A rapid dyeing method with ultra-low liquor ratio, high temperature and high pressure

A high-temperature, high-pressure, rapid dyeing technology, applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve the problems of low efficiency, high energy consumption, high sewage discharge, etc., and achieve the goal of reducing dyeing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

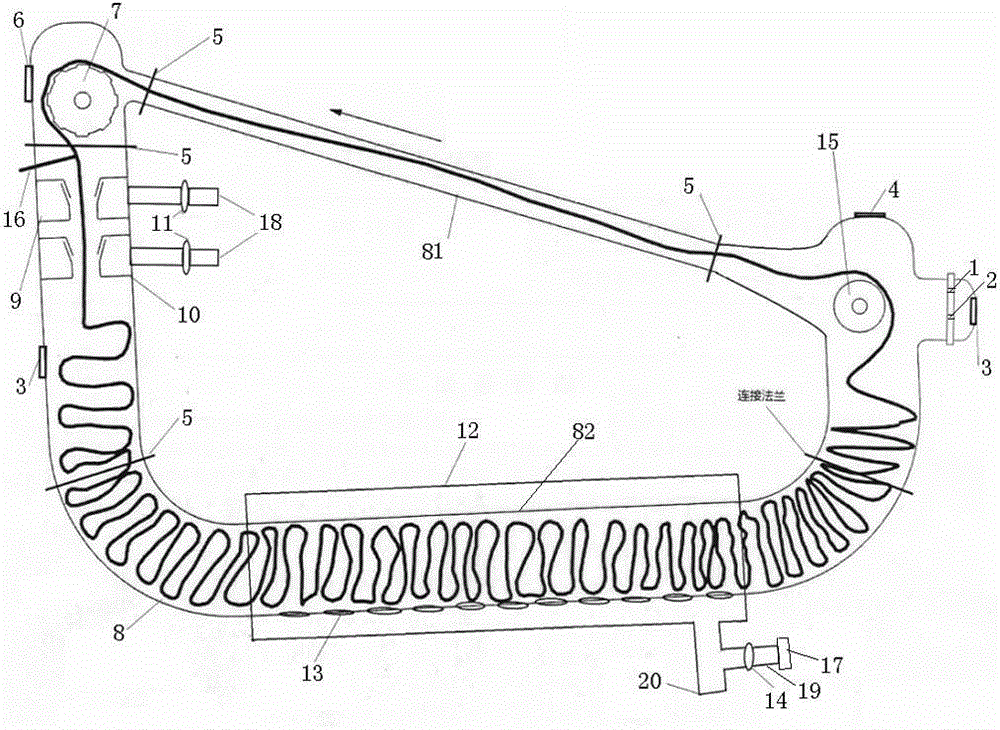

[0030] Knot the tail of the cloth-leading rope with the head of the gray cloth, and the rope end of the cloth-leading rope passes through the cloth inlet 1, enters the dyeing cylinder 8, bypasses the cloth feeding wheel 15 and the cloth guide wheel 7, and runs along the dyeing cylinder The inner wall of 8 passes through the cloth outlet 2, and then the knot tied between the rope tail and the gray cloth head is untied, and then the gray cloth head and the gray cloth tail are tied in the dyeing cylinder 8, so that the gray cloth is ring-shaped;

[0031] Through the rotation of the cloth feeding wheel 15 and the cloth guide wheel 7, the gray cloth is sent into the inclined cylinder 81 with a temperature of 60°C at a speed of 400 m / min, and the gray cloth moves obliquely upward along the inclined pipe 81 through the cloth feeding wheel 15. Effectively prevent the clogging of the dyeing cylinder 8, the gray cloth moves vertically downward through the cloth guide wheel 7 and the clot...

Embodiment 2

[0037] Knot the tail of the cloth-leading rope with the head of the gray cloth, and the rope end of the cloth-leading rope passes through the cloth inlet 1, enters the dyeing cylinder 8, bypasses the cloth feeding wheel 15 and the cloth guide wheel 7, and runs along the dyeing cylinder The inner wall of 8 passes through the cloth outlet 2, and then the knot tied between the rope tail and the gray cloth head is untied, and then the gray cloth head and the gray cloth tail are tied in the dyeing cylinder 8, so that the gray cloth is ring-shaped;

[0038] Through the rotation of the cloth feeding wheel 15 and the cloth guide wheel 7, the gray cloth is sent into the inclined cylinder 81 with a temperature of 105°C at a speed of 400 m / min, and the gray cloth moves obliquely upward along the inclined pipe 81 through the cloth feeding wheel 15. Effectively prevent the clogging of the dyeing cylinder 8, the gray cloth moves vertically downward through the cloth guide wheel 7 and the clo...

Embodiment 3

[0044] Knot the tail of the cloth-leading rope with the head of the gray cloth, and the rope end of the cloth-leading rope passes through the cloth inlet 1, enters the dyeing cylinder 8, bypasses the cloth feeding wheel 15 and the cloth guide wheel 7, and runs along the dyeing cylinder The inner wall of 8 passes through the cloth outlet 2, and then the knot tied between the rope tail and the gray cloth head is untied, and then the gray cloth head and the gray cloth tail are tied in the dyeing cylinder 8, so that the gray cloth is ring-shaped;

[0045] Through the rotation of the cloth feeding wheel 15 and the cloth guide wheel 7, the gray cloth is sent into the inclined cylinder 81 with a temperature of 135°C at a speed of 400 m / min, and the gray cloth moves obliquely upward along the inclined pipe 81 through the cloth feeding wheel 15. Effectively prevent the clogging of the dyeing cylinder 8, the gray cloth moves vertically downward through the cloth guide wheel 7 and the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com