Full-automatic rice steaming machine

A rice steamer, fully automatic technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of high purchase cost, installation cost and operating cost, low thermal efficiency of the rice steamer, low degree of automation, etc., to achieve convenient Automatic discharge, smooth appearance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

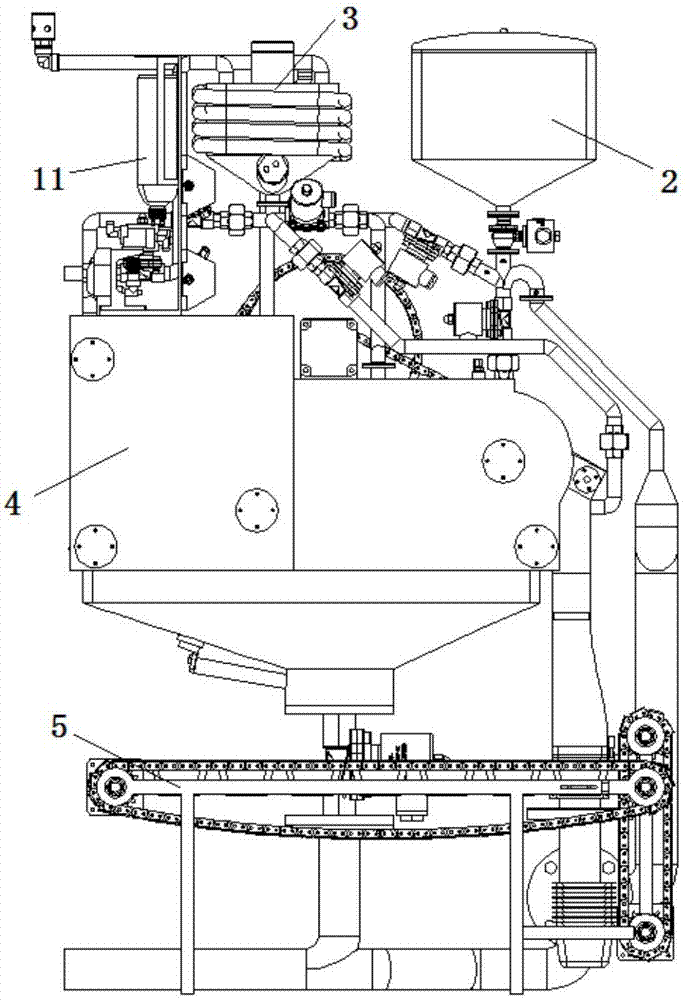

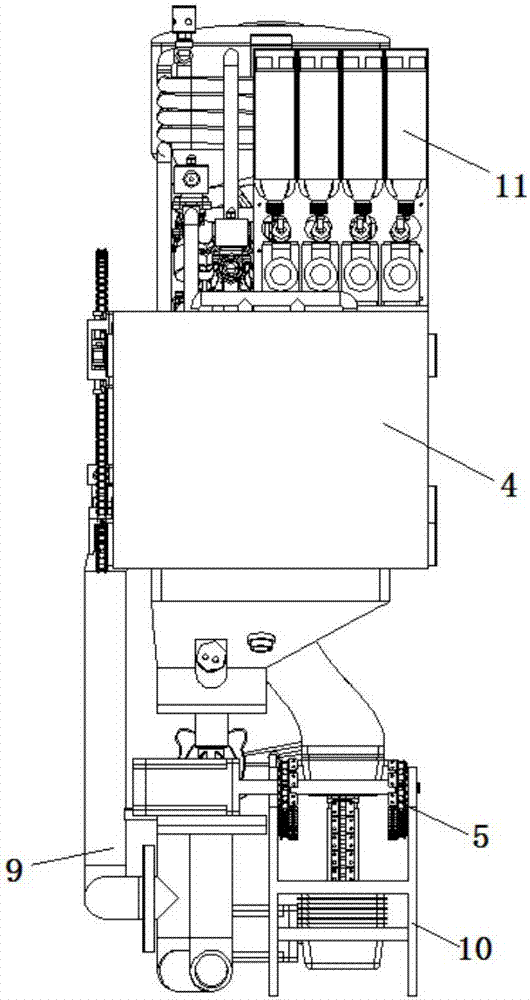

[0071] Depend on Figure 1 to Figure 11 It can be seen from the schematic diagram of the structure of a fully automatic rice steamer that the present invention includes a box body 1, a square three-dimensional stainless steel structure in the box body, which contains all the mechanical parts and electrical control parts of the rice steamer, and has a compact internal structure , high efficiency, simple appearance and beautiful appearance. Overall, this equipment has the advantages of convenient use, reliable performance, and long service life. Steam leakage, heat preservation and moisture resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com