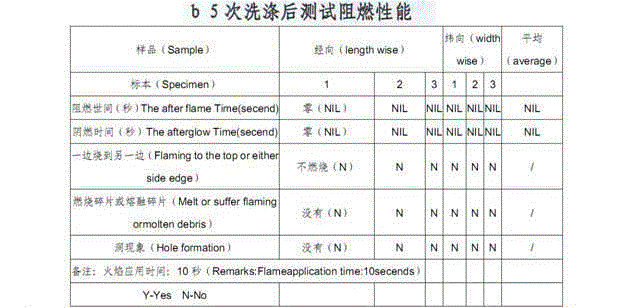

[0029]Provided is a flame-retardant fiber blended yarn and its production method, adding environmentally friendly and safe flame-retardant fibers to the components, and adjusting the mixing ratio; in terms of technology, Lenzing FR fibers and Twaron fibers are pretreated first, and all raw materials are uniformly cleaned Spend twice, comb the cotton uniformly, adjust the process to increase the mixing times between fibers, and avoid uneven coloring and small neps on the cloth surface. The steaming process of low-temperature vacuum and high humidity will not damage the original characteristics of the fiber and can shape the yarn well; the weight percentage of the flame-retardant fiber blended yarn includes: Lenzing FR fiber 40%, Protex-M Flame-retardant acrylic 30%, Lenzing A100 fiber 20%, Twaron 10%.

[0030] Preferably, the above-mentioned flame-retardant fiber Lenzing FR is Lenzing thermal protection fiber produced by Austrian Lenzing Fiber (Shanghai) Co., Ltd. The flame-re...

Embodiment 2

[0046] Provided is a flame-retardant fiber blended yarn and its production method, adding environmentally friendly and safe flame-retardant fibers to the components, and adjusting the mixing ratio; in terms of technology, Lenzing FR fibers and Twaron fibers are pretreated first, and all raw materials are uniformly cleaned Spend twice, comb the cotton uniformly, adjust the process to increase the mixing times between fibers, and avoid uneven coloring and small neps on the cloth surface. The steaming process of low-temperature vacuum and high humidity will not damage the original characteristics of the fiber and can shape the yarn well; the weight percentage of the flame-retardant fiber blended yarn includes: Lenzing FR fiber 32%, Protex-M Flame-retardant acrylic 35%, Lenzing A100 fiber 18%, Twaron 7%.

[0047] A production method for preparing flame-retardant fiber blended yarn, comprising the following steps in sequence: (1) Lenzing FR fiber and Twaron pretreatment respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com