Preparation method of dampness controllable fabric

A fabric and wet control technology, which is applied in the field of wet control fabric preparation, can solve the problems of slow surface water absorption speed of dipping method and poor wet control effect of spray method, so as to overcome slow surface water absorption speed and good wet control effect , the effect of saving additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

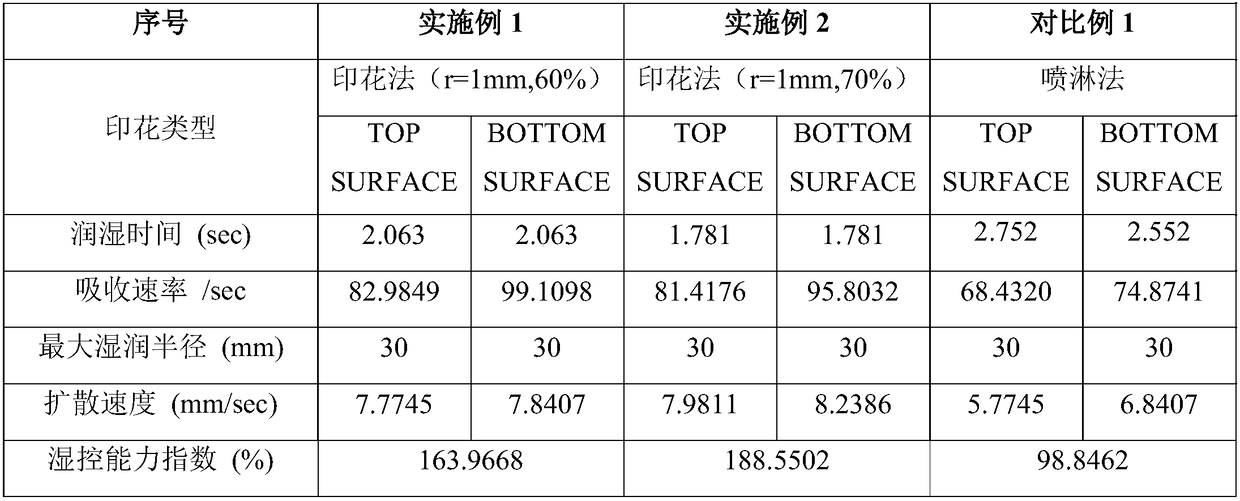

Embodiment 1

[0026] (1) Fabric: 30g spunlace cotton non-woven fabric;

[0027] (2) Allocate printing auxiliary agent: waterproofing agent 50wt%; Soft water 50wt%;

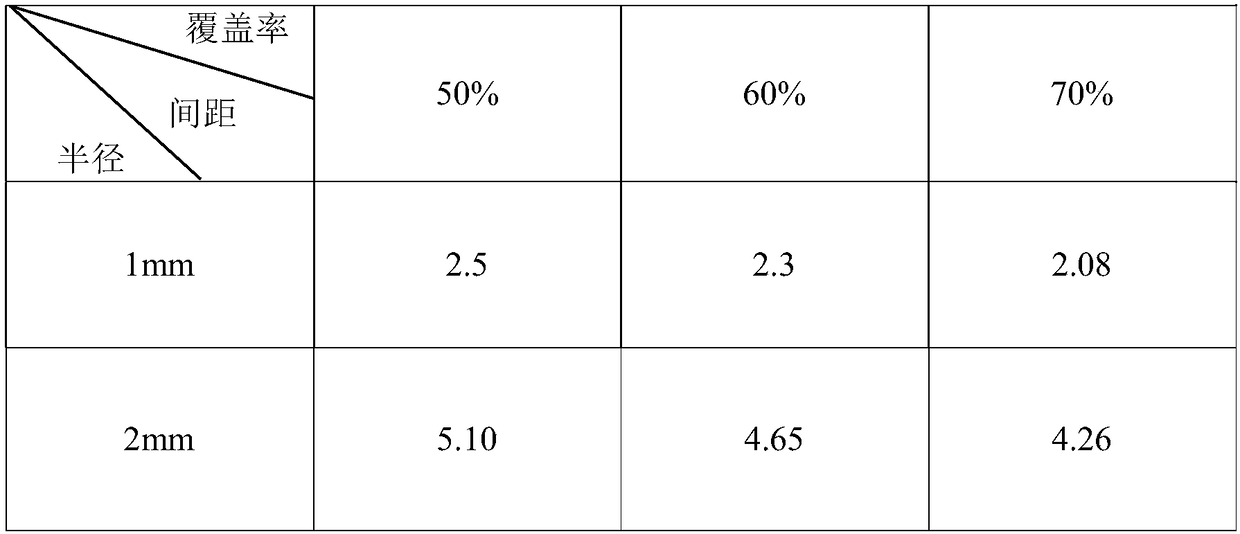

[0028] (3) Screen printing plate making: the printing coverage rate is 60%, and the printing pattern is a circle with a radius of 1mm;

[0029] (4) Screen printing: In order to ensure the content of waterproofing agent, the number of printings is 2 times;

[0030] (5) Drying: Dry at 140°C for 30s.

[0031] Finally, a moisture-controlling fabric is obtained.

Embodiment 2

[0033] (1) Fabric: 30g spunlace cotton non-woven fabric;

[0034] (2) Allocate printing auxiliary agent: waterproofing agent 50wt%; Soft water 50wt%;

[0035] (3) Screen printing plate making: the printing coverage rate is 70%, and the printing pattern is a circle with a radius of 1mm;

[0036] (4) Screen printing: In order to ensure the content of waterproofing agent, the number of printings is 2 times;

[0037] (5) Drying: Dry at 140°C for 30s.

[0038] Finally, a moisture-controlling fabric is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com