Polyamide fibers, fiber structure using same, and clothing

A polyamide fiber and polyamide technology, applied in the direction of single-component polyamide rayon, fiber type, fiber treatment, etc., can solve the problems of insufficient improvement and decline of hygroscopicity/water absorption, and achieve excellent The effect of humidity control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (Preparation of Polyamide Fiber)

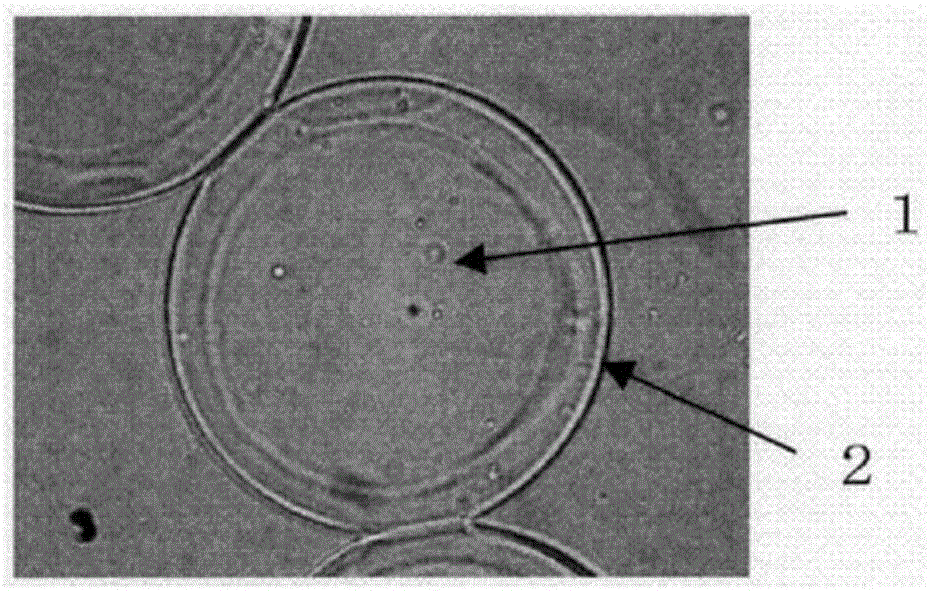

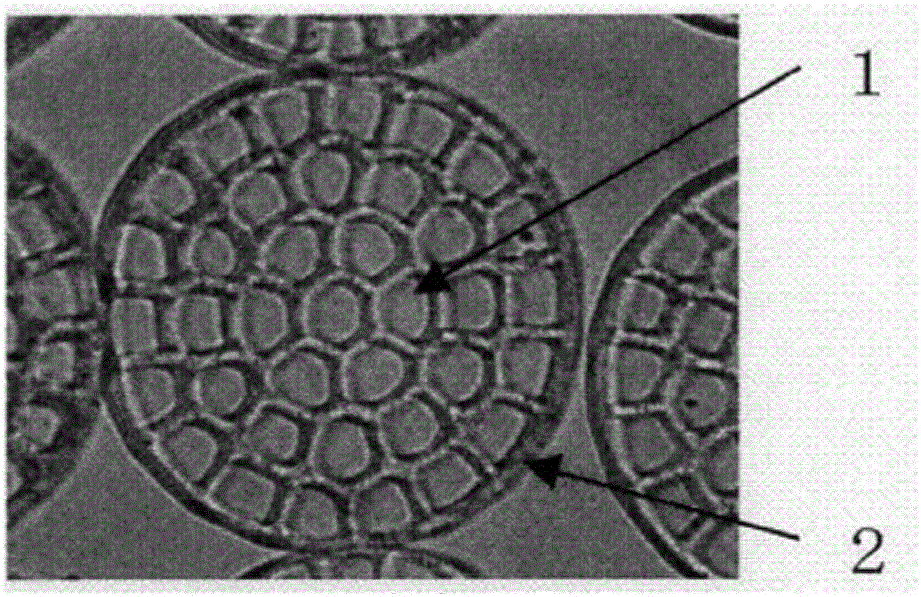

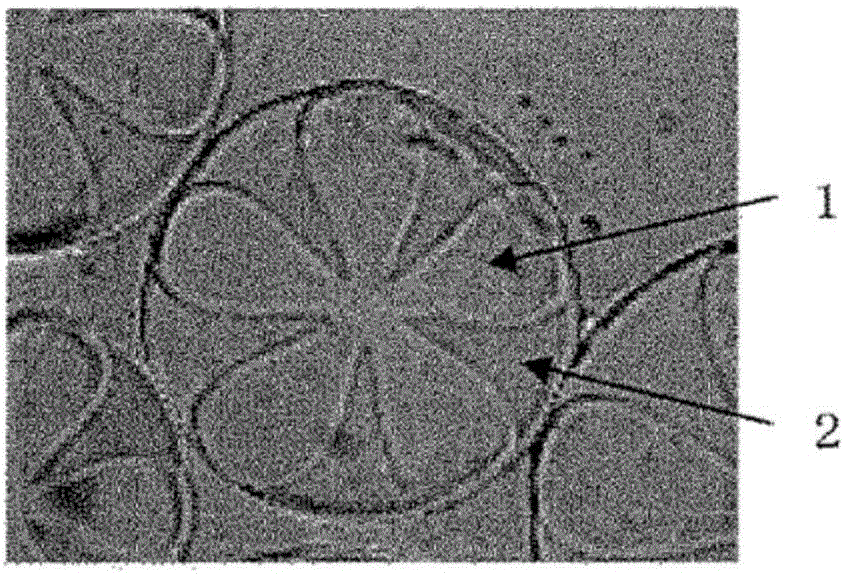

[0052] Nylon-6 with a reduced viscosity of 1.80dL / g (concentration in o-chlorophenol: 1g / dL, 30°C) was used as the polyamide component (component A), and thermoplastic modified polyvinyl alcohol (modified PVA) (KURARAY Made by a company, degree of saponification: 98.5, ethylene content: 8.0 mol%, degree of copolymerization: 390) as a soluble component (component B). Component A and component B are melted with separate extruders, set to: Nylon-6: modified PVA = 60: 40 (weight ratio), so that there is figure 1 The composite fibers of the cross-section shown were ejected from the composite spinneret. Next, the filaments ejected through the spinning head were cooled with a side blowing type cooling device having a length of 1.0 m, and then oiled with a spinning finish made of an antistatic agent component and a lubricant component not containing water. Next, the composite fiber of 111dtex / 24f was produced by taking up by a roll at a draw...

Embodiment 2

[0081]As component B, polyethylene terephthalate (copolyPET) was used, which was made of polyethylene glycol with a molecular weight of 2000 in an amount of 8% by weight and 5 Mole % of 5-sodium sulfoisophthalic acid was copolymerized, except that the intrinsic viscosity [η] was 0.52 dL / g. Polyamide fibers were prepared in the same manner as in Example 1, and the degree of orientation and moisture absorption were measured. rate, water absorption elongation, crimp elongation, and the wearing comfort of the fabric was evaluated. The above results are shown in Table 1.

Embodiment 3~4

[0083] As shown in Table 1, except that component A was changed to nylon-6,6 (Example 3), or component A was changed to Nylon-6 / 12 (Example 4), polyamide was prepared in the same manner as in Example 1. For amide fibers, the degree of orientation, moisture absorption, water absorption elongation, and crimp elongation were measured, and the wearing comfort of the fabric was evaluated. The above results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com