Patents

Literature

36results about How to "Save additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble organic/inorganic compound fertilizer prepared by molasses fermentation liquor and preparation method of fertilizer

The invention provides a water-soluble organic / inorganic compound fertilizer prepared by molasses fermentation liquor. The water-soluble organic / inorganic compound fertilizer is prepared by the following raw materials in percentage by weight: 30 to 75% of water-soluble nitrogenous fertilizer, water-soluble phosphatic fertilizer and water-soluble potash fertilizer, 0.5 to 5% of biological bacterium and the balance of 1 molasses fermentation liquor, wherein the molasses fermentation liquor is 45 to 95% molasses fermentation liquor. The preparation method comprises the following steps: pouring the molasses fermentation liquor into a fermenting tank; adding the biological bacterium; fermenting for 30 to 40 hours at 10 to 40 DEG C; removing colloid in the fermentation liquor; inactivating at high temperature; precipitating and then filtering to remove insoluble substance; adding the water-soluble nitrogenous fertilizer, the water-soluble phosphatic fertilizer or the water-soluble potash fertilizer to the fermentation liquor; granulating; and drying to obtain the finished product. The water-soluble organic / inorganic compound fertilizer provided by the invention is convenient to use, higher in nutrient element content, low in cost and remarkable in yield increasing effect.

Owner:湖南豫园(南宁)生物科技有限公司

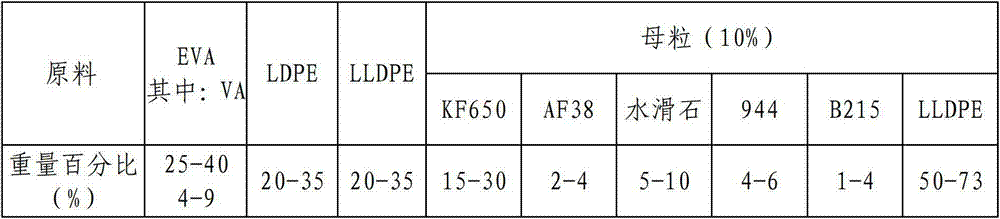

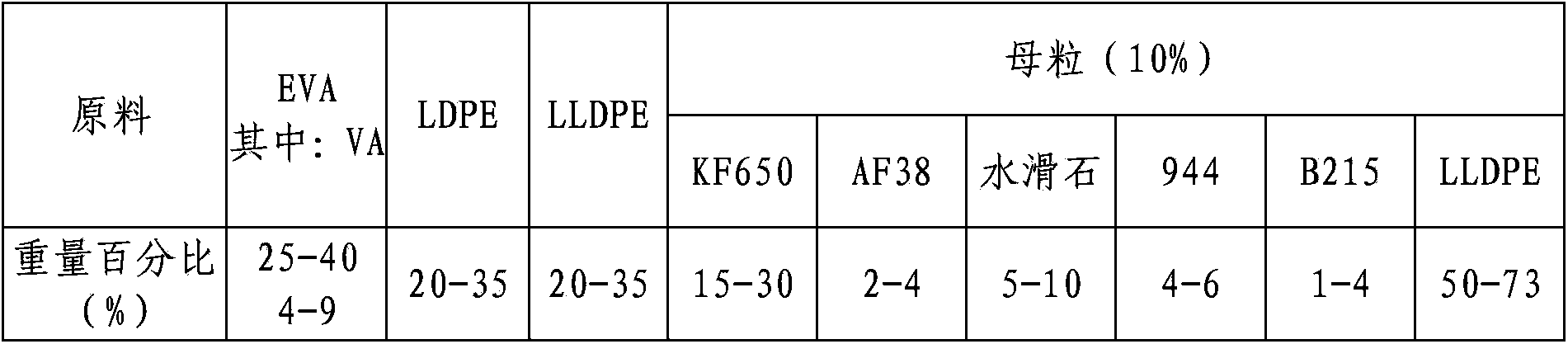

Five-layer-coextrusion, high-thermal-insulation, antifogging and drip-free agricultural greenhouse plastic film

ActiveCN103042782ASave additivesHeating up fastClimate change adaptationSynthetic resin layered productsBlow moldingFruit tree

The invention discloses a five-layer-coextrusion, high-thermal-insulation, antifogging and drip-free agricultural greenhouse plastic film which comprises the following raw materials by weight percentage: agricultural polyethylene resin (including EVA (ethylene vinyl acetute) resin), a thermal insulation agent, an antifogging agent, an antidripping agent and an ageing resisting agent. According to the agricultural greenhouse film formed by five-layer coextrusion blow molding according to a layering formula, the thermal insulation property and the usage period of the film can be improved and prolonged; the raw materials are saved; antidripping and antifogging periods are prolonged; the property of the agricultural greenhouse film is improved; the yield and quality of overwintering greenhouse vegetables, fruit trees, flowers, and the like covered with the film can be increased and improved obviously; and the film has better popularization and application prospects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

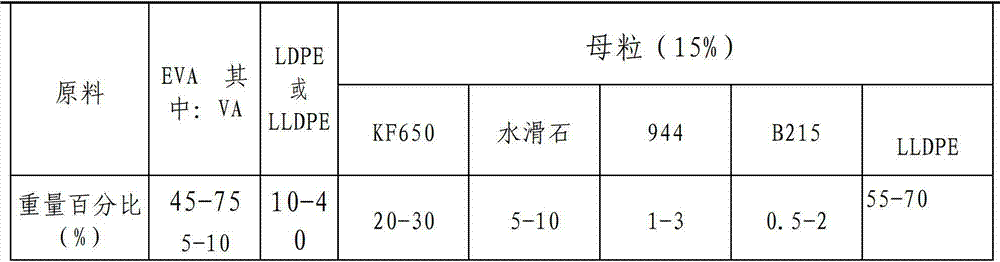

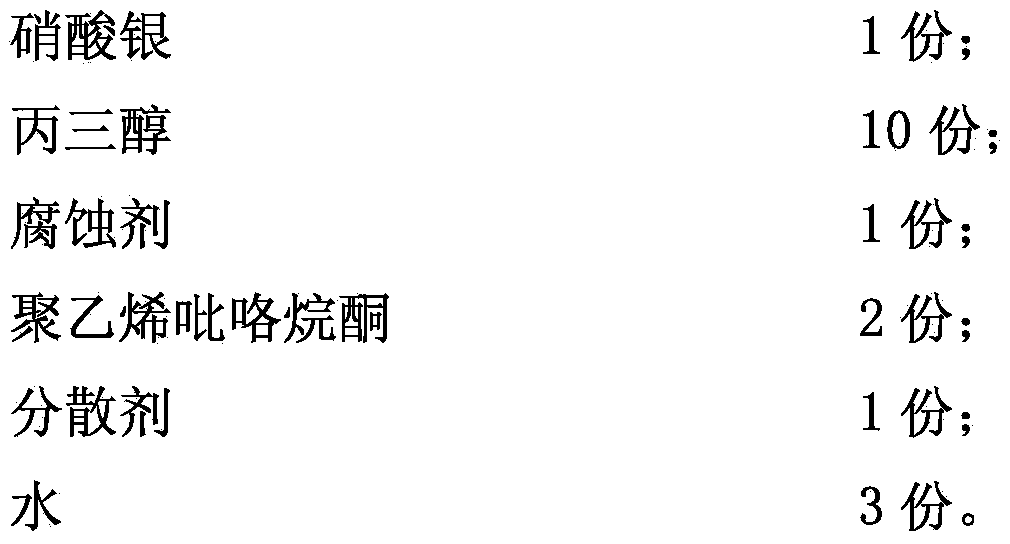

Nano silver conductive coating

ActiveCN103965674AImprove conductivityReduce manufacturing costElectrically-conductive paintsConductive coatingWater soluble

The invention discloses a water-soluble nano silver conductive coating. The raw material formula of the coating consists of the following materials in percentage by mass: 10-30% of nano silver wire dispersing liquid or 3-6% of nano silver wires, 30-50% of water soluble resin, 1-3% of leveling agent and the balance of water. According to the coating, the nano-grade conductive silver wires prepared by using an etching method are blended into the water soluble or oil soluble resin, so that the conductivity of the coating is greatly improved; compared with the prior art, the coating is very low in preparation cost, simple in preparation method, small in amount of added additives, gentle and free of pollution in reaction condition, and applicable to scale production, and the raw materials are low in price and easily obtained.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

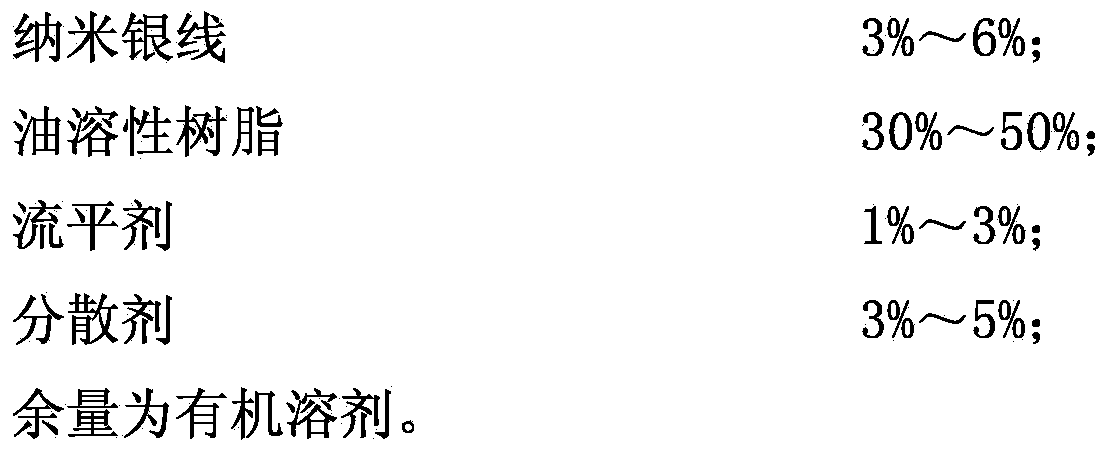

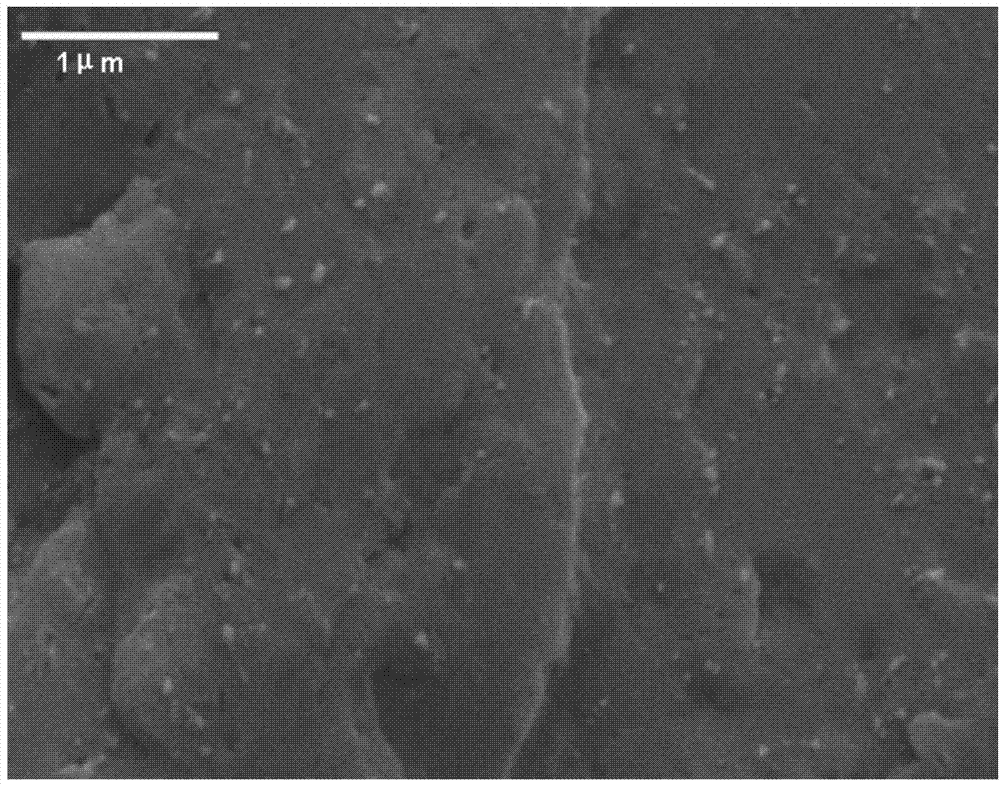

Full biodegrade mulch master batch as well as preparation method and application thereof

InactiveCN103756270AImprove mechanical propertiesGood compatibilityClimate change adaptationPlant protective coveringsUltimate tensile strengthSilicon dioxide

The invention discloses a full biodegrade mulch master batch which comprises the following components in percentage by weight: 70-80% of PBAT (Poly Butyleneadipate-co-Terephthalate), 10-30% of modified nano-silica, 4-7% of dispersing agent, 3-6% of lubrication machining additive and 0-5% of color powder. The invention further discloses a preparation method and an application of the master batch. A mulch product using the master batch has the following mechanical properties: the longitudinal tensile strength is more than or equal to 23MPa, the transverse tensile strength is more than or equal to 21MPa, the longitudinal elongation at break is more than 205%, the transverse elongation at break is more than 322%, and the right angle tear strengths in the longitudinal direction and the transverse direction are both more than 120N / mm.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

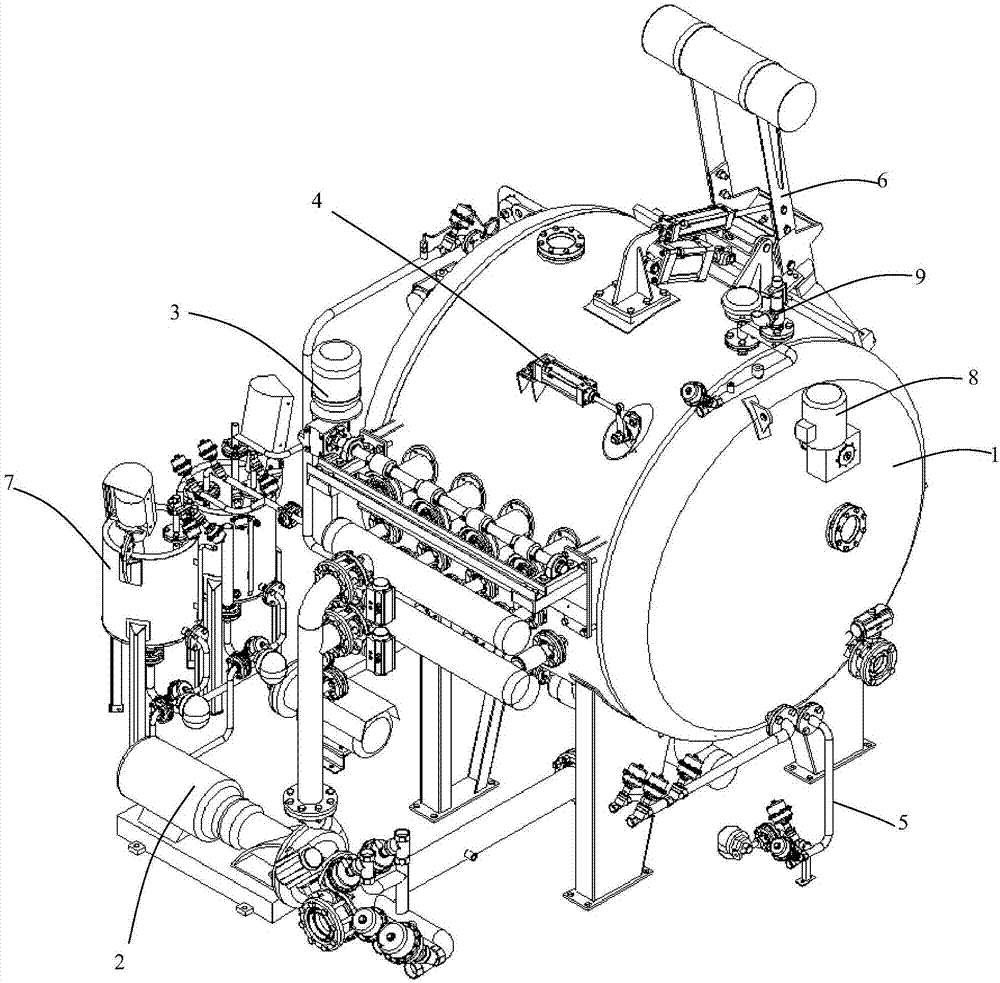

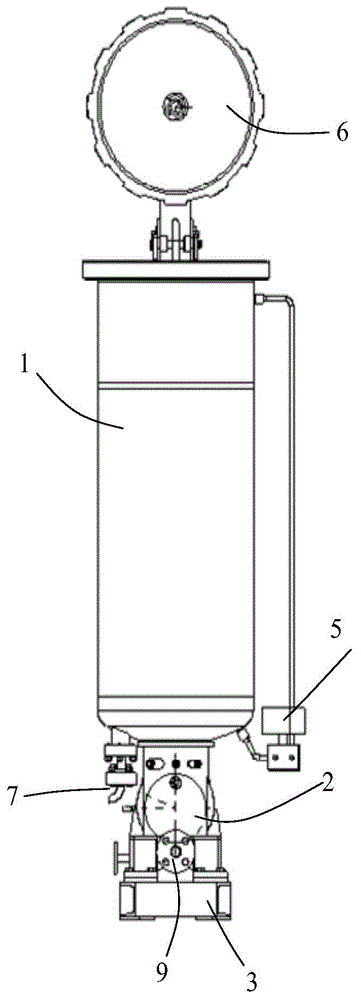

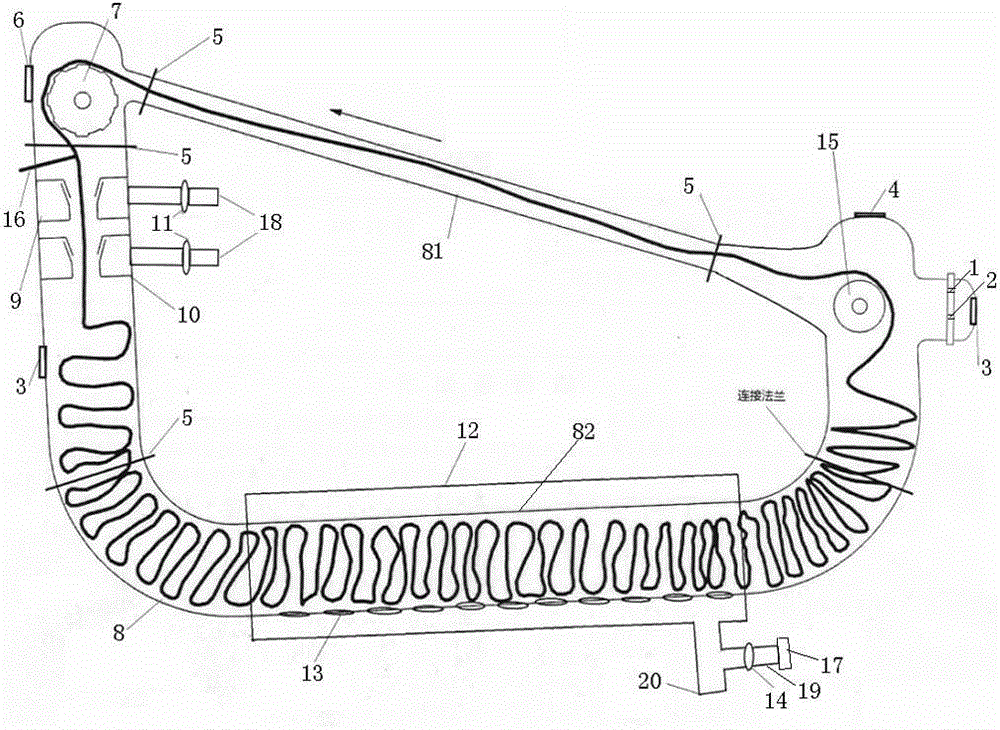

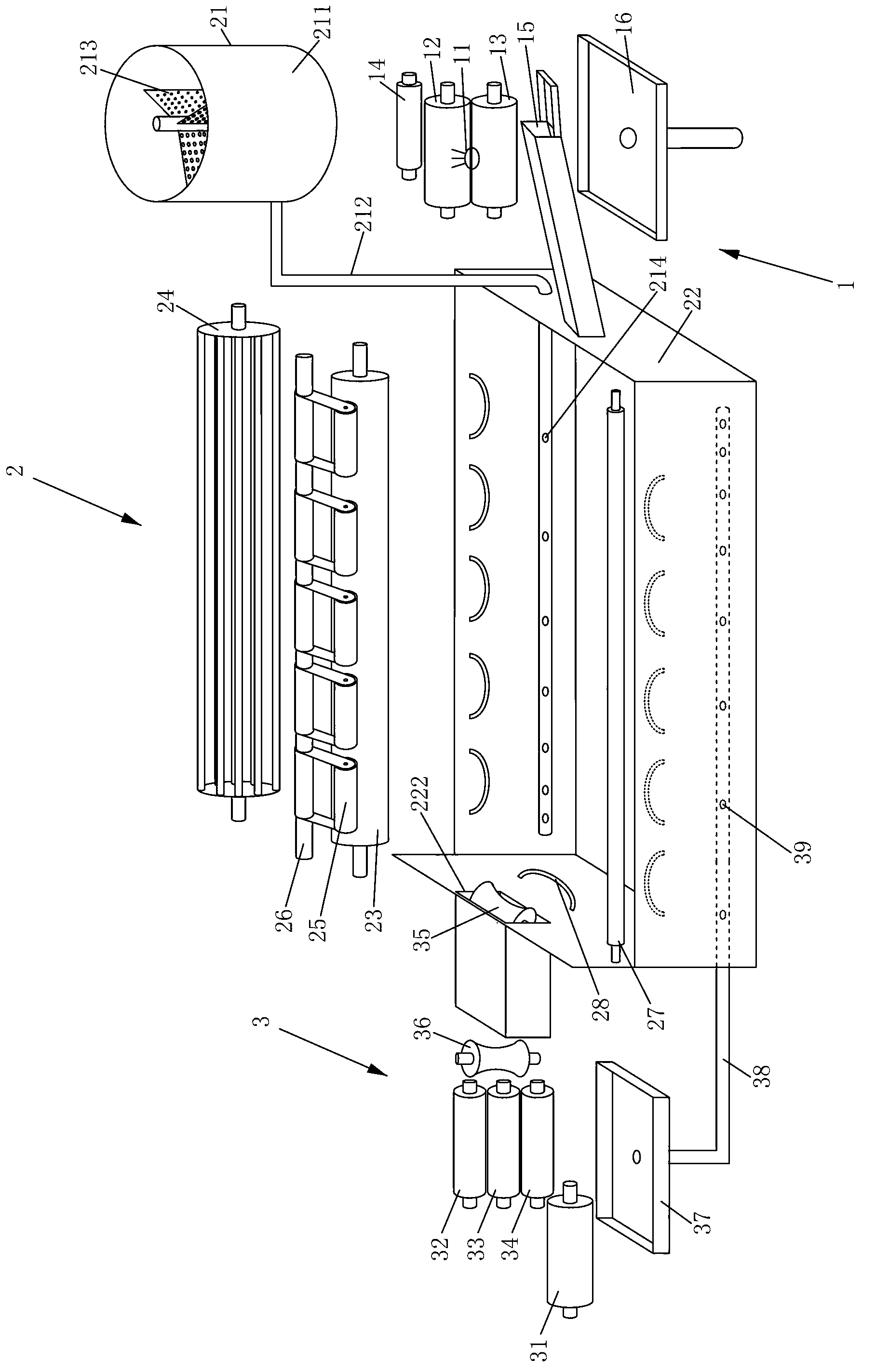

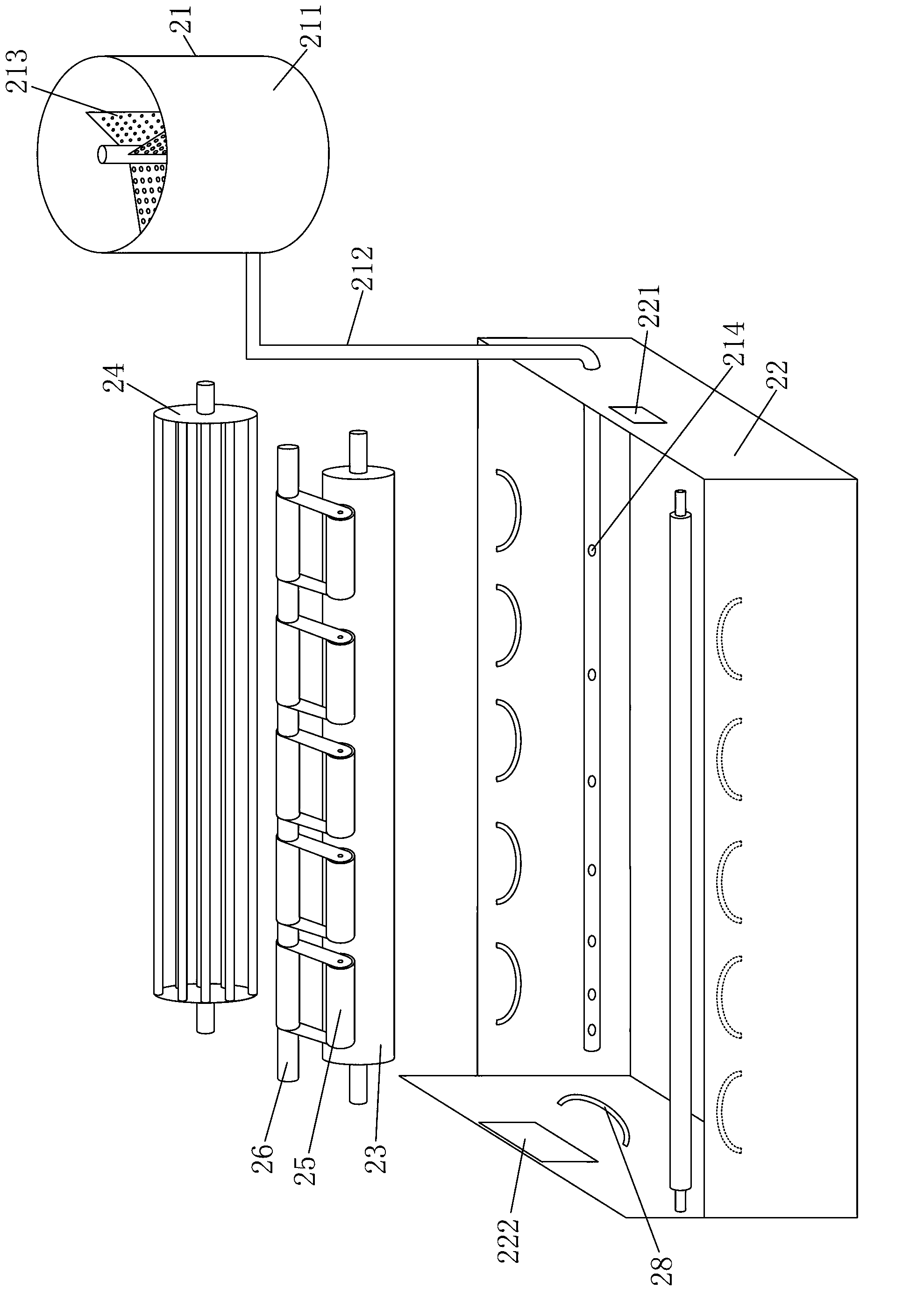

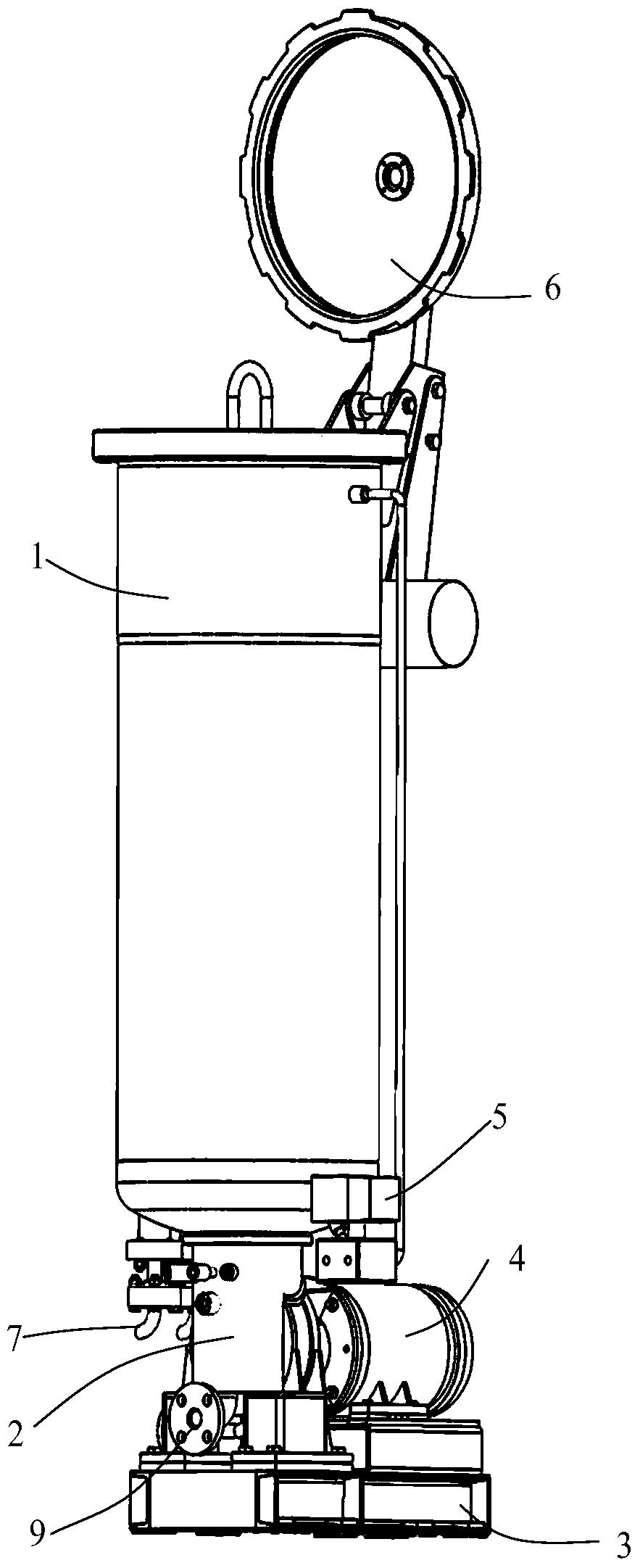

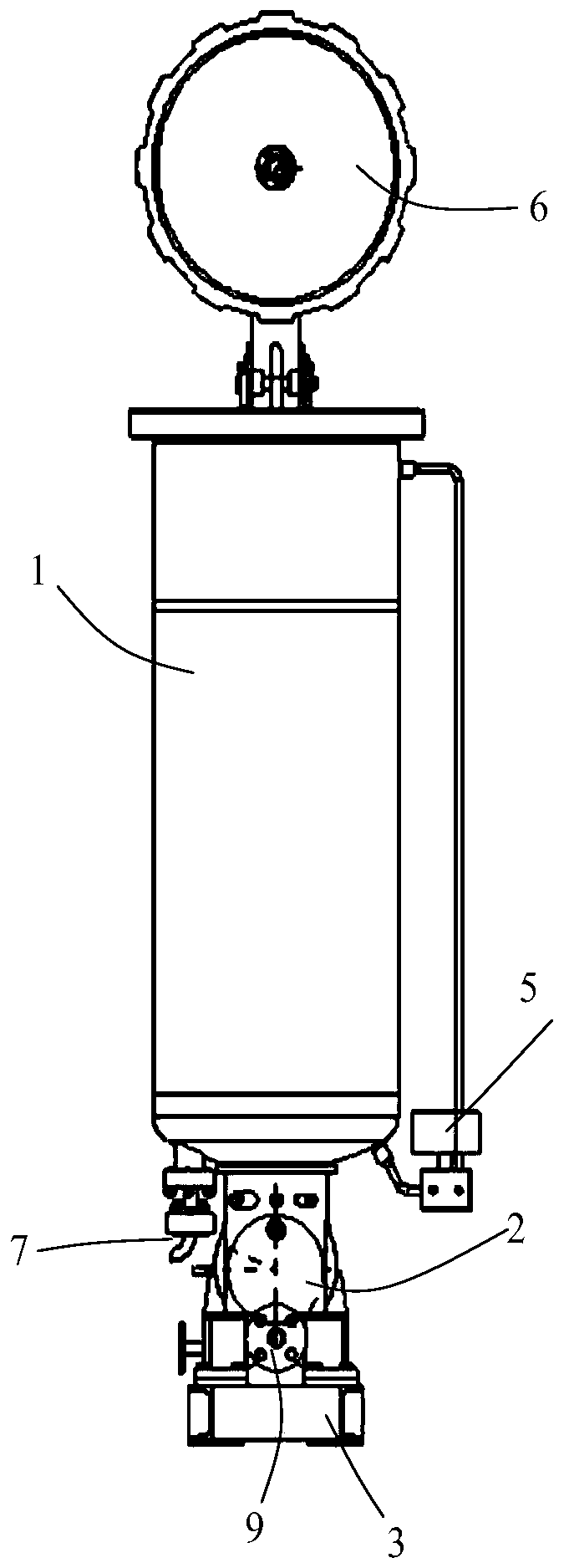

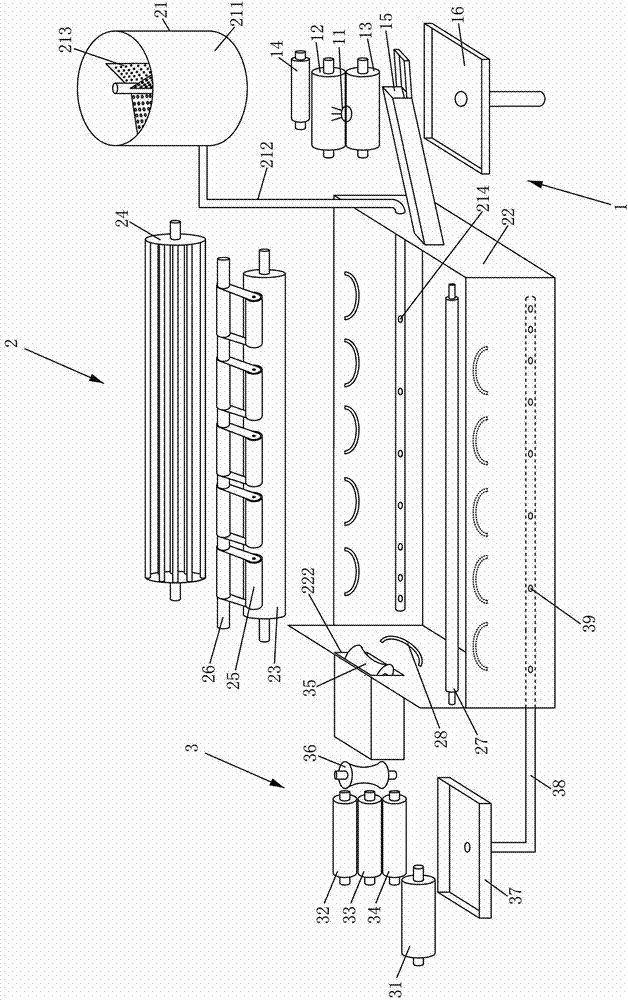

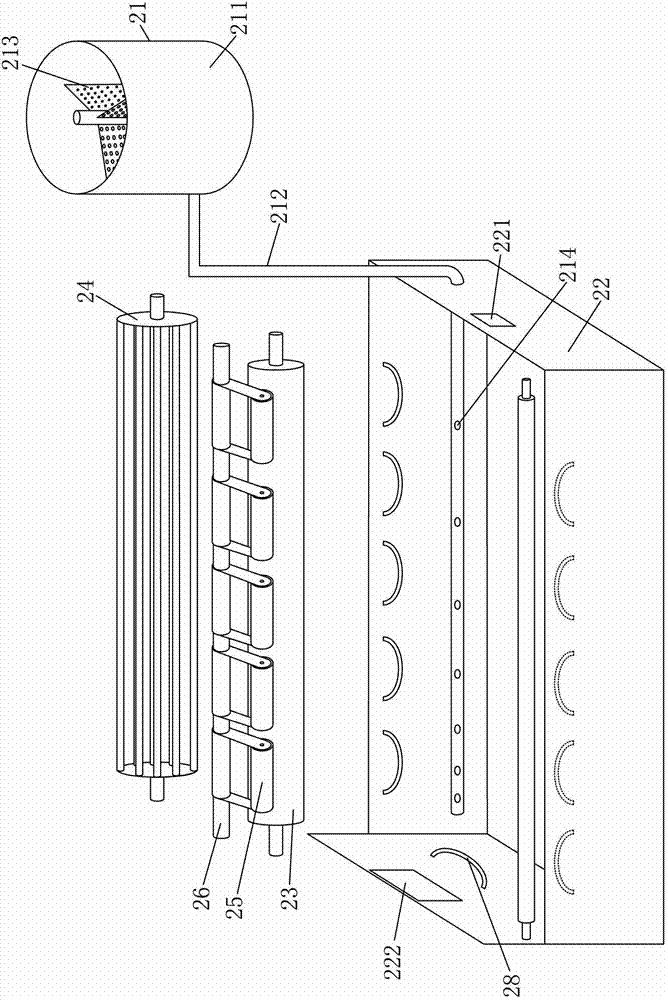

Low-bath-ratio segmented dyeing jet dyeing machine

PendingCN107488954AEmission reductionReduce manual operation timeTextile treatment containersTextile treatment machine arrangementsYarnLiquid waste

The invention discloses a low-bath-ratio segmented dyeing jet dyeing machine, mainly comprising a cylinder body, a dye liquor circulation system, a yarn hanging assembly transmission system, a yarn pressing assembly transmission system, a heat exchange system, a door opening assembly, a dyestuff auxiliary cylinder, a cylinder cleaning assembly, a pressure relieving system, a pressure gauge, a jet dyeing pipe, a water spray pipe, a water tank, a yarn pressing assembly, a yarn hanging assembly, a liquidometer, and other components. A servo motor is used to control an annular yarn to move according to a set stepping angle, to realize an annular yarn automatic segmentation process. The adjustable type water tank which can control depth of dye liquor is used to control segment length of segmented dyeing. Under coordination control of stepping motion of the yarns, dye liquor depth of the water tank, and dye liquor jet dyeing, a technical process of multi-color segmented dyeing of a fabric is realized. The jet dyeing machine automatically realizes the technical process of segmented dyeing, greatly reduces manual operation time, and improves dyeing quality and technological level. The jet dyeing machine can obviously save an auxiliary agent and dyestuff, reduces discharge of liquid waste, and has very obvious economical and social benefits.

Owner:高勋绿色智能装备(广州)有限公司

Jade green air-flow dyeing technology for single jersey

InactiveCN107083697AAvoid differences in dye adsorptionNo creasesBiochemical treatment with enzymes/microorganismsDyeing processAirflowDyeing

ThThe invention relates to jade green dyeing technology for single jersey. Hemming process is not needed and one process is omitted, based on dyeing technology, anhydrous sodium sulphate is added firstly and uniformly distributed on a cloth surface, in order to solve the problem of color spots; a smooth agent is added in order to eliminating the problem of fluffing or piling of fabrics due to stretching or friction by extraneous mechanical action; by means of matching relation of air quantity and linear velocity of cloth lifting rollers, after the fabric leaves a cloth guiding tube, an expansion process is provided, bundling position is continuously changed, so that folding parts can be rapidly expanded, creases of the fabric are not generated, and difference of dye adsorption generated at the crease parts is avoided. the fabric has good effects in the aspects of capillary effect, fineness, hand feeling, weight loss, and the like, and the technology saves time, auxiliary agents, and has low energy consumption and low emission; the technology enables the fabric to have better indices of each color fasteness and guarantees level-dyeing property; by means of control of dyeing time, the problems of uneven dyeing and the like due to bond breaking of dye after bond type reactions are prevented.

Owner:JIHUA 3543 KNITTING CLOTHING

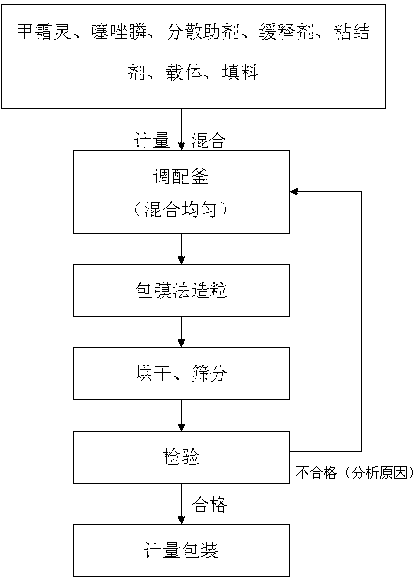

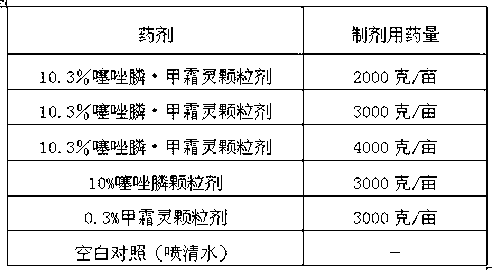

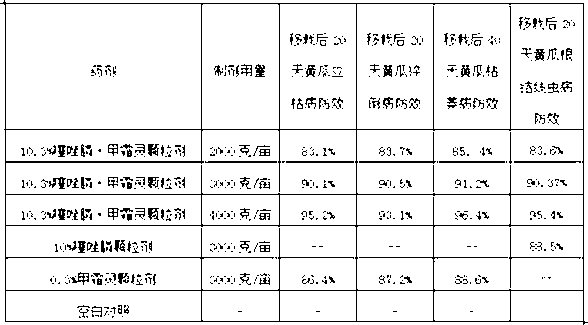

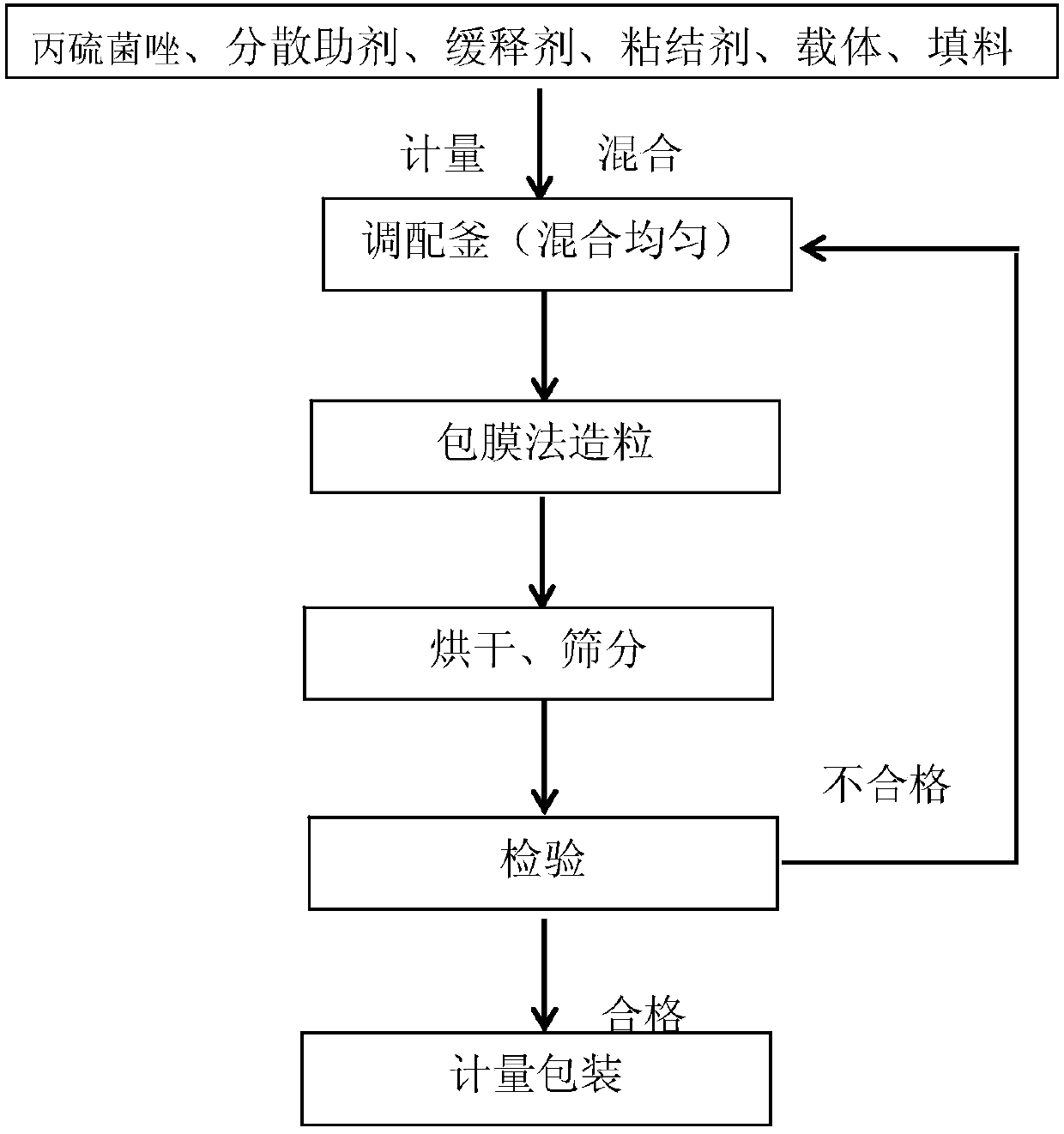

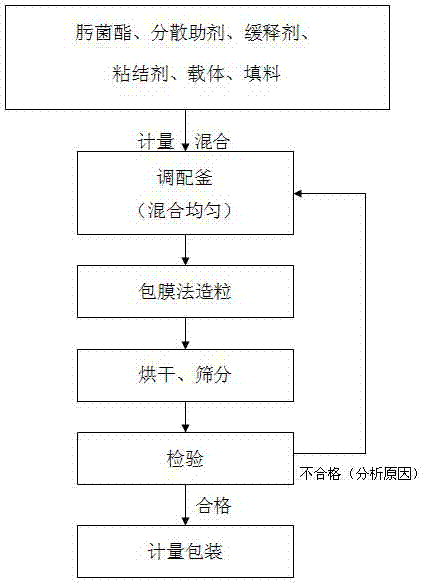

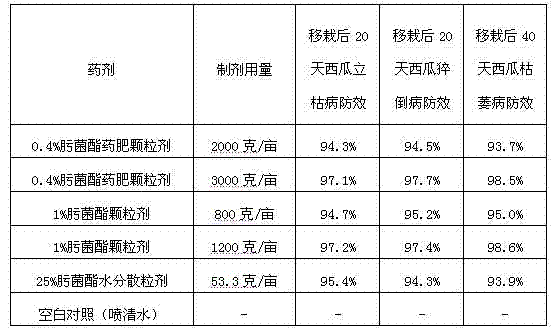

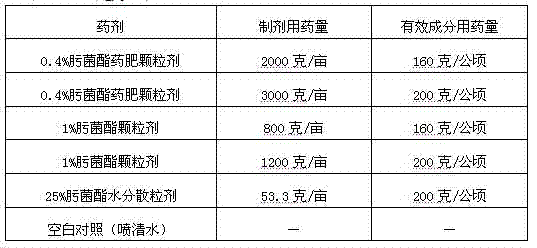

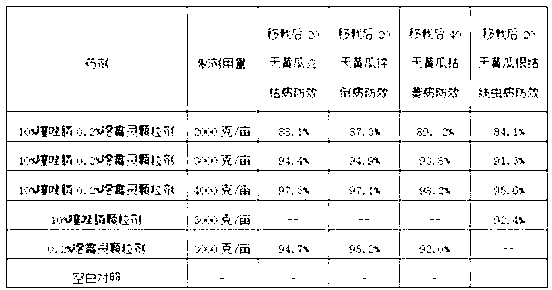

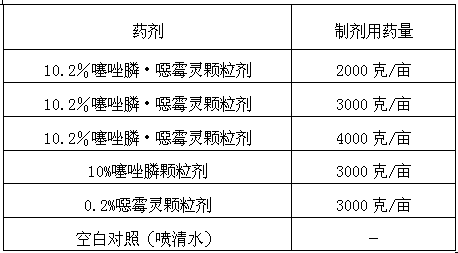

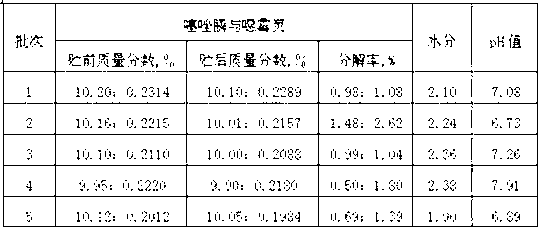

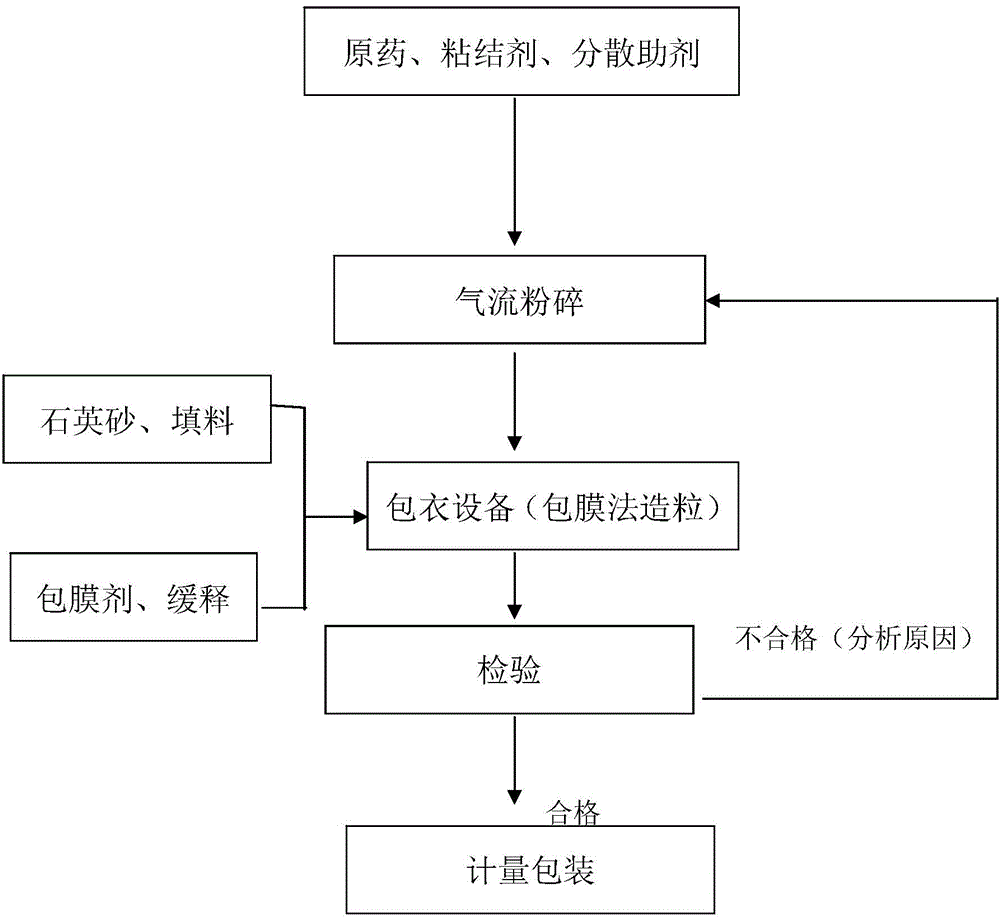

Thiazole phosphine and metalaxyl granule and preparation method thereof

The invention relates to a thiazole phosphine and metalaxyl granule and a preparation method thereof. The thiazole phosphine and metalaxyl granule includes the components by weight: 0.1%-20% of thiazole phosphine, 0.1%-5% of metalaxyl, 70%-80% of carrier attapulgite particles, 0.5%-3% of a dispersing agent, 0.1%-2% of a sustained-release agent, 0.1%-5% of a binder, and the balance a filler. The granule of the present invention is granulated by a film coating method. The invention effectively combines the control of plant nematodes and soil-borne diseases, uses resources efficiently, scientifically and rationally, has important significance on environment protection, and plays a positive role in reducing agricultural inputs and promoting agricultural output and income.

Owner:GUANGDONG ZHONGXUN AGRI TECH

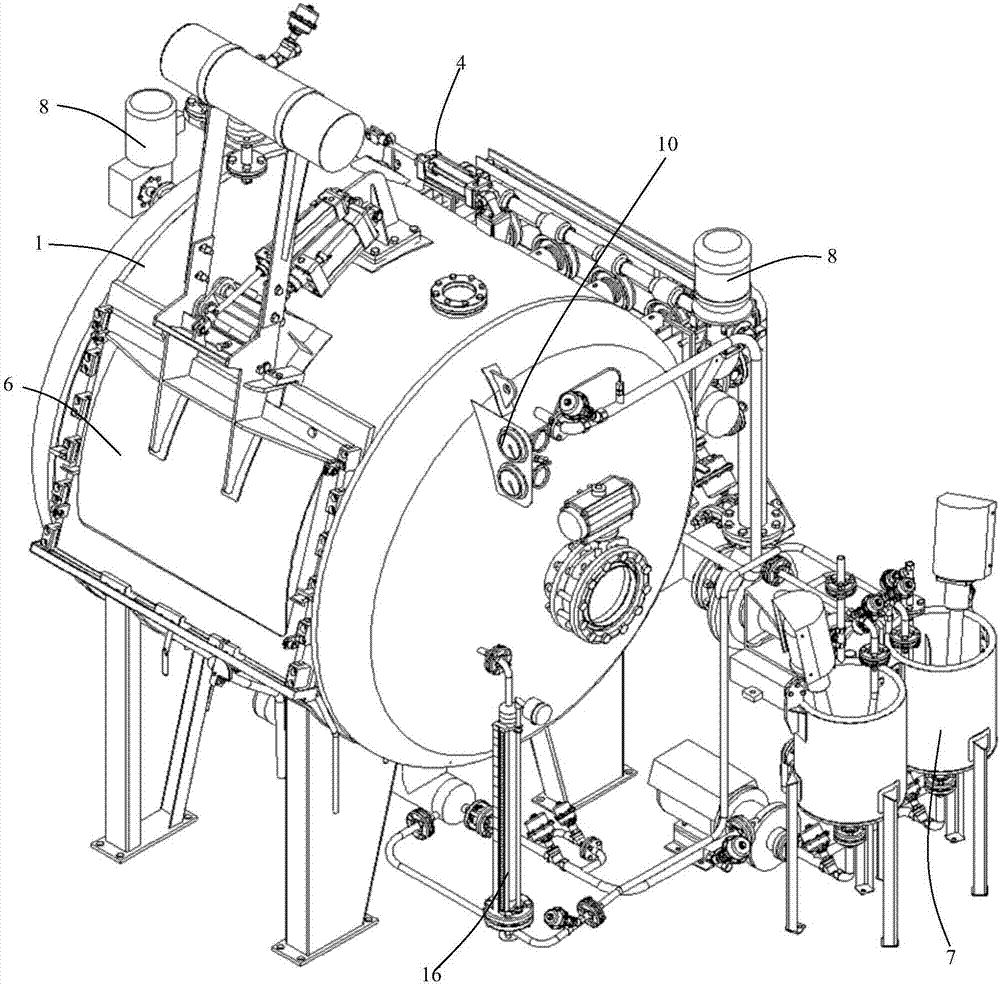

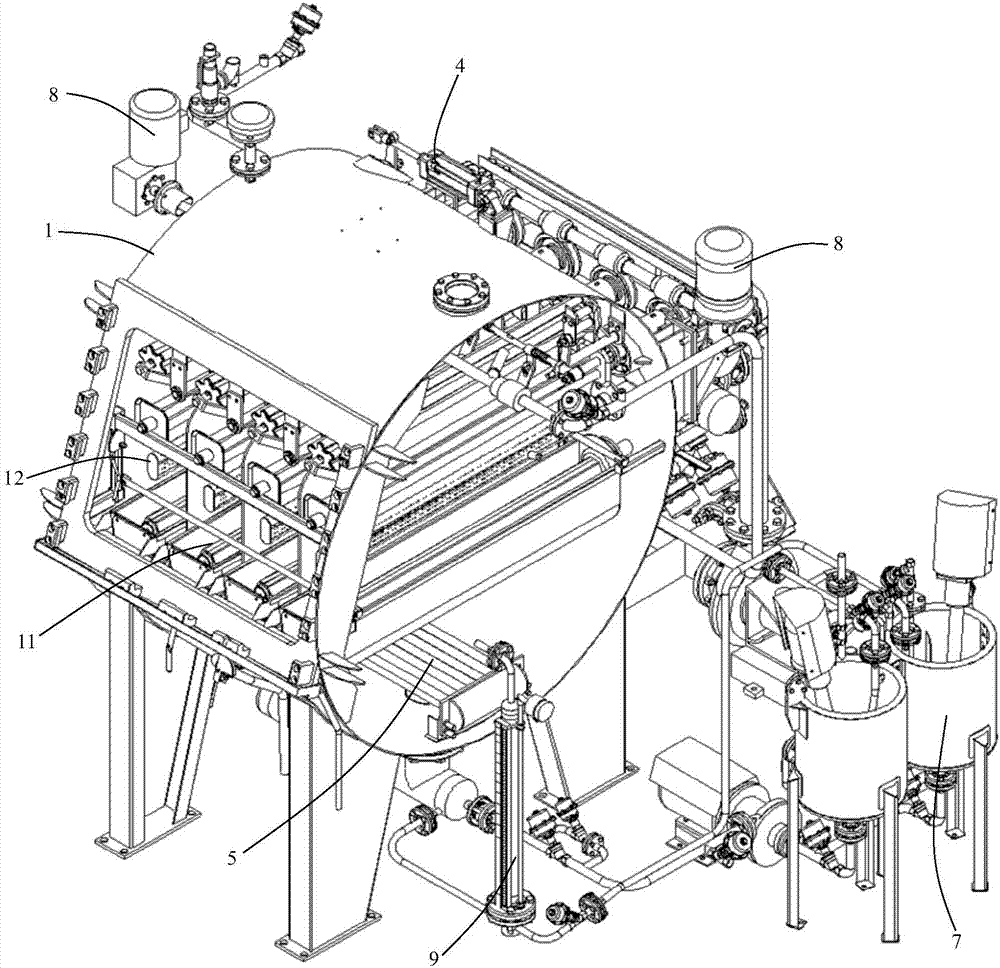

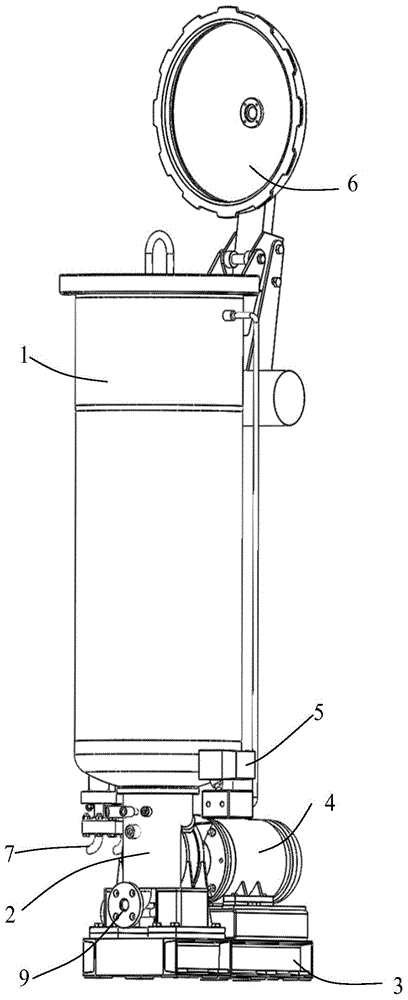

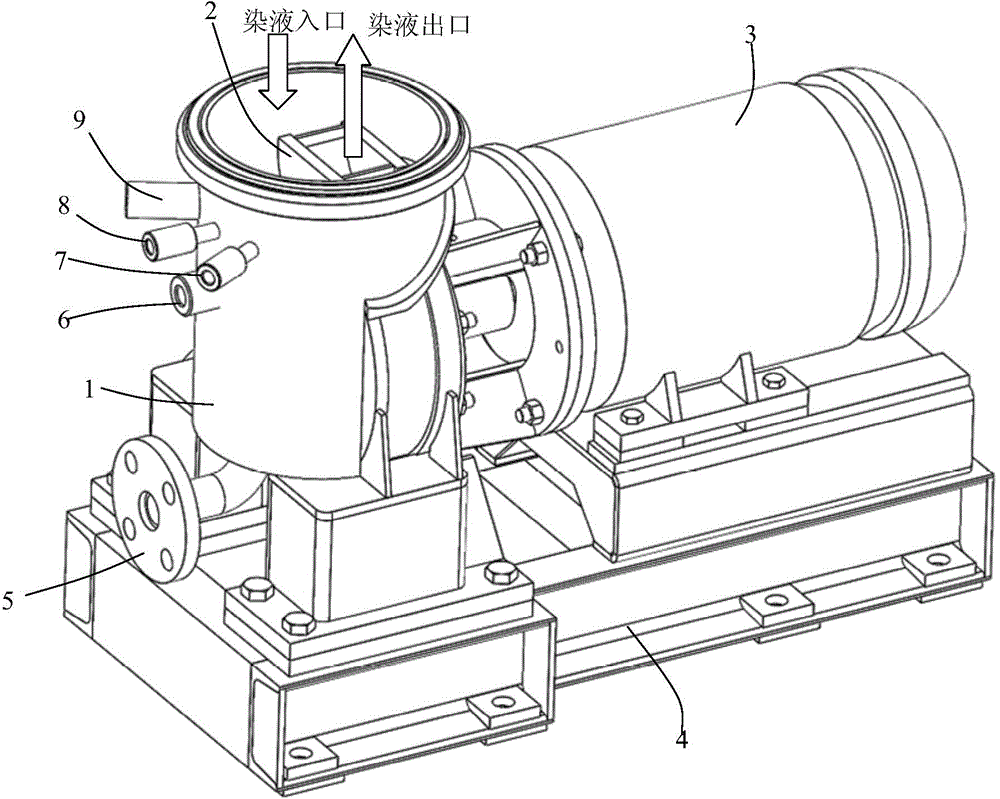

Yarn dyeing machine with 1:2 extremely-low bath ratio

ActiveCN104818591AEmission reductionIngenious structural designTextile treatment containersTextile treatment machine arrangementsYarnSocial benefits

The invention provides a yarn dyeing machine with a 1:2 extremely-low bath ratio. The yarn dyeing machine mainly comprises a yarn cylinder, a liquid collecting pipe, a base, a motor, a volumeter, a cylinder cover, a steam inlet, a steam outlet, liquid supply and discharging pipes, a liquid temperature meter, a high pressure meter, a low pressure meter, a hydro-acupuncture probing sleeve, a heat exchange pipe, a flow distribution disc, a round heaven and square earth pipe, a yarn bamboo pipe, a liquid collecting cavity, a mixed-flow pump, a flow guide pipe and a water baffle and the like. Due to the ingenious structural design, the 1:2 extremely-low bath ratio of the yarn dyeing machine close to the limit can be achieved, auxiliaries and dye are obviously saved, the waste liquid discharge is reduced, and the yarn dyeing machine is very obvious in economic and social benefits. The yarn dyeing machine is compact in structure, a flow channel is short, and the yarn dyeing machine has excellent energy efficiency.

Owner:高勋绿色智能装备(佛山)有限公司

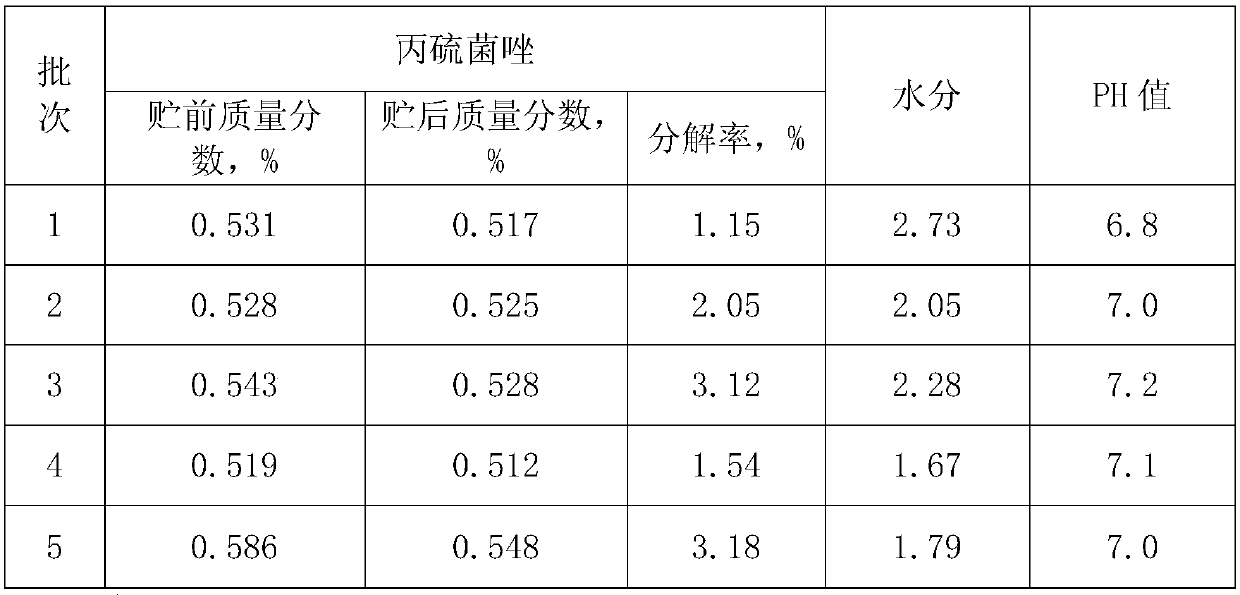

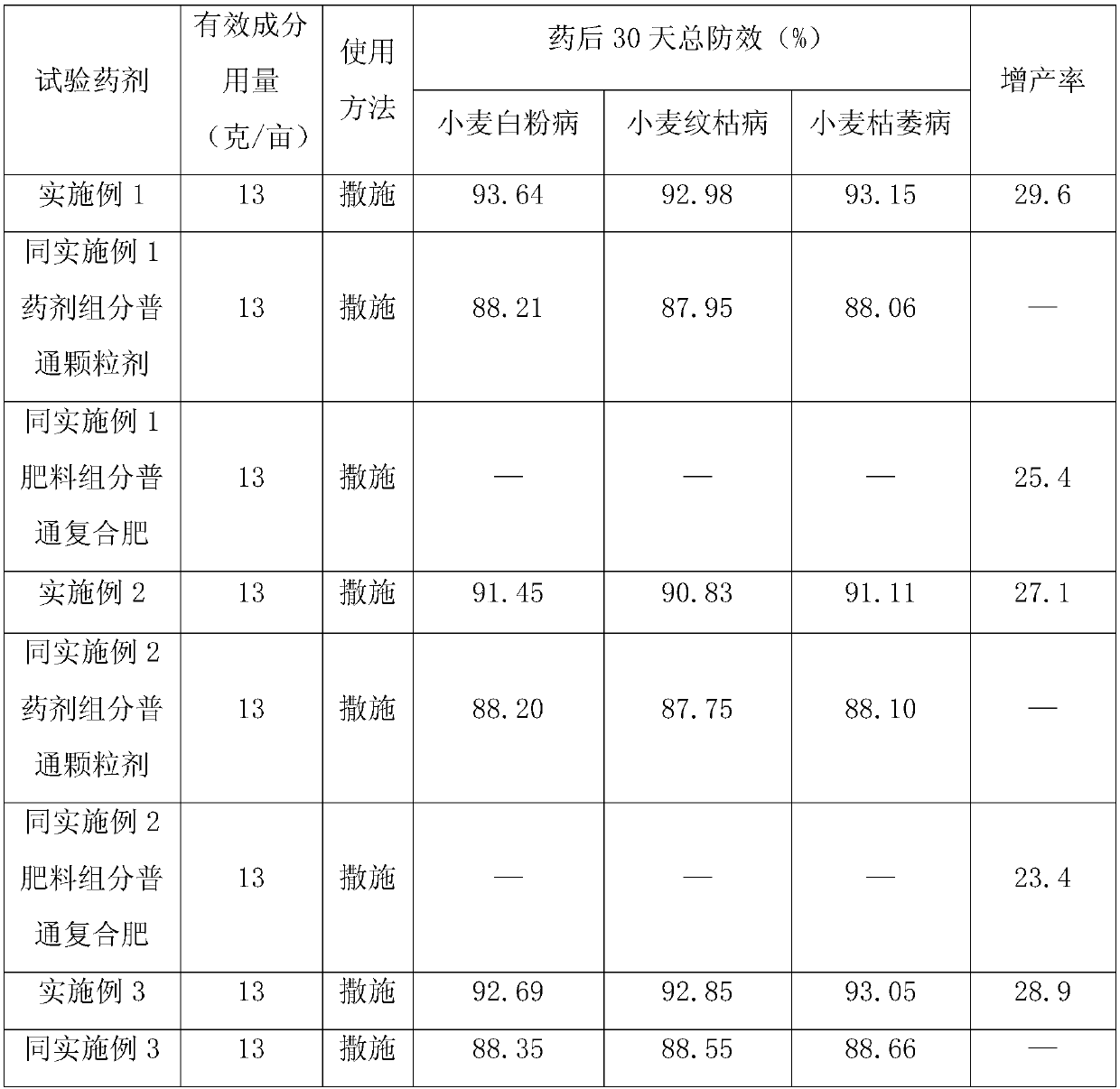

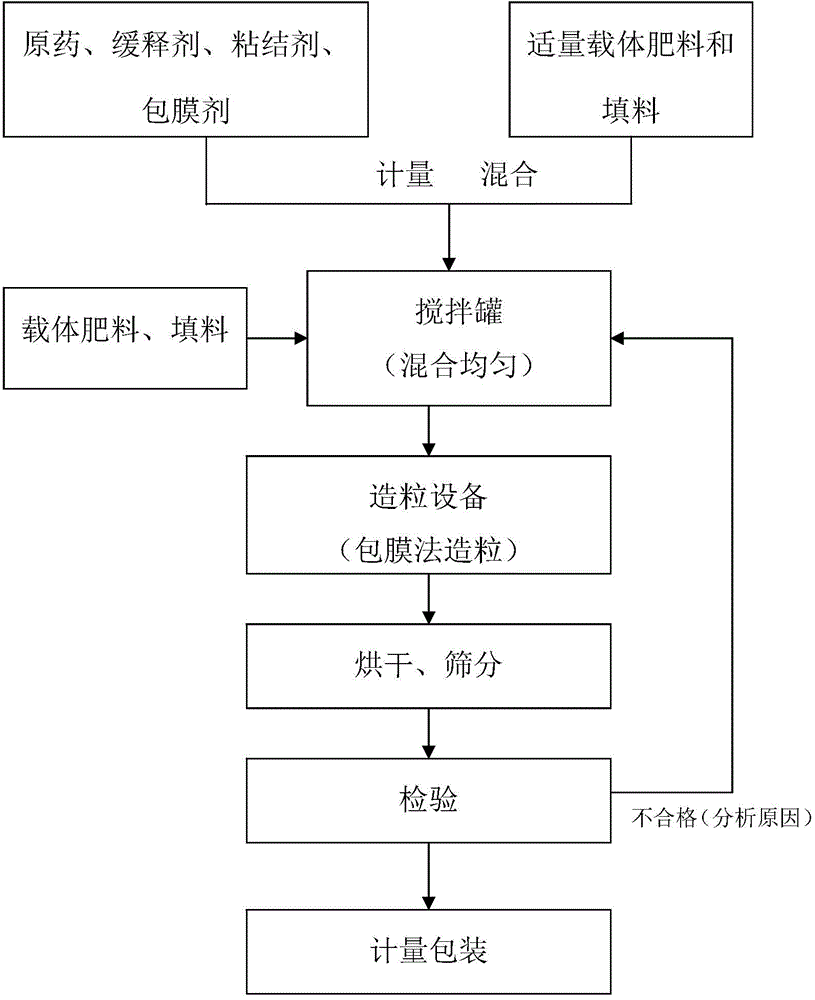

Bactericidal pesticidal fertilizer granules

InactiveCN107721646AEvenly distributedPromote absorptionCalcareous fertilisersAlkali orthophosphate fertiliserSheath blightPlant disease

The invention relates to bactericidal pesticidal fertilizer granules. The pesticidal fertilizer granules use prothioconazole as bactericide component and one or more than two of major elements N, P and K and trace elements of zinc and boron as a carrier fertilizer component. Based on the total weight, the pesticidal fertilizer granules comprise 0.1-2% of prothioconazole, 8-80% of a carrier fertilizer, 0.5-3% of a dispersing auxiliary, 0.1-2% of a slow release agent, 0.1-5% of a bonding agent and the balance of a filler. The bactericidal pesticidal fertilizer granules provided by the inventionare mainly applied to control of powdery mildew, sheath blight, wilt disease and other diseases of wheat. The dosage form of the bactericidal pesticidal fertilizer granules is a good dosage form whichis safe and convenient to use, long in lasting period and obvious in yield increasing effect.

Owner:SHAANXI JIAYI LANDE BIOENG CO LTD

A rapid dyeing method with ultra-low liquor ratio, high temperature and high pressure

ActiveCN103924401BBig spaceHigh energy consumptionLiquid/gas/vapor textile treatmentPhysical chemistryProcess engineering

Owner:TAICANG XINRUI ENERGY SAVING EQUIP

Silk uniformly dyeing method

InactiveCN109898253AIncrease profitImprove flatnessLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsSoft waterDyeing wastewater

The invention discloses a silk uniformly dyeing method. The silk uniformly dyeing method comprises A, dye liquor preparation including dissolving and uniformly mixing dye liquor of dye solution and auxiliary solution in soft water according to dyeing process requirements and storing the mixtures in liquor storage barrels for standby application;, B, dye liquor conveying including mixing and inputting the dye solution and the auxiliary solution at a ratio of 5:1 into a padding liquor tank at 18-35 DEG C, C, dye liquor padding including continuously and smoothly immersing silk fabrics into the dye liquor inside the padding liquor tank to absorb the dye liquor, and rolling up the dyed silk fabrics, and D, stacking including instantly wrapping the rolled silk fabrics and shaft ends tightly with films, stacking the wrapped silk fabrics in a rotating state with a rotating speed of 4-8 r / min and an environment temperature of 15-35 DEG C for 5-24 hours. The silk uniformly dyeing method saves vapor and auxiliaries and has the advantages of being high in dye utilization rate, low in dyeing wastewater and environmentally friendly; the dyed fabrics are higher in permeability, uniformity and flatness than fabrics dyed through conventional methods.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

Sterilizing granule containing trifloxystrobin and preparation method thereof

ActiveCN103044136AScientific useEfficient use ofBiocideFungicidesAgricultural scienceOrganic chemistry

The invention relates to a sterilizing granule containing trifloxystrobin and a preparation method thereof. In terms of total weight of the granule, the sterilizing granule comprises 0.1-10 % of trifloxystrobin, 30-70 % of carrier, 0.5-3 % of dispersing auxiliary, 0.1-2 % of sustained-release agent, 0.1-5 % of binding agent and the balance of filler. In the preparation method of the sterilizing granule provided by the invention, a coating method is used for granulation. According to the invention, resources are effectively, scientifically and reasonably utilized, important significance is obtained in protecting environment, and positive promoting effects on reducing agricultural input as well as increasing agricultural production and income are obtained.

Owner:浙江澳岚丁生物科技有限公司

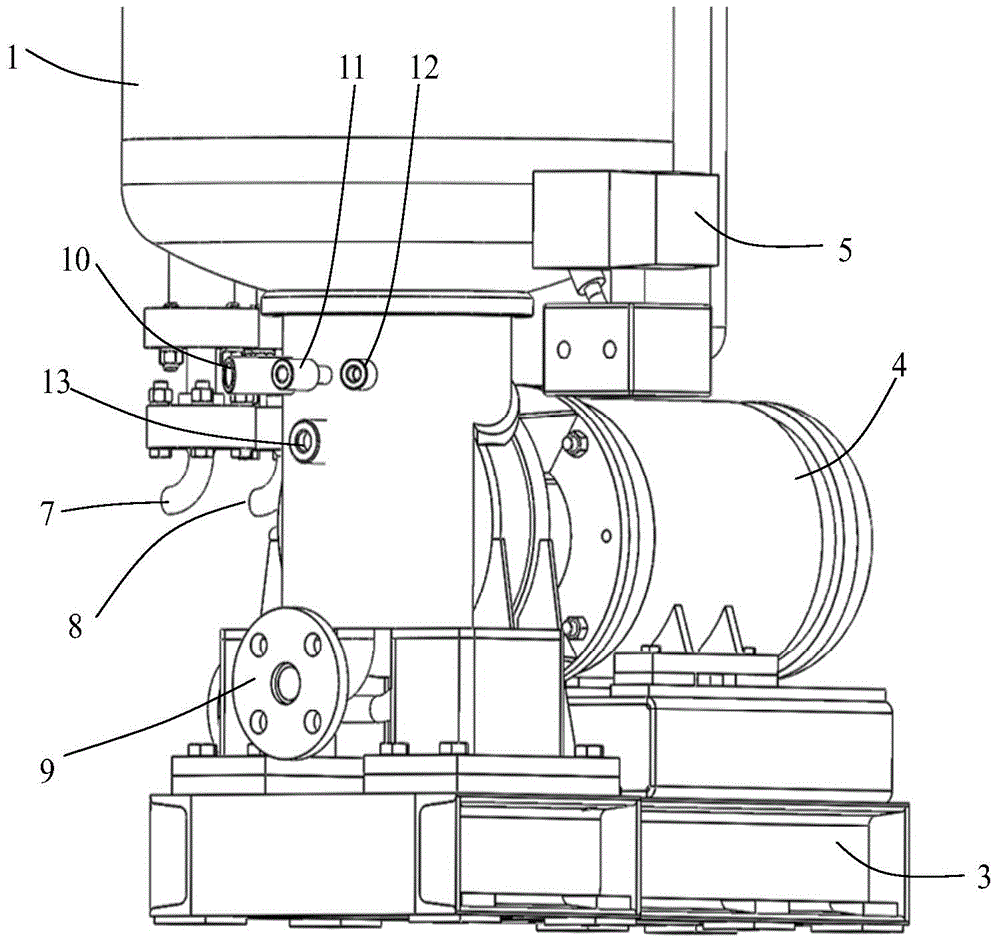

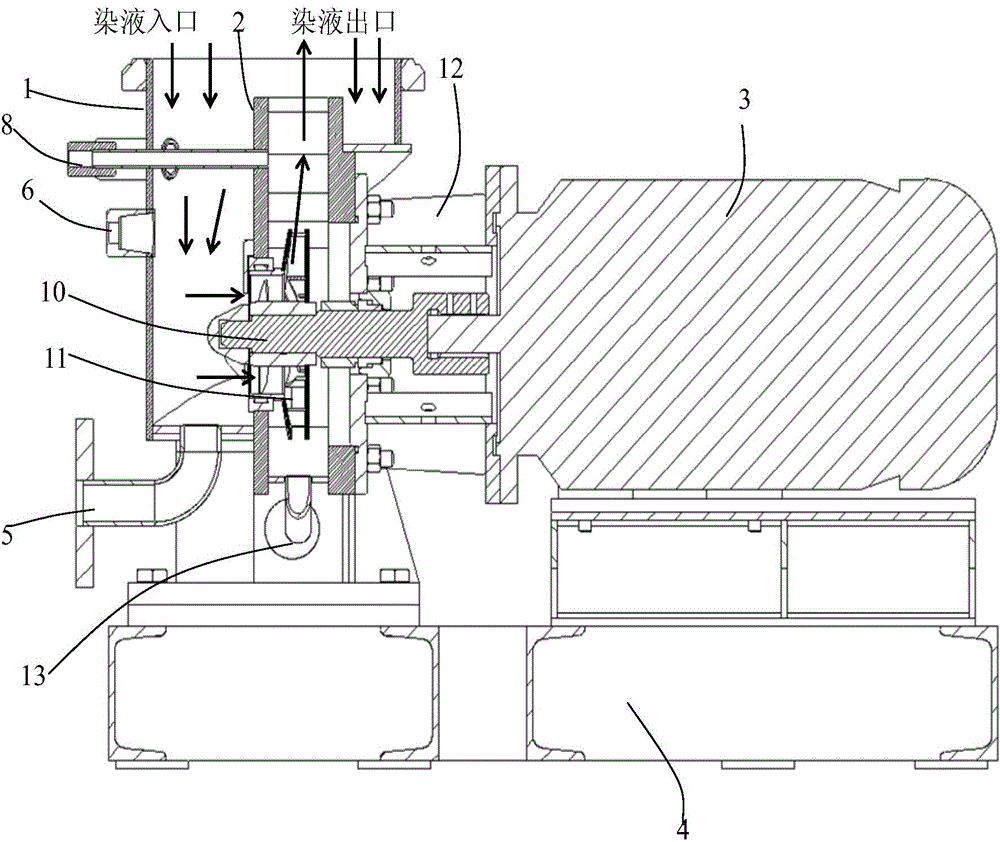

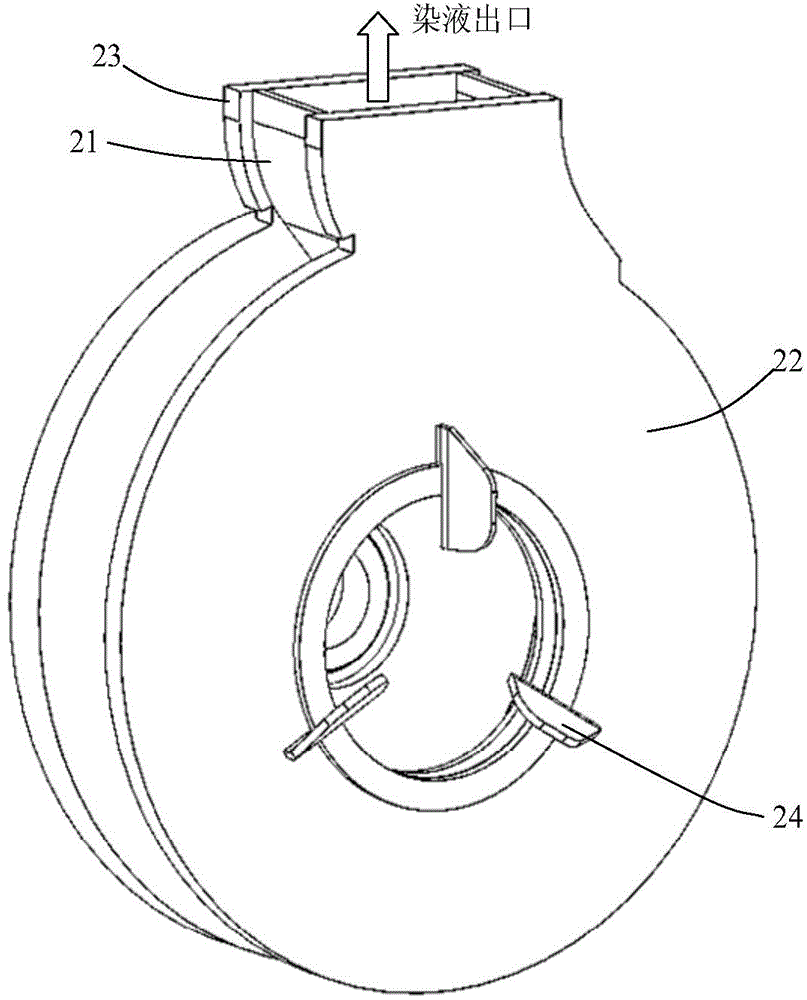

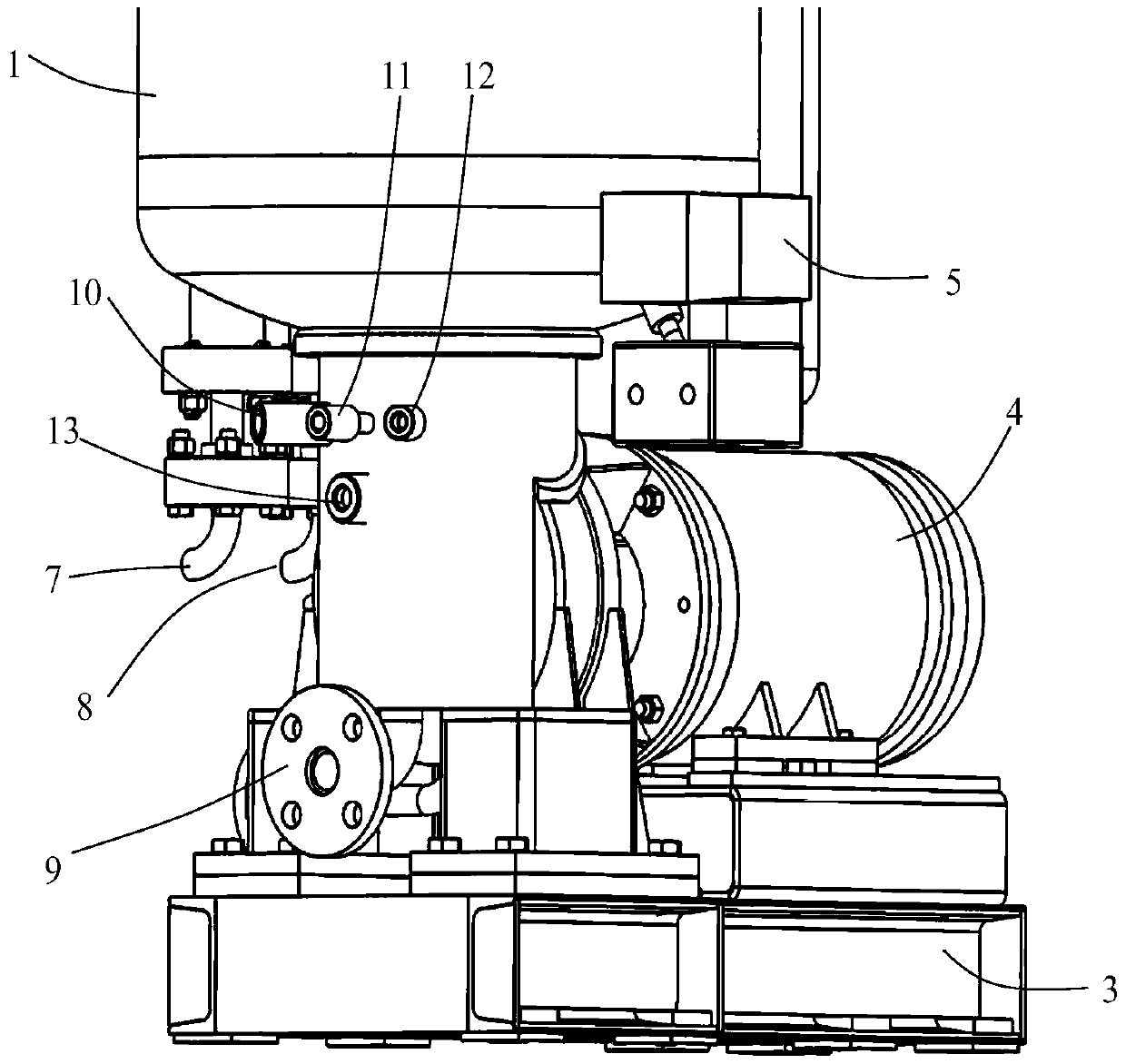

Power system of yarn dyeing machine with 1:2 extremely-low bath ratio and control method thereof

ActiveCN104818594AEmission reductionImprove energy efficiencyTextile treatment machine arrangementsYarnEngineering

The invention provides a power system of a yarn dyeing machine with a 1:2 extremely-low bath ratio and a control method thereof. The power system mainly comprises a drum, a liquid outlet flow guide module, a motor, a base a power shaft and a pump module, wherein the drum sleeves the outer portion of the liquid outlet flow guide module; and a drum inner cavity and the liquid outlet flow guide module are sealed through a sealing plate to form an independent liquid inlet flow channel. The liquid outlet flow guide module comprises a front disc, a flow guide plate and a rear disc. The two ends of the flow guide plate are connected with the front disc and the rear disc respectively to form a liquid outlet cavity which is a liquid outlet flow channel. The pump module is installed in the liquid outlet cavity of the liquid outlet flow guide module, and the flow guide plate is annular and is provided with a dye liquid outlet. A power source is provided for the pump module through the motor; and the drum, the liquid outlet flow guide module and the motor are installed on the base. The 1:2 extremely-low bath ratio of the yarn dyeing machine close to the limit can be achieved, auxiliaries and dye are obviously saved, and the waste liquid discharge is reduced. The power system is compact in structure, the flow channels are short, and the energy efficiency of the power system can be effectively improved.

Owner:高勋绿色智能装备(广州)有限公司

Soft washing dual-purpose machine

ActiveCN103306073AFinishing process optimizationGood flexibilityTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersDual purposeTherapeutic effect

The invention discloses a soft washing dual-purpose machine which comprises a cloth inlet mechanism, a soft washing mechanism and a cloth outlet mechanism, wherein the soft washing mechanism comprises a liquid adding device, a soft groove, a first cloth guide roll and an octagonal roll; the first cloth guide roll and the octagonal roll are arranged above the soft groove in parallel; a plurality of deadweight rolls which are parallel to the first cloth guide roll and can be contacted with the first cloth guide roll are arranged above the first cloth guide roll, and arranged on a support shaft in a side-by-side and vertically swingable manner at intervals; a cloth support roll parallel to the first cloth guide roll is arranged below the first cloth guide roll; and a plurality of cloth guide rings are arranged on side walls of the soft groove. The machine can achieve a softening or washing technology, is applicable to machining of knitted fabrics in different components, ingredients and specifications, has a good softening treatment effect, and improves the production efficiency greatly.

Owner:福建省鸿翔纺织科技有限公司

Fosthiazate and hymexazol granule and preparation method thereof

The invention relates to a fosthiazate and hymexazol granule. The fosthiazate and hymexazol granule comprises the following components in percentage by weight: 0.1-20% of fosthiazate, 0.1-5% of hymexazol, 60-80% of a carrier attapulgite grain, 0.5-3% of a dispersing auxiliary agent, 0.1-2% of a slow release agent, 0.1-5% of a bonding agent and residual fillers. The invention further discloses a preparation method of the fosthiazate and hymexazol granule; and the fosthiazate and hymexazol granule effectively combines the effects of preventing and treating plant nematode diseases and soil borne diseases, efficiently, scientifically and reasonably utilizes resources, has very important meanings on protecting an environment, and has the active propelling effects of reducing the agricultural input and increasing both production and income of agriculture.

Owner:GUANGDONG ZHONGXUN AGRI TECH

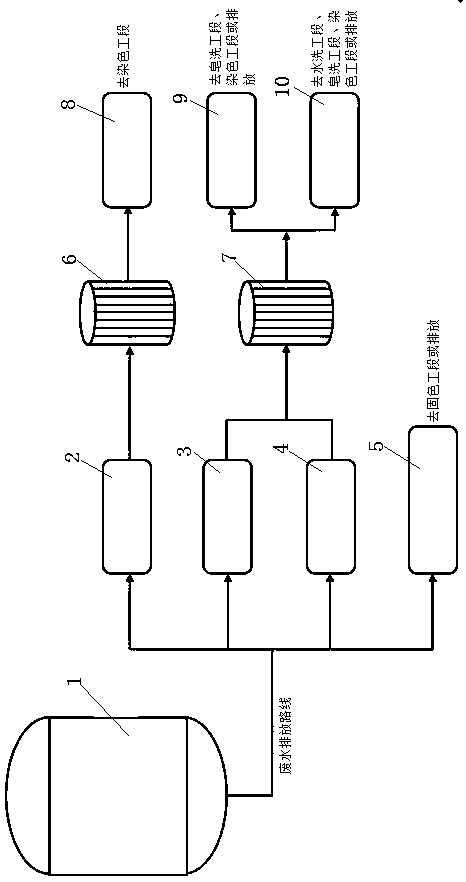

Whole-process circular dyeing method of real silk fabric and dyeing system

ActiveCN110983684AIncrease the difficulty of the processIncrease processing costTextile treatment machine arrangementsTextile/flexible product manufactureRing dyeingPulp and paper industry

The invention relates to a whole-process circular dyeing method of a real silk fabric and a dyeing system, and belongs to the technical field of printing and dyeing. The method comprises the followingsteps that (1) a reactive dye is used for dyeing, meanwhile, residual dyeing liquid is separated by a dyeing wastewater pool and a first dye separator to obtain colorless clear water, and the colorless clear water is stored in a dyeing clear water pool and is circularly used for a dyeing section; (2) wastewater in a soaping section is separated by a soaping wastewater pool and a second dye separator to obtain colorless clear water, and the colorless clear water is stored in a soaping clear water pool and is circularly used for the soaping section and the dyeing section or is discharged; and (3) wastewater in a water washing section is separated by a water washing wastewater pool and the second dye separator to obtain colorless clear water, and the colorless clear water is stored in a water washing clear water pool and is circularly used for the water washing section, the soaping section and the dyeing section or is discharged; and (4) wastewater in a color fixing section is directly circularly used for the color fixing section or is discharged after being temporarily stored in a color fixing wastewater and clear water pool.

Owner:ZHEJIANG SILK TECH

Isolation material, preparation method and applications thereof

ActiveCN111139680AHigh content of release agentEvenly distributedDefoamers additionNatural cellulose pulp/paperLatex rubberSS - Stainless steel

The invention belongs to the technical field of composite materials, particularly relates to an isolation material, a preparation method and applications thereof, and provides an isolation material, which comprises the following components in parts by mass: 60-80 parts of an isolating agent, 6-15 parts of mixed fiber, 14-20 parts of latex, 0.02-0.1 part of a flocculating agent, and 0.01-0.1 part of an antifoaming agent. According to the invention, through the combined action of all the components, the isolation material is designed into a paper-based material, and the isolating agent is uniformly distributed in the isolation material, so that the uniform distribution of the isolating agent is met, and secondary pollution caused by the isolating agent in a dust form is fundamentally avoided; the experimental results show that the content of the isolating agent in the isolation material provided by the invention can reach 80 wt.%, so that the content of the isolating agent is high; and when the isolation material is directly spread between stainless steel, the isolation material is uniformly distributed, has no skin cracking phenomenon and has a good isolation effect.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD +1

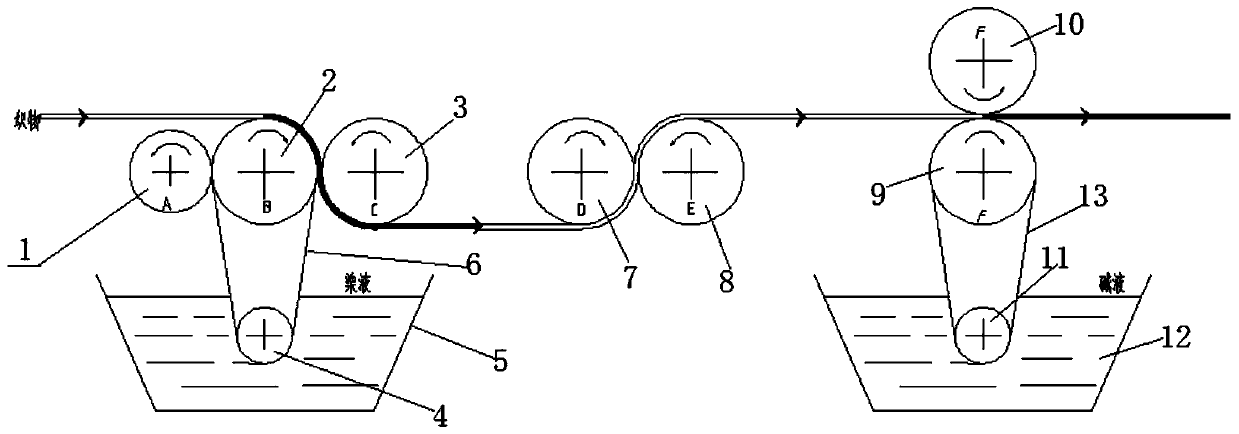

Single-sided dyeing liquid feeding equipment for reactive dyes of pure cotton heavy fabric and method

ActiveCN110130025AReduce hydrolysisFully contactedLiquid/gas/vapor removalDyeing processEngineeringWater consumption

The invention discloses single-sided dyeing liquid feeding equipment for reactive dyes of pure cotton heavy fabric. The equipment comprises a dyeing mechanism, a drying mechanism and a color fixationmechanism which are arranged sequentially, wherein the dyeing mechanism comprises a dye liquid tank as well as a rubber squeezing roll, a single-sided liquid feeding coloring roll and a rotating rubber roller which are arranged above the dye liquid tank, a dye liquid conveying roll is arranged in the dye liquid tank and connected with the single-sided liquid feeding coloring roll through a conveying belt, and two sides of the single-sided liquid feeding coloring roll are tangent with the rubber squeezing roll and the rotating rubber roll respectively. The invention also discloses a method fordyeing fabric by using the single-sided dyeing liquid feeding equipment for the reactive dyes of the pure cotton heavy fabric. By use of the device and the method, the defects that more dyes are wasted due to double-sided dyeing of the heavy cotton fabric, water consumption for printing and dyeing washing is large, and the quantity of vapor consumed during drying is large are overcome.

Owner:NANTONG UNIVERSITY +1

Five-layer-coextrusion, high-thermal-insulation, antifogging and drip-free agricultural greenhouse plastic film

ActiveCN103042782BSave additivesHeating up fastClimate change adaptationSynthetic resin layered productsBlow moldingGreenhouse

The invention discloses a five-layer-coextrusion, high-thermal-insulation, antifogging and drip-free agricultural greenhouse plastic film which comprises the following raw materials by weight percentage: agricultural polyethylene resin (including EVA (ethylene vinyl acetute) resin), a thermal insulation agent, an antifogging agent, an antidripping agent and an ageing resisting agent. According to the agricultural greenhouse film formed by five-layer coextrusion blow molding according to a layering formula, the thermal insulation property and the usage period of the film can be improved and prolonged; the raw materials are saved; antidripping and antifogging periods are prolonged; the property of the agricultural greenhouse film is improved; the yield and quality of overwintering greenhouse vegetables, fruit trees, flowers, and the like covered with the film can be increased and improved obviously; and the film has better popularization and application prospects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

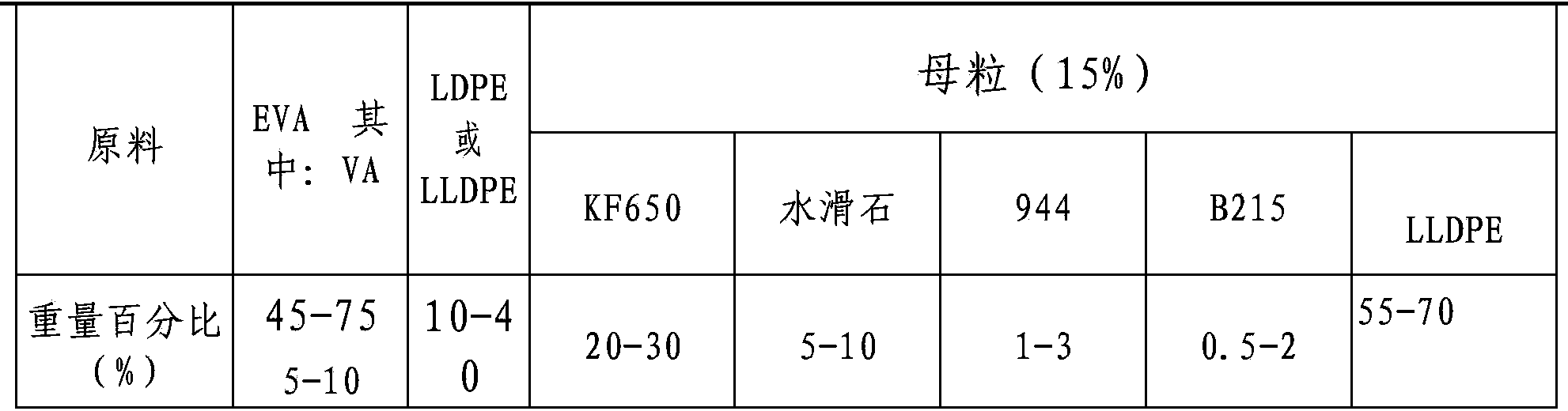

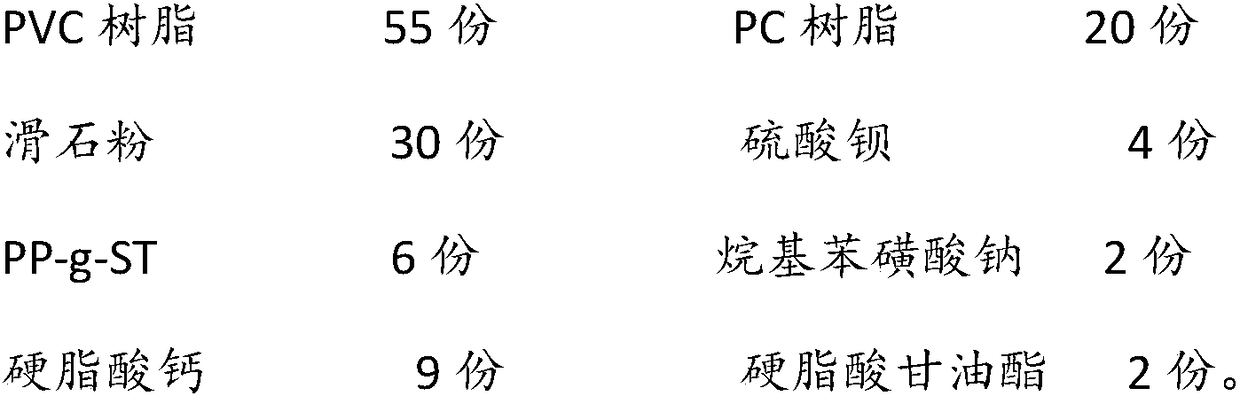

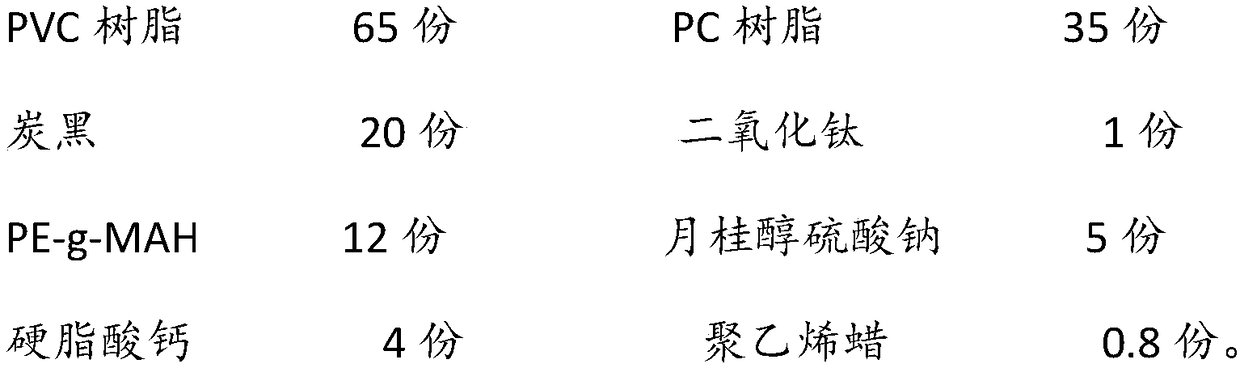

Preparation method of PVC composite material for plastic steel

The invention discloses a preparation method of a PVC composite material for plastic steel. The method comprises the following steps: sequentially adding PVC resin, PC resin, a filling agent, a coloring agent, a compatibilizer, a surfactant, a stabilizer and a lubricant into a high mixing machine, controlling the rotating speed of the high mixing machine to be 1100 to 1650 r / min and the temperature to be 120 to 135 DEG C, adjusting the rotating speed of the high mixing machine to be 700 to 1100 r / min after mixing for 5 to 8 minutes, obtaining a mixed material after mixing for 10 to 15 minutes,and discharging the mixed material; and standing the mixed material for 50 to 80 minutes, cooling to room temperature, adding the mixed material into a double-screw extruding machine, controlling thetemperature of each area of the extruding machine to be 195 to 250 DEG C and the temperature of a machine head to be 240 to 250 DEG C, setting the pressure of melt to be 4 to 9 MPa, performing melt extrusion on the mixed material, cooling and dicing to obtain the PVC composite material. The prepared PVC composite material has strong binding force, small expansion and contraction rate and high strength and can be widely applied in various fields; and the preparation method is simple, the aids are few and heavy metal is avoided.

Owner:陈丽

A 1:2 extremely low liquor ratio yarn dyeing machine

ActiveCN104818591BEmission reductionIngenious structural designTextile treatment containersTextile treatment machine arrangementsSocial benefitsYarn

The invention provides a yarn dyeing machine with a 1:2 extremely-low bath ratio. The yarn dyeing machine mainly comprises a yarn cylinder, a liquid collecting pipe, a base, a motor, a volumeter, a cylinder cover, a steam inlet, a steam outlet, liquid supply and discharging pipes, a liquid temperature meter, a high pressure meter, a low pressure meter, a hydro-acupuncture probing sleeve, a heat exchange pipe, a flow distribution disc, a round heaven and square earth pipe, a yarn bamboo pipe, a liquid collecting cavity, a mixed-flow pump, a flow guide pipe and a water baffle and the like. Due to the ingenious structural design, the 1:2 extremely-low bath ratio of the yarn dyeing machine close to the limit can be achieved, auxiliaries and dye are obviously saved, the waste liquid discharge is reduced, and the yarn dyeing machine is very obvious in economic and social benefits. The yarn dyeing machine is compact in structure, a flow channel is short, and the yarn dyeing machine has excellent energy efficiency.

Owner:高勋绿色智能装备(佛山)有限公司

Soft washing dual-purpose machine

ActiveCN103306073BFinishing process optimizationGood flexibilityTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersAdditive ingredientEngineering

The invention discloses a soft washing dual-purpose machine which comprises a cloth inlet mechanism, a soft washing mechanism and a cloth outlet mechanism, wherein the soft washing mechanism comprises a liquid adding device, a soft groove, a first cloth guide roll and an octagonal roll; the first cloth guide roll and the octagonal roll are arranged above the soft groove in parallel; a plurality of deadweight rolls which are parallel to the first cloth guide roll and can be contacted with the first cloth guide roll are arranged above the first cloth guide roll, and arranged on a support shaft in a side-by-side and vertically swingable manner at intervals; a cloth support roll parallel to the first cloth guide roll is arranged below the first cloth guide roll; and a plurality of cloth guide rings are arranged on side walls of the soft groove. The machine can achieve a softening or washing technology, is applicable to machining of knitted fabrics in different components, ingredients and specifications, has a good softening treatment effect, and improves the production efficiency greatly.

Owner:福建省鸿翔纺织科技有限公司

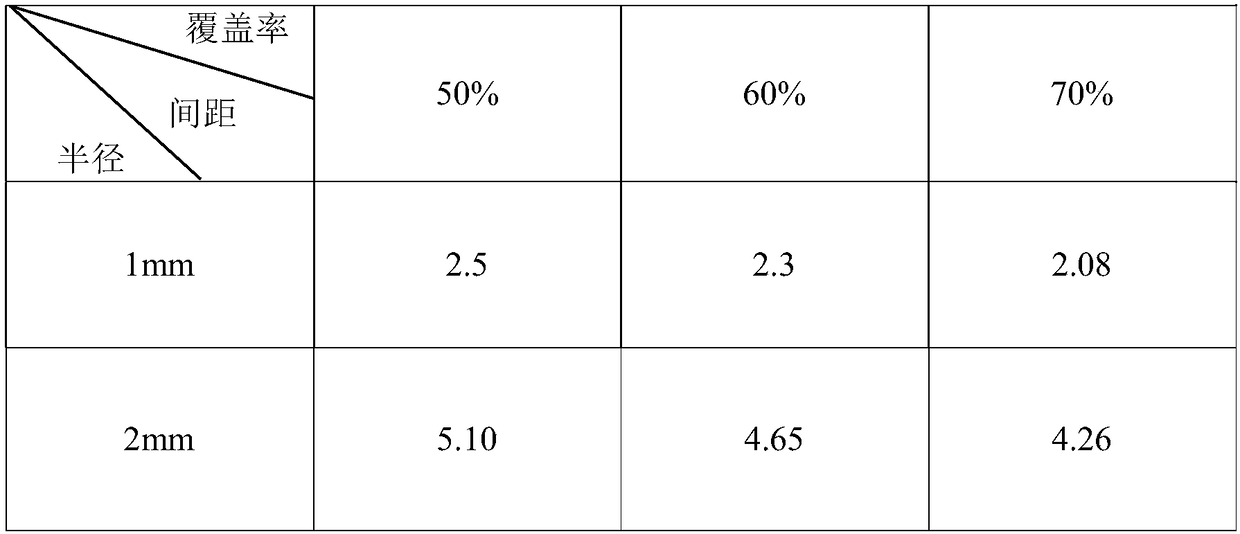

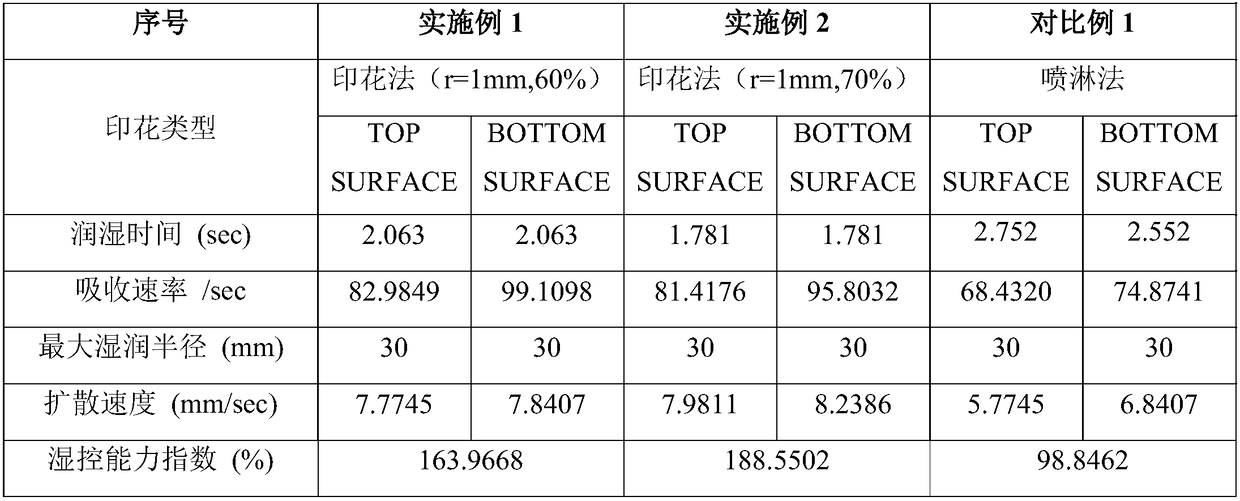

Preparation method of dampness controllable fabric

InactiveCN108611877AGood humidity control effectOvercome the shortcomings of slow surface water absorption and poor wet control effect of spray methodDyeing processScreen printingSoft water

The invention relates to a preparation method of a dampness controllable fabric, which comprises the steps of mixing and blending 50-60 mass percentage of water-proofing agent and 40-50 mass percentage of soft water to form a printing assistant, and performing screen printing on a water absorption fabric, and drying to form the dampness controllable fabric. The dampness controllable fabric is prepared by a special printing method; the assistant is saved; the method overcomes the disadvantages of low surface water absorption speed of an impregnation method and a poor dampness control effect ofa spray method; and the prepared fabric has a better dampness control effect.

Owner:SHANGHAI CHALLENGE TEXTILE

A kind of isolation material and its preparation method and application

ActiveCN111139680BSave additivesHigh content of release agentNatural cellulose pulp/paperDefoamers additionLatex rubberMechanical engineering

The invention belongs to the technical field of composite materials, and in particular relates to an isolation material and its preparation method and application. The invention provides a kind of isolation material, including components in parts by mass: 60-80 parts of isolation agent; 6-15 parts of mixed fiber; 14-20 parts of latex; 0.02-0.1 part of flocculant; ~0.1 parts. In the present invention, the isolation material is designed as a paper-based material through the joint action of each component, and the isolation agent is evenly distributed in the isolation material, which satisfies the uniform distribution of the isolation agent and fundamentally avoids the dust caused by the isolation agent in the form of dust. Secondary pollution. Experimental results show that the release agent content in the release material provided by the invention can reach 80wt.%, and the release agent content is high; when it is directly spread between stainless steels, the distribution is uniform and there is no "explosion" phenomenon, and it has a good isolation effect.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD +1

Yarn dyeing process

The invention discloses a yarn dyeing process, which is characterized in that: the yarn dyeing process is completed through a loose winding step, a warping step, a dyeing step and a post-treatment step; the advantage of the invention is that the invention saves the The oiling process is omitted in the pre-treatment process and the post-treatment process. The permeate will not be discharged after the auxiliary agent has penetrated, and the next step of coloring will be carried out directly. There is no need to add retarder or leveling agent during coloring, which helps The dye can help the dye to be directly dyed on the yarn and achieve the purpose of level dyeing; the invention greatly shortens the dyeing process time and reduces the discharge of sewage; saves the auxiliary agent used in the pretreatment process and makes the yarn The pH value of the fabric is lowered, making it more soft and durable.

Owner:JIANGSU YAOZHANG SPORTING GOODS

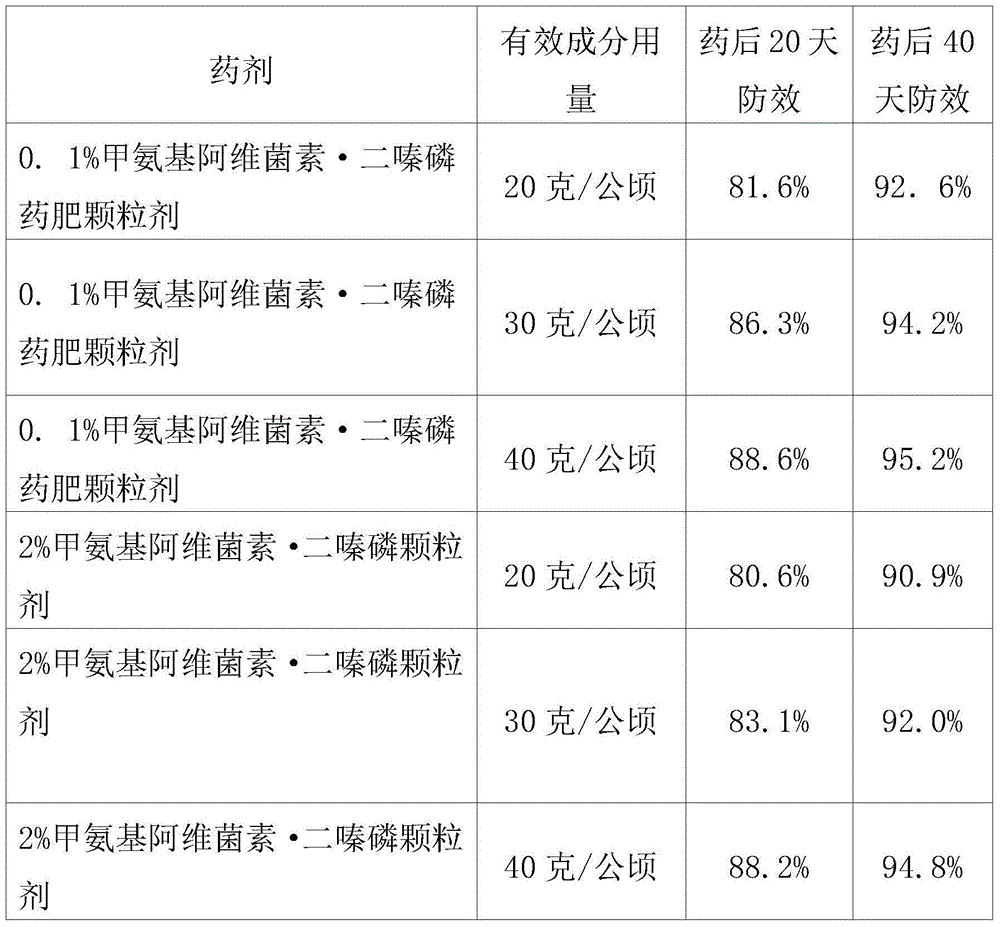

Methylaminoavermectin-diazinon particles

InactiveCN104304312AEfficient use ofScientific Utilization of Active Components Emamectin and Diazinon and CarriersBiocideNematocidesAgricultural scienceRoot-knot nematode

The invention discloses methylaminoavermectin-diazinon particles. The methylaminoavermectin-diazinon particles comprise methylaminoavermectin and diazinon as effective components and pesticide auxiliary agents, wherein a mass part ratio of methylaminoavermectin to diazinon is in a range of 1: 20 to 20: 1 and a ratio of methylaminoavermectin and diazinon in the methylaminoavermectin-diazinon particle is in a range of 0.01-20wt%. The methylaminoavermectin-diazinon particles are suitable for preventing and controlling root-knot nematode on crops such as vegetables, peanuts, watermelons and bananas. The methylaminoavermectin-diazinon particles effectively, scientifically and reasonably utilize resources, reduce pesticide-caused environmental pollution, have a low cost, are convenient for use and actively promote reduction of an agricultural investment and improvement of an agricultural product yield.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Method for improving dye uptake and fixation rate of reactive dye on kapok fiber by using rare earth

InactiveCN102561065BHigh color fastnessHigh color fixing rateDyeing processRare-earth elementKapok fiber

The invention relates to a method for improving the dye uptake and fixation rate of a reactive dye on a kapok fiber by using rare earth. The kapok fiber is pretreated by a rare earth element and a complex thereof and dyed by the reactive dye. Compared with the prior art, the method has the advantages that: the dye uptake and fixation rate of the reactive dye on the kapok fiber can be greatly improved, the effects of saving the dye and an aid, reducing the emission of dyeing wastewater and improving dyeing uniformity and brightness are achieved, and the color fastness of the kapok fiber dyed by the method is greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

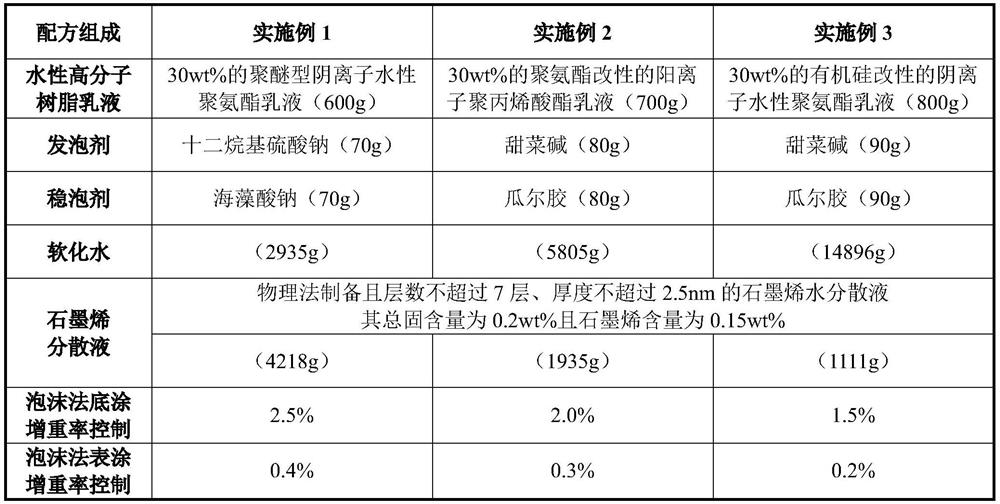

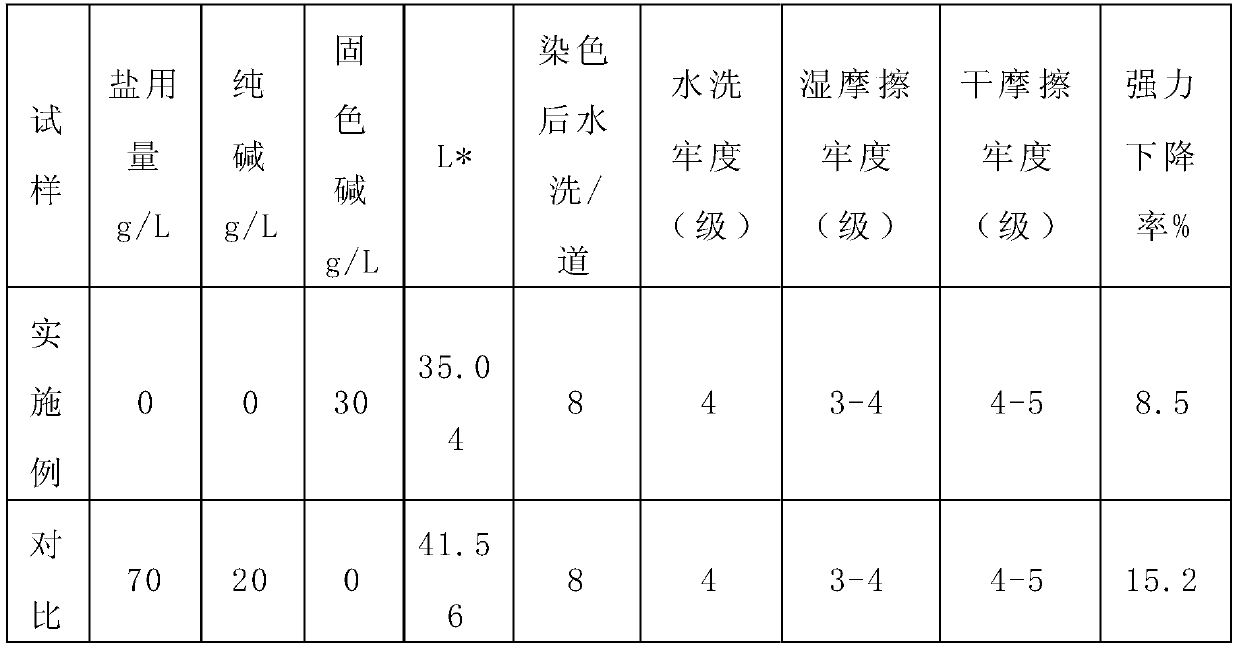

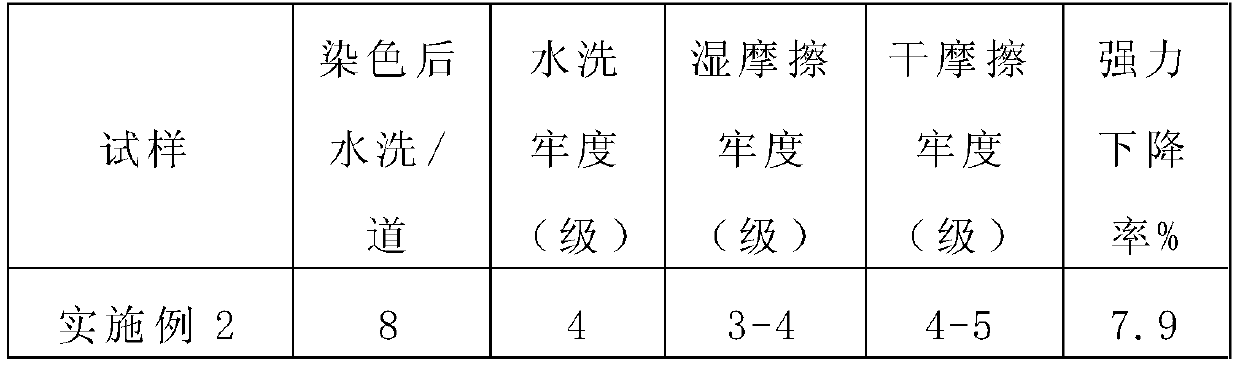

A cashmere textile foam method graphene finishing process based on water-based polymer resin

ActiveCN110485153BIncrease productivityReduce dosageBiochemical fibre treatmentGrip property fibresPolymer sciencePolymer resin

The invention relates to a cashmere textile foam method graphene finishing process based on water-based polymer resin. This finishing process can protect the natural hand style of cashmere textiles to the greatest extent, and endow it with excellent antistatic, anti-pilling, antibacterial, and warm-keeping functions without affecting the unique soft, fluffy and rebounding hand feel of cashmere products. Compared with the traditional impregnation method, the water-based polymer resin-based textile foam finishing process of the present invention requires significantly less textile auxiliaries, significantly reduces energy consumption and emissions, and has higher production efficiency and more obvious effects. By adopting the technology of the invention, the anti-pilling grade of cashmere textiles can be increased by 1.5-2.5 grades, and the static voltage half-life can be reduced by more than 85-95%. The technical method of the invention can be widely used in surface functional finishing of various textile products, is beneficial to environmental protection, and has good application effect and market prospect.

Owner:WUHAN TEXTILE UNIV +1

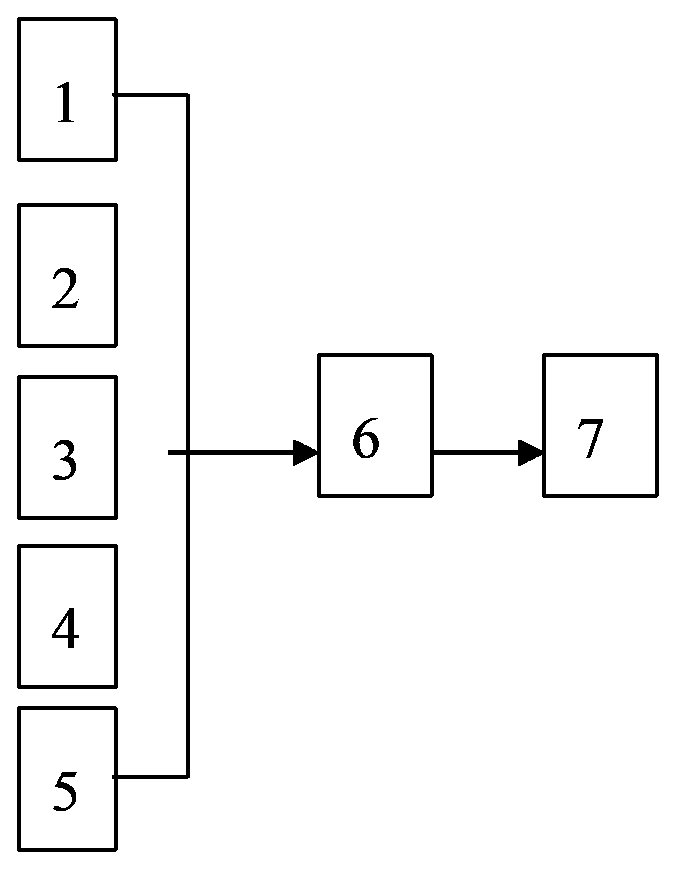

Fiber net forming continuous dyeing method

PendingCN111575940AReduce dosageIncrease profitTextile storage in superimposed formLiquid/gas/vapor removalFiberTextile printer

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a fiber net forming continuous dyeing method. By means of the method, fibers are carded and subjected to impurity removal through a fiber lapping machine to be made into reticular fibers, and then continuous dyeing is carried out. The method comprises the steps that original loose fibers are fed into the lapping machine to be made into reticular fibers, then the reticular fibers enter a dyeing device of the same speed, dye is sprayed to the reticular fibers, the reticular fibers with the dye are conveyed through a belt clamping device and are extruded through a padder, one time of spraying and multiple times of rolling are achieved to arrange dye on the fibers, coiling and stacking arecarried out, and dyed fibers are obtained after washing and drying. By means of the method, the continuous process is adopted, operation from original loose fibers to dyeing is completed at one step,loose fibers are directly made into reticular fibers, spray rolling and dyeing are carried out, the bath ratio is small, operation s simple, time and labor are saved, dyeing uniformity is good, and the dyeing effect is good; and the use level of dye is small, the dye utilization rate is high, dyeing materials and auxiliaries are saved, and energy saving and environment protection are achieved.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Self-dispersing aerogel heat-insulating film and preparation method thereof

InactiveCN114085408AGood heat insulationIncrease contentPolyurea/polyurethane coatingsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a self-dispersing aerogel heat-insulating film and a preparation method thereof. The self-dispersing aerogel heat-insulating film is composed of a base material, self-dispersing resin, aerogel powder and a defoaming agent. The preparation method comprises the following steps: mixing self-dispersing resin, aerogel powder and water, performing high-speed dispersion to obtain self-dispersing aerogel slurry, and then forming a film on a PET (Polyethylene Terephthalate) base material by using the aerogel slurry through a coating process to form the aerogel heat-insulating film. The self-dispersing resin is a dispersing agent and a binder, so that the content of aerogel is increased while the dosage of the dispersing agent is reduced, and the heat insulation performance of the aerogel heat insulation film is improved.

Owner:苏州热象纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com