Textile fabric tank-steaming device for textile processing

A technology for textile fabrics and pot steaming, which is applied in textile processing machine accessories, equipment configuration for processing textile materials, and processing of textile materials. It can solve the problems of not having the function of cloth brushing, achieve better results, avoid pollution, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

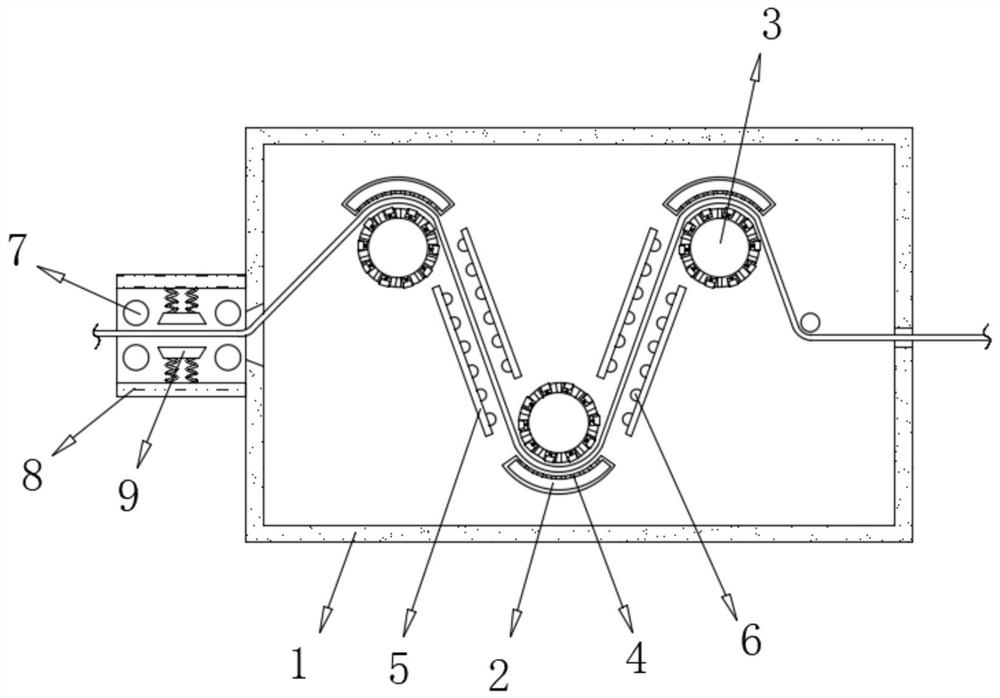

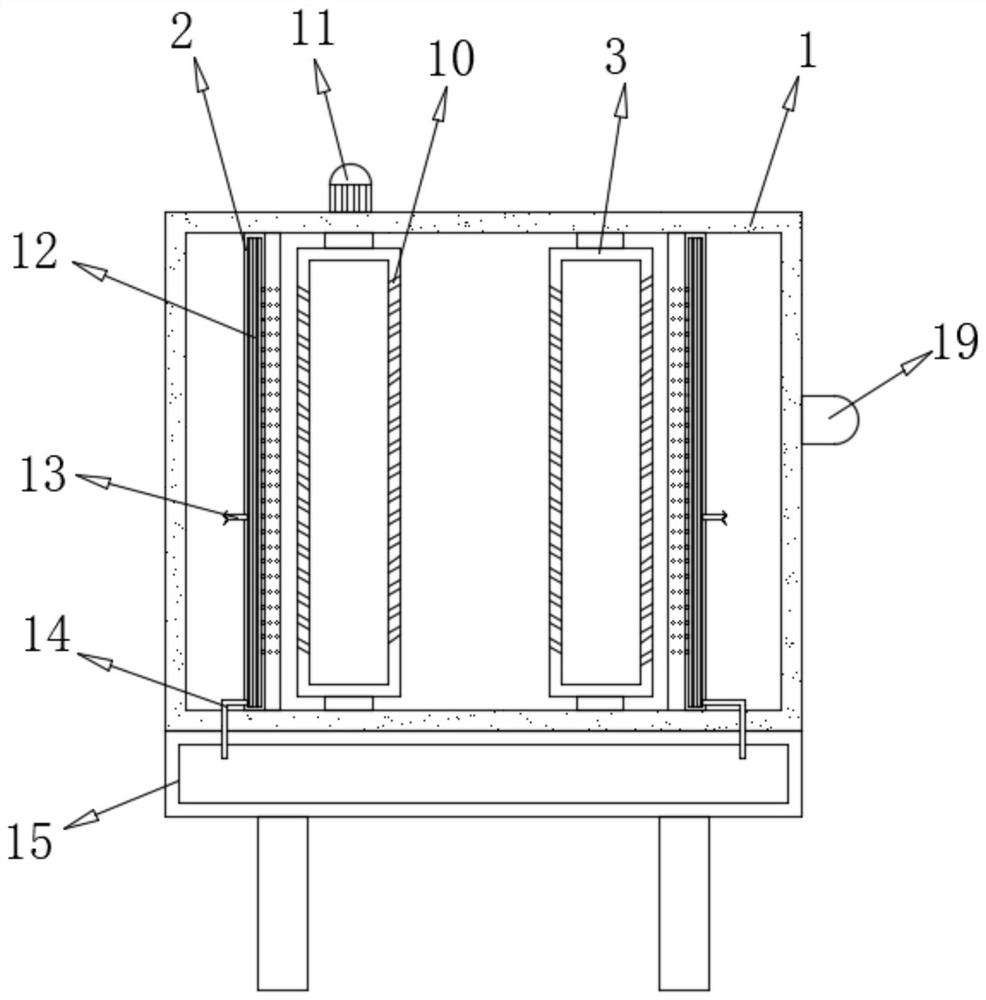

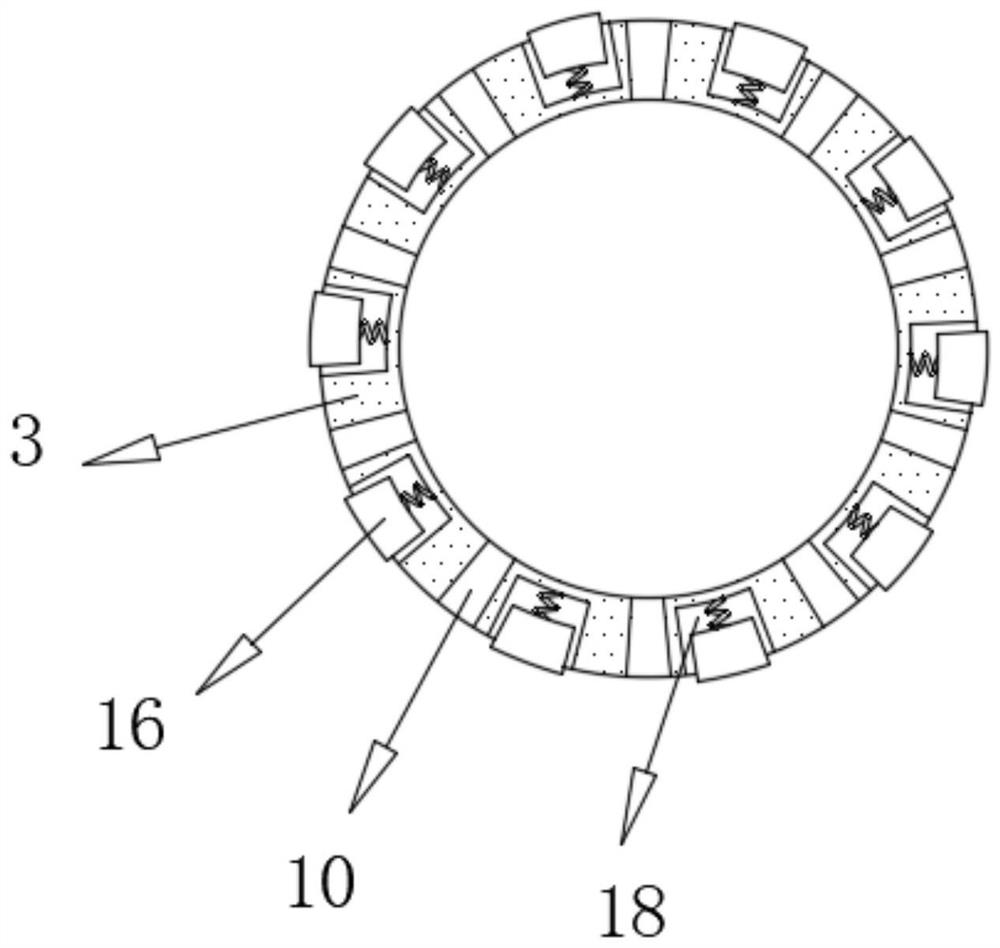

[0028] refer to Figure 1-4 , a textile fabric steaming device for textile processing, comprising a box body 1, the top inner wall and bottom inner wall of the box body 1 are connected with steaming rollers 3 arranged alternately through bearings, and the top outer wall of the box body 1 is connected by fastening bolts There is a driving motor 11, and the outer circumferential wall of the steaming roller 3 is provided with evenly distributed steam outlets 10, and the inner wall of the steam outlet 10 is inclined, and the outer circumferential wall of the steaming roller 3 is provided with evenly distributed grooves 18, and the grooves The inner wall of one side of 18 is connected with bristles 16 through springs, and the bristles 16 and the steam outlet 10 are arranged at intervals. The inside of the steaming roller 3 is connected with a steam generator through a connecting pipe, and the fabric is fed into the box body 1 and wound on the steamer in turn. On the roller 3, the f...

Embodiment 2

[0038] refer to Figure 5 , a textile fabric tank steaming device for textile processing. Compared with Embodiment 1, the inner wall of one side of the box body 1 is connected with the air outlet plate 20 by fastening bolts on both sides of the opening of the discharge port, and the two sides Perforations are provided on opposite sides of the two air outlet plates 20 , and the insides of the two air outlet plates 20 communicate with the air outlets of the air pump 19 .

[0039]Working principle: While the steaming roller 3 is steaming the fabric, the air pump 19 pumps negative pressure inside the arc-shaped plate 2, so that the airflow ejected through the steam outlet 10 can effectively pass through the fabric and enter through the suction hole 4 In the curved plate 2, the effective pot steaming of the fabric is ensured. The water vapor in the air entering the curved plate 2 contacts the mesh plate 12 and condenses on the mesh plate 12, and the condensed water stains flow to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com