A kind of isolation material and its preparation method and application

A technology of isolation material and isolation agent, which can be used in the fields of synthetic cellulose/non-cellulose material pulp/paper, textile and papermaking, fiber raw material processing, etc., and can solve the problem of not producing a large amount of gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

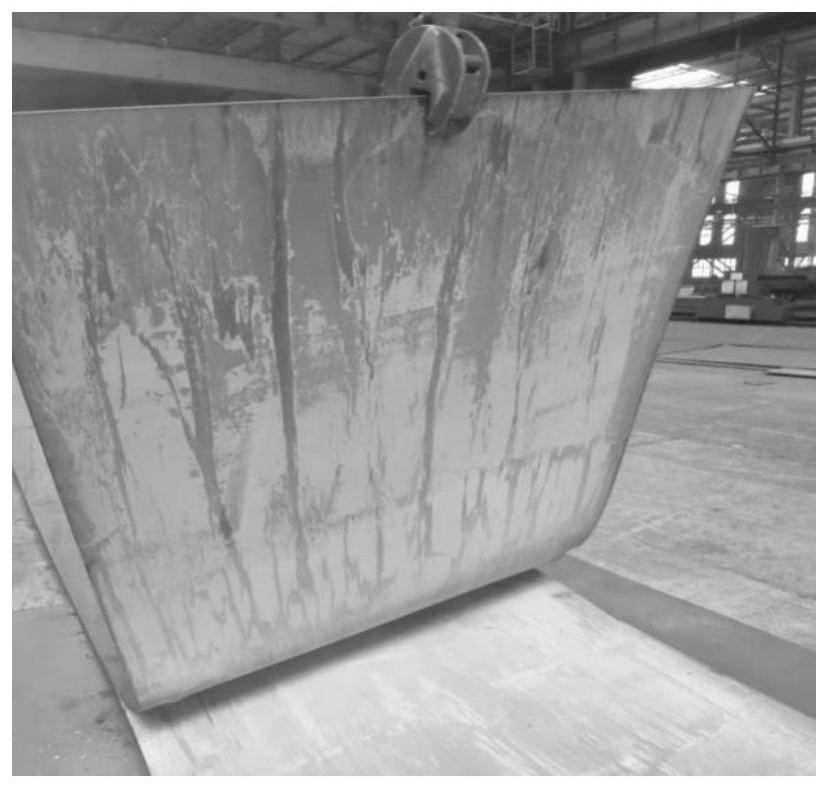

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method for the isolation material of the above-mentioned technical solution, comprising the following steps:

[0047] Provide mixed fiber dissolving liquid;

[0048] Mixing the mixed fiber disentangling liquid, release agent and latex to obtain the first mixture;

[0049] mixing the first mixture, flocculant and defoamer to obtain a second mixture;

[0050] diluting the second mixture to obtain a slurry;

[0051] Papermaking is performed on the slurry to obtain the insulating material.

[0052] In the present invention, the components in the preparation method are consistent with the components of the isolation material in the above technical solution, and will not be repeated here.

[0053] The invention provides a mixed fiber dissolving liquid. In the present invention, the mass concentration of the mixed fiber disintegrating liquid is preferably 0.5-2%, more preferably 0.7-1.7%, and still more preferably 1-1.5%. In...

Embodiment 1

[0061] In terms of parts by mass, the isolation material components are:

[0062] 78.1 parts of release agent, obtained by mixing 325 mesh magnesium oxide and 800 mesh magnesium oxide according to the mass ratio of 1:2;

[0063] 6.3 parts of mixed fiber, obtained by mixing coniferous wood fiber and glass wool at a mass ratio of 7:5;

[0064] 14.7 parts of latex, obtained by mixing styrene-butadiene latex and nitrile latex at a mass ratio of 4:3;

[0065] 0.1 part of flocculant, obtained by mixing polyaluminum chloride (PAC) and cationic polyacrylamide (CPAM) at a mass ratio of 1:1;

[0066] 0.05 part of defoamer, JF-05B type silicone defoamer, purchased from Beijing Shi Aode Rui Technology Co., Ltd.

[0067] The preparation method of the isolation material is:

[0068] Using water as the diluent, dilute the latex to a mass concentration of 10%, dilute the flocculant to a mass concentration of 1%, and dilute the defoamer to a mass concentration of 1%, and set aside;

[0069...

Embodiment 2

[0076] In terms of parts by mass, the isolation material components are:

[0077] 76.6 parts of release agent, obtained by mixing 325 mesh magnesia and 800 mesh alumina according to the mass ratio of 1:2;

[0078] 7.5 parts of mixed fiber, obtained by mixing coniferous wood fiber and glass wool at a mass ratio of 1:1;

[0079] 15.3 parts of latex, obtained by mixing styrene-butadiene latex and nitrile latex at a mass ratio of 1:1;

[0080] 0.1 part of flocculant, obtained by mixing polyaluminum chloride (PAC) and cationic polyacrylamide (CPAM) according to the mass ratio of 2:1;

[0081] 0.05 part of defoamer, JF-05B type silicone defoamer, purchased from Beijing Shi Aode Rui Technology Co., Ltd.

[0082] The preparation method of the isolation material is:

[0083] Using water as the diluent, dilute the latex to a mass concentration of 10%, dilute the flocculant to a mass concentration of 1%, and dilute the defoamer to a mass concentration of 1%, and set aside;

[0084] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com