Fabric steaming and sizing device

A cloth and steaming technology, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile material carrier, etc., can solve the problem of difficult control of the temperature of the steaming pre-shrinking machine, unstable steam volume, and affecting the quality of finished cloth products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

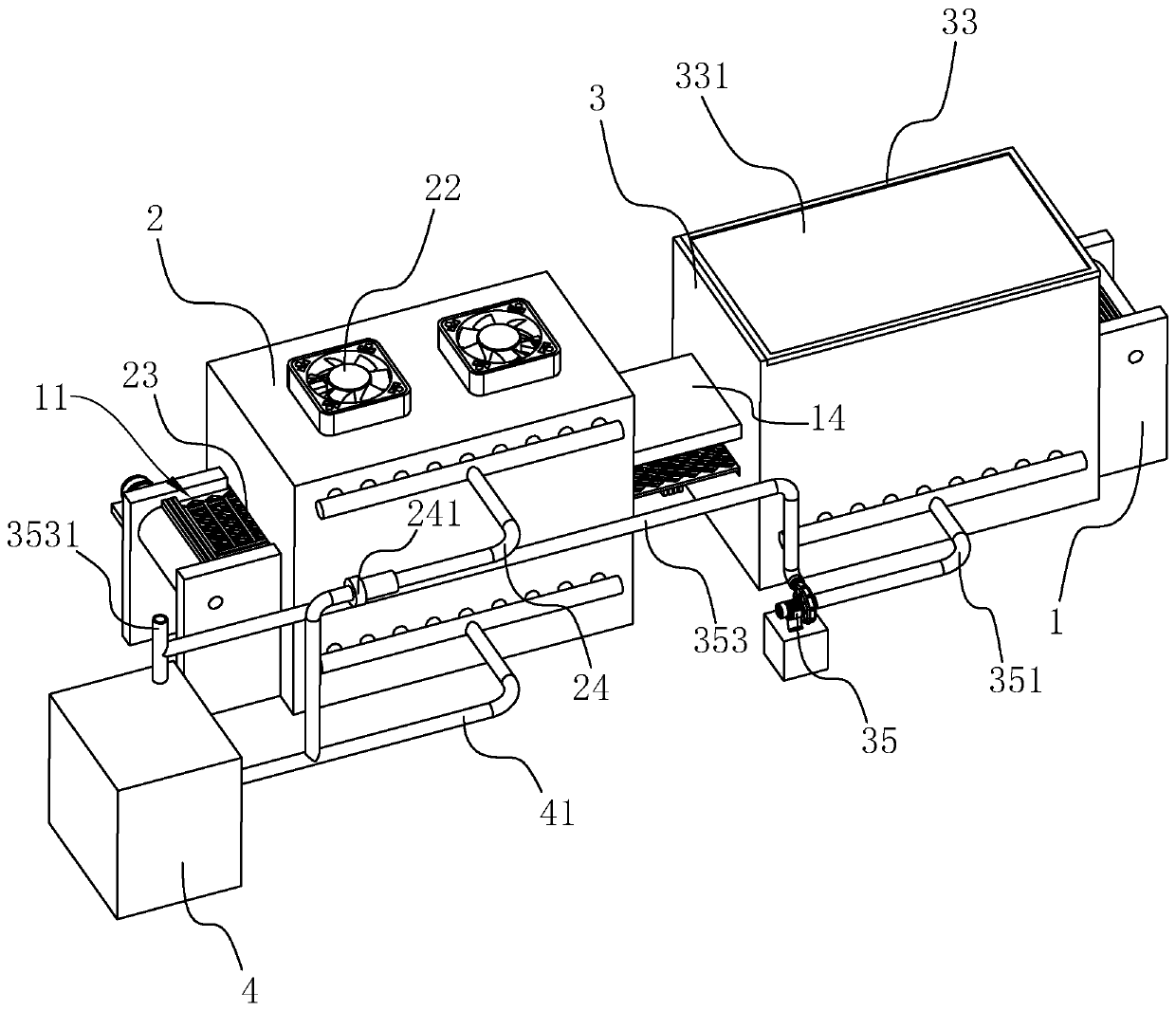

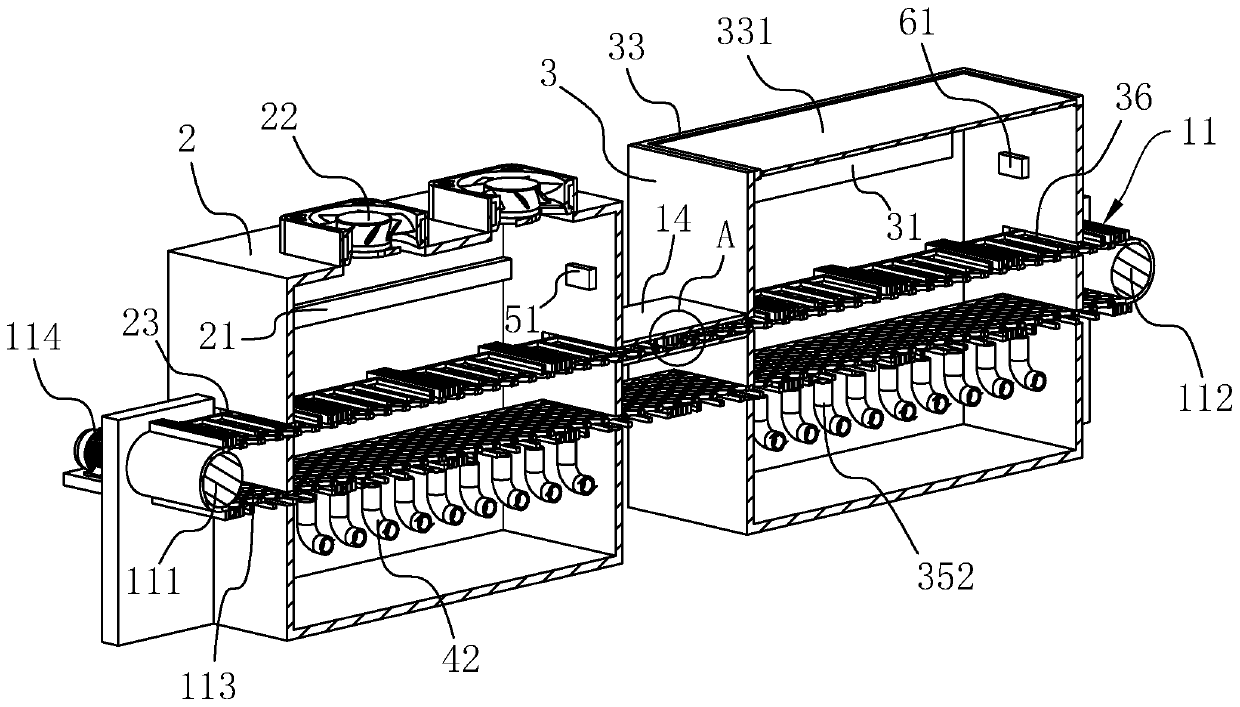

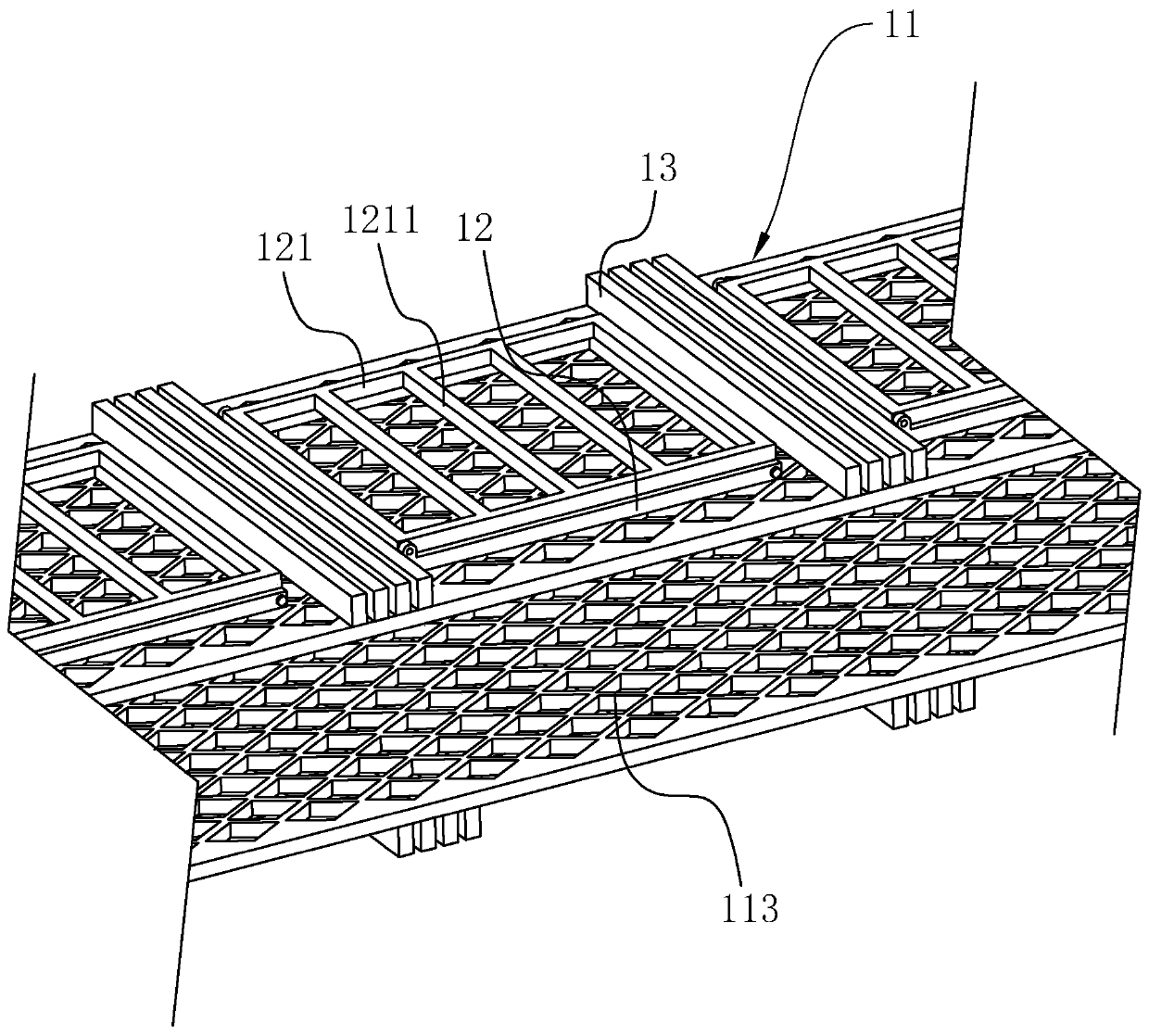

[0048] Embodiment: a kind of cloth steam setting equipment, as figure 1 with figure 2 As shown, a frame 1 and a conveyor belt 11 connected to the frame 1 are included. The frame 1 is fixedly connected to the heating box 2 and the cooling box 3 at the position corresponding to the conveyor belt 11 . The end of the heating box 2 away from the cooling box 3 is provided with a material inlet 23 , and the end of the cooling box 3 away from the heating box 2 is provided with a material outlet 36 . One end of the heating box 2 close to the cooling box 3 is fixedly connected with a channel 14 , the other end of the channel 14 is fixedly connected to the bottom of the cooling box 3 , and the conveyor belt 11 is set through the heating box 2 , the channel 14 and the cooling box 3 . The cloth is transported by the conveyor belt 11, enters the heating box 2 from the feed port 23, then enters the cooling box 3 through the channel 14, and finally leaves the cooling box 3 through the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com