Preparation method of PVC composite material for plastic steel

The technology of composite material and PVC resin is applied in the field of preparation of plastic-steel-PVC composite material, which can solve the problems of different interfacial surface tension, small deformation rate of metal, and many additives, and achieves simple preparation method, small change in expansion ratio, and bonding force. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

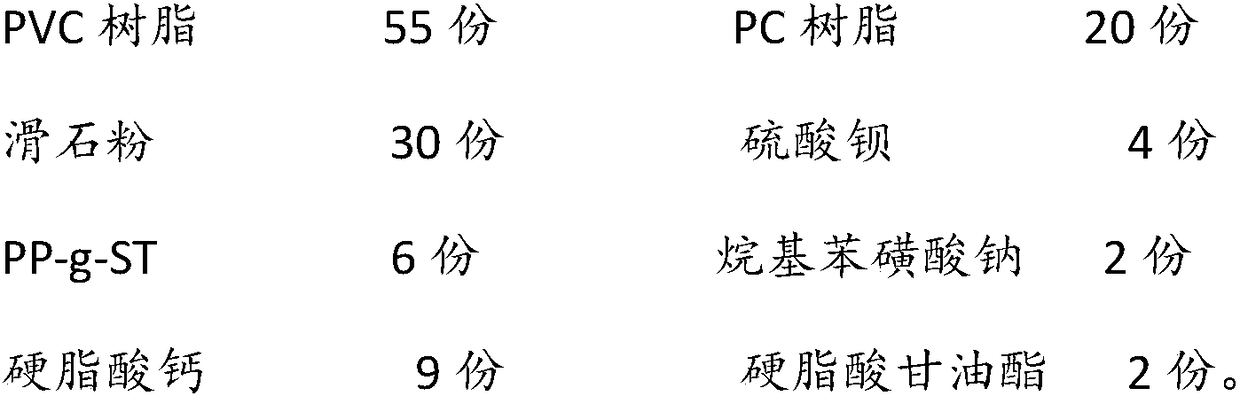

[0026] For plastic-steel PVC composite materials, the raw material components are as follows in parts by mass:

[0027]

[0028] Its preparation method is:

[0029] Add PVC resin, PC resin, talcum powder, barium sulfate, PP‐g‐ST, sodium alkylbenzenesulfonate, calcium stearate and glyceryl stearate to the high mixer in sequence, and control the speed of the high mixer to 1100r / min, the temperature is 135°C, after mixing for 8 minutes, the speed of the high mixer is adjusted to 700r / min, after mixing for 10 minutes, the mixed material is obtained, and the mixed material is discharged;

[0030] Let the mixture stand for 80 minutes, cool to room temperature, add the mixture to the twin-screw extruder, control the temperature of each zone of the extruder as follows: zone 1: 195°C, zone 2: 208°C, zone 3: 215°C, Zone 4: 225°C, Zone 5: 230°C, Zone 6: 230°C, Zone 7: 240°C, Zone 8: 240°C, Zone 9: 250°C, head temperature is 250°C, and melt pressure is set to 4MPa , the mixed materi...

Embodiment 2

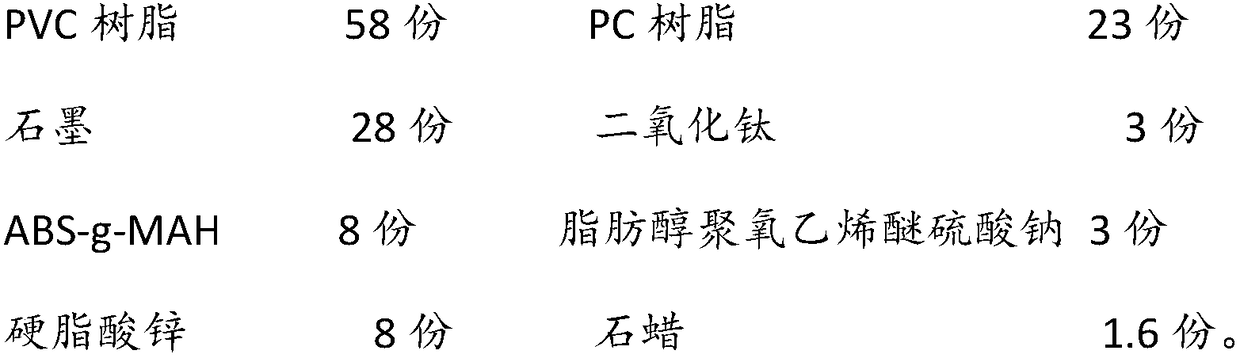

[0033] For plastic-steel PVC composite materials, the raw material components are as follows in parts by mass:

[0034]

[0035] Its preparation method is:

[0036] Add PVC resin, PC resin, graphite, titanium dioxide, ABS‐g‐MAH, sodium fatty alcohol polyoxyethylene ether sulfate, zinc stearate and paraffin to the high mixer in sequence, control the speed of the high mixer to 1200r / min, and the temperature is 131°C, after mixing for 7 minutes, adjust the speed of the high-speed mixer to 800r / min, and after mixing for 14 minutes, the mixture is obtained and the mixture is discharged;

[0037] Let the mixture stand for 75 minutes, cool to room temperature, add the mixture to the twin-screw extruder, and control the temperature of each zone of the extruder as follows: Zone 1: 196°C, Zone 2: 213°C, Zone 3: 216°C, Zone 4: 224°C, Zone 5: 226°C, Zone 6: 234°C, Zone 7: 236°C, Zone 8: 242°C, Zone 9: 249°C, head temperature is 245°C, and melt pressure is set to 5MPa , the mixed mate...

Embodiment 3

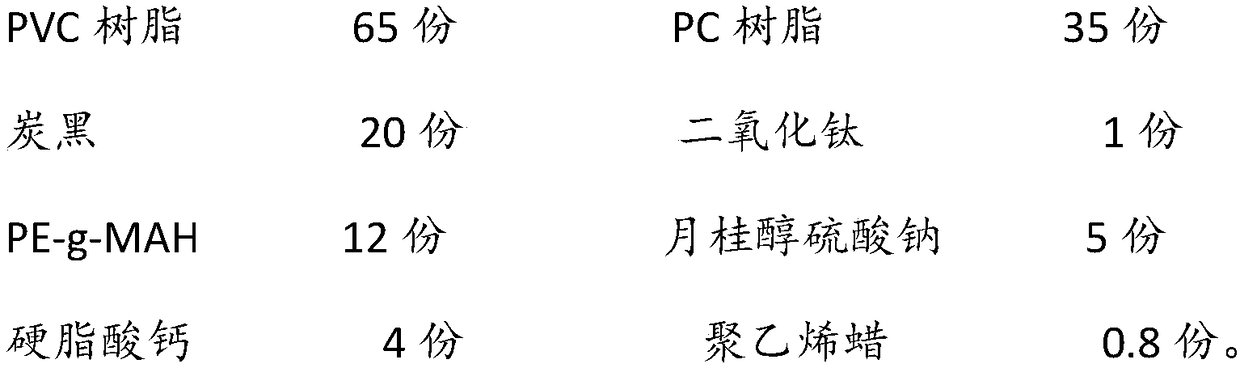

[0040] For plastic-steel PVC composite materials, the raw material components are as follows in parts by mass:

[0041]

[0042] Its preparation method is:

[0043] Add PVC resin, PC resin, carbon black, titanium dioxide, PE‐g‐MAH, sodium lauryl sulfate, calcium stearate and polyethylene wax to the high mixer in sequence, control the speed of the high mixer to 1650r / min, and the temperature to 120 ℃, after mixing for 5 minutes, adjust the speed of the high-speed mixer to 1100r / min, and after mixing for 15 minutes, the mixed material is obtained and the mixed material is discharged;

[0044] Let the mixture stand for 50 minutes, cool to room temperature, add the mixture to the twin-screw extruder, and control the temperature of each zone of the extruder as follows: Zone 1: 208°C, Zone 2: 208°C, Zone 3: 220°C, Zone 4: 220°C, Zone 5: 225°C, Zone 6: 235°C, Zone 7: 235°C, Zone 8: 250°C, Zone 9: 245°C, head temperature is 240°C, and melt pressure is set to 9MPa , the mixed mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com