Steaming device for fibrilia

A hemp fiber and steaming technology, which is applied to the equipment configuration for processing textile materials, spraying/spraying textile material treatment, and processing textile material containers, etc., can solve the problems of uneven heating area of hemp fiber and poor steaming effect of hemp fiber , to achieve the effect of improving production efficiency and steaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

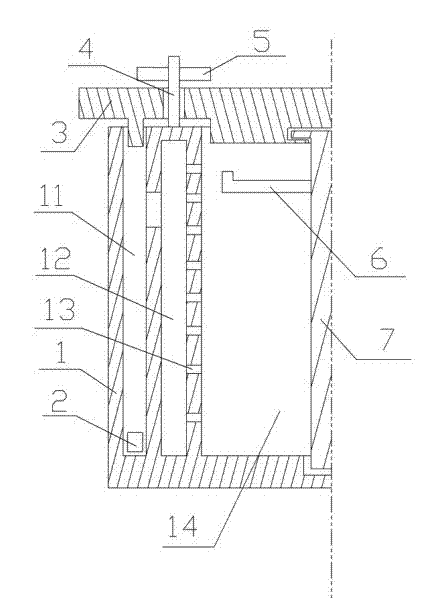

[0010] The accompanying drawing is an embodiment of the present invention, which will be described in detail in conjunction with the accompanying drawings. There are an outer cavity 11, an intermediate cavity 12 and an inner cavity 14, a heater 2 is arranged in the outer cavity 11 of the housing 1, a rotating shaft 7 is arranged in the inner cavity 14, and the outer cavity of the housing 1 11 is set to communicate with the middle cavity 12 of the shell 1, the middle cavity 12 of the shell 1 is set to communicate with the inner cavity 14 of the shell 1 through the air hole 13, and the air hole 13 is set in the inner cavity of the shell 1 The cavity 14 is distributed along a spiral line centered on the center line of the inner cavity 14 of the housing 1, the upper cover 3 is arranged on the port of the housing 1, and the connecting bolt 4 is set to be connected with the housing 1 and set to pass through The upper cover 3, the nut 5 is set to be threadedly connected with the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com