A kind of anti-ultraviolet exterior wall paint and preparation method thereof

A technology for exterior wall coatings and UV protection, applied in coatings and other directions, can solve the problem of unsolved compatibility between nano-titanium dioxide and polymers, and achieve environmental protection and construction safety, excellent stability, and enhanced hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In terms of parts by mass, the formula of the anti-ultraviolet exterior wall paint consists of:

[0056] Styrene Acrylic Lotion 25

[0057] Nano titanium dioxide / acrylate polymer composite emulsion 5

[0058] Titanium dioxide 5

[0059] Heavy Calcium Powder 20

[0060] Ethylene glycol 1.5

[0061] PE100 0.2

[0062] Ethylene glycol 1.8

[0063] Sodium Lauryl Sulfate 0.6

[0064] Butanol 0.4

[0065] Dibutyl phthalate 0.1

[0066] BIT 0.2

[0067] AMP-95 0.1

[0068] Ammonia 0.1

[0069] Deionized water 40

[0070] Prepare UV-resistant exterior paints as follows:

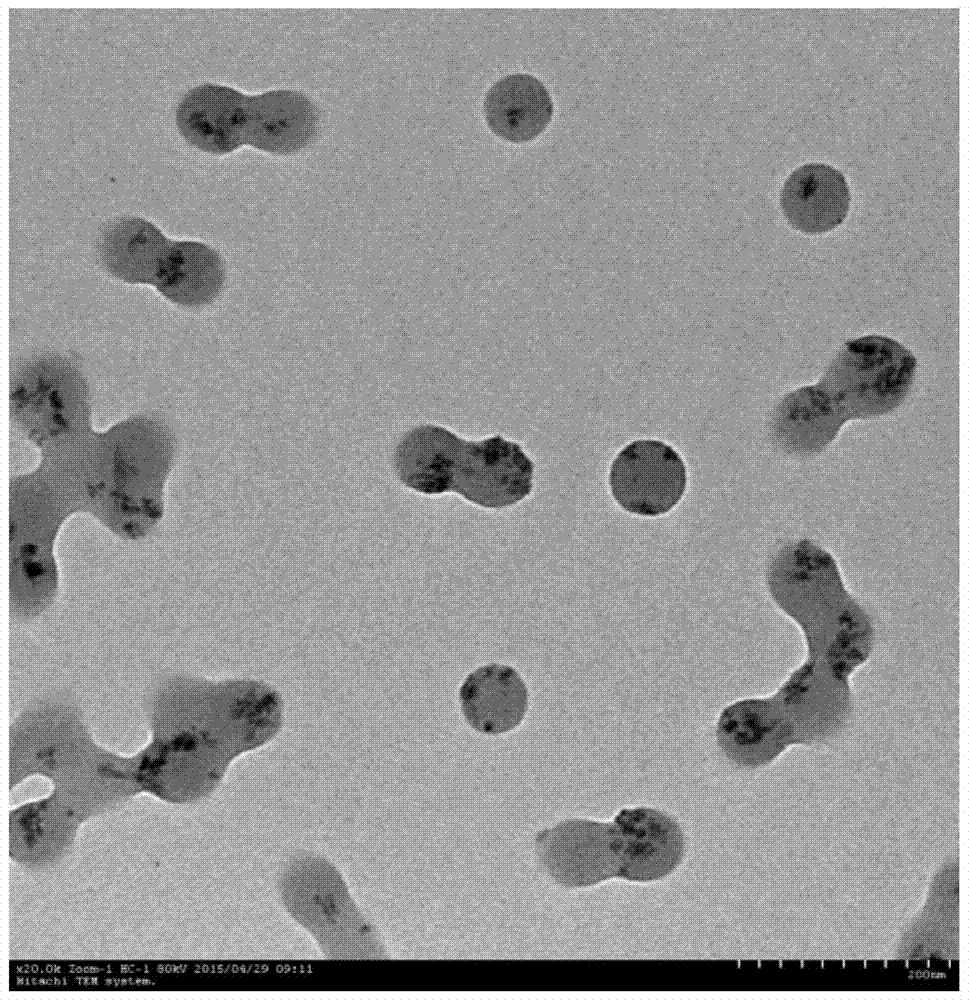

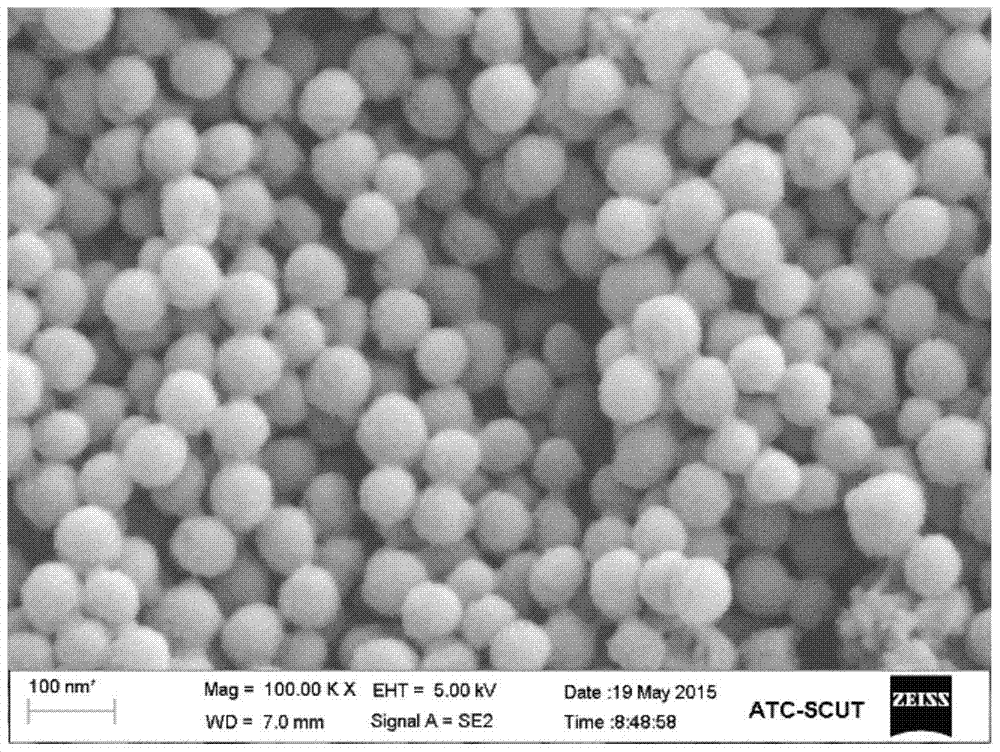

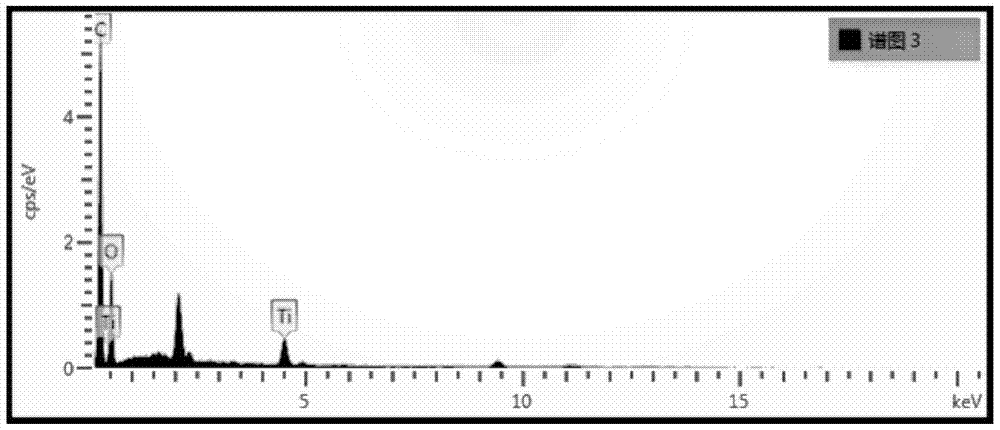

[0071] (1) Preparation of Nano Titanium Dioxide / Acrylic Ester Polymer Composite Emulsion

[0072] 1) Preparation of modified nano titanium dioxide

[0073] In terms of parts by mass, mix 5 parts of nano-titanium dioxide with 200 parts of ethanol, 800W ultrasonic dispersion for 35 minutes, add 5 parts of vinyltriethoxysilane, react at 80°C for 6 hours, centrifuge, wash with absolute ethanol, centr...

Embodiment 2

[0082] In terms of parts by mass, the formula of the anti-ultraviolet exterior wall paint consists of:

[0083] Pure acrylic emulsion 30

[0084] Nano titanium dioxide / acrylate polymer composite emulsion 7

[0085] Titanium dioxide 6

[0086] Mica powder 17

[0087] Ethylene glycol 1.5

[0088] Ethanol 0.2

[0089] Propylene glycol 1.7

[0090] Polyoxyethylene alkylphenyl ether 0.5

[0091] 1,2-Propanediol 0.3

[0092] Hydroxymethylcellulose 0.3

[0093] BIT / MIT0.3

[0094] AMP-95 0.1

[0095] Ammonia 0.1

[0096] Deionized water 35

[0097] Prepare UV-resistant exterior paints as follows:

[0098] (1) Preparation of Nano Titanium Dioxide / Acrylic Ester Polymer Composite Emulsion

[0099] 1) Preparation of modified nano titanium dioxide

[0100] In terms of parts by mass, mix 3.2 parts of nano-titanium dioxide with 150 parts of isopropanol, disperse with 400W ultrasonic for 20 minutes, add 1.2 parts of vinyltrimethoxysilane, react at 70°C for 3.5h, centrifuge, was...

Embodiment 3

[0109] In terms of parts by mass, the formula of the anti-ultraviolet exterior wall paint consists of:

[0110] Ethylene Propylene Emulsion 33

[0111] Nano titanium dioxide / acrylate polymer composite emulsion 9

[0112] Titanium dioxide 7

[0113] Kaolin 14

[0114] Ethylene glycol 1.5

[0115] Propylene glycol 0.2

[0116] Hexylene glycol 1.8

[0117] 2-Amino-2-methyl-1-propanol 0.5

[0118] Octanol 0.3

[0119] Hydroxyethylcellulose 0.2

[0120] BIT 0.3

[0121] Ammonia 0.1

[0122] AMP-95 0.1

[0123] Deionized water 32

[0124] Prepare UV-resistant exterior paints as follows:

[0125] (1) Preparation of Nano Titanium Dioxide / Acrylic Ester Polymer Composite Emulsion

[0126] 1) Preparation of modified nano titanium dioxide

[0127]In terms of parts by mass, mix 2.25 parts of nano-titanium dioxide with 110 parts of methanol, 600W ultrasonic dispersion for 10 minutes, add 2.25 parts of γ-methacryloxypropyltrimethoxysilane, react at 60°C for 3.5h, centrifuge, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com