Secondary cake-steaming machine

A secondary steaming and racking technology, which is applied in application, food preparation, food science, etc., can solve the problems of high heat transfer, slow steam flow, and good steaming effect, and achieve high heat transfer, uniform heating, and steaming heat good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

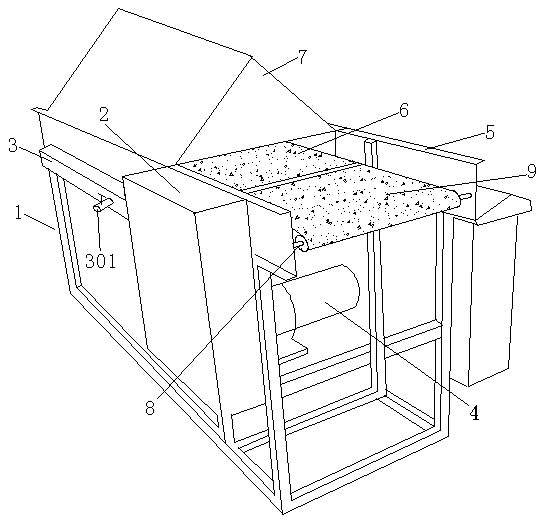

[0016] Referring to the accompanying drawings, the secondary cake steaming machine includes a frame 1, a heating box 2, a water tank 3 and a power unit and a transmission mechanism 4, the heating box 2 is arranged on both sides of the water tank 3 to heat the water tank, and the upper end of the frame 1 is provided with a water tank 3, Both sides of the upper end of the water tank 3 are provided with fixed plates 5, and a transmission belt 6 is arranged between the fixed plates 5 on both sides. The fixed plate 5 is provided with a fixed cover 7. The two ends of the transmission belt 6 are fixed by the fixed shaft 8, and the bottom of the transmission belt 6 Pass through the water tank 3, the upper part is above the water tank 3, the transmission belt 6 is connected with the power device and the transmission mechanism 4, the front and rear ends of the transmission belt 6 are provided with a receiving conveyor belt, a feeding conveyor belt 9, and a drain port is provided on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com