Process for producing biogas by dry fermentation of crop straws

A technology for crop straw and dry fermentation, which is applied in gas production bioreactors, fermentation, waste fuels, etc., and can solve problems such as no successful precedents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation process of the present invention will be further described below in conjunction with the accompanying drawings.

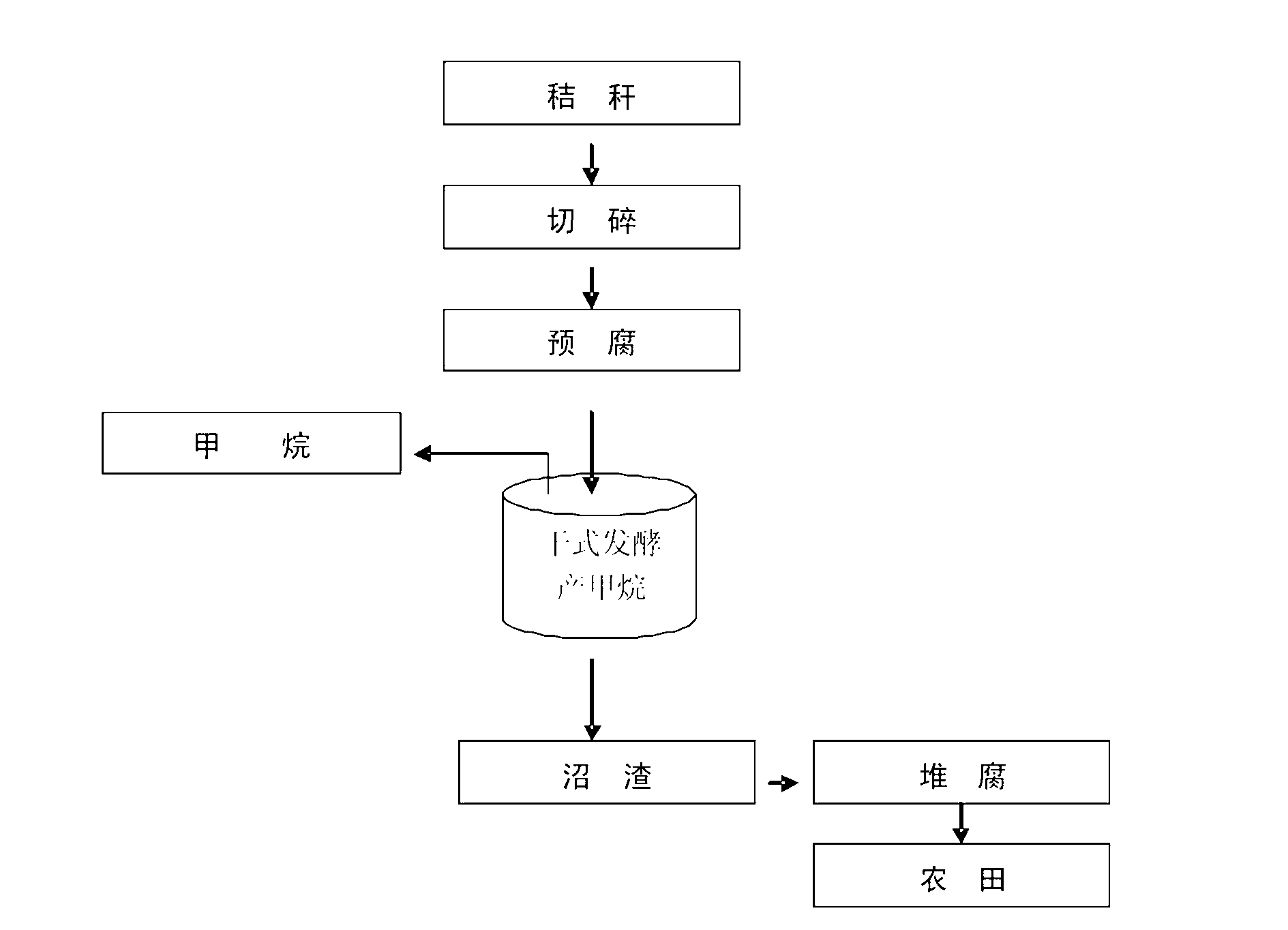

[0028] see figure 1 , select crop stalks, and make proportions according to different crops and different water contents, for example: fresh corn stalks: dry wheat straws = 3:1 (weight ratio), and can choose corresponding crop stalks as raw materials according to different seasons. Choose a certain ratio according to the humidity and chop, then pre-rot and store it in a dry reactor for dry fermentation, and the generated biogas is exported for use. After a certain period of time, the fully reacted substrates are automatically slag-extracted and piled up to be used as organic fertilizers for crops.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com