Mosquito-repellent incense type large scattered plate production method and system

A production method and a mosquito-repellent incense-type technology are applied in the field of production methods and systems for mosquito-repellent incense-type large scattered coils, which can solve the problems of inability to purge oily impurities in copper pipes, the cleanliness of pipes cannot meet customer requirements, and the coiling density of copper pipes is small. , to save the cost of human resources, ensure the use of hardness requirements, reduce the effect of pipe damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

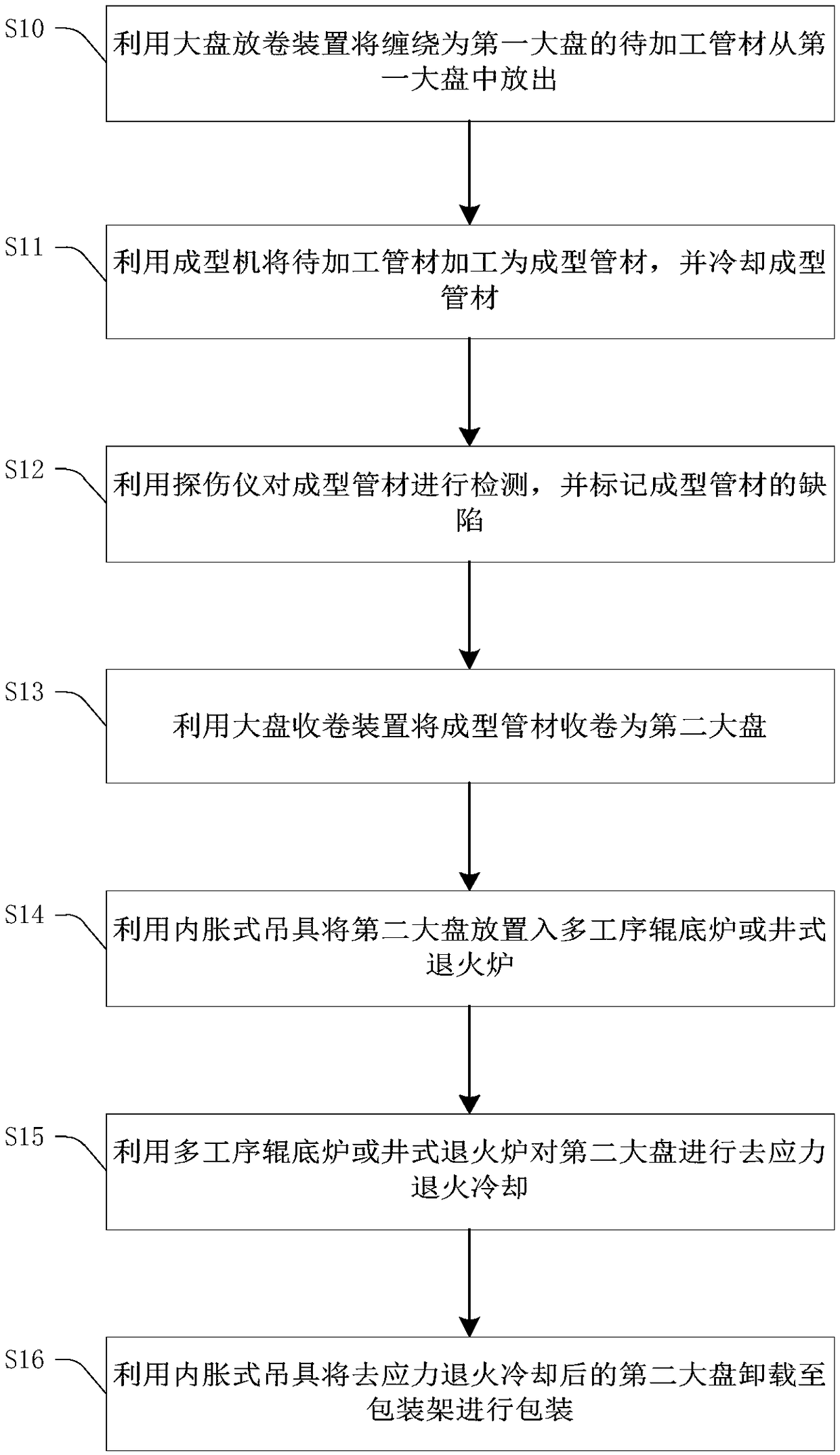

[0040] figure 1 It shows the flow chart of the production method of the mosquito-repellent-repellent-repellent-repellent-type large bulk disc provided by the embodiment of the present invention. The method can be divided into two stages: forming rewinding and annealing packaging. In the forming and rewinding stage, the pipe to be processed is processed into a shaped pipe and wound into a large mosquito-repellent coil, corresponding to steps S10 to S13. The large bulk discs are cooled and packaged to form the final product, which corresponds to step S14 to step S16.

[0041] refer to figure 1 , the method includes the following steps:

[0042] Step S10: Unwind the pipe to be processed wound into the first large disk from the first large disk by using the large disk unwinding device.

[0043] The pipe to be processed is relative to the formed pipe, and refers to the unprocessed pipe, which can also be called the mother pipe. For example, for internal thread pipe processing, ...

no. 2 example

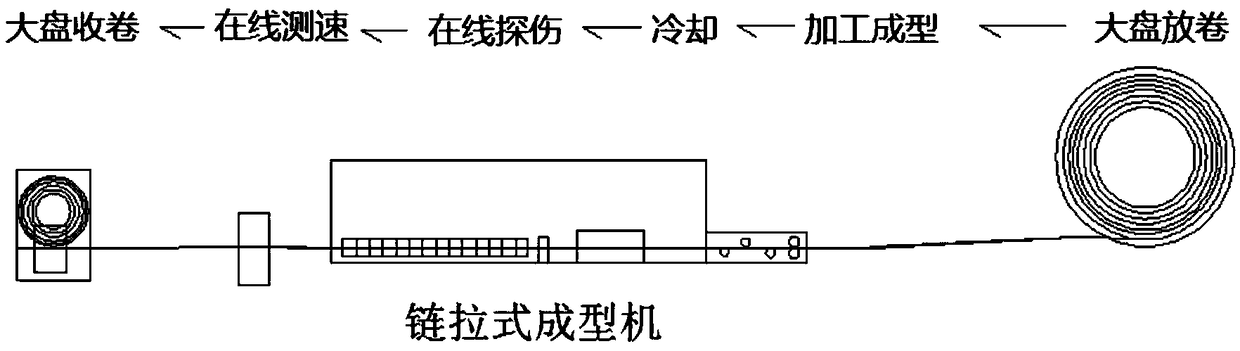

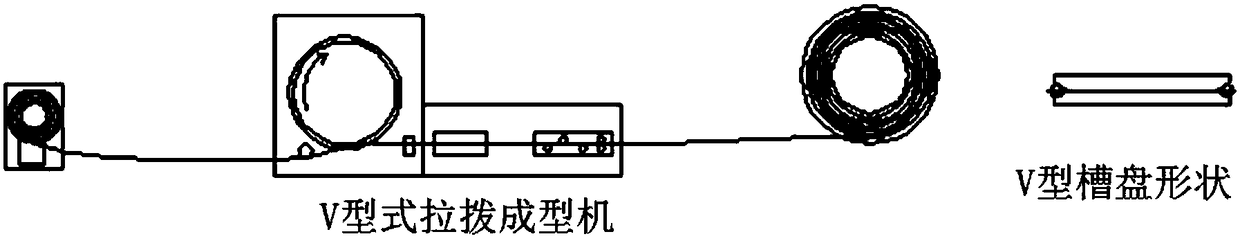

[0091] The embodiment of the present invention also provides a pipe processing system, which includes a large plate unwinding device, a forming machine, a flaw detector, a large plate rewinding device, an encoder, an internal expansion spreader, a multi-process roller hearth furnace or a pit annealing furnace and packing racks.

[0092] A large plate unwinding device is used to unwind the pipe to be processed which is wound into the first large plate from the first large plate;

[0093] Forming machine for processing the pipe to be processed into a formed pipe and cooling the formed pipe;

[0094] Flaw detector, used to inspect the formed pipe and mark the defects of the formed pipe;

[0095] Large plate winding device, used to wind the formed pipe into the second large plate, and the second large plate is a mosquito-repellent incense large loose plate;

[0096] The encoder is used to measure the unwinding speed of the large reel unwinding device during the rewinding process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com