Patents

Literature

94results about How to "Improve steaming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

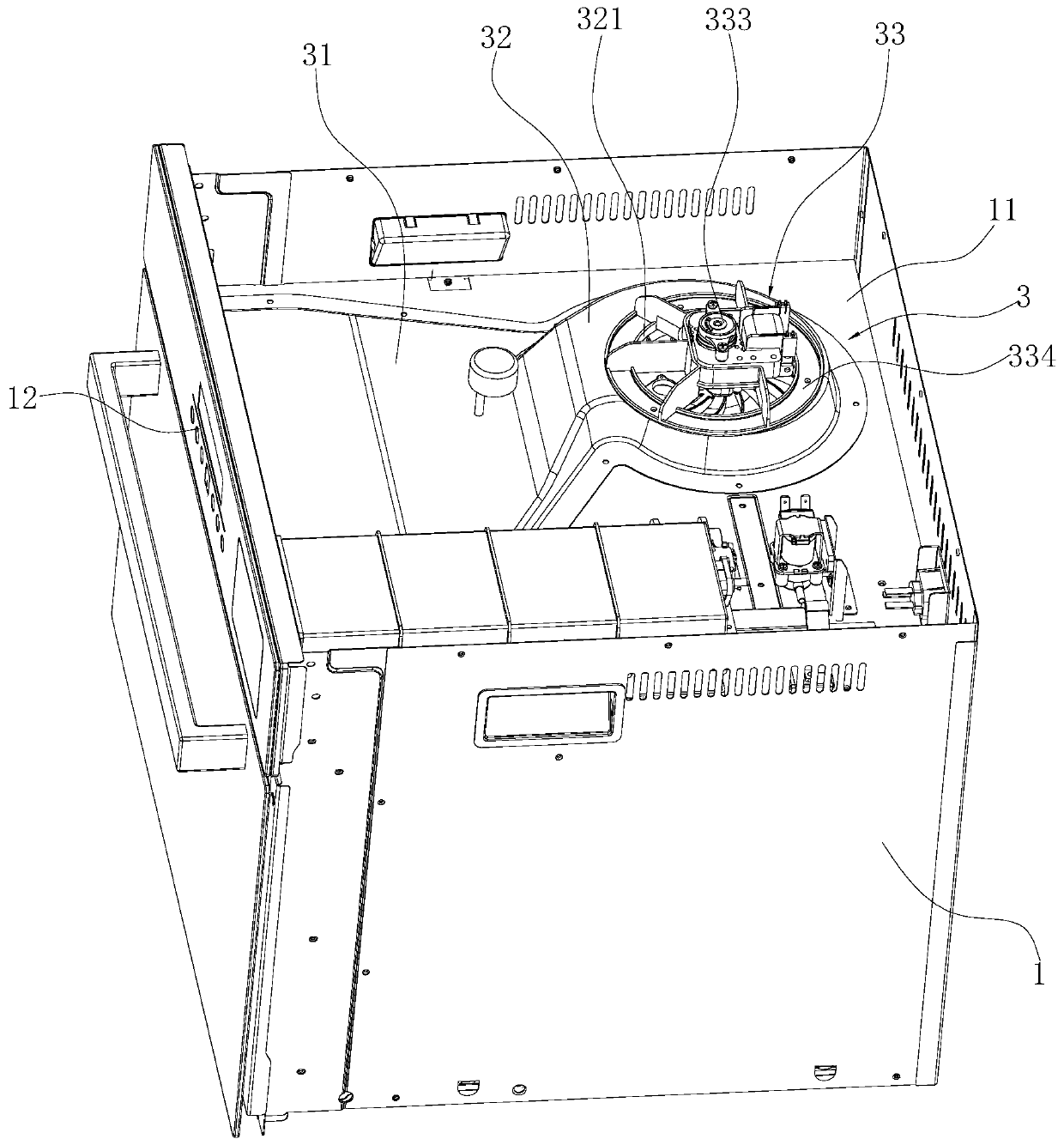

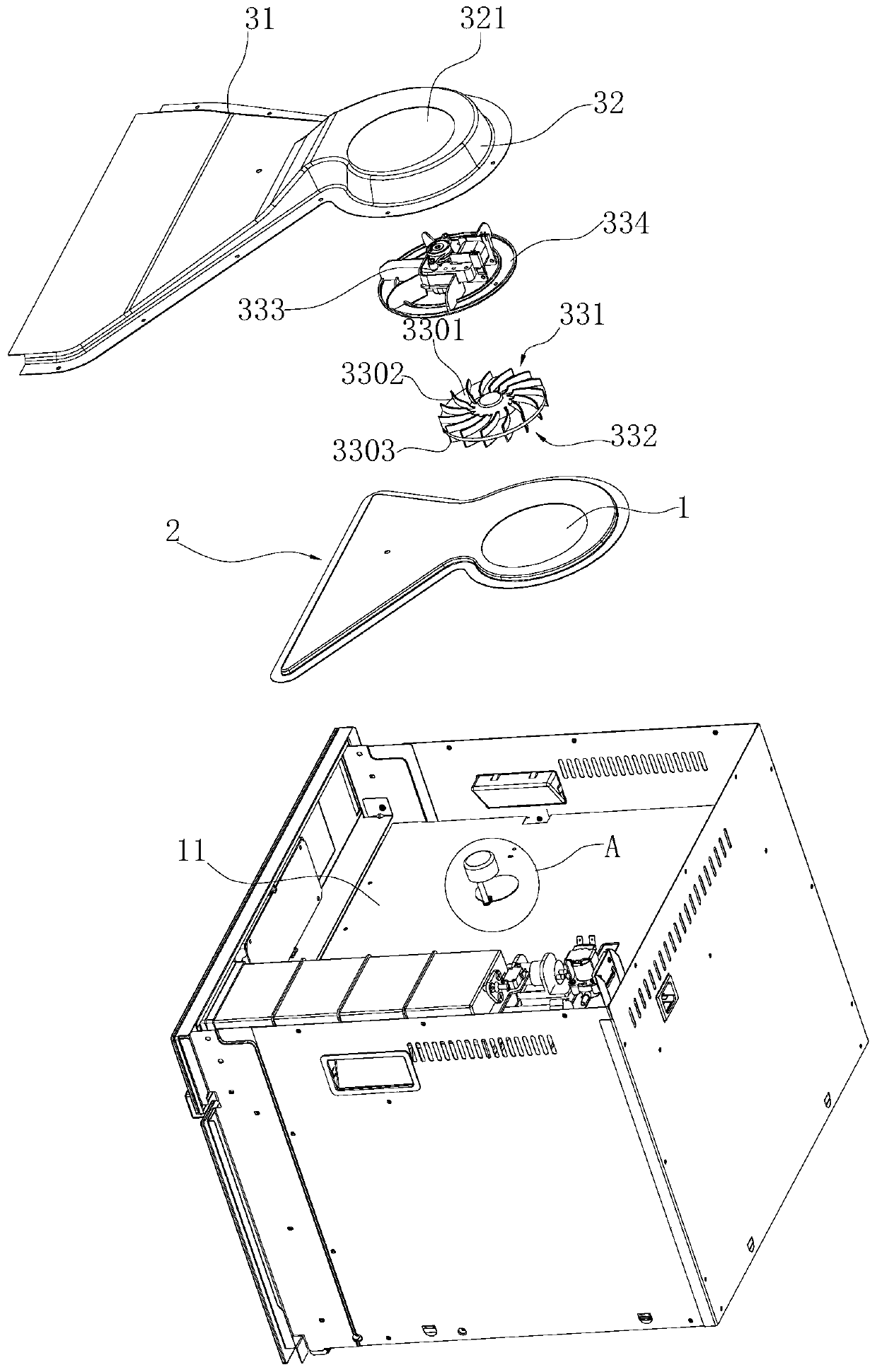

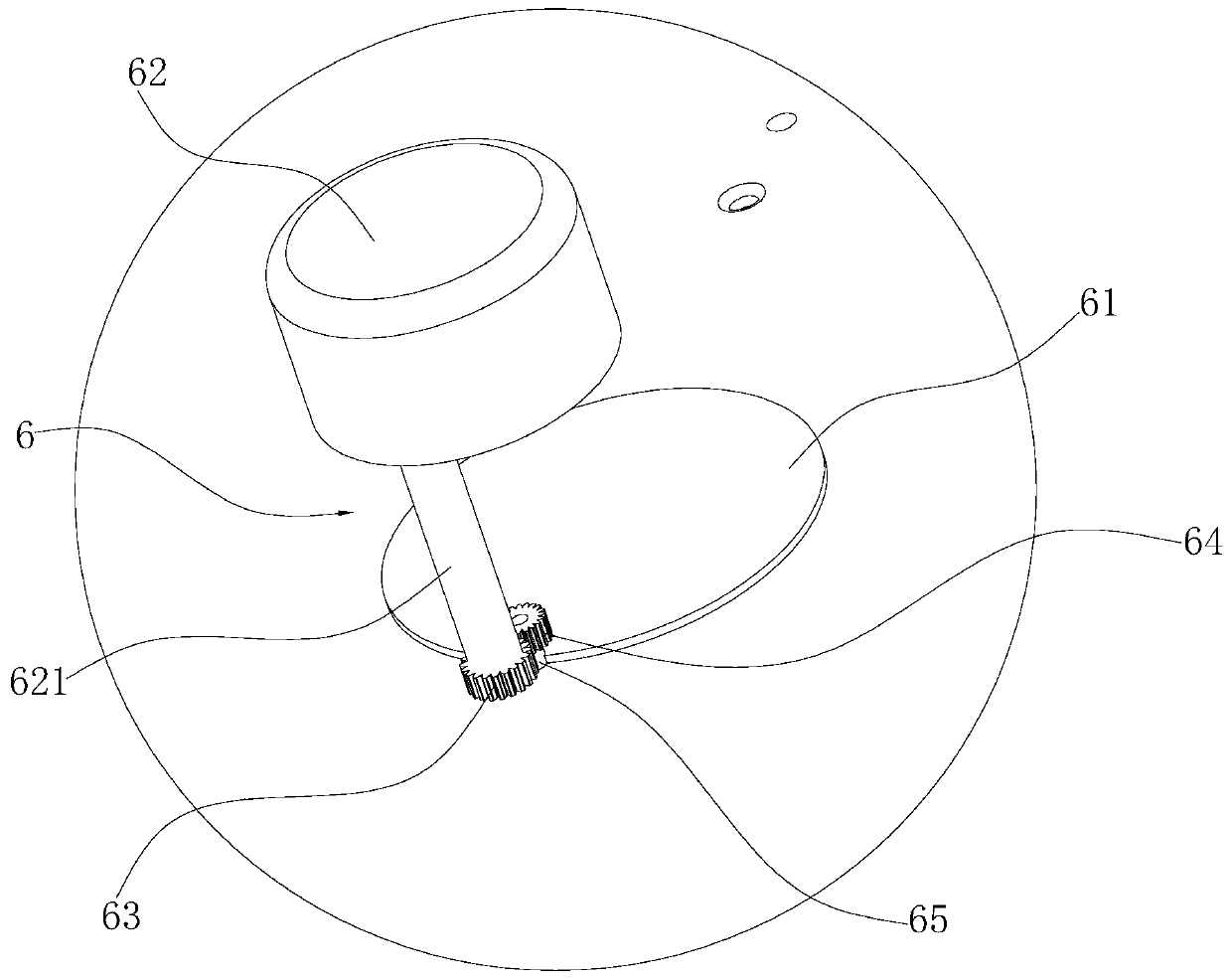

Exhaust structure, cooking device with exhaust structure, and exhaust method of cooking device

ActiveCN110477761AEasy dischargeImprove exhaust efficiencySteam cooking vesselsRoasters/grillsImpellerUsage experience

The invention relates to an exhaust structure. The exhaust structure comprises an inner container and an upper mounting plate positioned above the inner container; an exhaust hole is formed in the topwall of the inner container; the exhaust structure is characterized by further comprising an exhaust system with a fan and an exhaust cavity; an air inlet of the exhaust cavity is in fluid communication with the exhaust hole; the exhaust system comprises an exhaust channel communicating with the outside and a fan cavity used for installing the fan; the fan is provided with an upper impeller and alower impeller which are arranged in an up-down manner; the fan cavity is provided with an upper air inlet and a lower air inlet corresponding to the upper impeller and the lower impeller respectively; the lower air inlet of the fan cavity is in fluid communication with an air outlet of the exhaust cavity; and an air outlet of the fan cavity is in fluid communication with an air inlet of the exhaust channel. The invention further relates to a cooking device with the exhaust structure and an exhaust method of the cooking device. The exhaust efficiency of the cooking device can be improved; steam in the inner container can be prevented from being directly sprayed to a user after steaming; and the usage experience of the user is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

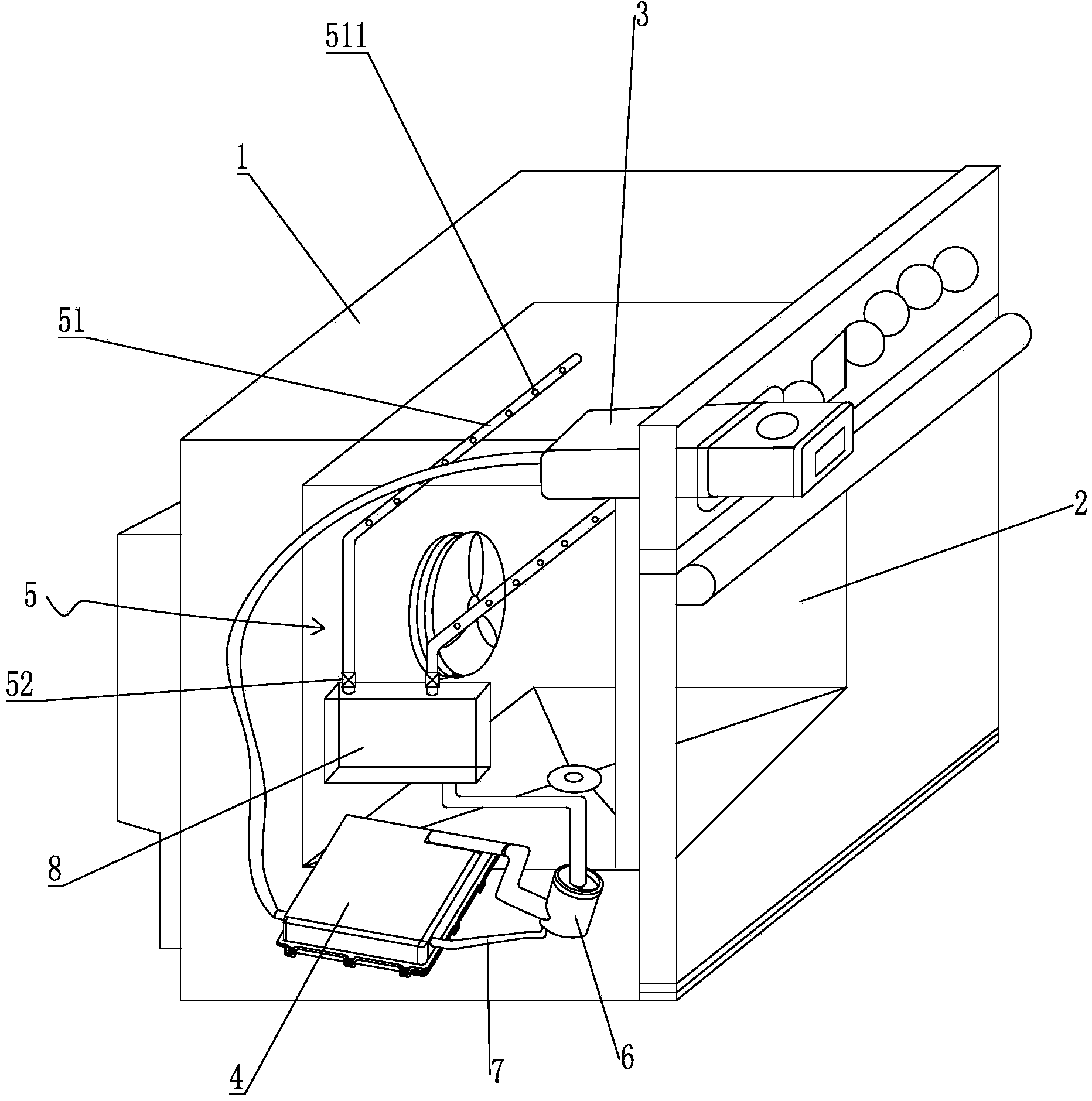

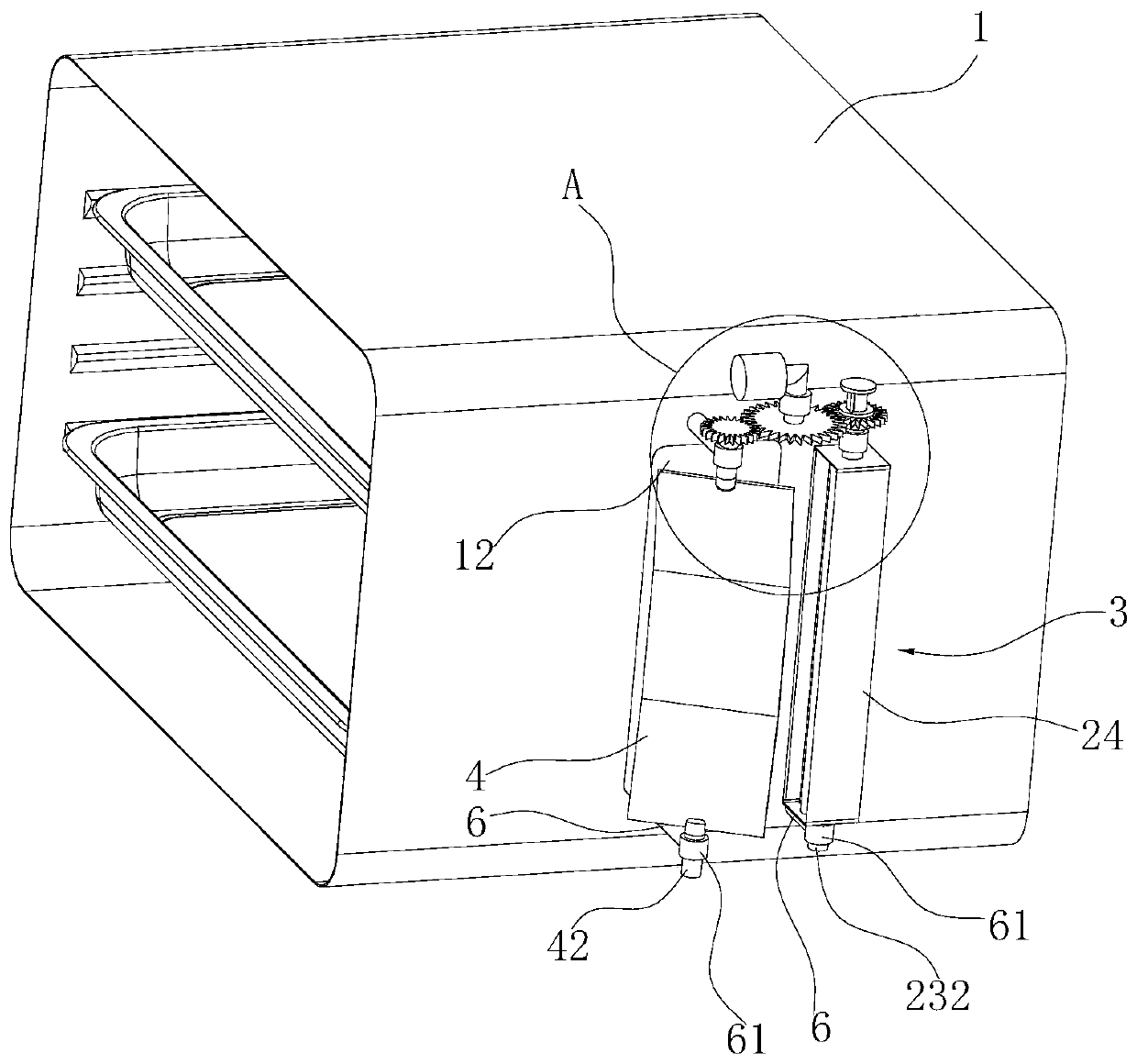

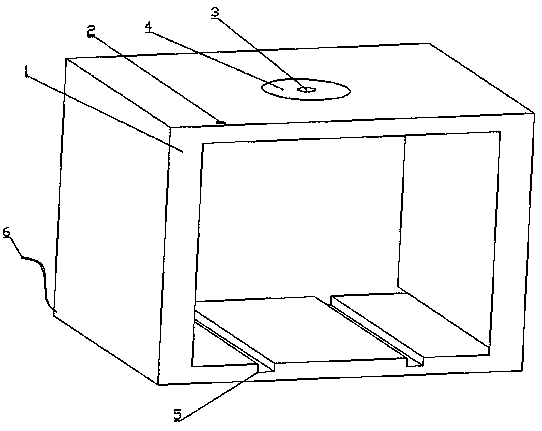

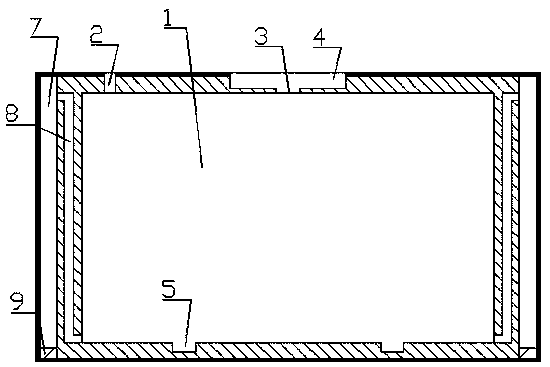

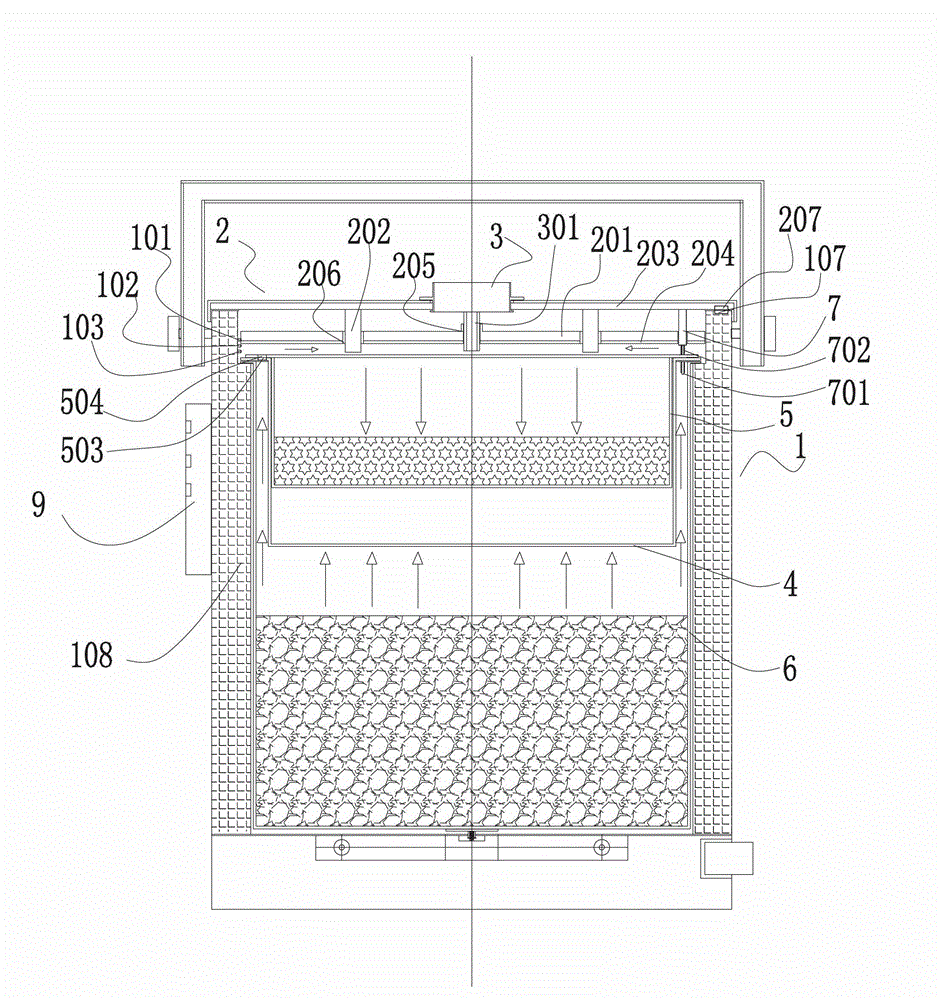

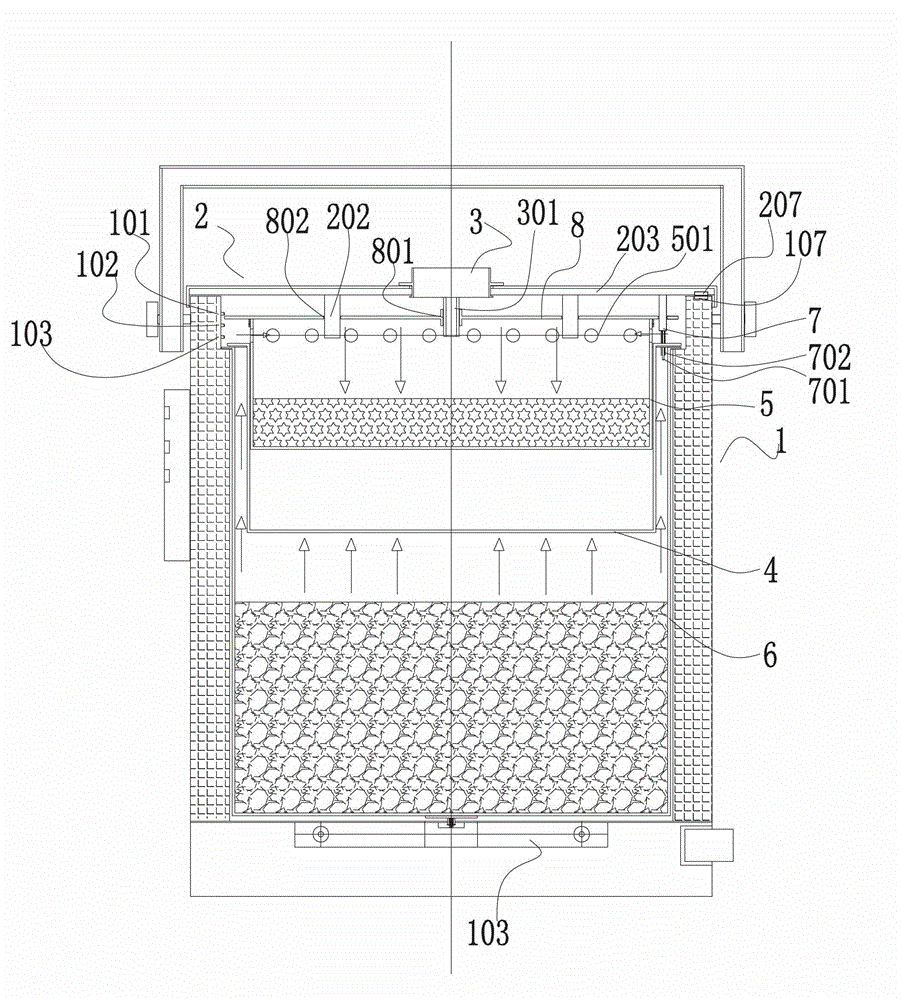

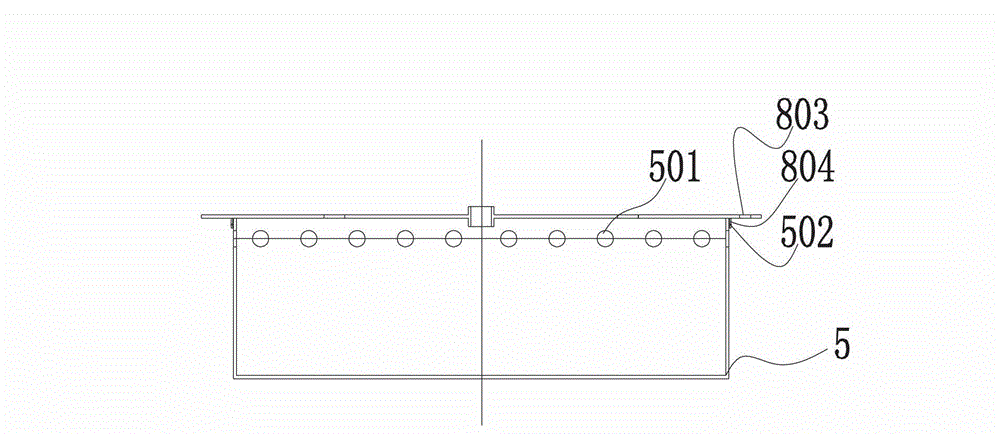

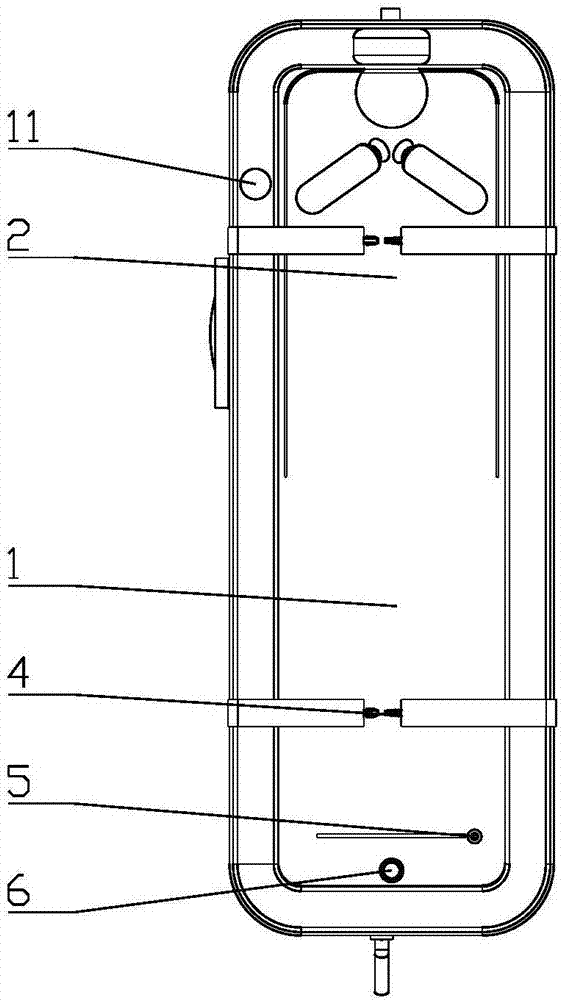

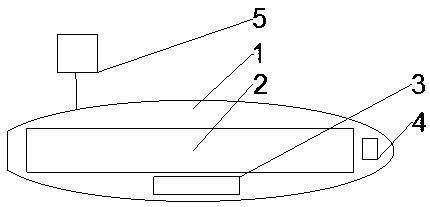

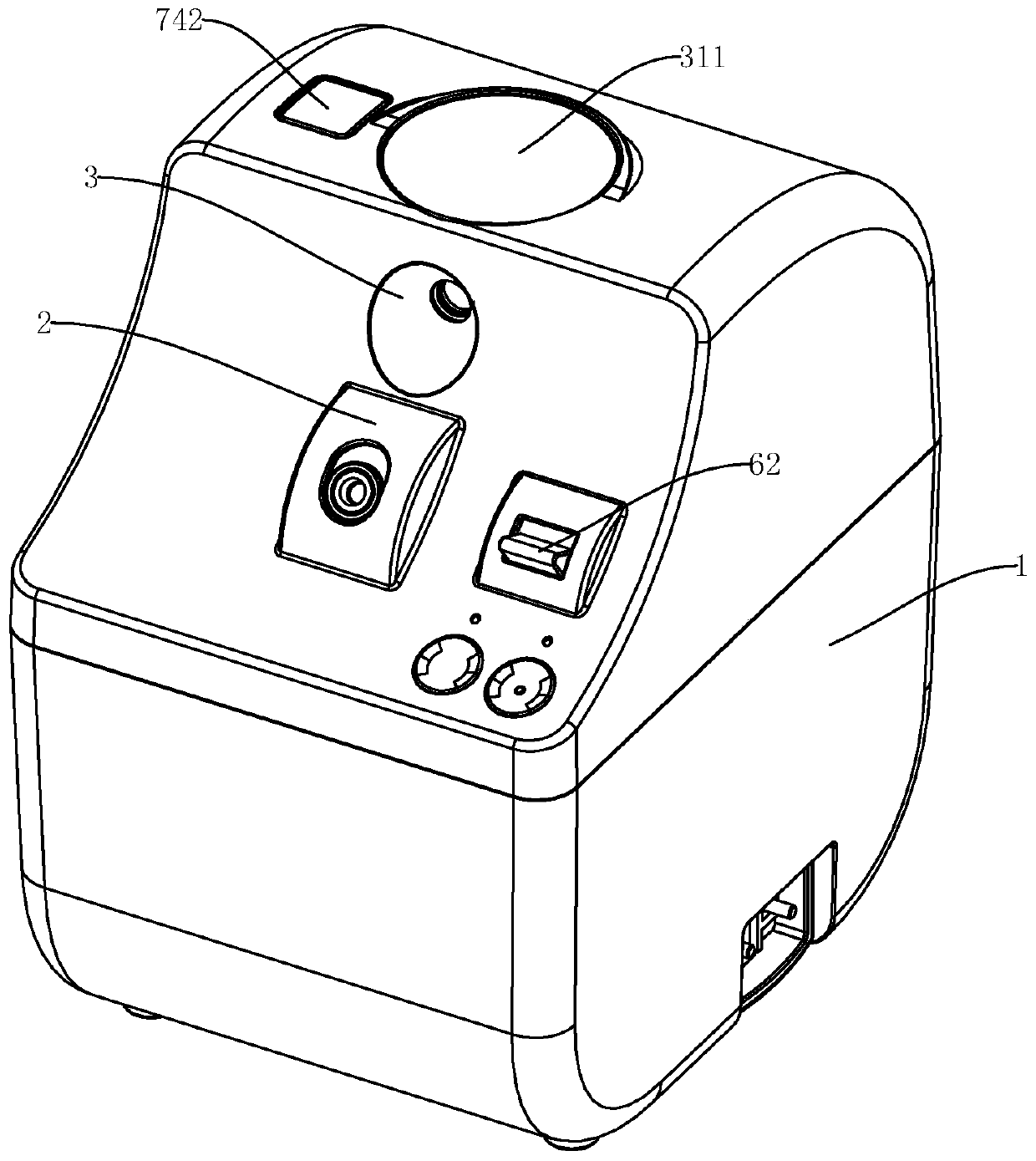

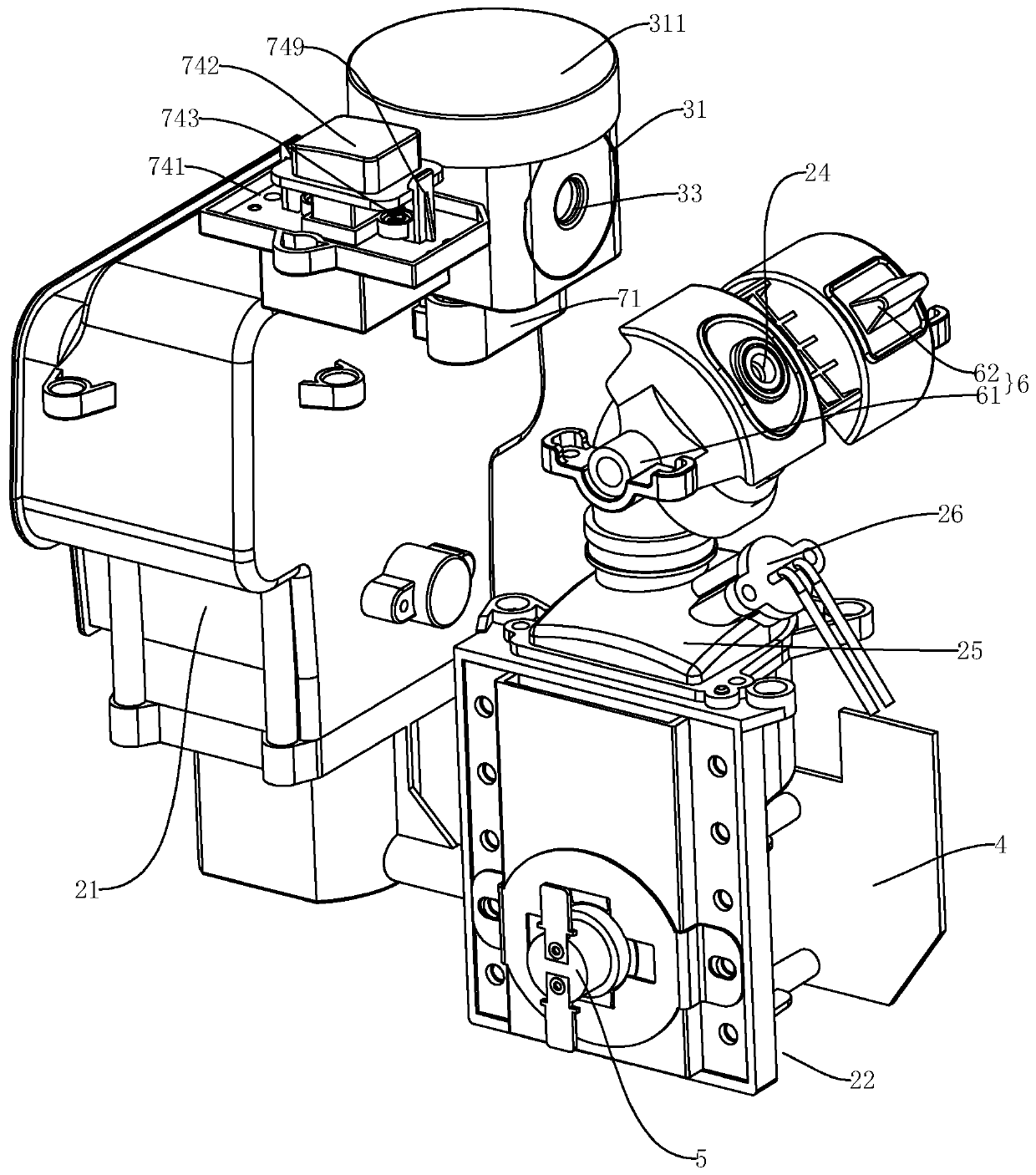

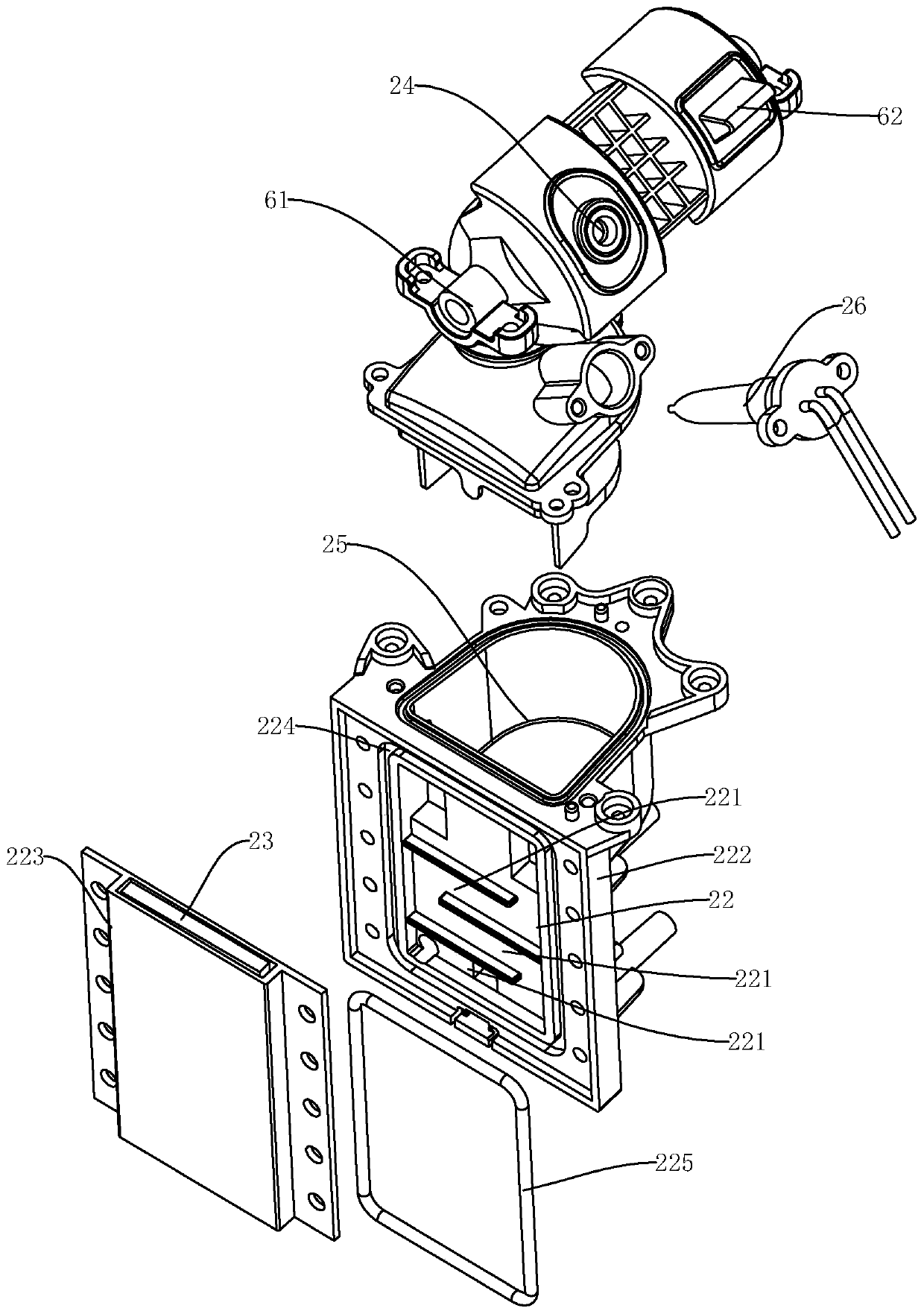

Steaming oven

The invention relates to a steaming oven. The steaming oven is characterized by comprising a tank body (1) and a steaming oven chamber (2), wherein a water filling device (3) is arranged on the tank body (1); a steam generator (4) is connected to the water filling device (3); a steam spraying device (5) is connected to the steam generator (4); a drying device (6) for reducing moisture in steam is arranged between the steam generator (4) and the steam spraying device (5). The drying device for reducing the moisture in the steam is arranged between the steam generator and the steam spraying device so as to greatly reduce the moisture in the steam, so that food cooked by the steaming oven is better in mouth feel and more delicious.

Owner:VATTI CORP LTD

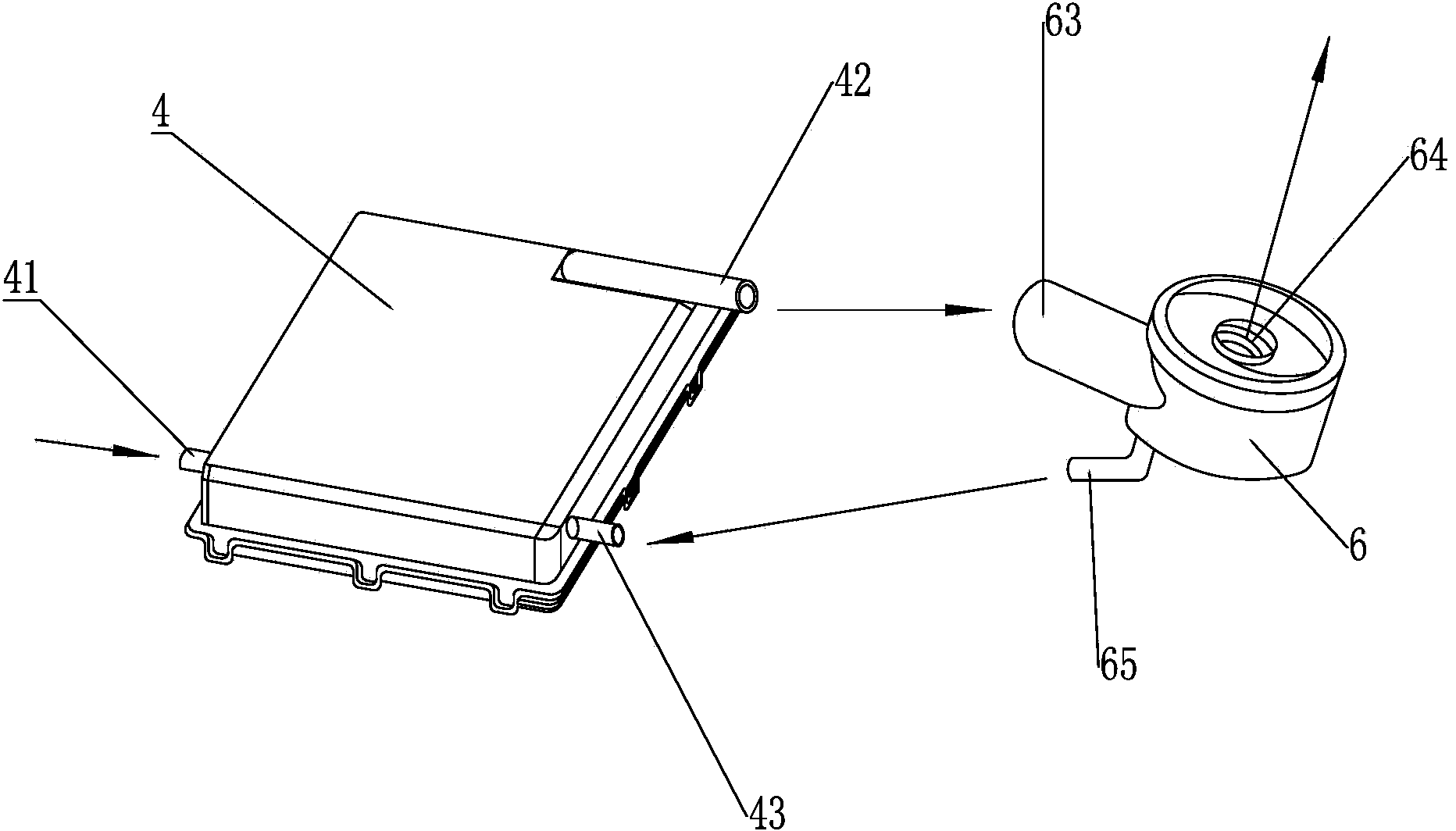

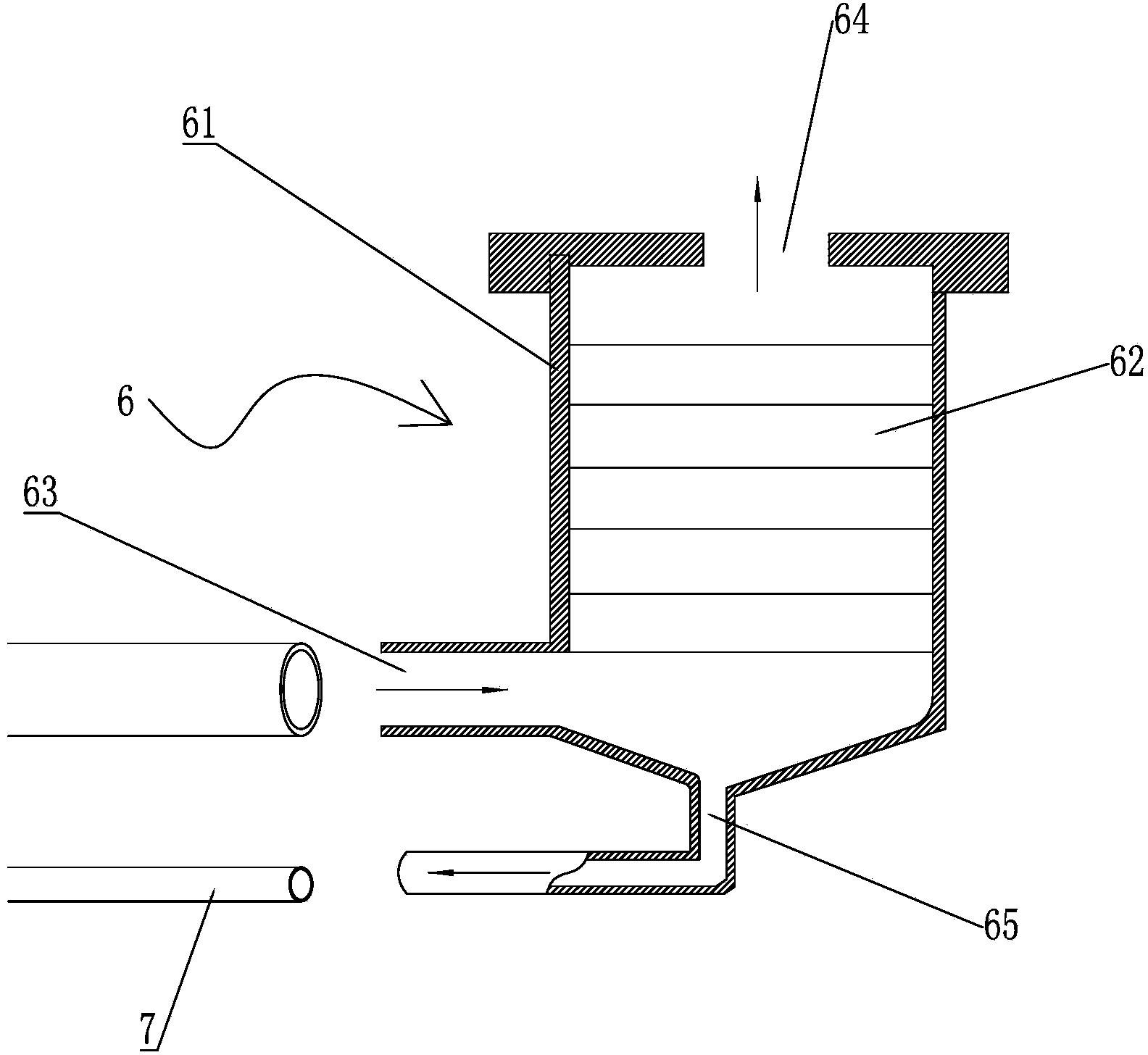

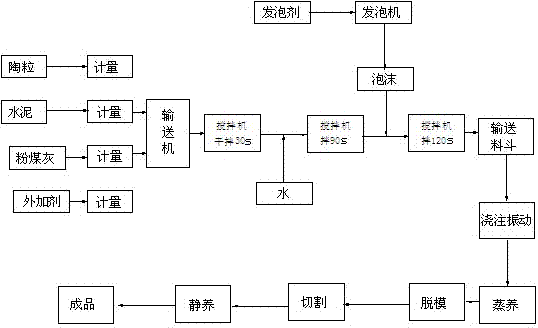

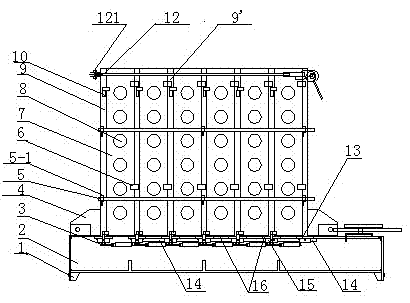

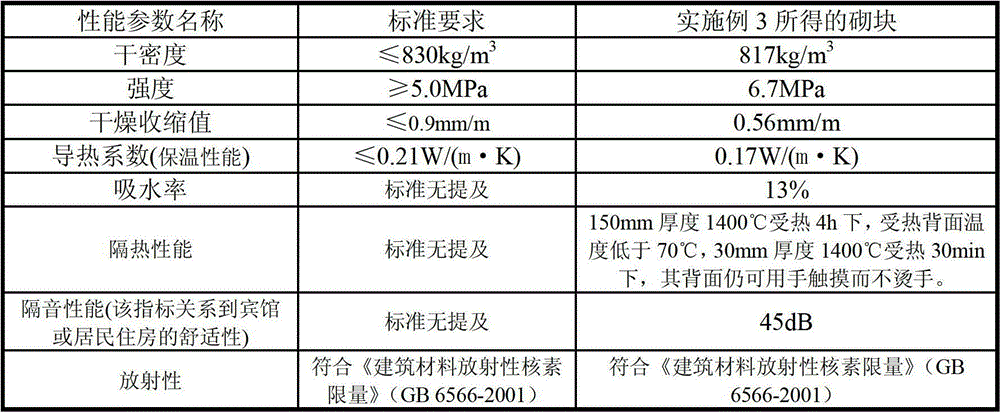

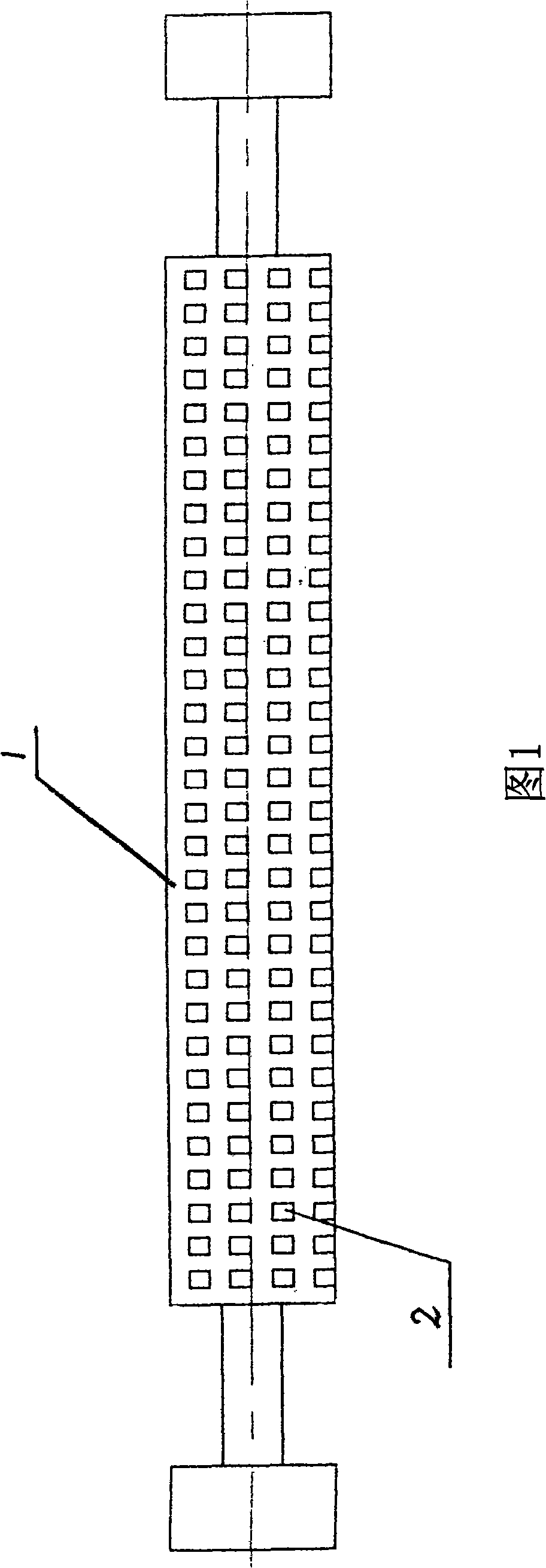

Energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould

ActiveCN102503522ALow water absorptionGood energy saving effectCeramic shaping apparatusCeramicwareCorrosion resistantEarthquake resistant

The invention relates to an energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould. The energy-saving self-heat-insulation ceramsite building block is made of, by weight, 35-50% of ceramsite, 20-29% of cement, 15-30% of coal ash, 0.5-1% of fibers, 2-5% of foaming agent, 0.3-0.5% of water reducing agent, 0.1-0.3% of waterproof agent and 0.2-0.5% of catalyst, wherein the volume of the ceramsite accounts for more than 80% of that of the whole building block. The manufacturing method of the building block includes steps of material selecting, metering, stirring, pouring, vibrating, steaming, tube drawing for demoulding, cutting forming and stacking for rest. The forming mould of the building block can be used for once forming of multiple medium-sized rectangular ceramsite building blocks, and each building block can be conveniently cut into standard small ceramsite building blocks. The energy-saving self-heat-insulation ceramsite building block is high in ceramsite content and has the advantages of light weight, warm retention, heat insulation, sound insulation, sound adsorption, low water adsorption, fire resistance, freezing resistance, quake proofing, corrosion resistance and the like.

Owner:NINGBO PINGHAI BUILDING MATERIALS

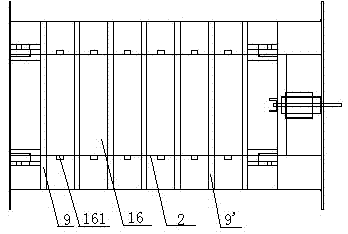

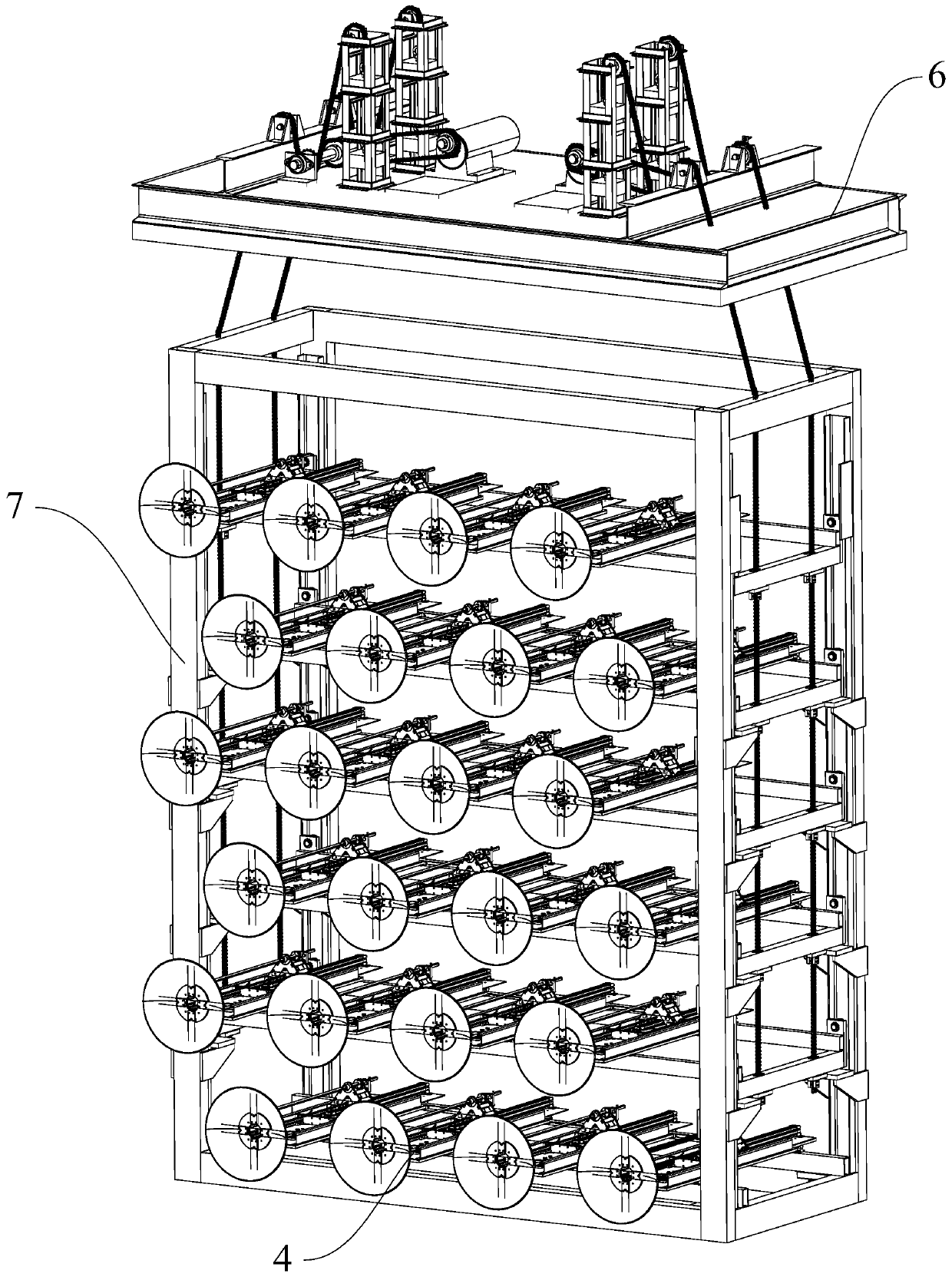

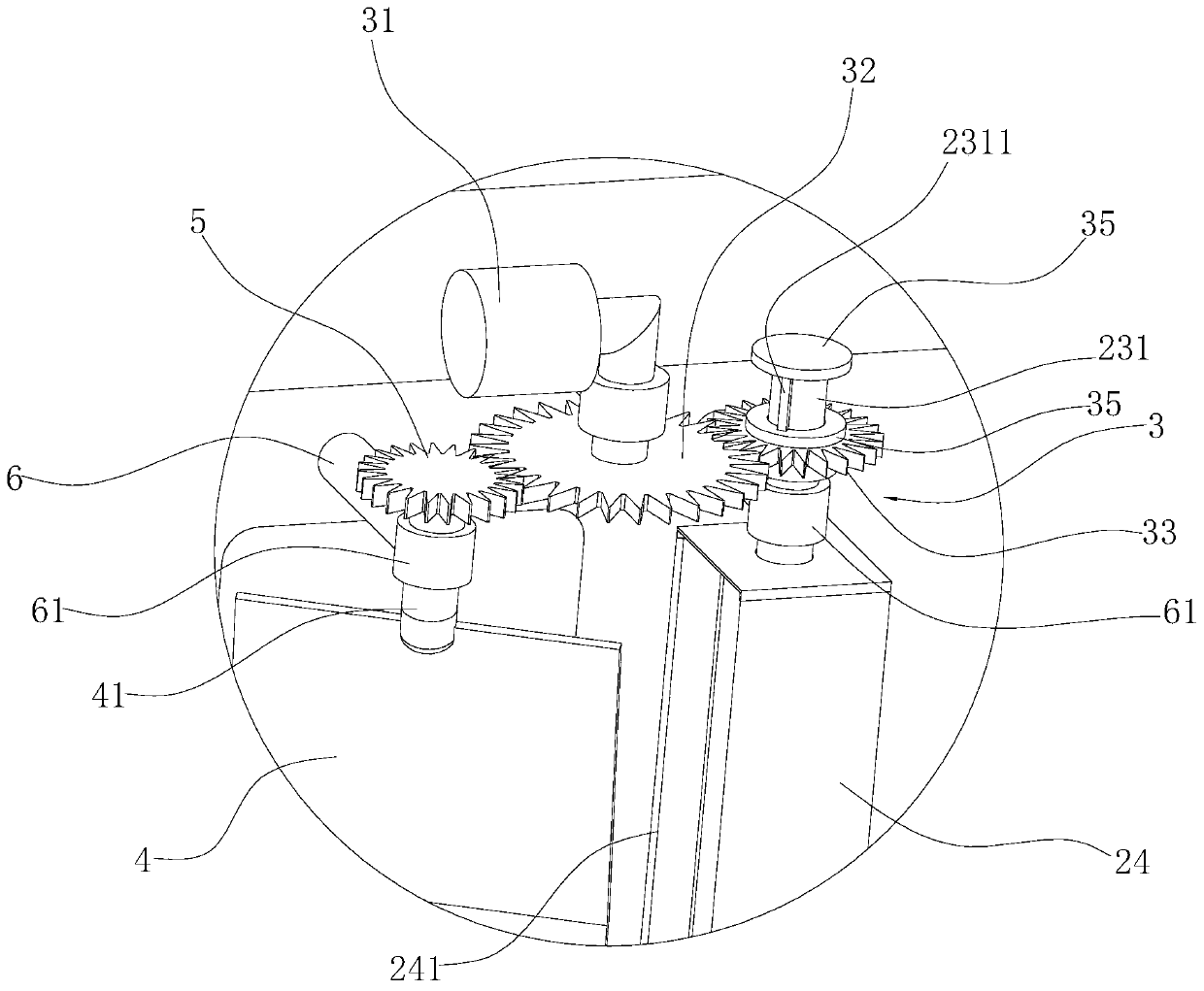

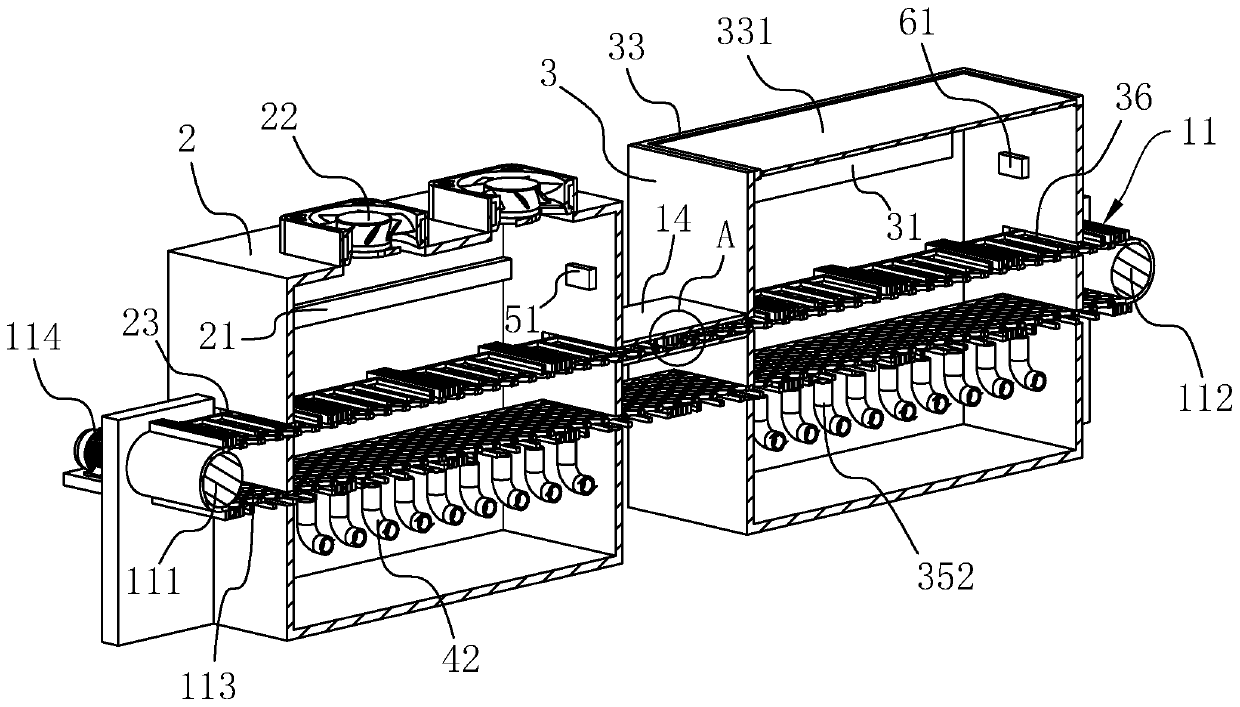

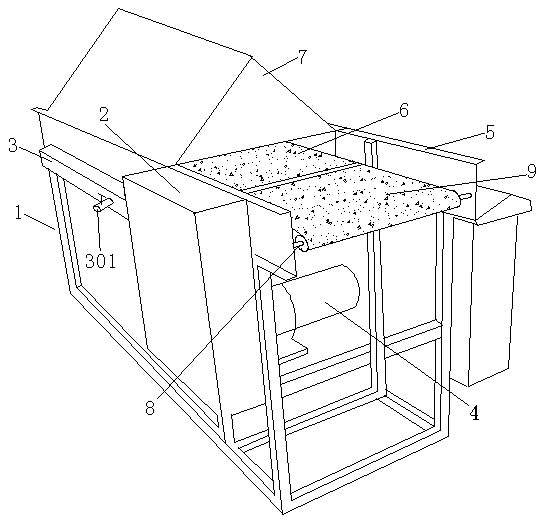

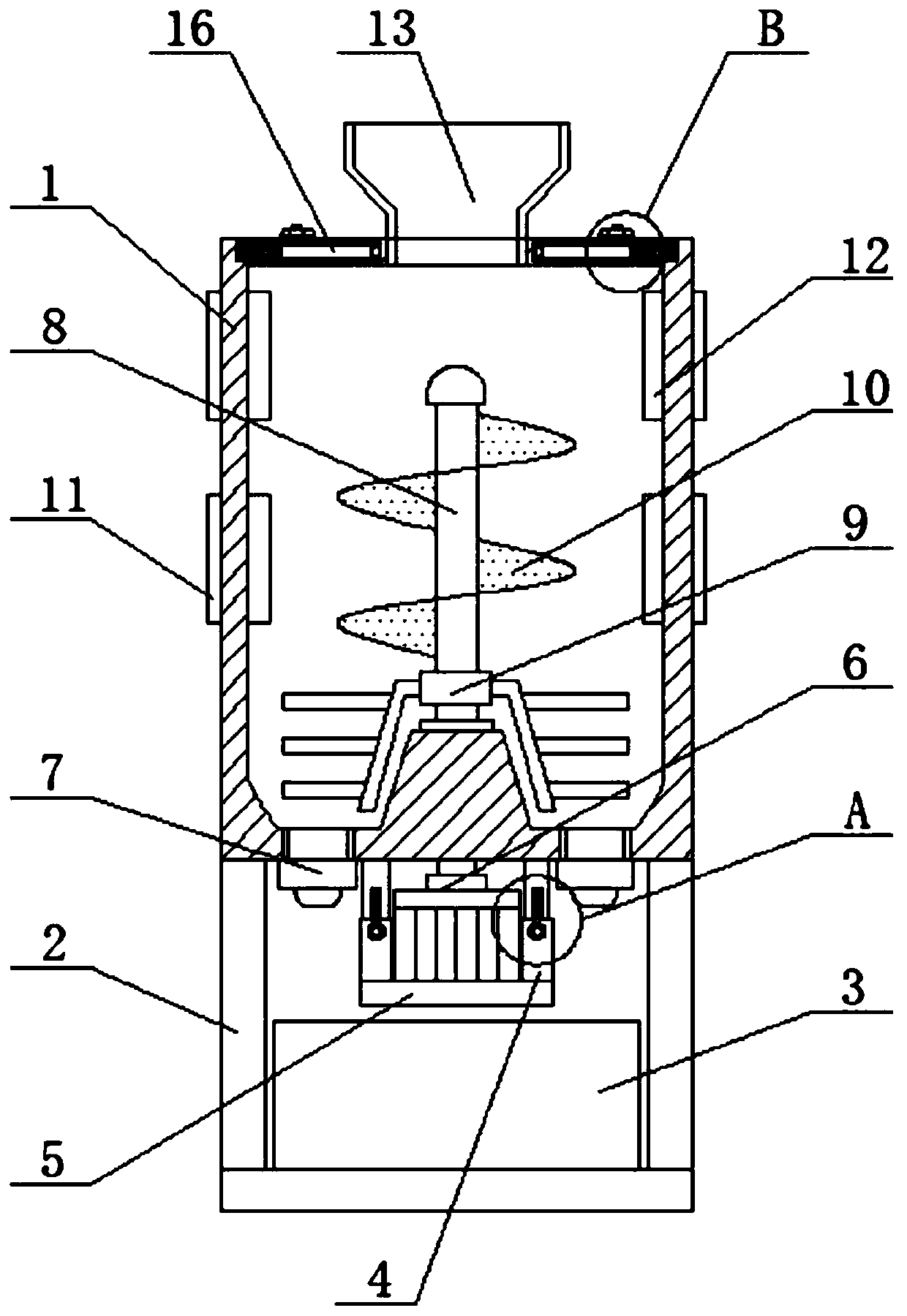

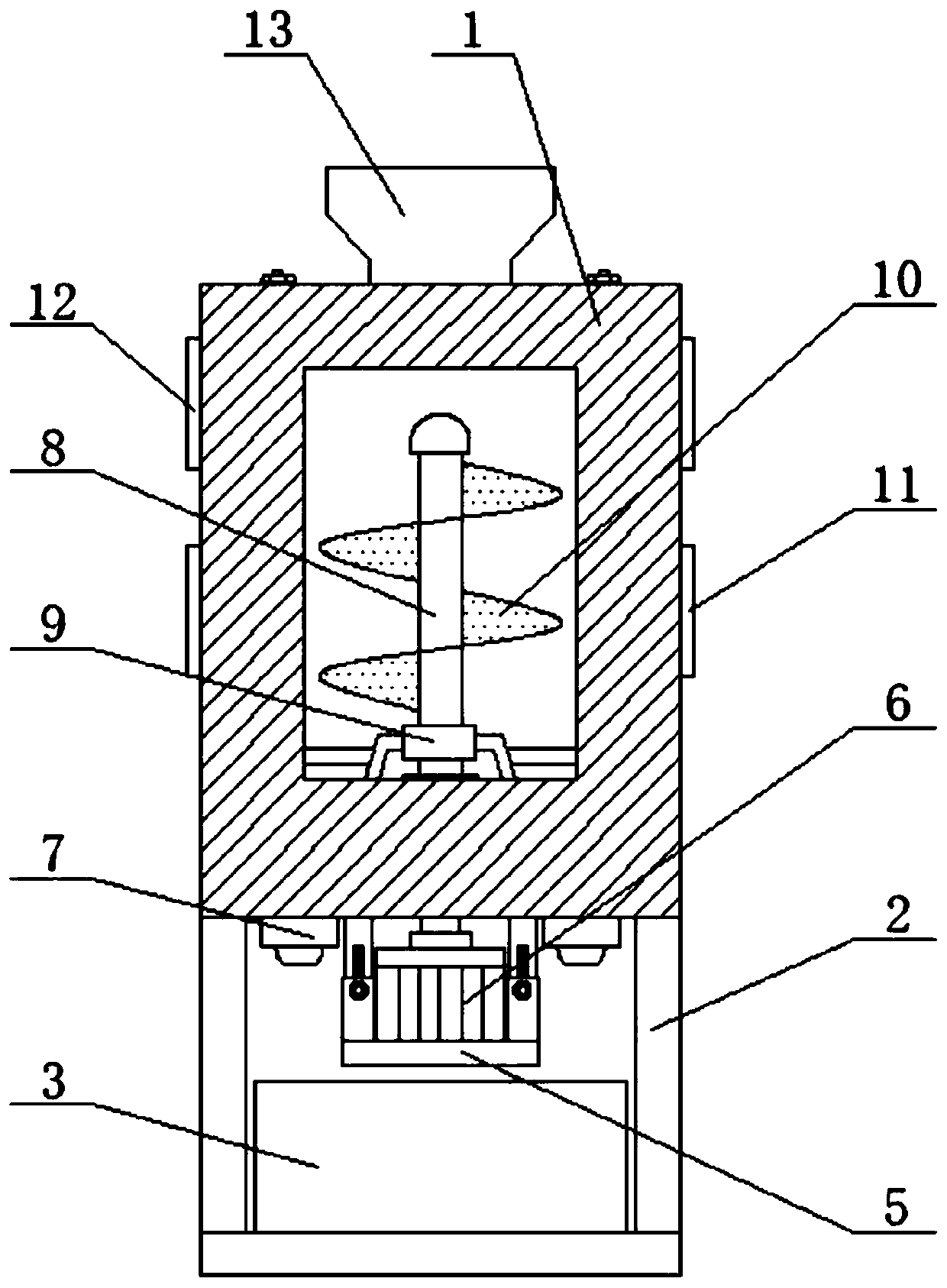

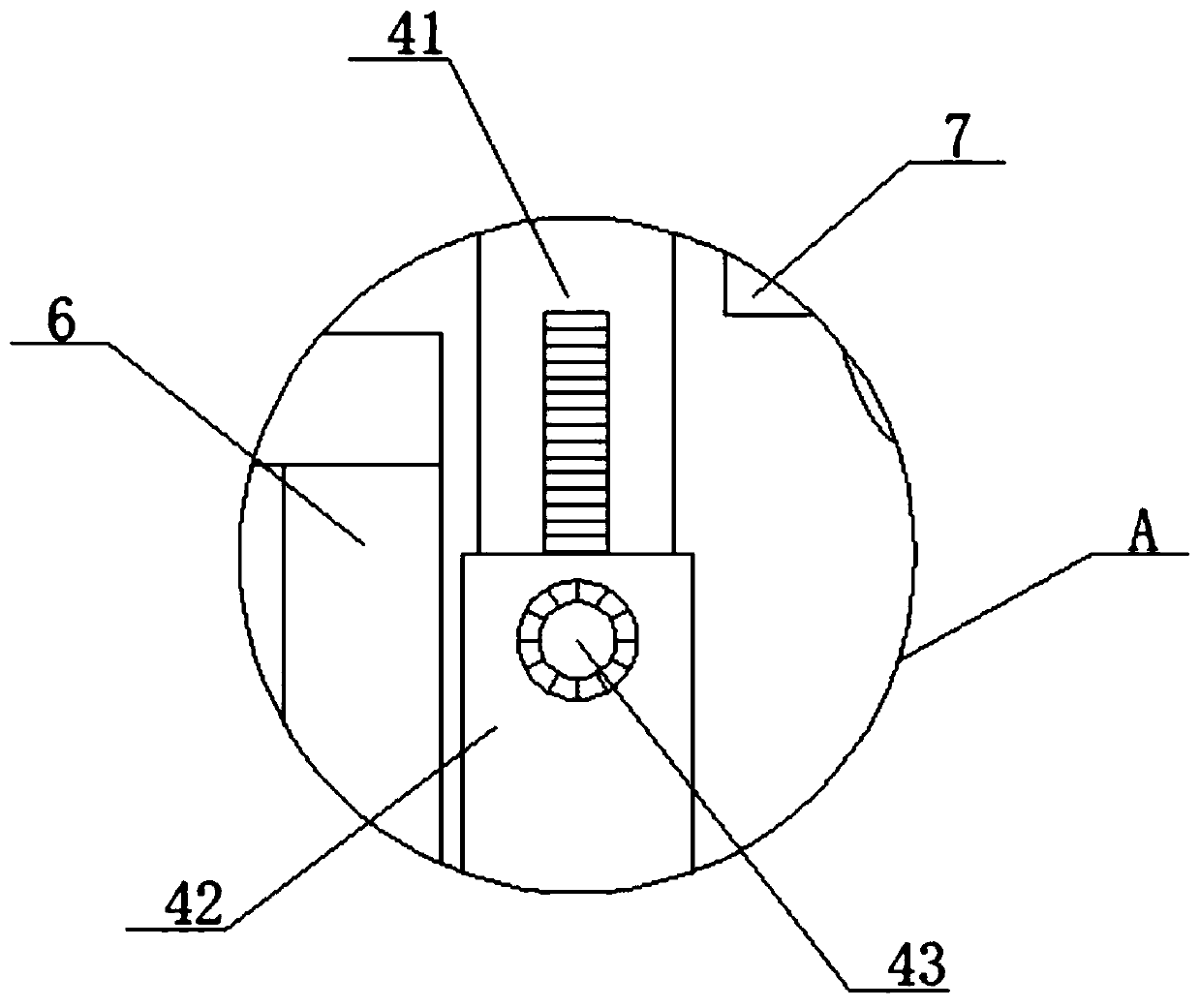

Fully-automatic brick tea forming equipment

ActiveCN106900890AAccurate quality controlImprove qualityPre-extraction tea treatmentClimate change adaptationBrickRobotic arm

The invention relates to fully-automatic brick tea forming equipment which is matched with a press machine (135) during use and comprises a weighing component (127), a steaming component (128), a mechanical arm demolding component (129), a mold component (130), a template conveying and discharging component (131) and an electric control system; an outlet of the weighing component (127) corresponds to an inlet of the steaming component (128); an outlet of the steaming component (128) corresponds to a feeding port of the mold component (130); the mechanical arm demolding component (129) is respectively matched with the template conveying and discharging component (131). The fully-automatic brick tea forming equipment provided by the invention has the benefits that the quality control of raw materials is accurate, a steaming effect is good, uniform and consistent, the quality of a finished brick is good, the pressing process is accurate to control, and a fully-automatic demolding effect is good.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

Steam-cured high-performance foam concrete block, production method and application thereof

The invention discloses a steam-cured high-performance foam concrete block which comprises 55-60% of cement, 7-9% of slag powder, 5-8% of sand, 0.5-1.0% of a water reducing agent, 0.88-3% of a curing agent, 0.06-0.3% of a foaming agent and 24-26% of water, wherein the mass of the slag powder is less than 20% of that of the cement which is P.O42.5R cement. According to the foam concrete block, the curing agent is used, so that structural pulverization, collapse of dies and the like are avoided, and the steam-curing effect is improved; water-proof, heat preservation and thermal insulation effects of products are good, and building energy saving is facilitated; the products have good durability and the same service life with a main construction; and the problems of low strength, pulverization, large shrinkage, collapse of dies and the like of low-density foam concrete are solved.

Owner:罗云峰 +2

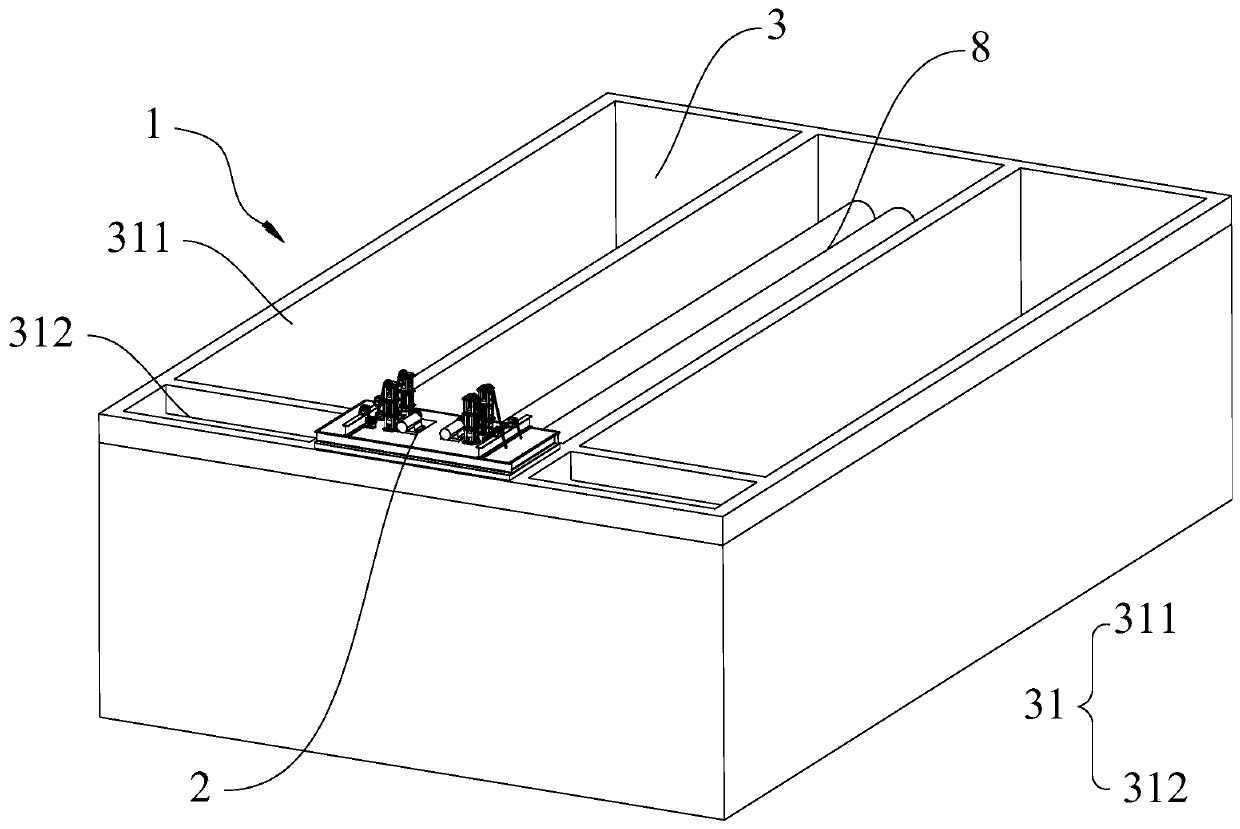

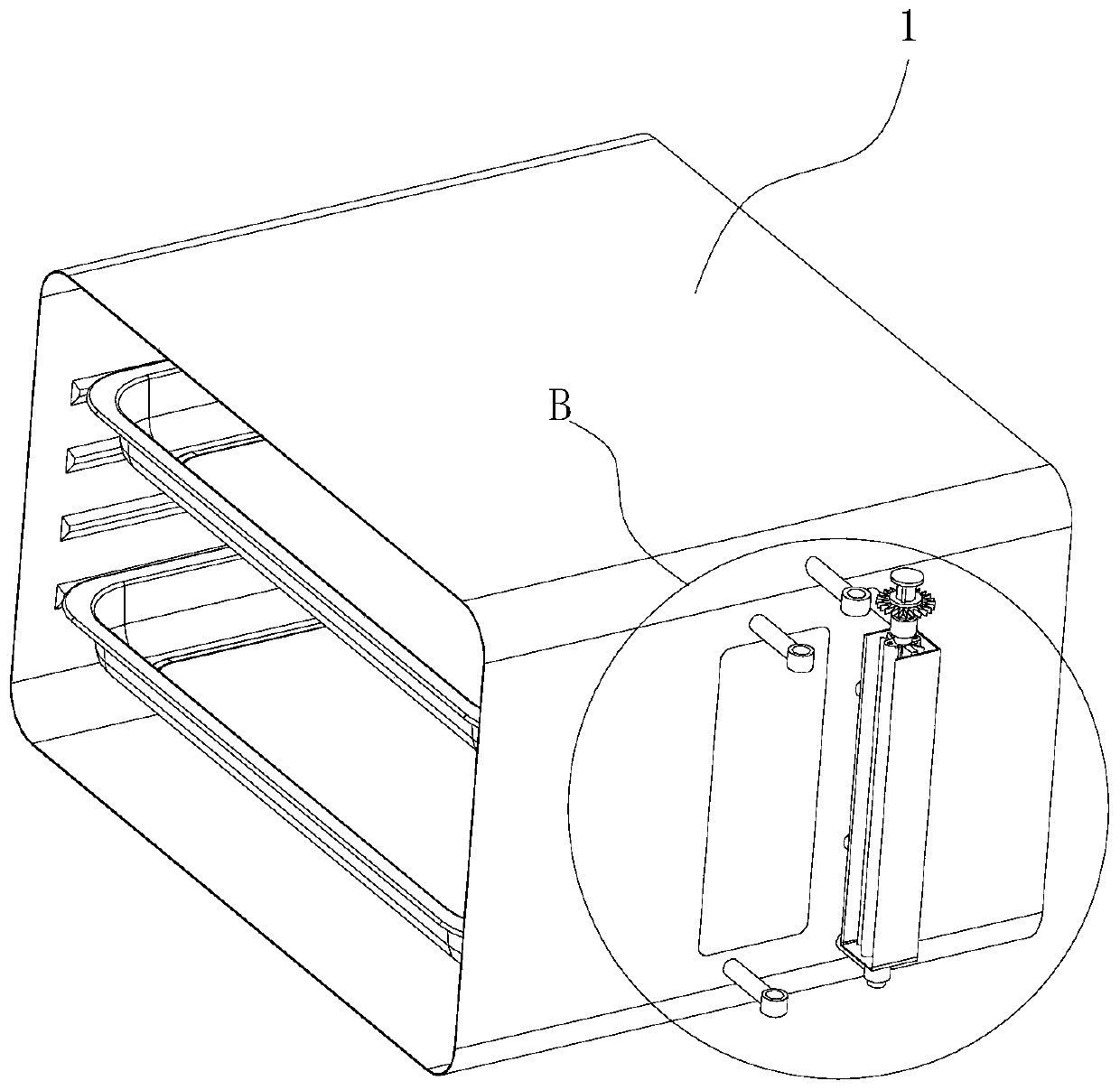

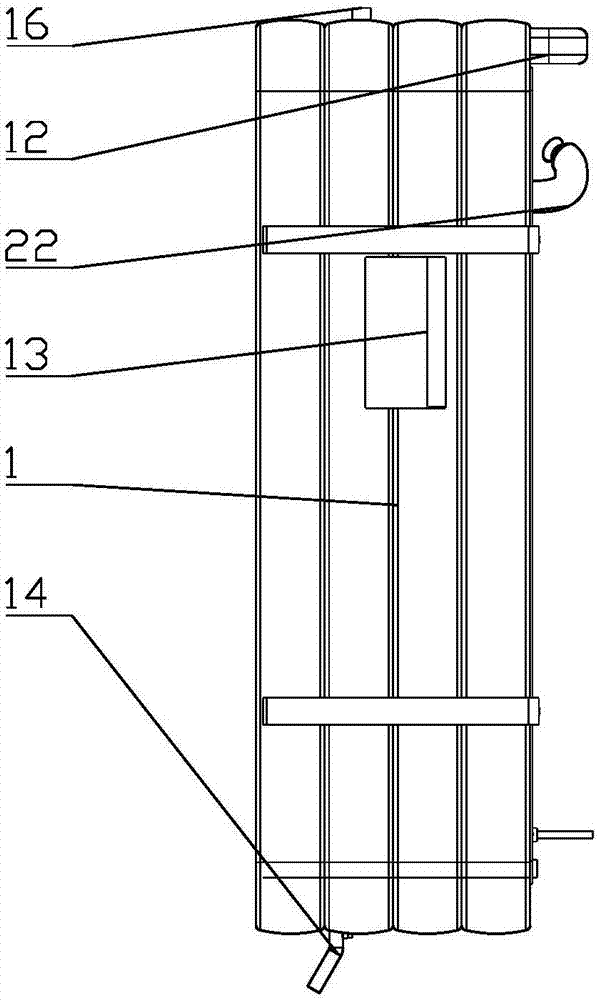

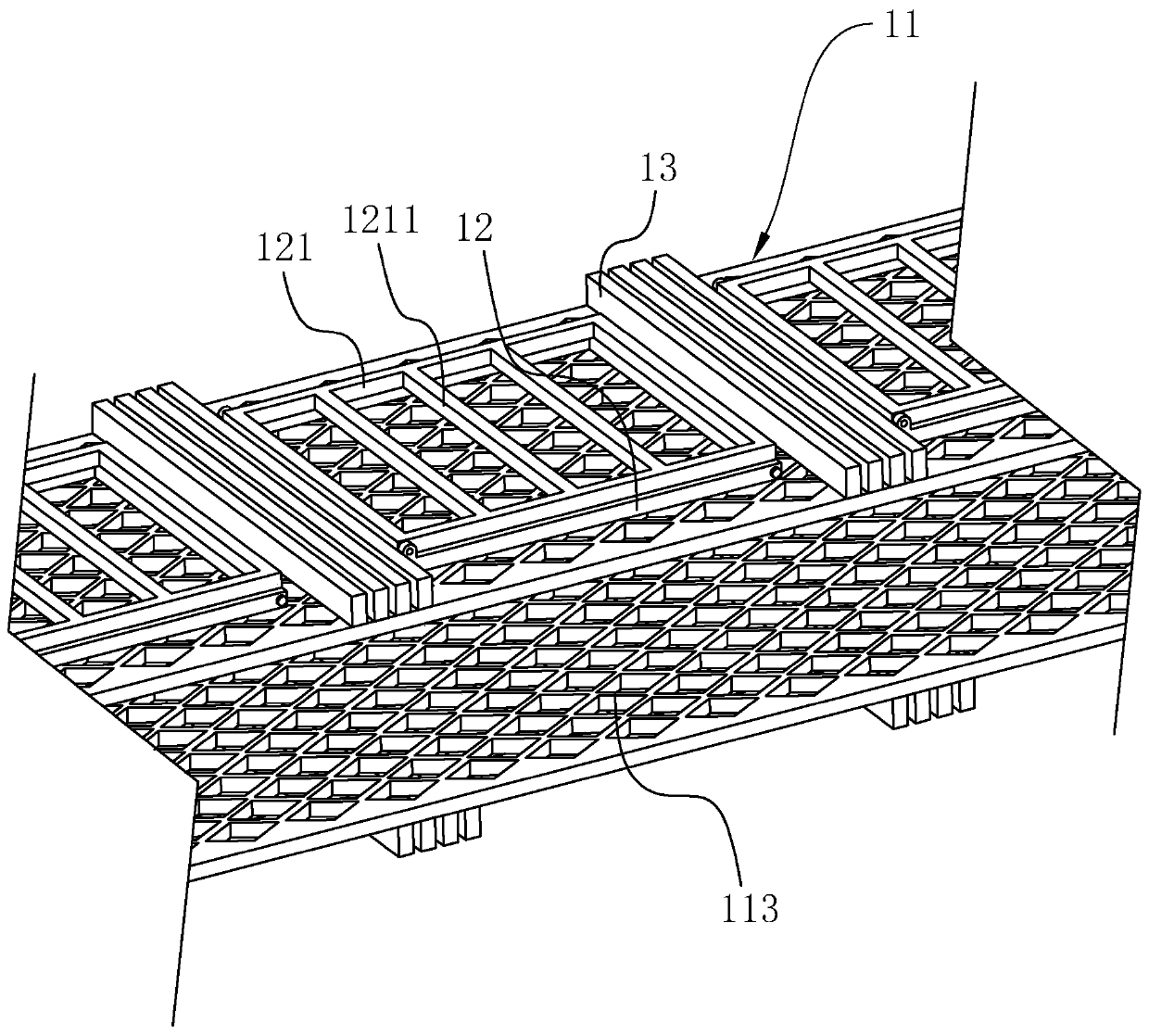

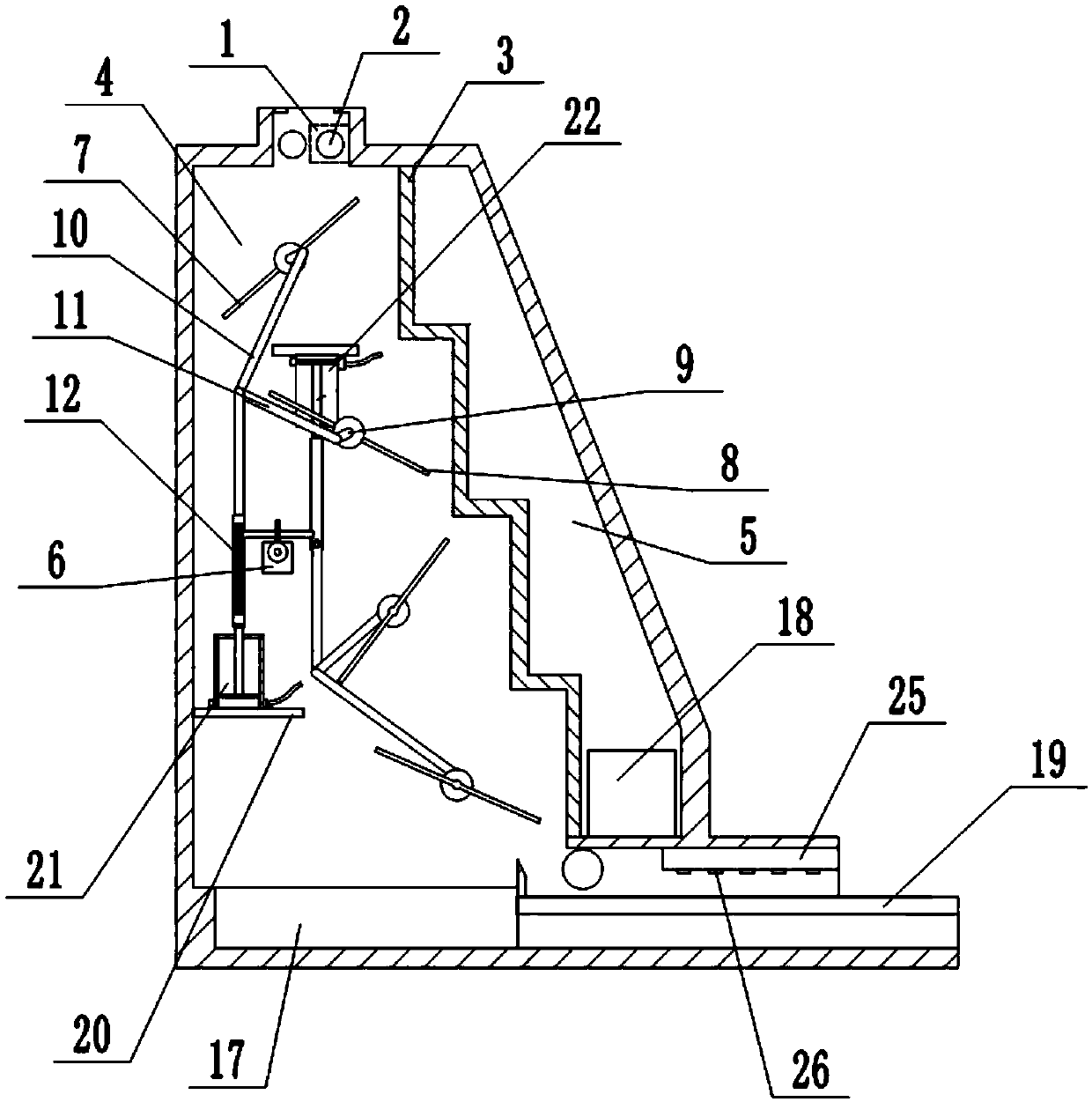

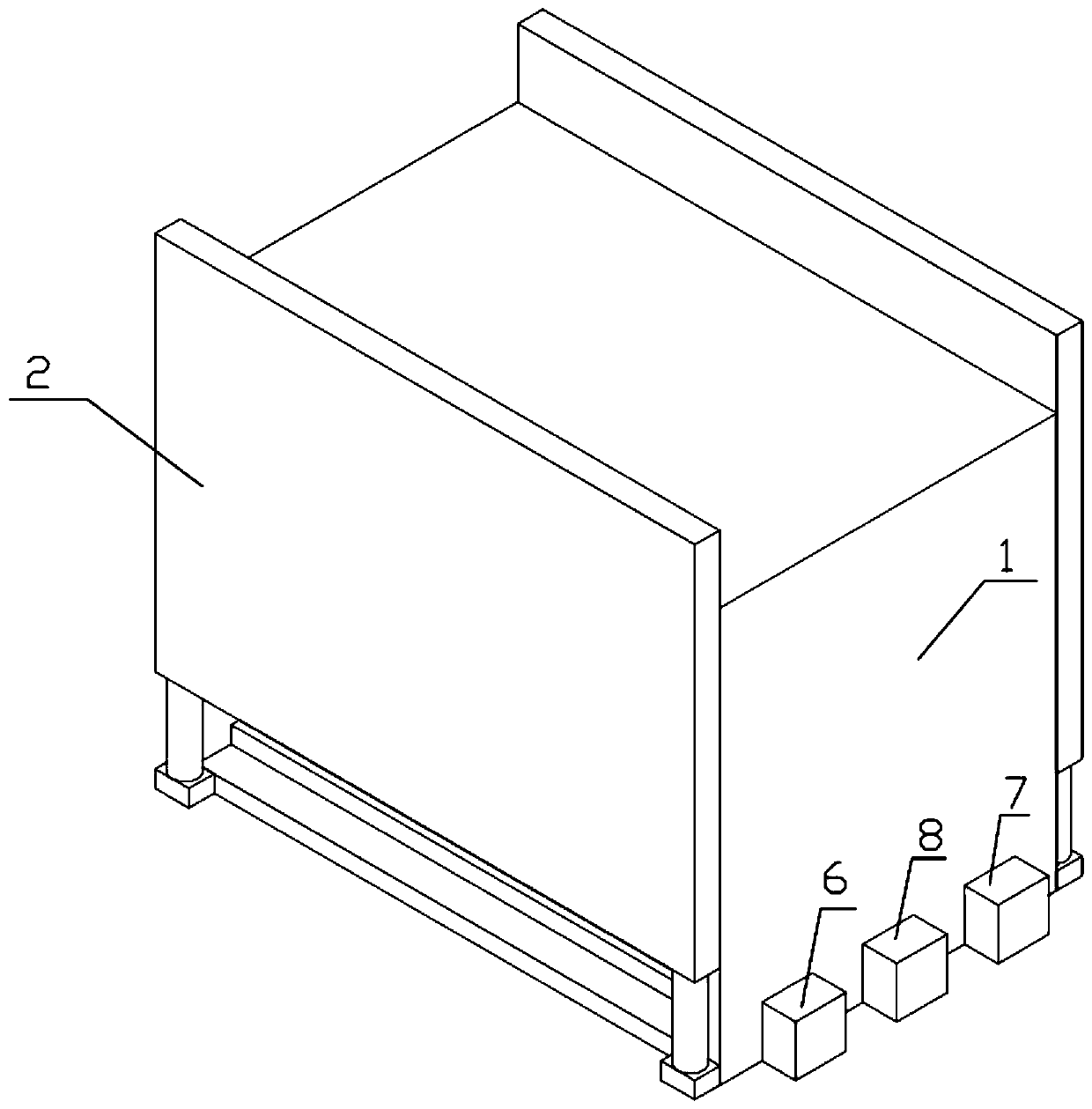

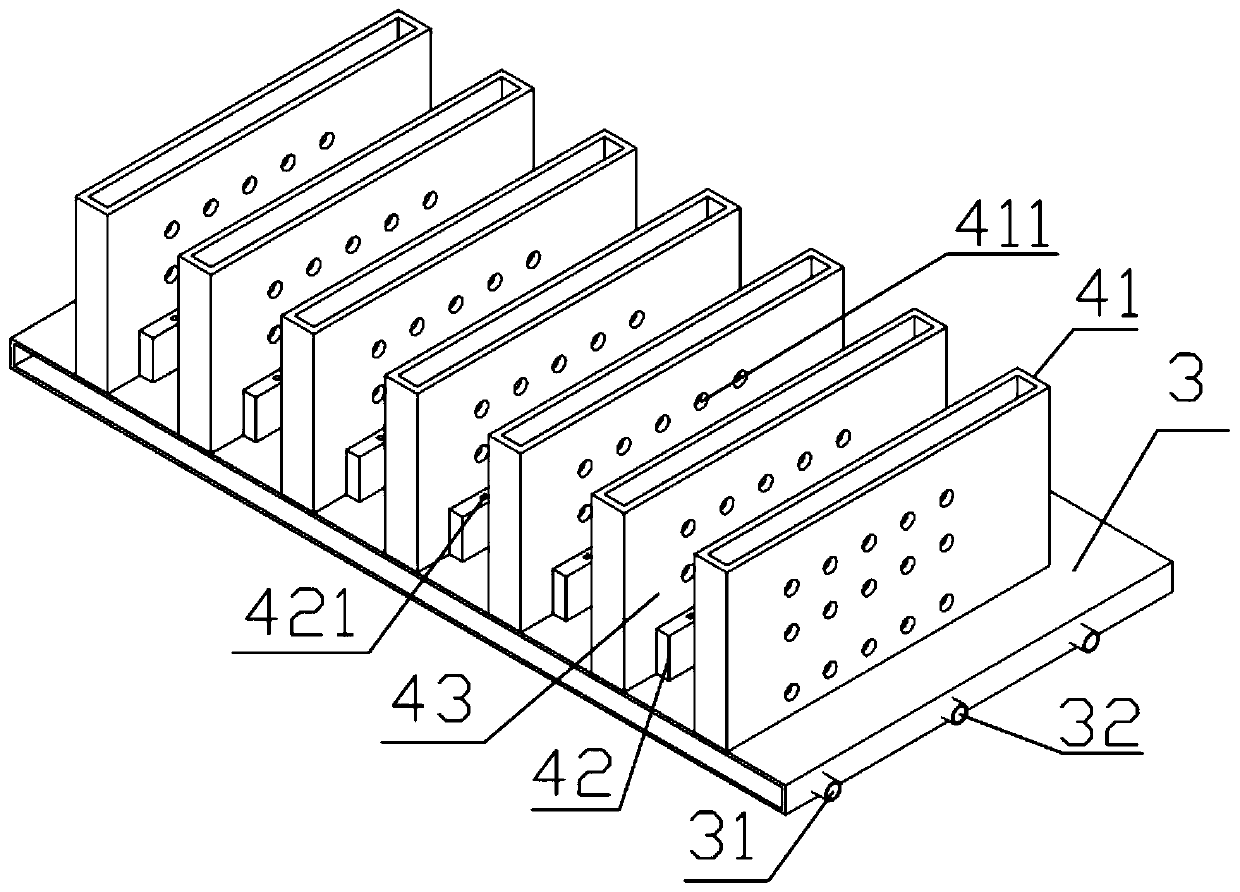

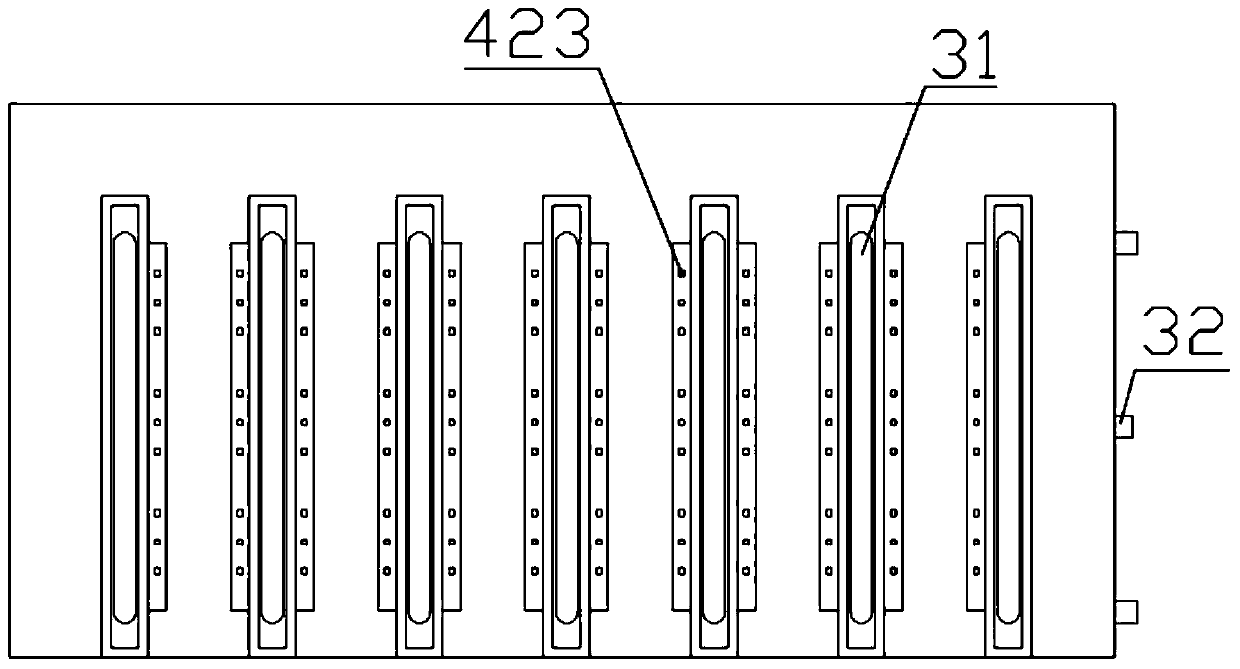

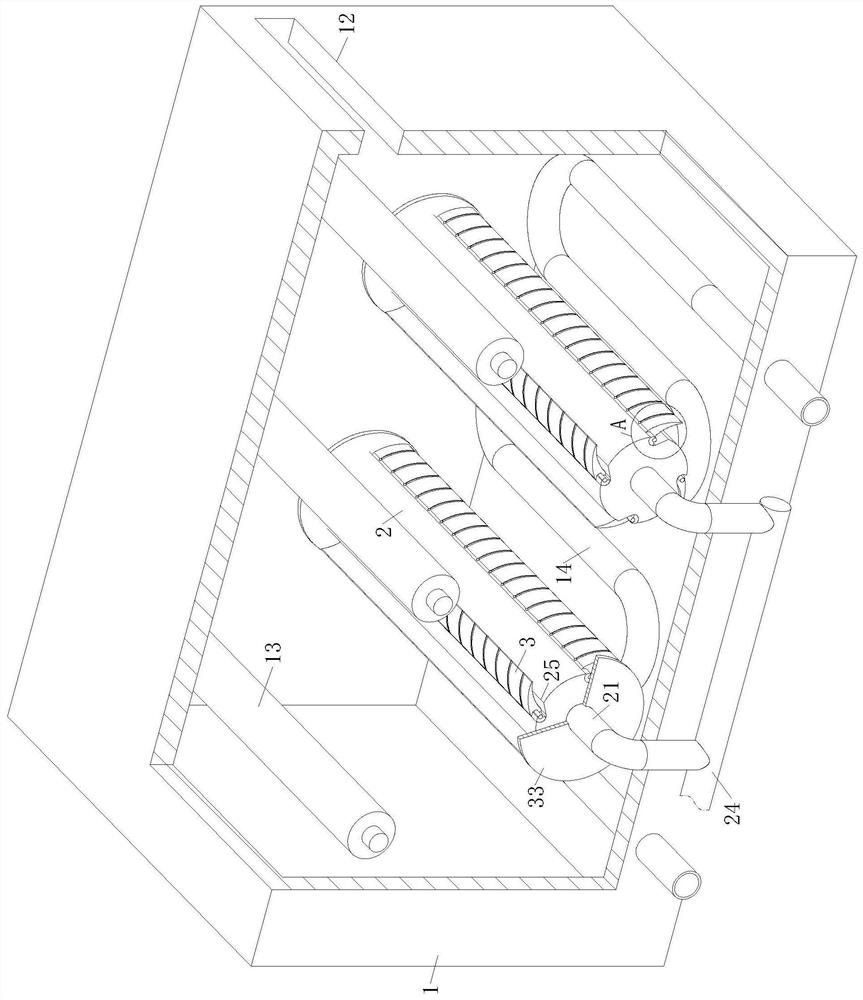

Tubular pile steam-curing system

PendingCN111015913AImprove steaming effectReduce lossCeramic shaping apparatusBulkheads/pilesGas cylinderProcess engineering

The invention discloses a tubular pile steam-curing system which comprises a plurality of pieces of tubular pile steam-curing equipment used for steam-curing and a steam-curing pool for placing the tubular pile steam-curing equipment, wherein the tubular pile steam-curing equipment comprises a plurality of steam-curing structures which are correspondingly arranged at the front end of a tubular pile residual slurry hole one by one; each steam-curing structure comprises a bottom plate, linear slide rails which are fixed on the bottom plate, and are arranged along the tubular pile residual slurryhole, a mounting frame mounted on the linear slide rail, a gas cylinder for driving the mounting frame to slide, and a steam tube which is fixedly mounted on the mounting frame, and communicates witha steam generating device; and during steam-curing, the gas cylinder pushes the mounting frame and the steam tube until the mounting frame and the steam tube enter the tubular pile residual slurry hole. The steam-curing system is arranged for introducing steam into each tubular pile independently, so that steam heat is directly transmitted to the whole tubular pile product from the inner cavity of the tubular pile product, and the space of the steam-curing pool does not need to firstly fill for transmitting the heat to the tubular pile product from a tubular pile mould. The tubular pile steam-curing system reduces loss of heat, improves heat conduction efficiency, reduces the cost, and enables the tubular pile steam-curing effect to be better.

Owner:GUANGDONG SANHE PILE CO LTD

Low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil

ActiveCN106118875AReduce high temperature timeInhibitory conditionsFatty-oils/fats refiningEdible oils/fatsPlasticizerAcid value

The invention discloses a low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil. The process specifically comprises the following steps: (1) degumming; (2) de-coloring; (3) carrying out low-temperature deodorization; (4) carrying out high-temperature deacidification. A packing tower is additionally arranged behind a plate tower of a deodorization and deacidification process, and an alkali refining neutralization reaction section is removed; oil is uniformly distributed in a thin film form and a manner of directly adding saturated steam from the bottom is adopted to effectively remove undesirable odor; high-temperature time of an oil product is shortened; two sets of packing deacidification towers are additionally arranged, wherein the temperature of the #1 deacidification tower is controlled to be 260 DEG C and is used for instantly distilling to remove a large part of acid value, and the temperature of the #2 deacidification tower is controlled to be 265 DEG C and is used for removing the acid value in the oil again, so that the acid value of finished-product oil is reasonably controlled; furthermore, the time of staying at a high-temperature section of the oil is short, the content of the trans-fatty acid is only increased by 0.2 percent to 0.3 percent and the acid value can be controlled to be about 0.1; the alkali refining neutralization section is removed so that the loss of neutral oil is reduced and the yield is improved; the consumption is reduced by about 0.03 percent to 0.05 percent by one acid value; meanwhile, a plasticizer and the acid value in the oil product can be effectively removed.

Owner:青岛天祥食品集团有限公司

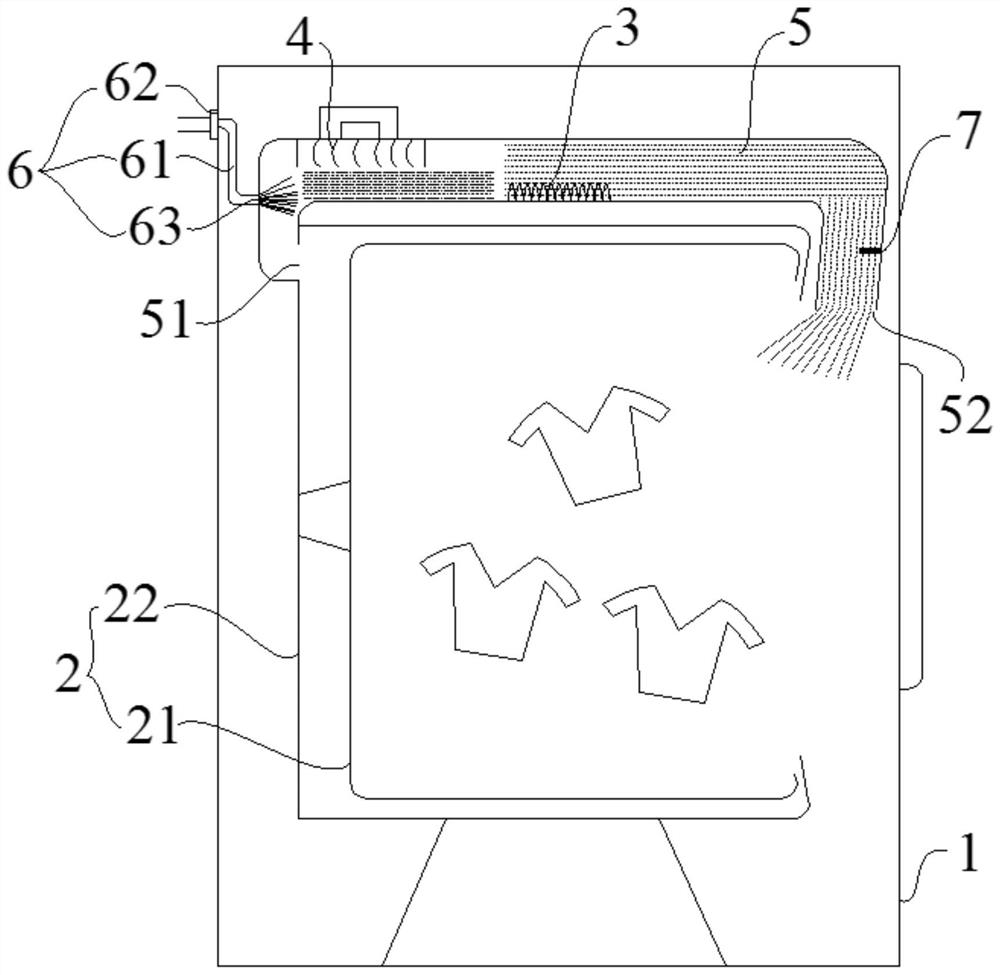

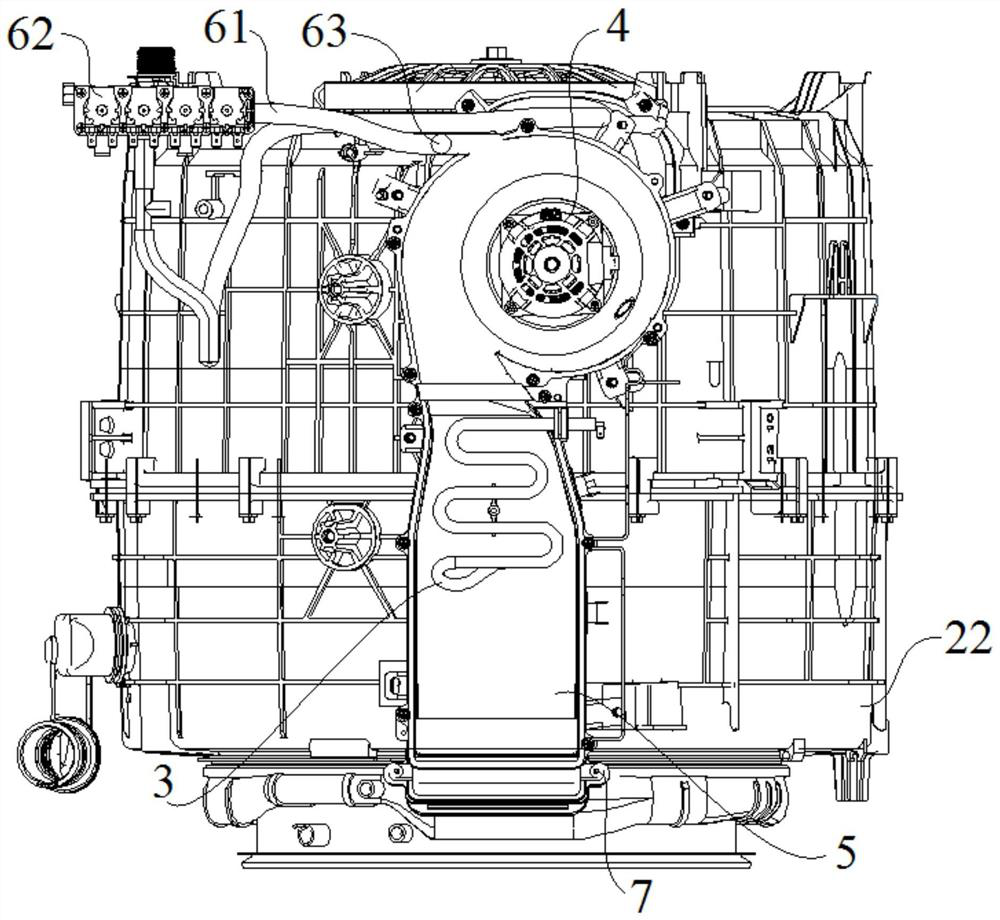

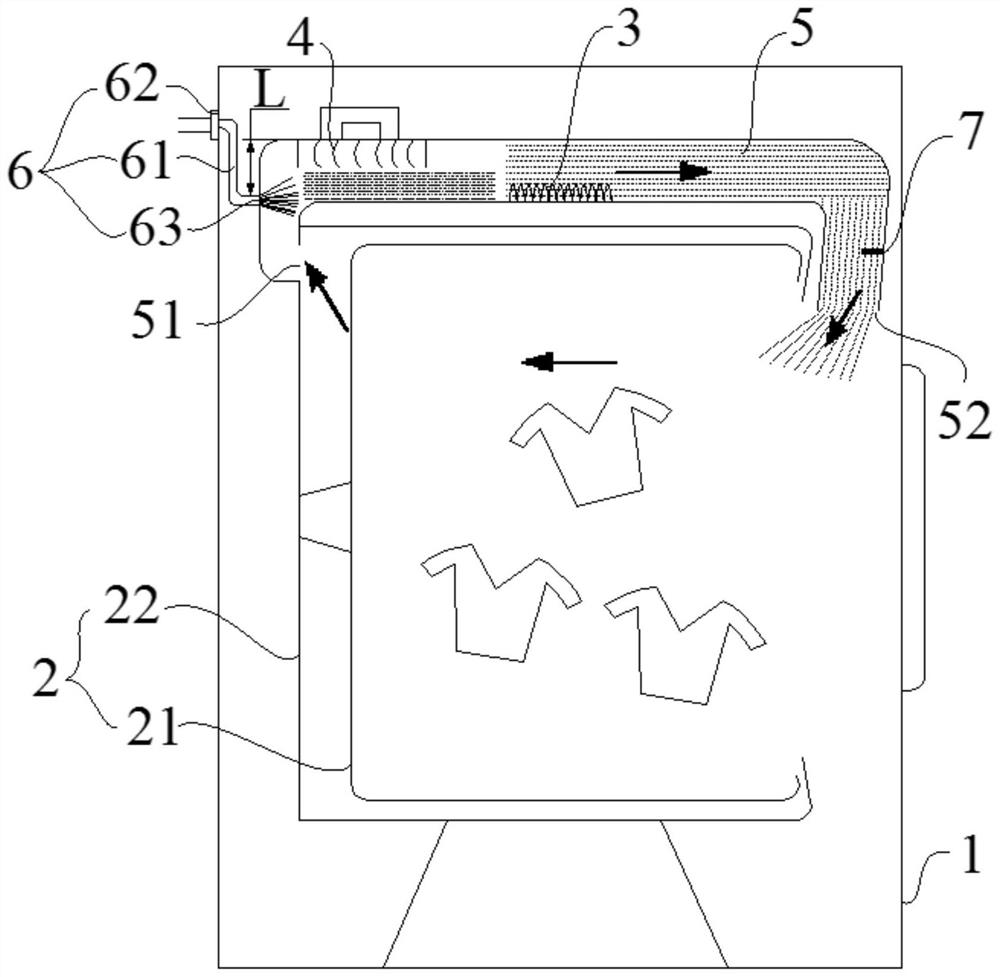

Control method of washing machine

PendingCN112160119AWith steaming and scalding functionLow costControl devices for washing apparatusTextiles and paperLaundry washing machineElectric machinery

The invention discloses a control method of a washing machine, and relates to the technical field of washing machine control. The control method is used for solving the problem of high cost of a washing machine with a wrinkle removing function. The washing machine comprises a spraying device, a motor and a drying air duct between a shell and a washing drum, the drying air duct communicates with different positions of the washing drum, and a heating device and a fan are installed in the drying air duct. The spraying device comprises a spray head mounted in the drying air duct, the spraying direction of the spray head is consistent with the air guide direction of the drying air duct, and the fan is used for guiding water sprayed out by the spray head to the heating device. The control methodcomprises the steps that after a steaming washing operation signal is received, the motor is controlled to drive the washing drum to rotate to a preset rotating speed, and the current weight value ofthe washing drum is obtained; according to the current weight value, the total number of times of the steaming washing process needing to be carried out is determined; the heating device is controlled to be started, the fan and the spraying device are controlled to circularly execute the steaming washing process, and the number of times of executing the steaming washing process is counted; and after the number of times of counting reaches the total number of times, the washing machine exits from the steaming washing process.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

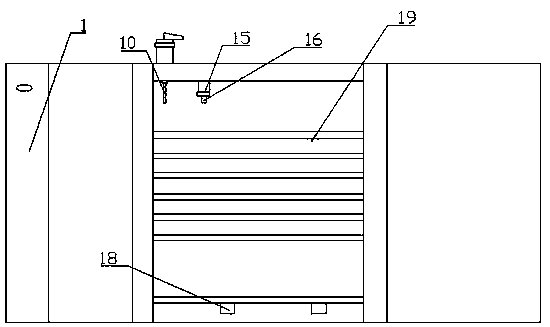

Inner container structure and cooking device thereof

ActiveCN110859503AGood choiceImprove efficiencyLighting elementsSteam cooking vesselsEngineeringFood coloring

The invention relates to an inner container structure. The inner container structure comprises an inner container and a lamp with an illuminating lamp tube, the lamp also comprises a heating lamp tube, a sidewall of the inner container is provided with an illuminating opening, a high-temperature-resistant light-transmitting plate is arranged in the illuminating opening in a sealed manner, the lampis arranged at the outside of the high-temperature-resistant light-transmitting plate, the illuminating lamp tube and the heating lamp tube of the lamp can move under the effect of an adjusting mechanism so that the light emitted during operation of one lamp tube can be emitted into the inner container through the high-temperature-resistant light-transmitting plate. According to the inner container structure, the food coloring effect can be improved through the heating lamp tube in a baking mode; the vapor efficiency can be improved in a steaming mode, and the problem of residue of condensateon the surface of the inner container after finishing of steaming can be effectively solved after finishing of steaming; besides, relative positions of the illuminating lamp tube and the heating lamptube can be adjusted through the adjusting mechanism so that the lamp can emit illuminating light or heating light according to the requirement, and selection of different functions of the lamp for users is facilitated according to the requirement.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Traditional Chinese medicinal material preparation device and traditional Chinese medicinal material preparation method

InactiveCN111035959ASimple structureGood conditionPharmaceutical product form changeDomestic articlesAtomizer nozzleDistilled water

The invention relates to a traditional Chinese medicinal material preparation device and a traditional Chinese medicinal material preparation method. The device comprises a box body and a rhizoma polygonati placing frame arranged in the box body, wherein a distilled water tank, a yellow rice wine tank and an ultrasonic wave transmitter are arranged on the box body, a heating block is arranged in the distilled water tank, the distilled water tank communicates with the interior of the box body, the yellow rice wine tank is connected with an atomizing nozzle extending into the box body, the atomizing nozzle is located above the rhizoma polygonati placing frame, and is arranged towards the rhizoma polygonati placing frame, and the ultrasonic wave transmitter is arranged towards the rhizoma polygonati placing rack. The traditional Chinese medicinal material preparation device is simple in structure, can solve the problem that manual steaming is not easy to control, avoids too high temperature and too high pressure, and is high in steaming efficiency and good in steaming effect.

Owner:PINGDINGSHAN UNIVERSITY

Electric cooker cover structure, electric cooker, and control method of electric cooker

ActiveCN102715845ASolve puzzles with different kinds of vegetablesSolve the problem of easily overflowing rice soupCooking-vessel lids/coversProgramme control in sequence/logic controllersThermal insulationElectric machinery

The invention discloses an electric cooker cover structure, an electric cooker and a control method of the electric cooker. The electric cooker cover structure comprises a cooker body and a cooker cover assembly, wherein the cooker cover assembly consists of an outer cover covered on the cooker body and an inner cover covered on an inner pot, the outer cover is provided with a motor, and an output shaft of the motor is connected with the inner pot. Compared with the prior art, the electric cooker cover structure has the beneficial effects that the motor rotates to automatically adjust the quantity of steam entering a steaming pot, so that the difficulty existed in small electric cookers in steaming different dishes is solved, and a better effect in the steaming of the dishes can be achieved; moreover, anti-overflow probes are arranged on the cooker body and the inner pot, so that the problem that rice soup easily overflows out of the conventional rice cooker in a cooking process is effectively solved; a thermal insulation layer is arranged on the cooker body, so that cooked food and dishes can be well kept warm for a long time, and a good energy-saving effect is achieved; and the portable electric cooker, provided for users, is sanitary and energy-saving and is convenient to use.

Owner:深圳市北鼎晶辉科技有限公司

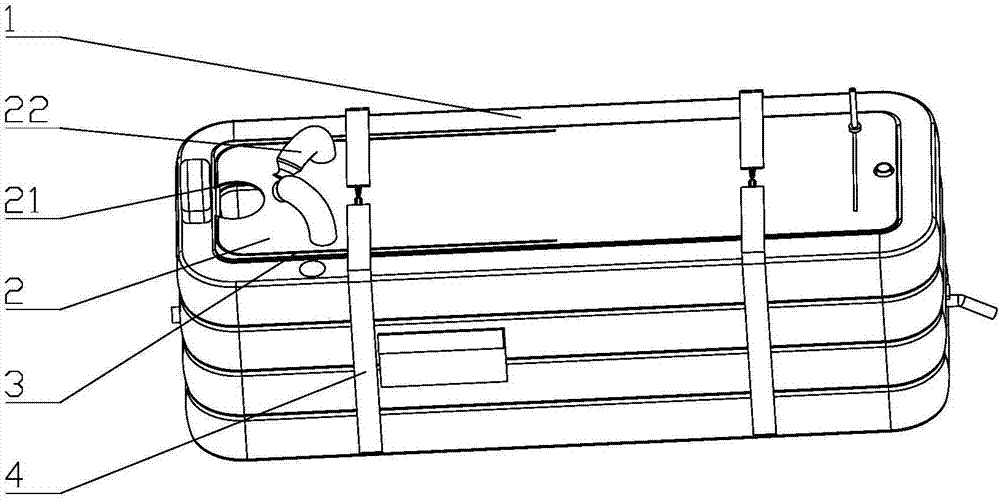

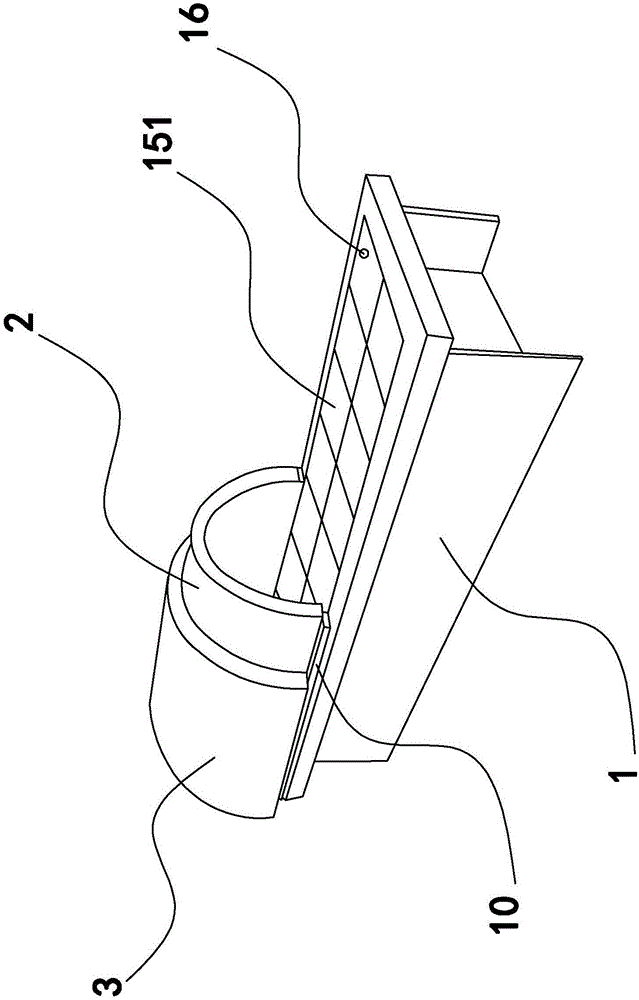

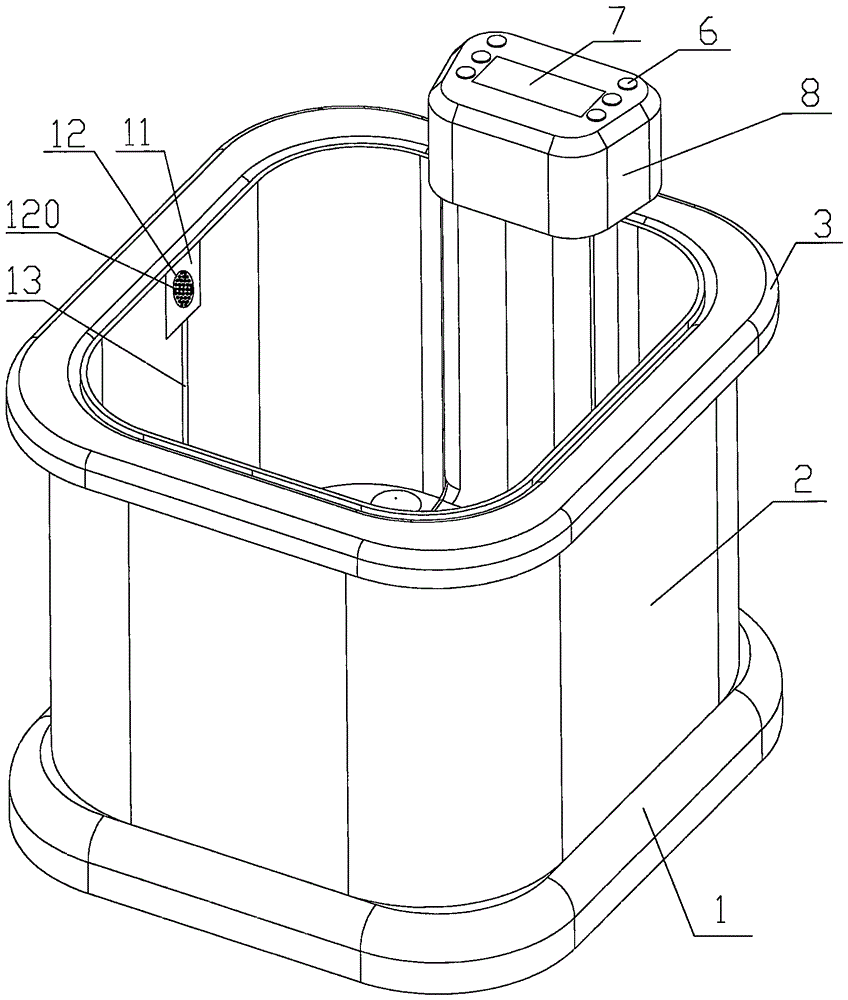

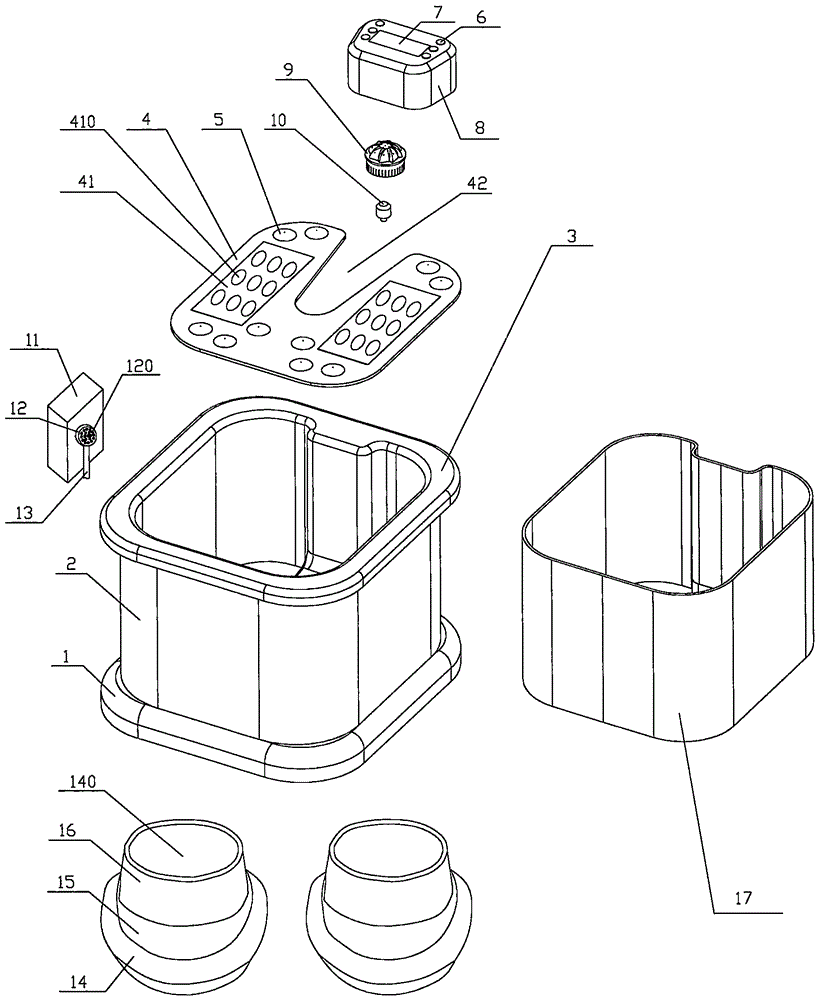

Sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub

The invention provides a sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub. The sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub has the advantages that the sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub is provided with a flexible cover, zippers for opening or closing openings of a bathtub are arranged on the flexible cover, and accordingly users can conveniently enter the sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub; a neck opening and hand protective sleeves are arranged at an opening end of the flexible cover, accordingly, opposite accommodating cavities for accommodating human bodies can be formed by the flexible cover and the bathtub when the sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub is used, steam can be injected into the bathtub, and the sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub can have sauna functions; air can be injected into gap cavities at the bottom of the bathtub by a bubble bath hydrotherapy machine via an air outlet pipe, air can be exhausted via regular air escape holes in the bottom of the bathtub, accordingly, boiling bubble bath effects can be realized by water in the bathtub, airflow at the bottom of the water can be intermittently sprayed out, the human bodies can be repeatedly impacted by bubble, and channels and collaterals of the human bodies can be patted and massaged; the sweat steam and bubble bath hydrotherapy integrated foldable inflation bathtub is simple and compact in structure, convenient to carry and store, flexible in use and reasonable in design, can be conveniently and quickly mounted and operated, has abundant functions, is economical and practical and has an excellent market prospect.

Owner:ANHUI GUTONGMEI ELECTRONICS TECH

Fabric steaming and sizing device

ActiveCN109944004AGuaranteed temperature differenceEnough temperature differenceTextile treatment machine arrangementsTextile treatment carriersTemperature controlTemperature difference

The invention discloses a fabric steaming and sizing device, and belongs to the field of fabric steaming devices. The fabric steaming and sizing device comprises a machine frame and a conveying belt connected to the machine frame. The conveying belt comprises a mesh-shaped belt. A heating box and a cooling box are fixedly connected with the position, corresponding to the conveying belt, of the machine frame. The end, close to the cooling box, of the heating box is fixedly connected with a channel. The other end of the channel is fixedly connected to the bottom of the cooling box. The conveyingbelt penetrates through the heating box, the channel and the cooling box. An electric heating plate is fixedly connected into the heating box. A refrigerator is fixedly connected into the cooling box. The electric heating plate and the refrigerator are connected with a control circuit. The control circuit comprises a first temperature collecting module, a second temperature collecting module, a high-temperature control module and a temperature difference control module. The control circuit controls the electric heating plate and the refrigerator according to the temperatures in the heating box and the cooling box. The fabric steaming and sizing device has the advantages that the temperatures in the heating box and the cooling box can be accurately controlled, residual moisture in fabricscan be taken away during refrigeration of an exhaust fan, and the quality of the finished fabrics is ensured.

Owner:北京君杰一鸣企业服装发展有限公司

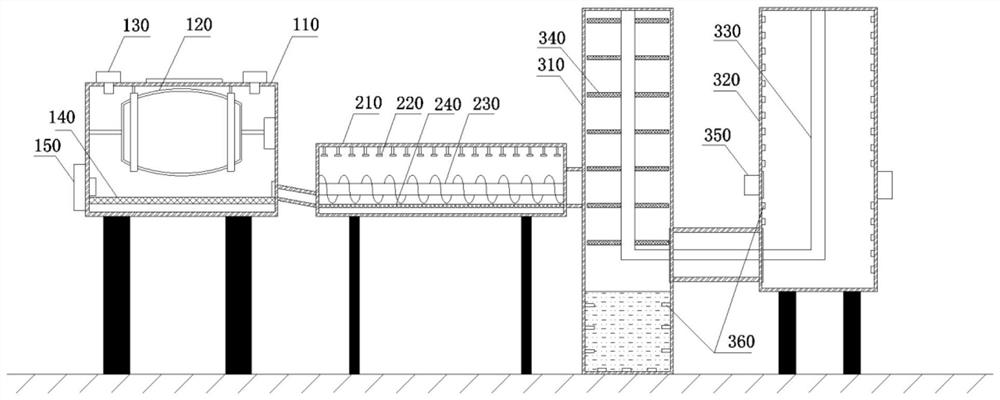

Polygonatum sibiricum red. harvesting and processing production line

ActiveCN111780525AImprove processing efficiencyImprove processing outputDrying gas arrangementsDrying solid materialsProcess engineeringAir blower

The invention discloses a polygonatum sibiricum red. harvesting and processing production line. The polygonatum sibiricum red. harvesting and processing production line involves air-drying equipment,drip washing equipment and steaming and drying equipment, wherein the air-drying equipment comprises an air-drying box body, an air-drying cylinder body, a plurality of hot air blowers, a vibrating screen and an air-drying feeding assembly, the drip washing equipment comprises a drip washing box body, a plurality of drip washing nozzles, a spiral conveyor and a drip washing filter screen, the steaming and drying equipment comprises a steaming box body, a drying box body, a pair of guide rails, a plurality of guide plates and a drying and feeding assembly. Mechanical operation in the whole process from harvesting to rough machining to finish machining can be achieved, the machining efficiency and yield are improved, and the product quality is improved.

Owner:西藏天虹科技股份有限责任公司

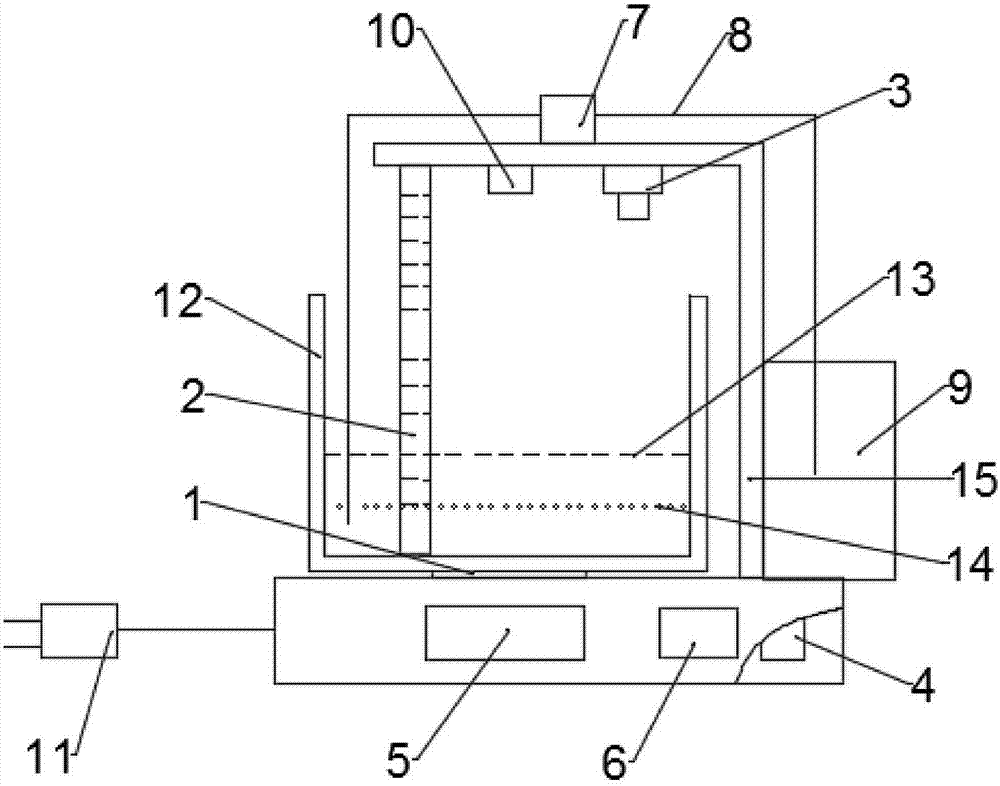

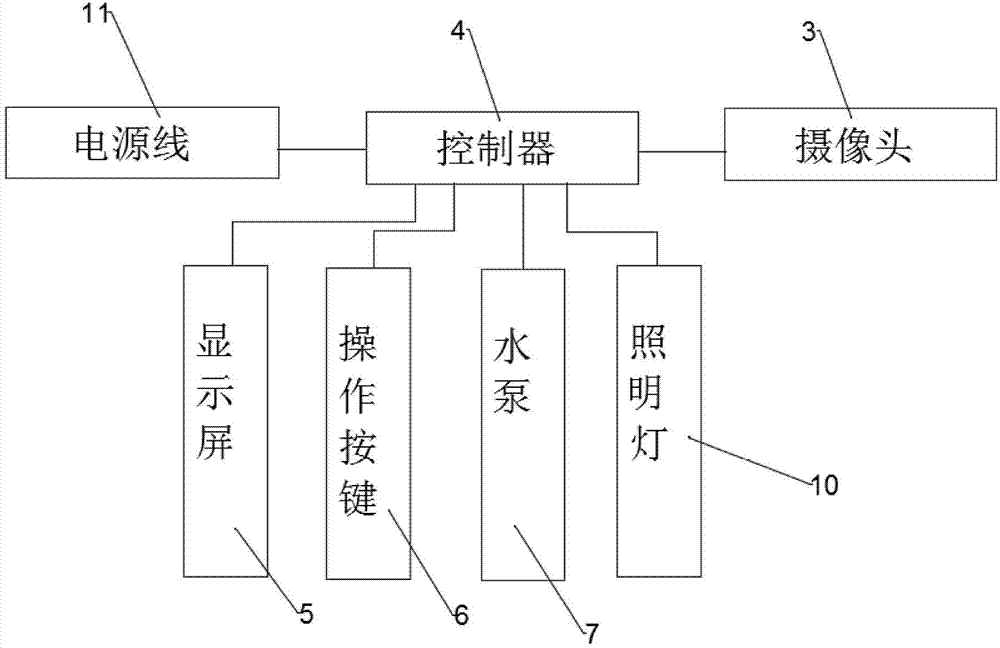

Water level control device based on machine vision during rice cooking

InactiveCN107348836AGood steaming effectSave time resourcesSteam cooking vesselsElectricityAutomatic control

The invention discloses a water level control device based on machine vision during rice cooking. The control device comprises a base, a measurement element, a rack, a rice pot, a power source wire, a water pump, a controller, a camera and a spotlight, wherein the rice pot is arranged on the base; the front surface of the base is provided with operation buttons and a display screen, and the operation buttons and the display screen are all electrically connected to the controller. The water level control device has the advantages that after rice is washed in a manual mode, an appropriate amount of water is poured into the rice pot, the rice pot is placed into an automatic water level control device for rice cooking, the measurement element is inserted into the rice pot, and the camera conducts water level detection and judgement on the locations of the rice and the water inside the rice pot; an accurate proportion of the water and the rice is set by a setting program in the controller or in a manual mode, and a control command in which the water level is controlled by the controller for automatic control is sent; by using the water level control device based on the machine vision during rice cooking, the time and water resources can be saved, and it is ensured that the demands can be met; as for different bands of rice, the proportion of rice and water can be automatically controlled, and the rice cooking effect is great.

Owner:重庆深度视觉科技有限公司

A rapid dyeing method with ultra-low liquor ratio, high temperature and high pressure

ActiveCN103924401BBig spaceHigh energy consumptionLiquid/gas/vapor textile treatmentPhysical chemistryProcess engineering

Owner:TAICANG XINRUI ENERGY SAVING EQUIP

Quick cloth color fixation device

ActiveCN109554869AReduce moisture contentAvoid the problem of color difference between front and backLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsConveyor beltTurbine

The invention relates to the field of cloth processing, in particular to a quick cloth color fixation device which comprises a machine. A feed tank and a conveyor belt are arranged on the machine, a first motor and second rollers are arranged on the feed tank, and a first roller is connected with an output shaft of the first motor; a gas outlet plate is fixedly connected into the machine, gas delivery holes are densely formed in the gas outlet plate, the inside of the machine is divided into a turnover chamber and a steam chamber by the gas outlet plate, a second motor is arranged in the turnover chamber, first turning plates and second turning plates are rotationally connected into the turnover chamber and are connected with turntables and rotary rods, first connecting rods and second connecting rods are connected onto the rotary rods and are fixedly connected with a rack, worms are connected with an output shaft of the second motor and mesh with turbines, and gears are connected withthe turbines; a steam machine is arranged in the steam chamber. According to the technical scheme, the quick cloth color fixation device has the advantage that the problems of incomprehensive cloth steaming effects and color difference between the front and back surfaces of cloth in the prior art can be solved by the aid of the quick cloth color fixation device.

Owner:象山平悦环保科技有限公司

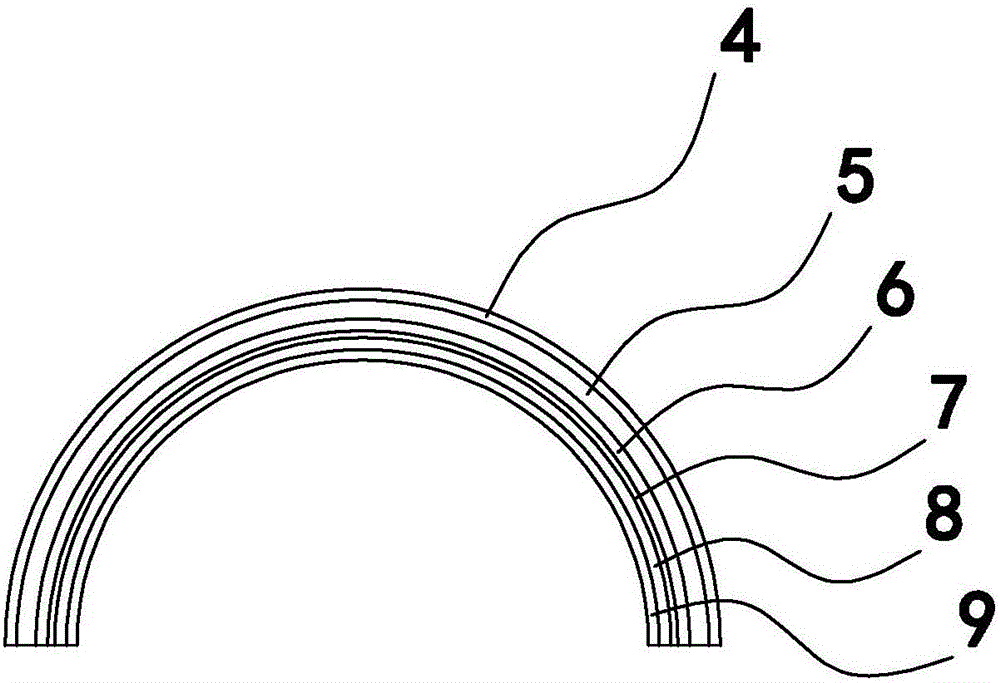

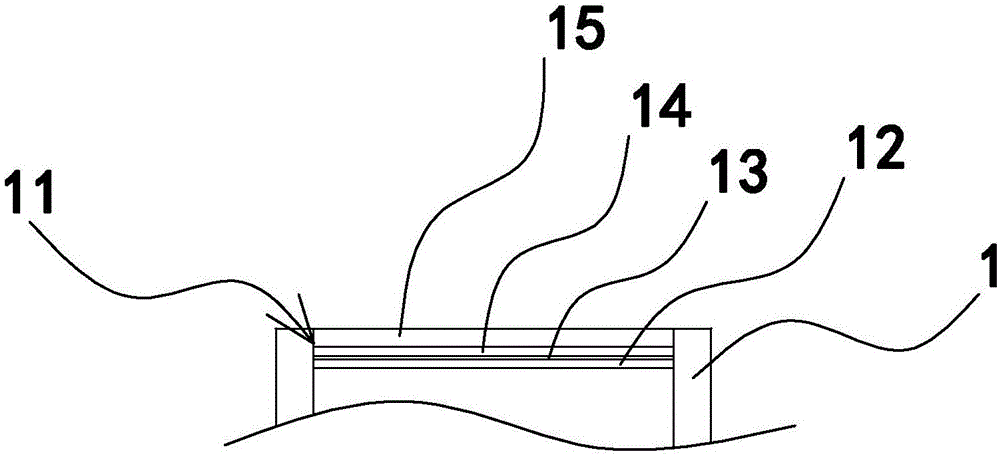

Single Khan steam bin

The invention provides a single Khan steam bin and belongs to the technical field of Khan steam heating. The problem that an existing single Khan steam bin is poor in comfort and low in safety is solved. The single Khan steam bin comprises a lying bed, an upper left cover and an upper right cover, the upper left cover and the upper right cover are arranged on the lying bed, the cross section of the upper left cover and the cross section of the upper right cover are both in an arc shape, the upper left cover and the upper right cover are installed on the upper end face of the lying bed through sliding rail structures, and the upper right cover is located on the outer side of the upper left cover. During Khan steam, closed semi-cylindrical Khan steam cavities are formed between the upper left cover and the lying bed and between the upper right cover and the lying bed, the upper left cover comprises a first circuit system, an outer leather layer located on the outermost side, an inner leather layer located on the innermost side, a supporting layer, a first heat-preserving layer, a first reflection film and a first carbon fiber heating film, and the supporting layer, the first heat-preserving layer, the first reflection film and the first carbon fiber heating film are sequentially arranged between the outer leather layer and the inner leather layer. The upper right cover and the upper left cover are identical in structure and mutually independent. The single Khan steam bin has the advantages of being good in comfort, safe and reliable.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

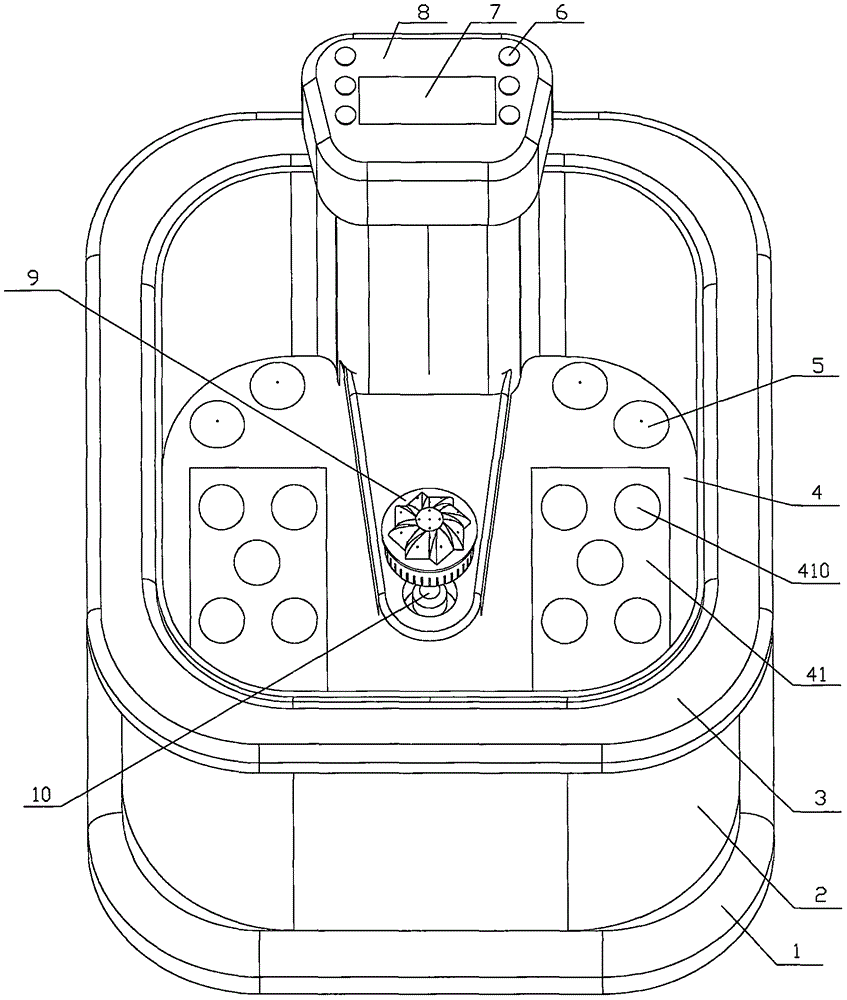

Steaming machine and intelligent temperature control method thereof

The invention relates to a steaming machine, and discloses the steaming machine and an intelligent temperature control method thereof.The steaming machine comprises a basin-shaped shell and steaming devices.The steaming devices include the first steaming device fixedly arranged at the bottom of the basin-shaped shell, the second steaming device fixedly arranged at the bottoms of the double feet and the third steaming device fixedly arranged at the upper portion of the basin-shaped shell.According to the steaming machine, the three steaming devices are arranged; the whole-body basis steaming function is provided for a user through the first steaming device arranged at the bottom of the shell; due to the second steaming device below the feet and the third steaming device at the upper portion of the shell, the poor steaming effect caused by local overheating or local overcooling in the steaming process is avoided, balanced whole-body steaming of the body can be achieved, the good steaming effect is achieved, energy is saved, and environment protection is achieved; due to intelligent control over the chemical steam temperature, the user can experience the body building effect and the comfortable steaming effect in the steaming process.

Owner:NINGBO HEALTHOME ELECTRICAL APPLIANCE

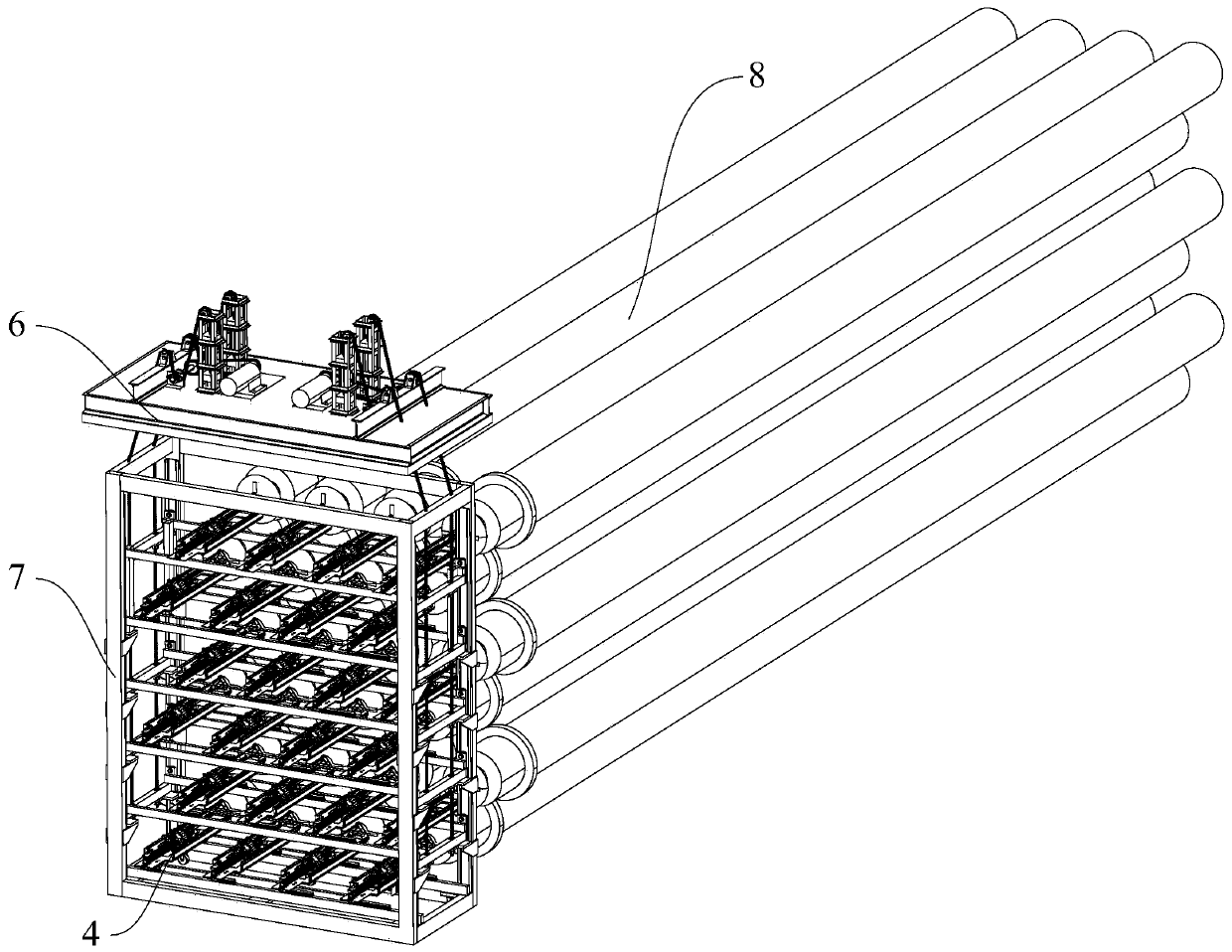

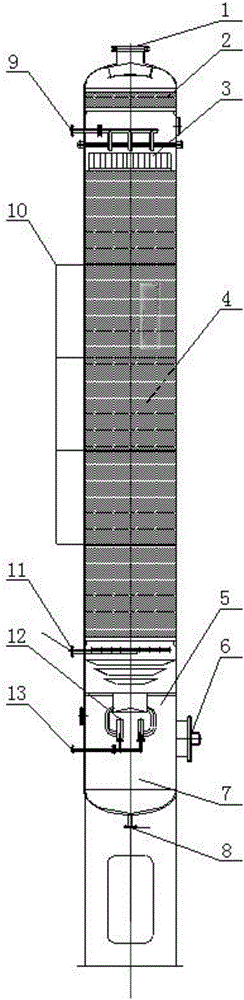

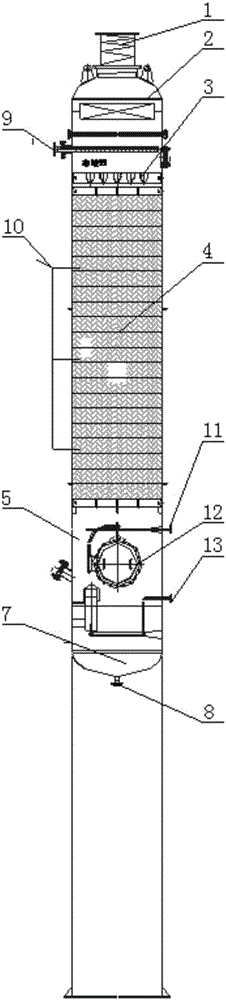

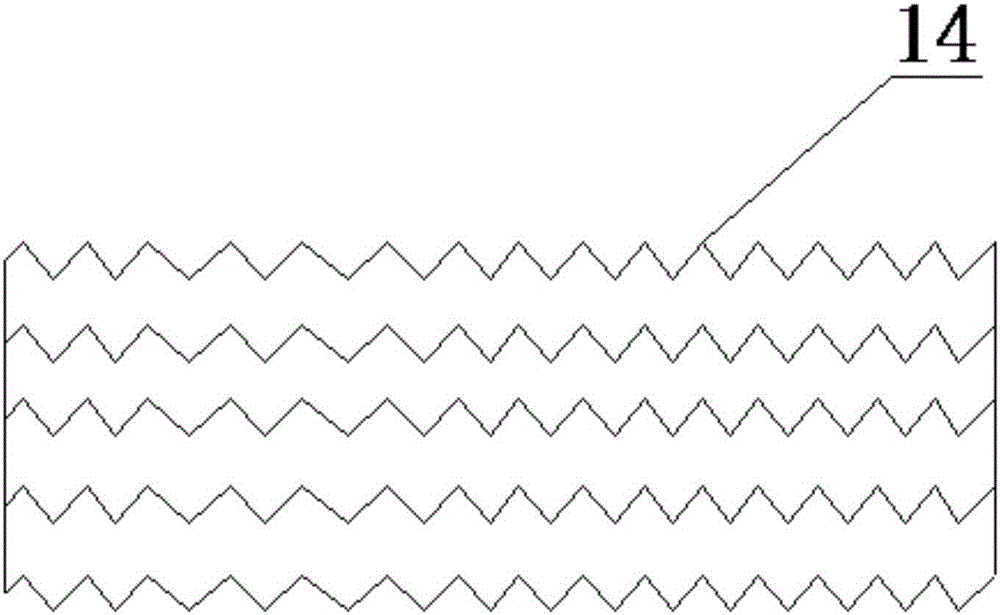

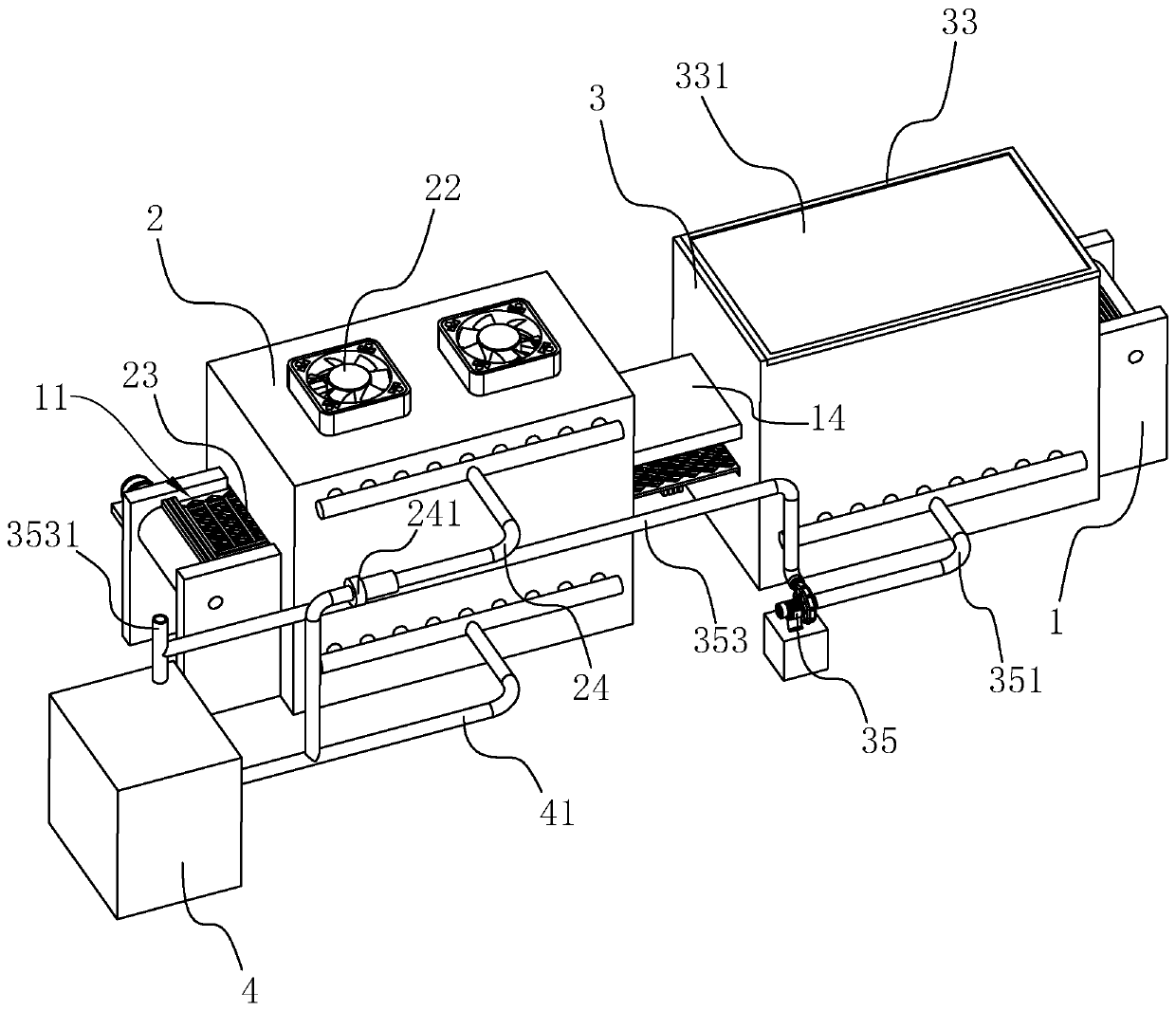

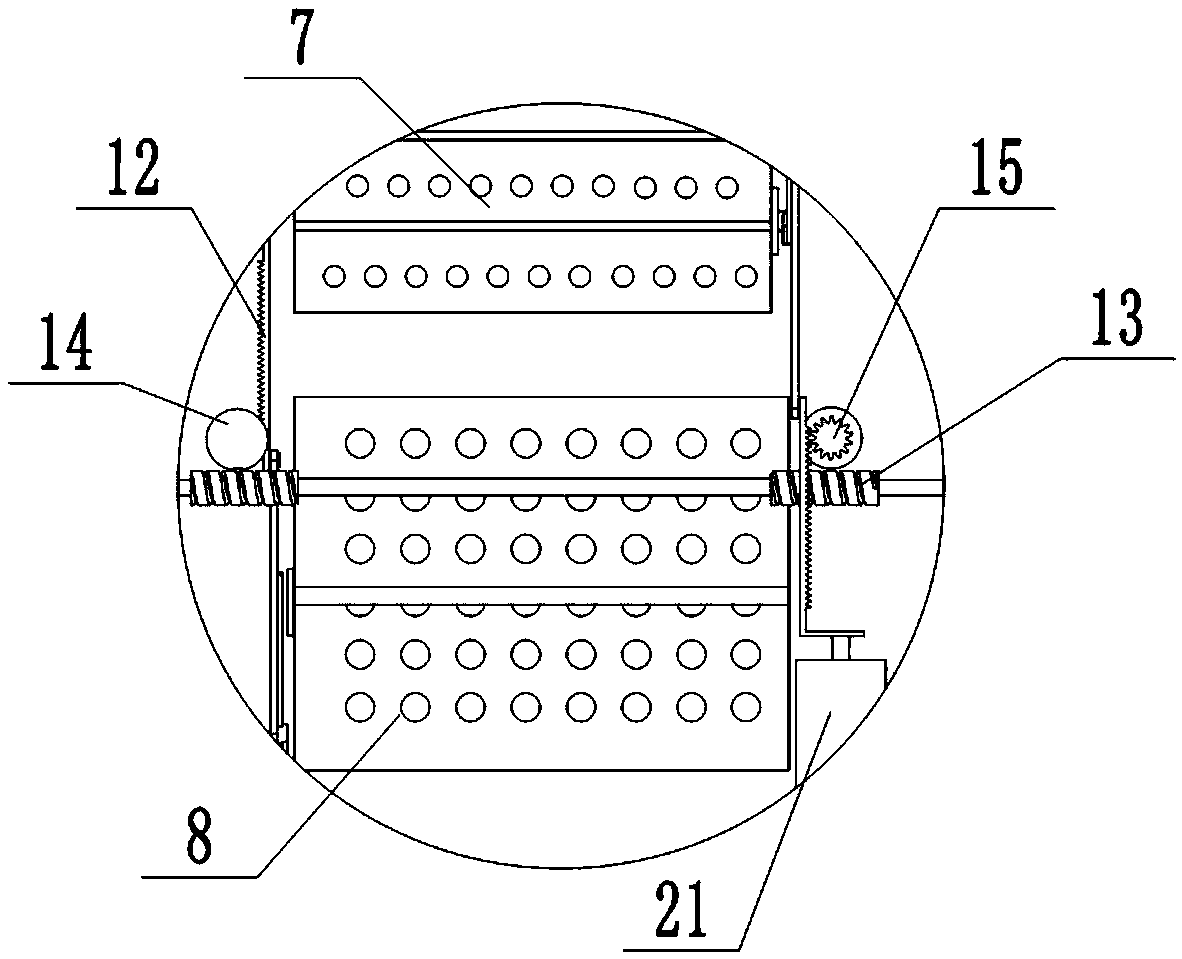

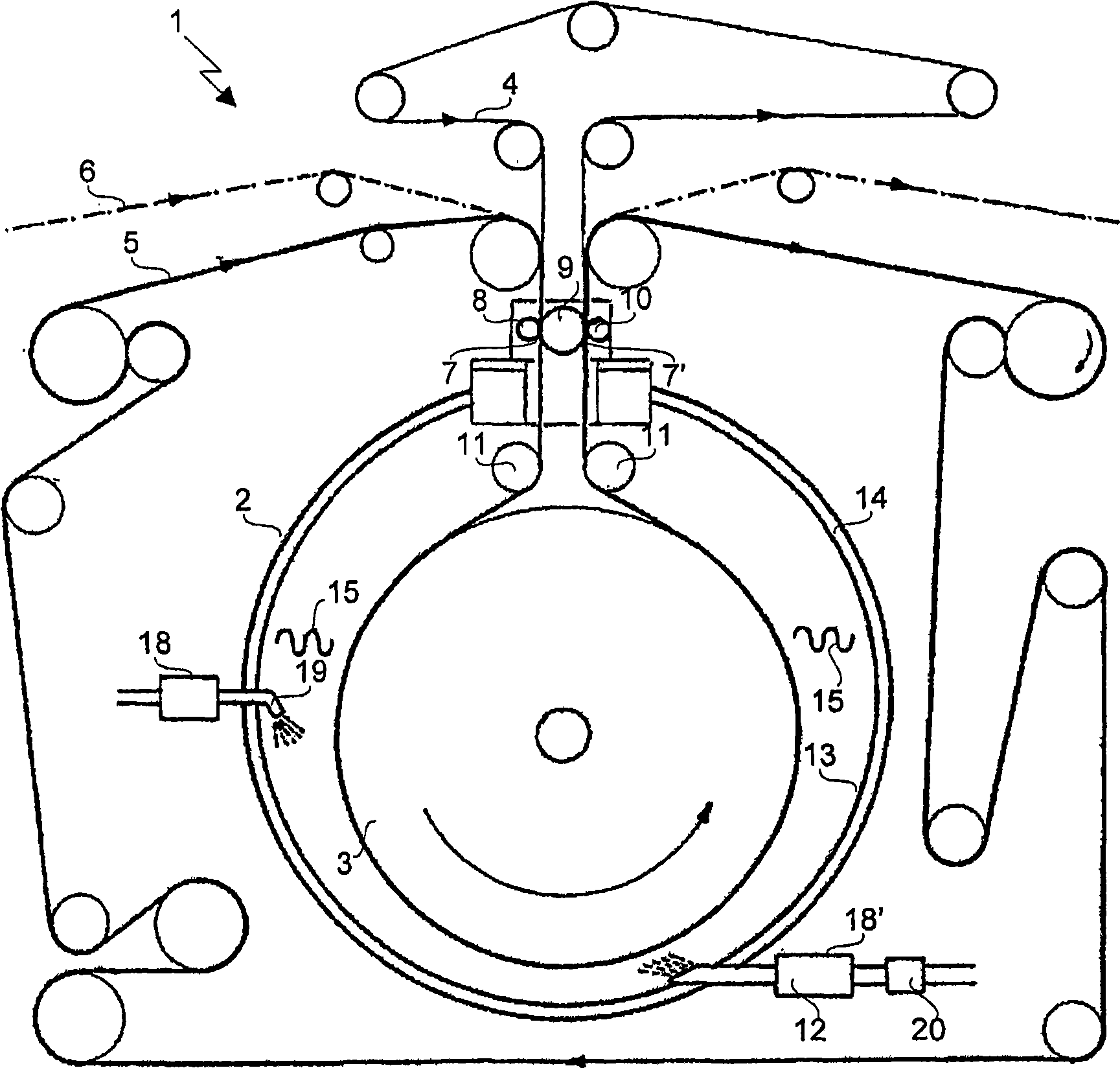

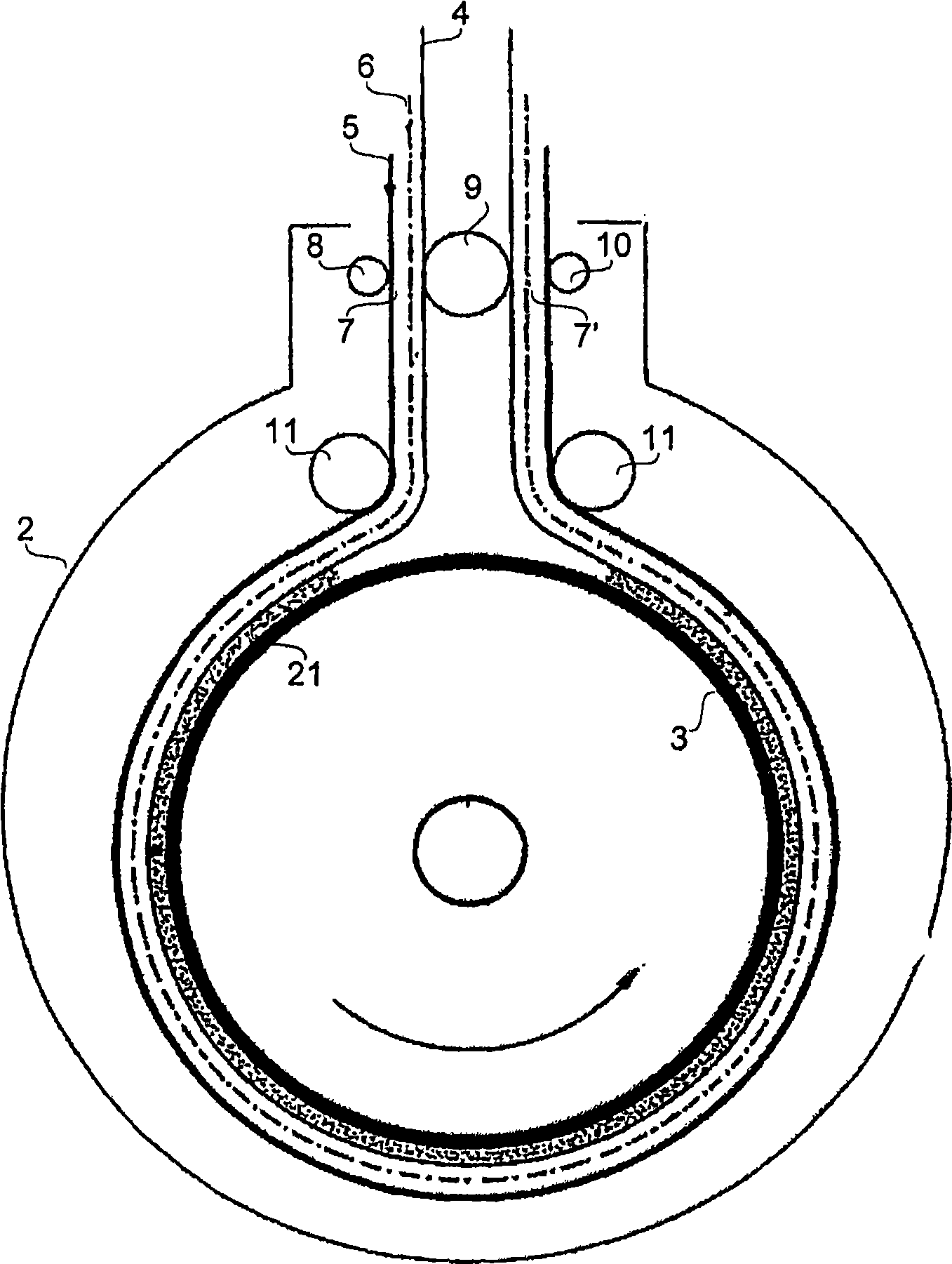

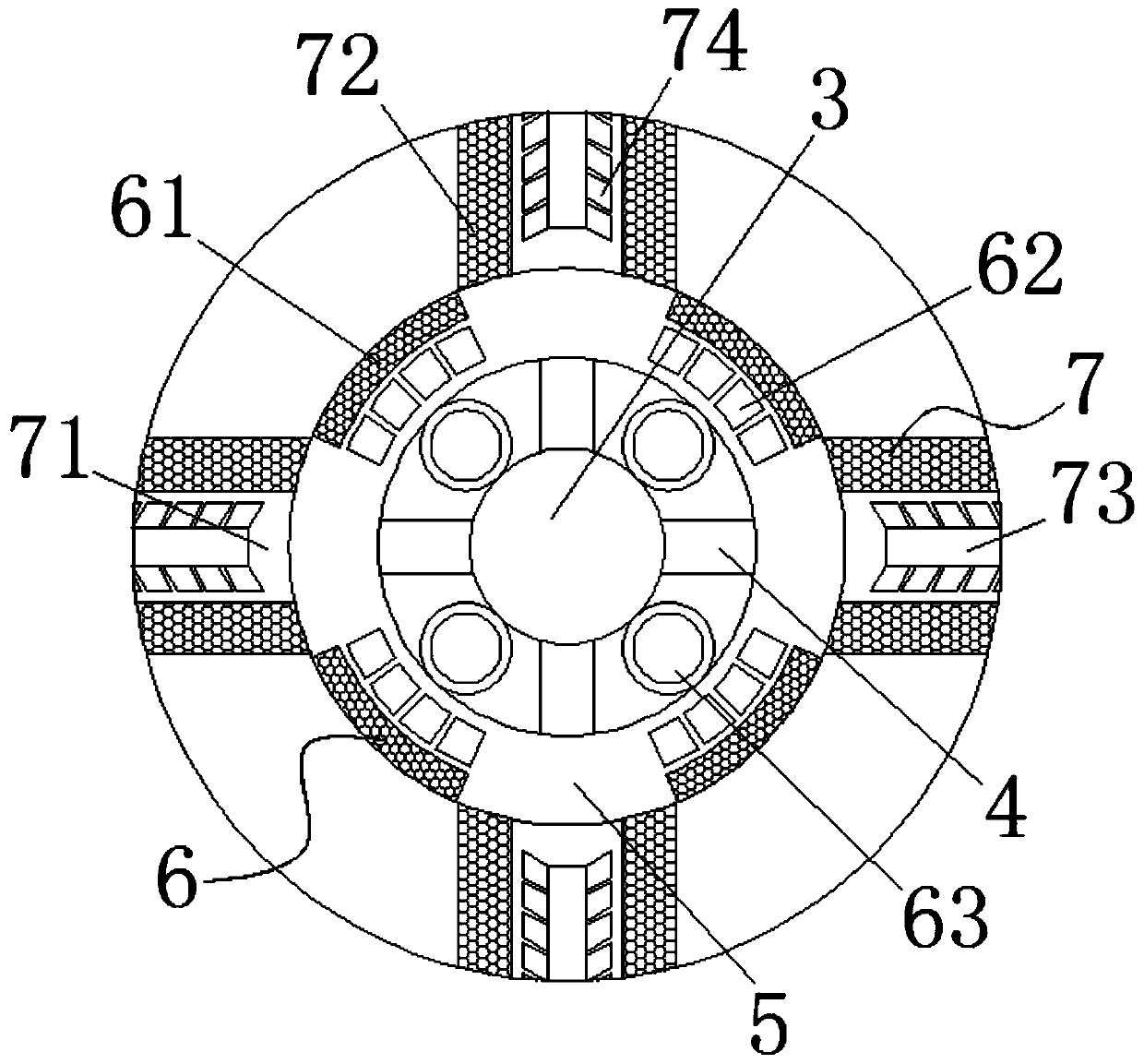

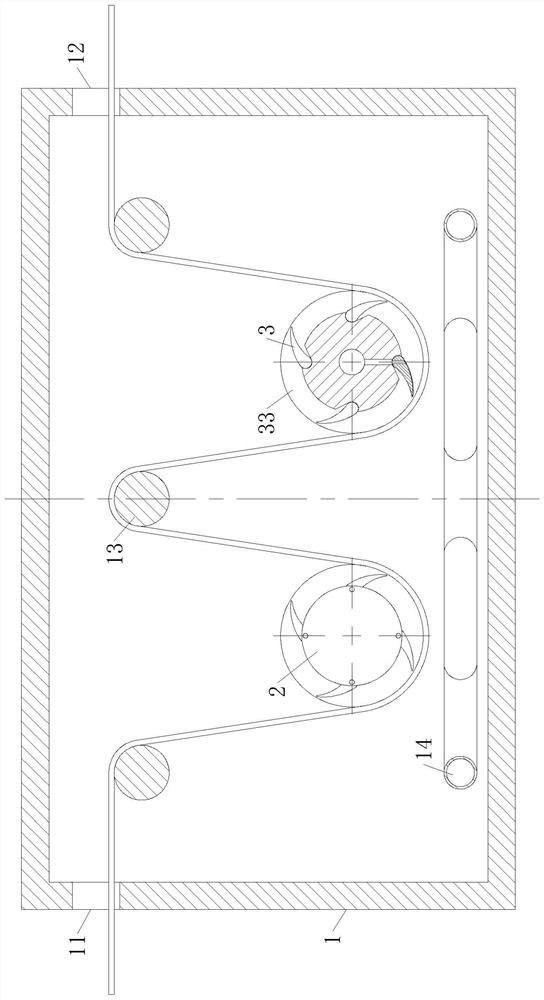

Apparatus for continuous decatizing in autoclave

InactiveCN101522977AGood steaming effectImprove steaming effectHeating/cooling textile fabricsFabric steaming/decatisingEngineeringMechanical engineering

An apparatus (1) for continuous autoclave decatizing which comprises an autoclave (2) containing a cylinder (3) being heated and rotatable around its axis. Said apparatus (1) further comprises a firstconveyor belt (4) and a second conveyor belt (5) which are supported by rolls and suitable to sandwich between themselves a fabric to be treated (6) and to carry said fabric (6) into the autoclave (2) through an inlet sealing slot (7) and out of the autoclave (2) through an outlet sealing slot (7'). The conveyor belts (4, 5) are arranged so as to surround the cylinder (3) and adhere to the cylindrical lateral surface thereof. Further, said apparatus (1) is provided with an internal jacket (13) which can be heated by heating means (14) and is coaxial to the autoclave (2). Said internal jacket(13) and said heated cylinder (3) are suitable to be heated up to temperatures ranging from 160 DEG C to 200 DEG C in order to overheat in a combined way the interior of the autoclave (2) up to a temperature higher than 14O DEG C and the apparatus is provided with means (12) for injecting steam into the autoclave (2). The apparatus (1) is also provided with water injecting means (12, 18, 18', 19)suitable to inject water into the autoclave (2).

Owner:BIELLA SHRUNK PROCESS S A S DI PIETRO ALBERTO & C

Secondary cake-steaming machine

The invention discloses a second cake-steaming machine which comprises a rack, heater boxes, a water tank, a power unit and a transmission mechanism. The heater boxes are arranged at two sides of the water tank to heat the water tank. The upper end of the rack is provided with the water tank. Two sides of the upper end of the water tank are provided with fixed plates. A conveyor belt is disposed between the fixed plates at two sides. The fixed plates are provided with fixed covers. Two ends of the conveyor belt are fixed through a stationary shaft. The lower part of the conveyor belt passes through the water tank, and the upper part of the conveyor belt is arranged above the water tank. The conveyor belt is connected with the power unit and the transmission mechanism. Present cake-steaming machines have problems of nonuniform heating and slow flow of steam during cake steaming. The problems are solved by the adoption of the secondary cake-steaming machine provided by the invention. The secondary cake-steaming machine has advantages of simple design and reasonable structure. Through back and forth operation of the conveyor belt on the upper end of the water tank, cakes are steamed when walking on the conveyor belt and are uniformly heated. The secondary cake-steaming machine has high heat transfer and good steaming effect.

Owner:ANHUI PROVINCE HUAINING DINGXUE FOOD

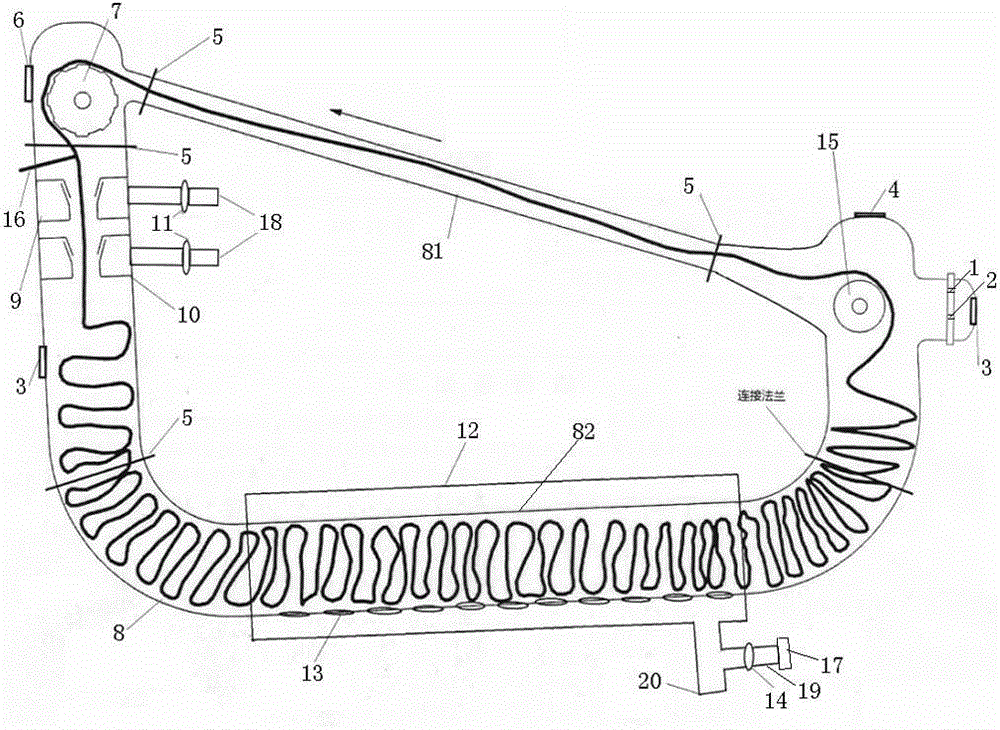

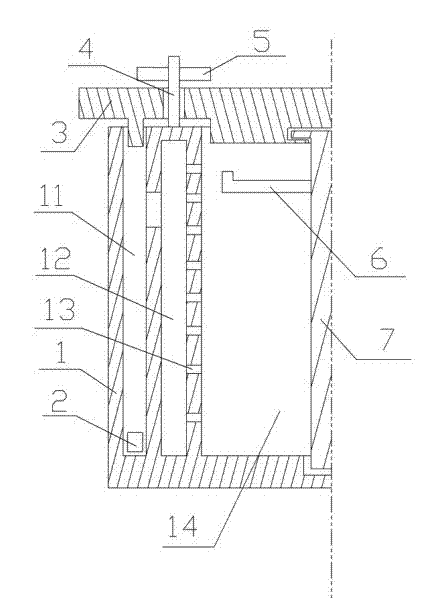

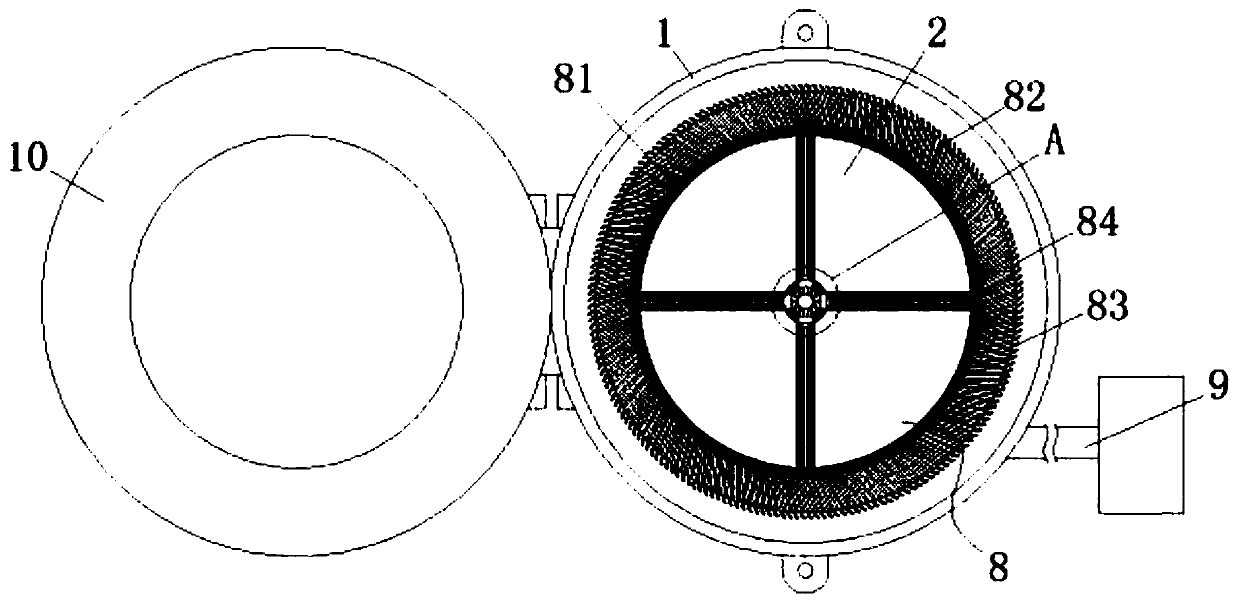

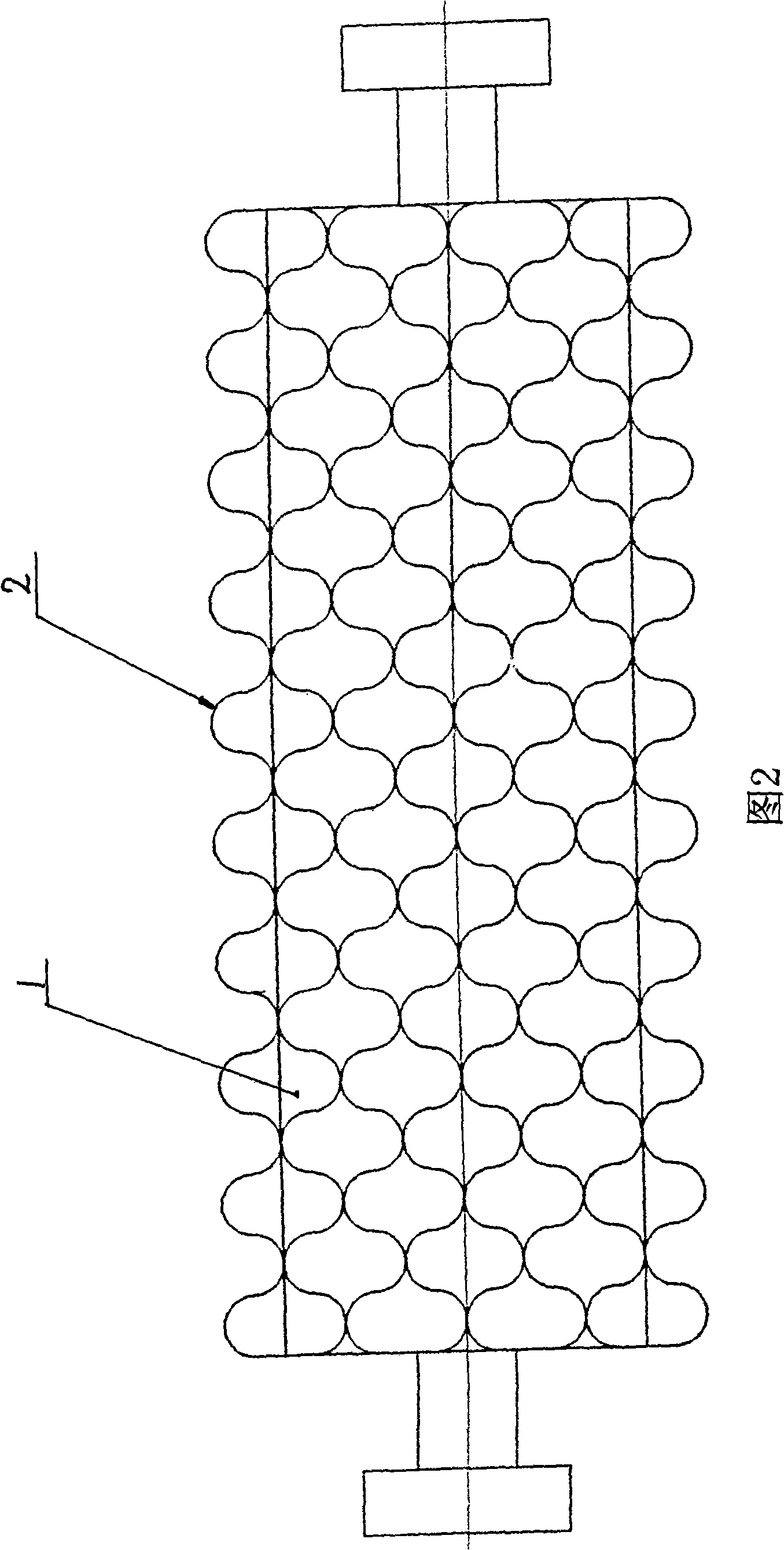

Steaming device for fibrilia

InactiveCN102787457AGood steaming effectIncrease productivityTextile treatment containersTextile treatment machine arrangementsFiberMechanical engineering

The invention discloses a steaming device for fibrilia, which comprises a casing (1), an upper cover (3), a rotary shaft (7) and a bracket (6), wherein the casing (1) is provided with at least two cavity bodies which are communicated mutually; the upper cover (3) is arranged on the end opening of the casing (1) and linked with the casing (1) in a seal manner; the rotary shaft (7) capable of rotating is arranged in one of the cavity bodies of the casing (1) and between the upper cover (3) and the bottom end of the casing (1); and the bracket (6) is arranged on the rotary shaft (7). The steam is buffered in the cavity bodies to increase the heating surface to the fibrilia, and simultaneously promotes the rotary shaft (7) to rotate to increase the heat-absorbing surface of the fibrilia, so that the steaming effect on the fibrilia is good, and the production efficiency is improved.

Owner:张琳

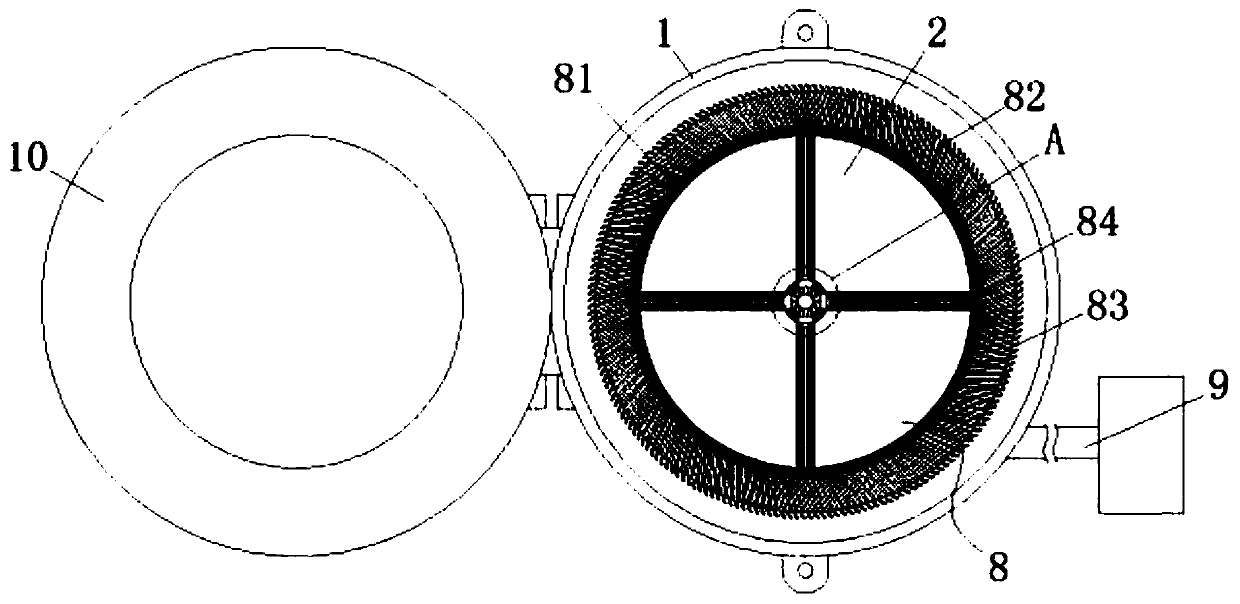

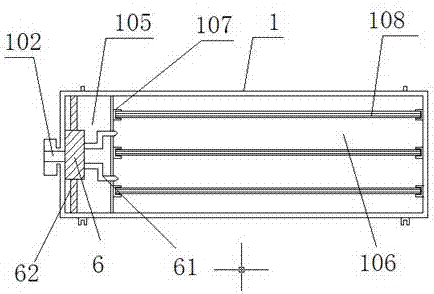

Glutinous rice steaming equipment

InactiveCN110037229AImprove steaming efficiencyEvenly steamedFood scienceBiochemical engineeringSteaming

The invention relates to the technical field of steamed dumpling processing equipment, and discloses glutinous rice steaming equipment. The glutinous rice steaming equipment comprises a box body, wherein the box body is in the shape of a column of which two ends are opened. The glutinous rice steaming equipment also comprises a base plate, a rotating rod, a separation column, a pumping mechanism,a diversion mechanism and an air inlet mechanism, wherein the base plate is rotatably arranged in the box body; one end of the rotating rod is arranged at an axis position of the base plate in a penetrating manner, and supporting rods are fixedly arranged outside the rotating rod in the circumferential direction at an equal interval; the separation column is arranged on the outer side of the rotating rod in a sleeving manner, and the inner wall of the separation column is fixedly connected with one end of the supporting rod; the pumping mechanism is arranged on the separation column; the diversion mechanism is arranged between the box body and the separation column, and is used for performing diversion on steam; and the air inlet mechanism is arranged outside the diversion mechanism. Through the adoption of the glutinous rice steaming equipment disclosed by the invention, the contact degree of the steam and glutinous rice is improved, and the steaming effect of the glutinous rice is effectively improved.

Owner:安徽乐川食品有限公司

A sleeping bag type sweat steamer sauna equipment

InactiveCN109106583ASmall footprintImprove steaming effectBathing devicesRemote controlFrequency meter

The invention relates to sleeping bag type sweat steamer sauna equipment including a steamer housing, an energy board, a frequency meter, a remote control and a controller, the energy plate, a frequency meter and a controller are arranged in a sweat steamer housing, the remote controller is connected with the sweat steamer shell, the remote controller is connected with the controller, and the energy plate, the frequency meter and the controller are connected in series. The sweat steamer shell is in the shape of a sleeping bag and has a neckline at one end, which can greatly reduce the occupiedspace of the sweat steamer, has better sweat steamer effect and saves energy.

Owner:徐州雅来基健康科技发展有限公司

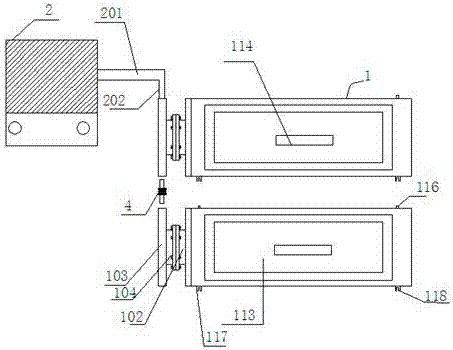

Pressurizing steam box device

ActiveCN106859312AFlexible assemblyEasy to replaceWarming devicesElectrical and Electronics engineering

The invention discloses a pressurizing steam box device which comprises at least two box shells stacked up and down and a heating device arranged on the left upper side of the box shells, wherein air guide ports are formed on the left side of the box shells; air guide pipes are matched with the air guide ports; pressurizing chambers and pushing chambers are arranged in the box shells; more than two sets of clamping blocks are correspondingly arranged on left chamber walls and right chamber walls of the pushing chambers; steaming plates are arranged between the clamping blocks; and the steaming plates can stretch back and forth in the pushing chambers under the effect of the clamping blocks. The pressurizing steam box device has the advantages of simple overall structure, random assembling and disassembling, convenience in carrying, low cost, excellent steaming effect and suitability for popularization.

Owner:徐州新风空调设备有限公司

Ash concrete steam-curing kiln control system and steam-curing method thereof

InactiveCN110900805AImprove steaming effectUniform temperature controlCeramic shaping apparatusHeating oilProcess engineering

The invention discloses an ash concrete steam-curing kiln control system and a steam-curing method thereof. The ash concrete steam-curing kiln control system comprises a curing room, curing room doorplates arranged on the front face and the back face of the curing room, curing plates arranged in the curing room, steam-curing layers formed by dividing the adjacent curing plates, ash concrete loading plates matched with the steam-curing layers, and an oil heat transfer boiler, a steam supply boiler and a control room which are arranged on the side face of the curing room. Each steam-curing layer comprises a heating plate and a steam plate, and the steam-curing layers are divided into a plurality of steam-curing rooms by the heating plates; the steam plates are arranged on the two sides of the heating plates, and the ash concrete loading plates are clamped between the steam plates. Heating oil pipelines communicating with the heating plates and steam pipelines communicating with the steam plates are arranged in the curing plates. Each steam-curing layer comprises the heating plate and the steam plate, wherein the steam-curing layers are divided into the plurality of steam-curing rooms by the heating plates; and each steam-curing room can independently steam-cure ash concrete in the steam-curing room, and the steam-curing effect is good.

Owner:四川德胜绿色新材料科技有限公司

Cross-mixed spraying device and facial vaporizer applying same

PendingCN110339048AImprove the mixing effectWell mixedBathing devicesMedical atomisersLiquid stateNutrient solution

The invention discloses a cross-mixed spraying device and a facial vaporizer applying the same. The cross-mixed spraying device comprises a main case and a first spraying mechanism and a second spraying mechanism which are arranged on the main case. The emitting trajectory of the first spraying mechanism and the emitting trajectory of the second spraying mechanism are crossed; two kinds of liquid(such as water and a nutrient solution) can be atomized and then sprayed out, small liquid particles are formed by the atomized water and nutrient solution and float overhead, and the emitting trajectory of the first spraying mechanism and the emitting trajectory of the second spraying mechanism are crossed, so that floating particles of the two kinds of liquid collide with each other and are combined; accordingly, the mixing effect is greatly improved, and is more uniform.

Owner:ZHONGSHAN OKAY PLASTICS & ELECTRONICS

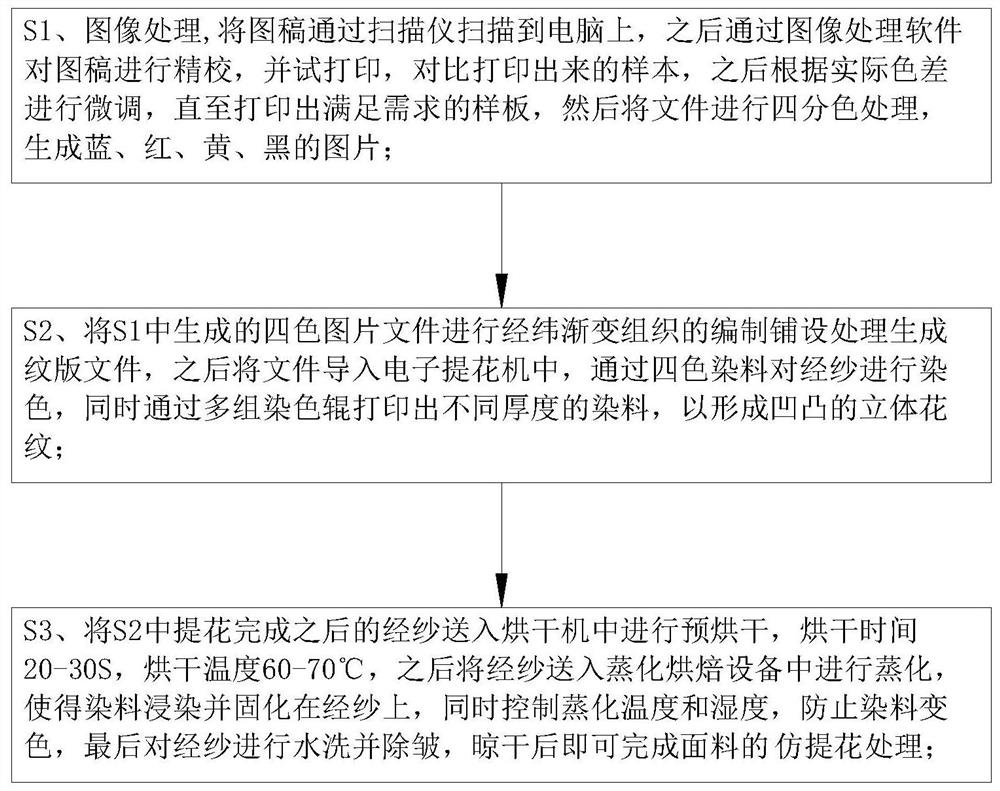

Wax-like printing fabric jacquard imitation process

ActiveCN111778617AControl tensionImprove steaming effectLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingTextile printerStructural engineering

The invention belongs to the technical field of jacquard imitating printing, and particularly provides a wax-like printing fabric jacquard imitation process. Ageing baking equipment adopted in the process comprises a box body; a material inlet and a material outlet are respectively formed in the positions near the top on two sides of the box body; a set of guiding rollers are rotatably connected with a position inside the box body corresponding to the material inlet; tensioning rollers are arranged between adjacent guiding rollers at positions near the bottom of the box body; rotary shafts ofthe tensioning rollers are rotatably connected with the box body; an S-shaped pipe is arranged at the bottom of the box body; hot oil is led into the S-shaped pipe and is used for heating the box body; first holes are formed in the rotary shafts; a set of second holes are formed in the positions where the first holes are positioned in the tensioning rollers and the second holes communicate with the first holes; a set of grooves are evenly formed in the periphery of the tensioning rollers; arc-shaped plates are arranged in the grooves; one ends, near the grooves, of the arc-shaped plates are connected with the side walls of the grooves in a hinged mode; and a set of springs are arranged between the arc-shaped plates and the tensioning rollers. According to the process, the springs are matched with the arc-shaped plates in tensioning warp, so the ageing effect of the warp is improved.

Owner:宣城凯欧纺织有限公司

Carrying roll

InactiveCN101307543AImprove steaming effectFully contactedTextile treatment carriersAgricultural engineering

The invention discloses a guide roll for stacking fabrics in the process of steaming fabrics in the printing and dyeing machinery industry. The guide roll comprises a roll body, wherein a ventilation device is arranged on the roll body as well; the ventilation device is a ventilation through hole arranged on the guide roll, or a rigid ventilation net arranged outside the roll body; the ventilation device is the ventilation through hole arranged on the roll body. The guide roll can ensure that fabrics stacked on the guide roll are in sufficient and uniform contact with steam, thereby greatly improving the effect of steaming fabrics.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

Material steaming box for brewing Hunan pearl wine

The invention relates to the technical field of wine brewing equipment, and discloses a material steaming box for brewing pearl wine, which comprises a material steaming box, wherein a supporting frame is fixedly mounted at the bottom of the material steaming box; a storage box is arranged at the bottom of an inner cavity of the supporting frame; a telescopic mechanism is fixedly mounted at the bottom of the material steaming box; a supporting plate is fixedly mounted at the bottom of the telescopic mechanism; a rotating motor is fixedly mounted at the top of the supporting plate; switch valves are fixedly mounted on one side at the bottom of the material steaming box; and a rotating rod is connected to the bottom of the inner cavity of the material steaming box in a rotary manner. According to the material steaming box for brewing Hunan pearl wine, through the mutual cooperation among connecting rods, sealing plates, springs, moving blocks and clamping blocks, the sealing treatment ofthe top of the inner cavity of the material steaming box is facilitated, and thus the phenomenon that steam in the material steaming box cannot be effectively fully utilized in the steaming process,so that part of the steam is lost is solved, and the sealing property of the top of the inner cavity of the material steaming box is improved.

Owner:南方葡萄沟酒庄有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com