Thiazole phosphine and metalaxyl granule and preparation method thereof

A technology of metalaxyl and granules, applied in the field of pesticide granules and their preparation, can solve the problems such as the related reports on the preparation methods and applications of thiazophosphine and metalaxyl granules and the like that have not been found, and achieve the advantages of absorption, utilization, distribution and the like. The effect of uniformity and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 : Based on the total weight of the granules, active ingredients thiazophosphine 10%, metalaxyl 0.3%, dispersing aid corn starch 0.5%, slow-release agent polyvinyl alcohol 0.1%, binder polyethylene glycol 0.1%, carrier A mixture of 70-80% attapulgite particles and the rest filler calcium bicarbonate and white kaolin.

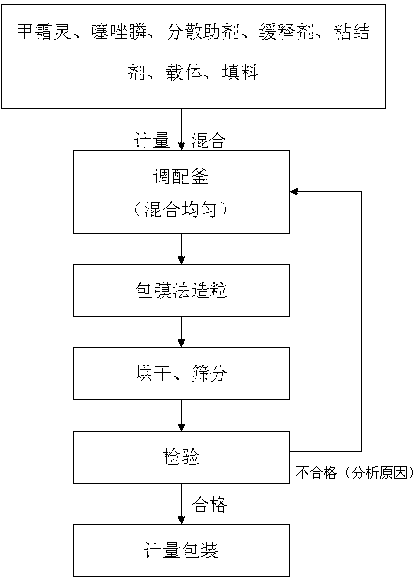

[0032] See figure 1 As shown, according to the granule preparation method of the present invention, thiazophosphine, metalaxyl, dispersing aid, and slow-release agent are metered and mixed evenly, and the attapulgite particles are used for adsorption to obtain a carrier material. Qualified analysis causes formulating a plan to re-adsorb, and after passing the test, it is ready for use; after mixing the filler, dispersing aid, and binder evenly, the coated material is prepared for use, and finally the carrier material and the coated material are granulated by the coating method. Dry at 110°C to 120°C until the water content of the granules is ...

Embodiment 2

[0033] Example 2 : Based on the total weight of the granules, active ingredients thiazophosphine 8%, metalaxyl 0.2%, dispersing aid corn starch 0.5%, slow-release agent polyvinyl alcohol 0.1%, binder polyethylene glycol 0.1%, carrier A mixture of 70-80% attapulgite particles and the rest filler calcium bicarbonate and white kaolin.

[0034] See figure 1 As shown, according to the granule preparation method of the present invention, thiazophosphine, metalaxyl, dispersing aid, and slow-release agent are metered and mixed evenly, and the attapulgite particles are used for adsorption to obtain a carrier material. Qualified analysis causes formulating a plan to re-adsorb, and after passing the test, it is ready for use; after mixing the filler, dispersing aid, and binder evenly, the coated material is prepared for use, and finally the carrier material and the coated material are granulated by the coating method. Dry at 110°C to 120°C until the water content of the granules is l...

Embodiment 3

[0035] Example 3 : Based on the total weight of the granules, active ingredients thiazophosphine 15%, metalaxyl 0.6%, dispersing aid corn starch 0.5%, slow-release agent polyvinyl alcohol 0.1%, binder polyethylene glycol 0.1%, carrier A mixture of 70-80% attapulgite particles and the rest filler calcium bicarbonate and white kaolin.

[0036] See figure 1 As shown, according to the preparation method of granules of the present invention, thiazophosphine, metalaxyl, dispersing aid, and slow-release agent are metered and mixed evenly, and the attapulgite particles are used for adsorption to obtain a carrier material. Qualified analysis causes formulating a plan for re-adsorption, and after passing the test, it is ready for use; after mixing the filler, dispersing aid, and binder evenly, the coated material is prepared for use, and finally the carrier material and the coated material are granulated by the coating method. Dry at 110°C to 120°C until the water content of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com