A cashmere textile foam method graphene finishing process based on water-based polymer resin

A water-based polymer and resin foam technology, which is applied in textiles and papermaking, fiber treatment, wear-resistant fibers, etc., can solve the problem of simultaneously obtaining the anti-pilling performance and antistatic effect of cashmere products, and the style and feel of cashmere products are too affected. Problems such as complex process and process, to achieve good market prospects, good application effect, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

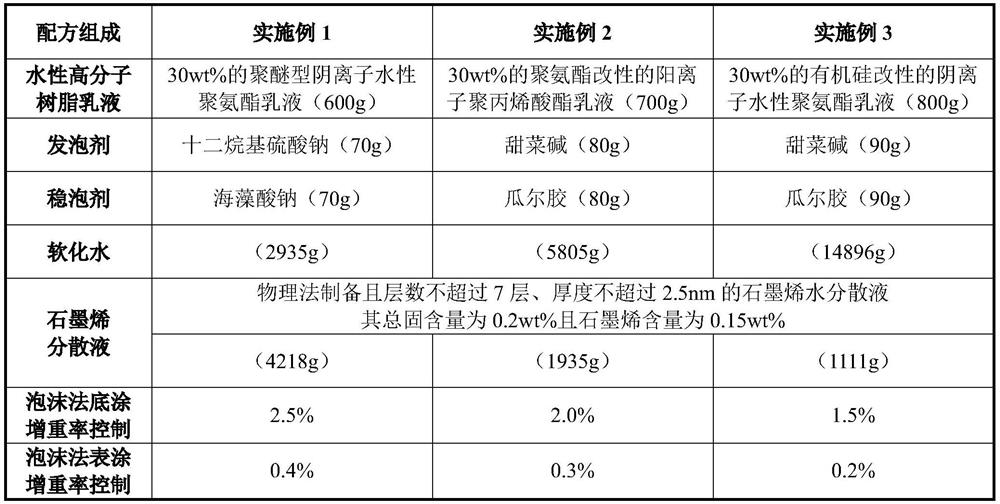

Examples

Embodiment 1

[0059] The specific steps of the cashmere textile foam method graphene finishing technology and process based on water-based polymer resin are:

[0060] (1) The steps of water-based polymer foaming liquid configuration and foaming: In this step, part of the water-based polymer resin emulsion, part of the foaming agent, part of the foam stabilizer, and all demineralized water are mixed to obtain the water-based polymer foaming liquid and foamed, Obtain water-based polymer resin foam, specifically:

[0061] (1.1) The demineralized water that accounts for 85% of the total amount is put into the foaming machine batching tank, and 70% of the foaming agent and 70% of the foam stabilizer that are pre-dissolved with the remaining demineralized water are put into the foaming machine's batching tank, and then Add 70% polymer resin emulsion under stirring and stir evenly;

[0062] (1.2) Turn on the foaming machine, prepare water-based polymer resin foam at 25-30°C, and set aside.

[00...

Embodiment 2

[0075] The specific steps of the cashmere textile foam method graphene finishing technology and process based on water-based polymer resin are:

[0076] (1) The steps of water-based polymer foaming liquid configuration and foaming: In this step, part of the water-based polymer resin emulsion, part of the foaming agent, part of the foam stabilizer, and all demineralized water are mixed to obtain the water-based polymer foaming liquid and foamed, Obtain water-based polymer resin foam, specifically:

[0077] (1.1) The demineralized water that will account for 85% of the total amount is put into the foaming machine batching tank, and 75% foaming agent and 75% foam stabilizer that are pre-dissolved with the remaining demineralized water are put into the foaming machine batching tank, and then Add 75% polymer resin emulsion under stirring and stir evenly;

[0078] (1.2) Turn on the foaming machine, prepare water-based polymer resin foam at 25-30°C, and set aside.

[0079] (2) Step...

Embodiment 3

[0091] The specific steps of the cashmere textile foam method graphene finishing technology and process based on water-based polymer resin are:

[0092] (1) The steps of water-based polymer foaming liquid configuration and foaming: In this step, part of the water-based polymer resin emulsion, part of the foaming agent, part of the foam stabilizer, and all demineralized water are mixed to obtain the water-based polymer foaming liquid and foamed, Obtain water-based polymer resin foam, specifically:

[0093] (1.1) The demineralized water that accounts for 85% of the total amount is put into the foaming machine batching tank, and 80% of the foaming agent and 80% of the foam stabilizer that have been dissolved in advance with the remaining demineralized water are put into the foaming machine's batching tank, and then Add 80% polymer resin emulsion under stirring and stir evenly;

[0094] (1.2) Turn on the foaming machine, prepare water-based polymer resin foam at 25-30°C, and set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com