High-nutrient microbial bacterium composite fertilizer and production method thereof

A technology of microbial bacteria and compound fertilizers, applied in urea compound fertilizers, layered/coated fertilizers, inorganic fertilizers, etc., can solve the problems of waste of manpower and material resources, degradation of strains, etc., and achieve improved soil moisture, sufficient content, and reduced disease rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

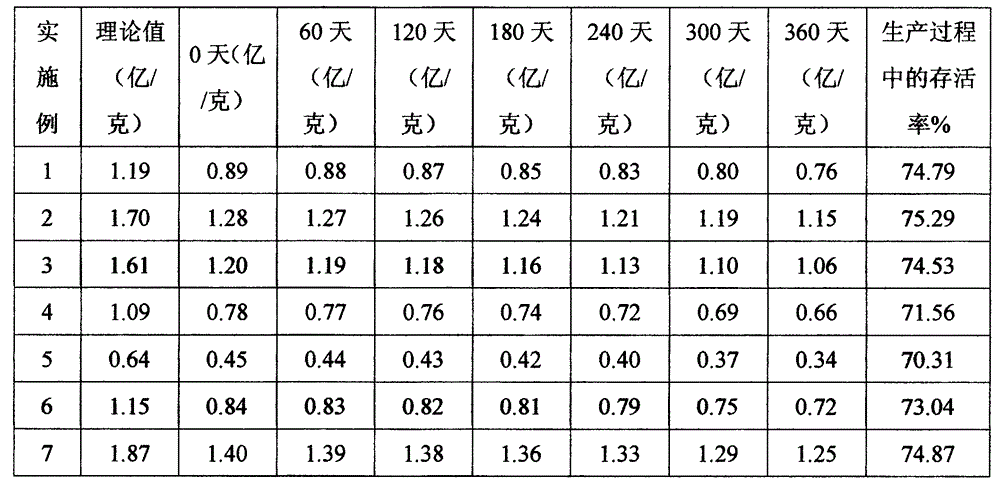

Examples

Embodiment 1

[0046] (1) Preparation and activation of adsorbent: Weigh 5.22 kg of diatomite, add 0.03 kg of nano-carbon, mix well, soak in 1mol / L hydrochloric acid solution for 48 hours, rinse with diatomite until the diatomite reaches neutrality, and pump Consider it, put it in an oven and dry it at 105°C until it reaches a constant weight, which is the adsorbent, and put it in a desiccator for later use.

[0047] (2) Adsorption of nutrients: Weigh 0.175kg of beef extract, 0.35kg of peptone, add water to dissolve, and then sterilize at 121°C for 30min, then slowly pour it into 0.525kg of the adsorbent described in step (1), and stir at the same time , let it stand for 1h, centrifuge after the adsorbent fully absorbs the nutrients, and obtain the core material A.

[0048] (3) Adsorption of microbial bacteria: get Bacillus subtilis 1.2kg, Bacillus lateralis 0.4kg, Bacillus megaterium 0.6kg, Bacillus cereus 0.4kg, Bacillus circulus 1.2kg and Bacillus colloidus 0.6kg, effective The number of...

Embodiment 2

[0056] (1) Preparation and activation of adsorbent: Weigh 4.23 kg of diatomite, add 0.02 kg of nano-carbon, mix well, soak in 1mol / L hydrochloric acid solution for 48 hours, rinse with distilled water until the diatomite reaches neutrality, and pump Consider it, put it in an oven and dry it at 105°C until it reaches a constant weight, which is the adsorbent, and put it in a desiccator for later use.

[0057] (2) Adsorption of nutrients: Weigh 0.142kg of beef extract, 0.283kg of peptone, dissolve in water and sterilize at 121°C for 30min, then slowly pour it into the adsorbent described in step (1) of 0.425kg, while stirring, Let it stand for 1 hour, and then centrifuge after the adsorbent fully absorbs the nutrients to obtain the core material A.

[0058] (3) Adsorption of microbial bacteria: get Bacillus subtilis 0.2kg, Bacillus lateralis 0.8kg, Bacillus megaterium 0.2kg, Bacillus cereus 0.8kg, Bacillus circulus 0.6kg and Bacillus colloidus 0.8kg, effective The number of via...

Embodiment 3

[0066] (1) Preparation and activation of adsorbent: Weigh 5.47kg of diatomite, add 0.03kg of nano-carbon, mix evenly, soak in 1mol / L hydrochloric acid solution for 48 hours, rinse with distilled water until the diatomite reaches neutrality, and pump Consider it, put it in an oven and dry it at 105°C until it reaches a constant weight, which is the adsorbent, and put it in a desiccator for later use.

[0067] (2) Adsorption of nutrients: Weigh 0.183kg of beef extract, 0.367kg of peptone, add water to dissolve, then sterilize at 121°C for 30min, then slowly pour it into 0.55kg of the adsorbent in step (1), while stirring, Let it stand for 1 hour, and then centrifuge after the adsorbent fully absorbs the nutrients to obtain the core material A.

[0068] (3) Adsorption of microorganisms: get 1.6kg of Bacillus subtilis, 0.4kg of Bacillus lateralis, 0.4kg of Bacillus megaterium, 0.6kg of Bacillus cereus, 0.6kg of Bacillus circulus and 0.8kg of Bacillus colioids, effective The number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com