A kind of humidity control microcapsule and its preparation method and its application in interior wall humidity control paint

A technology of microcapsules and humidity control, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., which can solve the problems of poor scrub resistance, water resistance and low moisture absorption of the coating film, and achieve good buffering effect and good humidity control effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

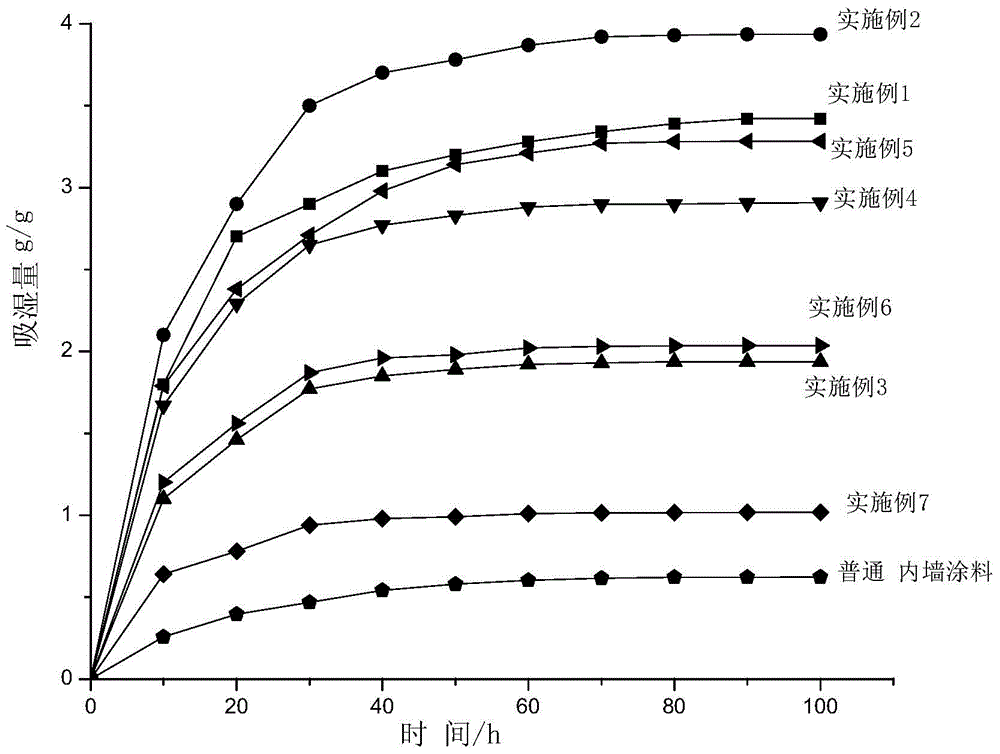

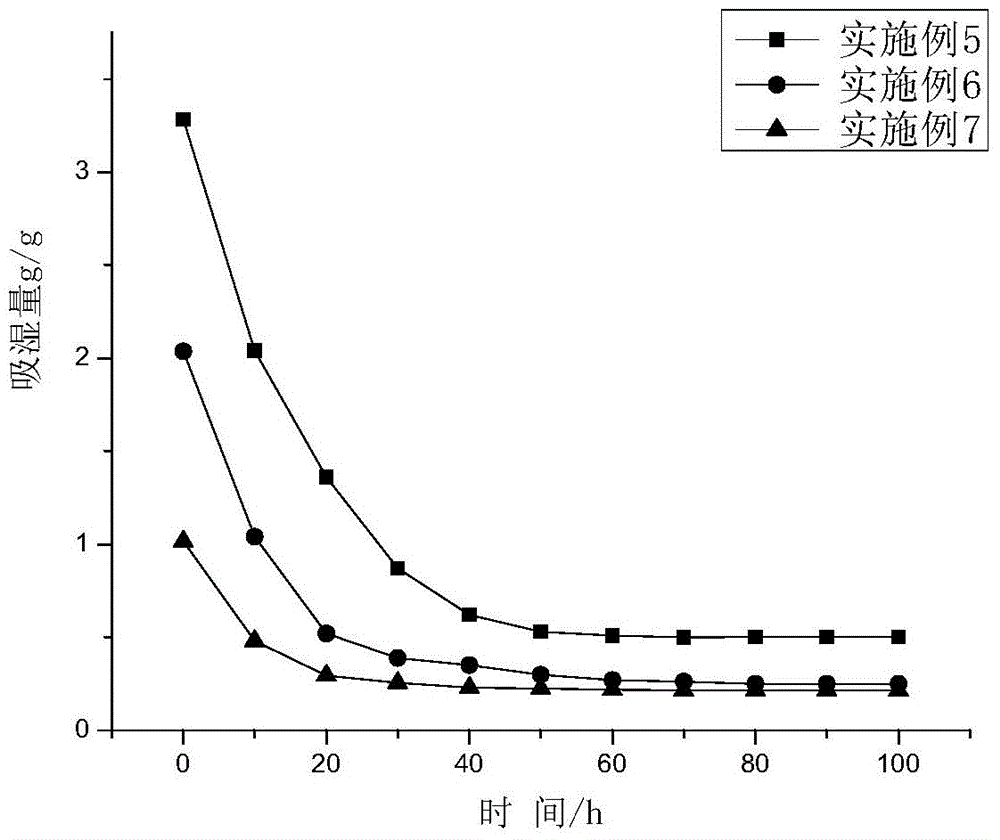

Examples

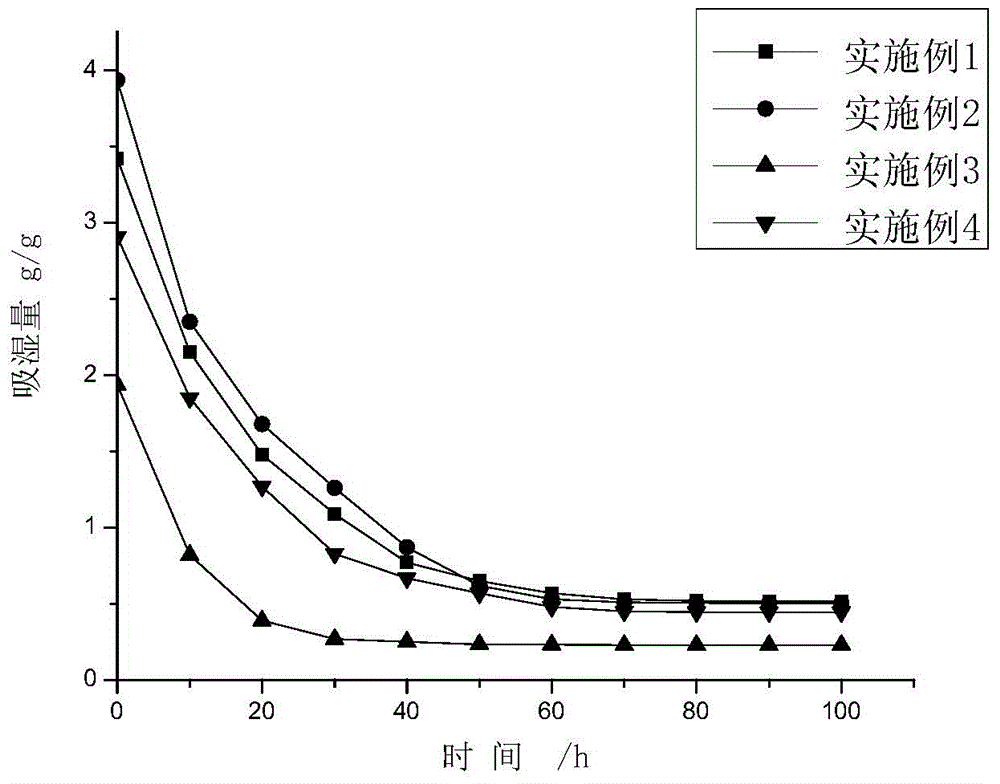

Embodiment 1

[0036] 1. Preparation of humidity-adjusting microcapsules

[0037] Get 5 mass parts of acrylic acid, under ice bath conditions, add 6 mass parts of NaOH solution to adjust the neutralization degree to 40% and then return to room temperature; add 5 mass parts of acrylamide and 5 mass parts of the neutralized acrylic acid solution Hydroxymethylcellulose, 0.05 parts by mass of potassium persulfate, and 0.01 parts by mass of N,N-dimethylbisacrylamide were uniformly mixed and used as the water phase.

[0038] 0.22 parts by mass of polyoxyethylene sorbitan monostearate and 0.53 parts by mass of sorbitan monostearate were added to 50 parts by mass of toluene, and mixed uniformly as an oil phase. After mixing the water phase and the oil phase, pre-emulsify at 500rmp for 30min, reduce the rotation speed to 250rmp, and react at 65°C for 4 hours to obtain the core material emulsion.

[0039]Get 0.05 parts by mass of potassium persulfate and dissolve it in 10 parts by mass of deionized w...

Embodiment 2

[0045] Preparation of humidity-adjusting microcapsules

[0046] Take 5 parts by mass of acrylic acid, under ice bath conditions, add 6 parts by mass of NaOH solution to adjust the degree of neutralization to 40%, and then return to room temperature; add 10 parts by mass of acrylamide and 8 parts by mass of acrylic acid to the neutralized acrylic acid solution Hydroxymethylcellulose, 0.075 parts by mass of potassium persulfate, and 0.01 parts by mass of N,N-dimethylbisacrylamide were uniformly mixed and used as the water phase. 0.15 parts by mass of polyoxyethylene sorbitan monostearate and 0.60 parts by mass of sorbitan monooleate were added to 50 parts by mass of toluene, and mixed uniformly as an oil phase. After mixing the water phase and the oil phase, pre-emulsify at 1000rmp for 20min, reduce the rotation speed to 200rmp, and react at 75°C for 2 hours to obtain the core material emulsion.

[0047] Dissolve 0.025 parts by mass of potassium persulfate in 10 parts by mass o...

Embodiment 3

[0053] Preparation of humidity-adjusting microcapsules

[0054] Take 10 mass parts of acrylic acid, under ice bath conditions, add 14 mass parts of NaOH solution to adjust the degree of neutralization to 50% and return to room temperature; add 10 mass parts of acrylamide and 5 mass parts of the neutralized acrylic acid solution Hydroxymethylcellulose, 0.1 parts by mass of potassium persulfate, and 0.013 parts by mass of N,N-dimethylbisacrylamide were uniformly mixed and used as the water phase. 0.60 parts by mass of polyoxyethylene sorbitan monooleate and 1.4 parts by mass of sorbitan monooleate were added to 60 parts by mass of toluene, and mixed uniformly as an oil phase. After the water phase and the oil phase were mixed, they were pre-emulsified at 1500rmp for 15min, the rotation speed was reduced to 200rmp, and they were reacted at 70°C for 3 hours to obtain the core layer emulsion.

[0055] Get 0.05 parts by mass of potassium persulfate and dissolve it in 30 parts by ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com