Fiber net forming continuous dyeing method

A dyeing method and fiber technology, which is applied in the field of textile printing and dyeing, can solve the problems of affecting the final effect of cotton fiber dyeing, continuous dyeing, and uneven dyeing, so as to save dyeing materials and auxiliaries, and achieve good dyeing effect. Good dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

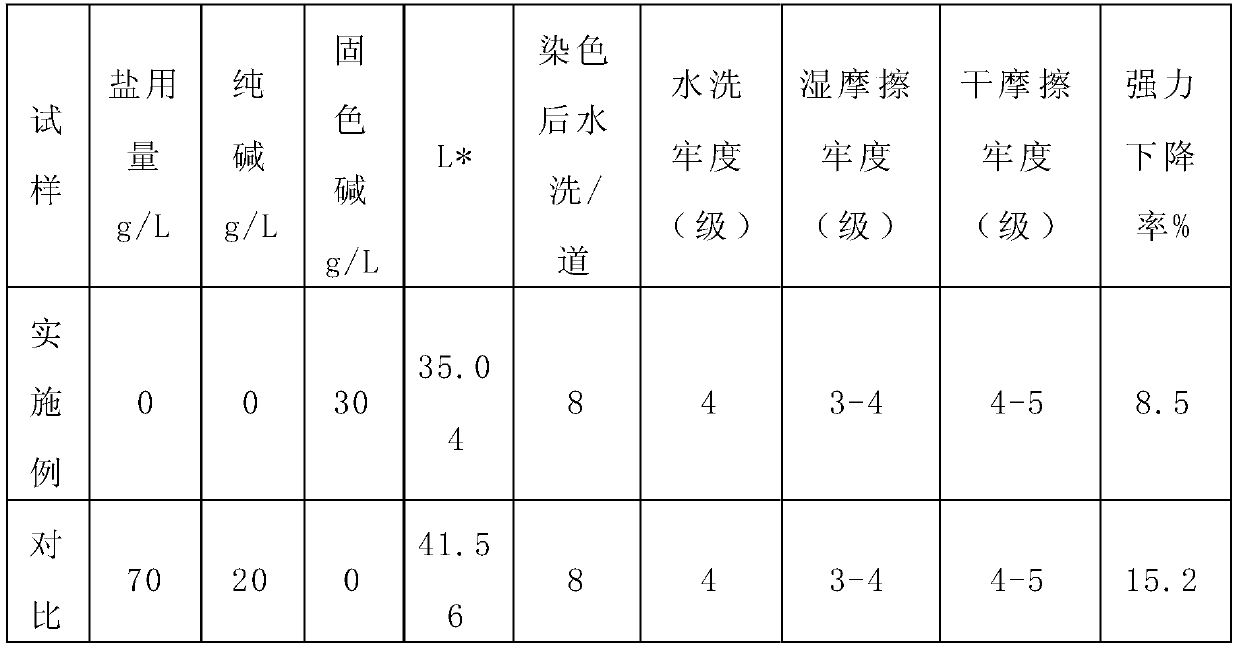

Embodiment 1

[0023] Continuous dyeing of cotton fibers. The specific steps are:

[0024] (1) Cotton fiber laying: put the raw cotton fiber into the cotton feeding machine part of the laying equipment, pass through the double-roller and double licker-in roller drawing and laying machine, comb and remove impurities, and draw to form a net, the net speed is 12m / min, cotton net weight is 200g / m 2 , The impurity removal rate is 94%.

[0025] (2) Dyeing: Adjust the speed of the fiber dyeing equipment to 12m / min, which is consistent with the speed of the previous net laying equipment. The fibers after exiting the net directly enter the dyeing equipment through the conveyor belt. There are 2 fan-shaped nozzles at 110 degrees. The dye prescription is: Reactive Brilliant Blue 3%, Color Fixing Soda TC 30g / L, Leveling Agent 10g / L, in which the amount of dyeing liquor: alkali dosage = 4:1, uniformly mixed by peristaltic pump, the ratio of spraying liquid to fiber weight is 1:1 , the dyed fibers out...

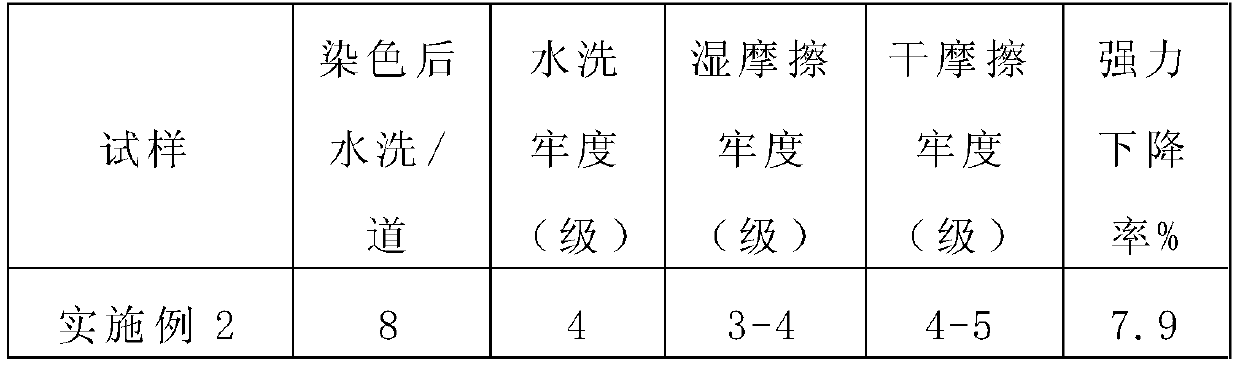

Embodiment 2

[0036] Continuous dyeing of viscose fibers. The specific steps are:

[0037] (1) Laying of viscose fiber: put the original viscose fiber into the cotton feeding machine part of the web laying equipment, pass through the double roller double licker-in roller drawing and laminating machine, comb and remove impurities, draw to form a mesh, and go out of the net The speed is 5m / min, and the cotton net weight is 100g / m 2 , The impurity removal rate is 94%.

[0038] (2) Dyeing: Adjust the speed of the fiber dyeing equipment to 6m / min, which is consistent with the speed of the previous net-laying equipment. The fibers after exiting the net directly enter the dyeing equipment through the conveyor belt. The nozzles are 110-degree fan-shaped nozzles. The dye prescription is: Reactive Brilliant Blue 0.01g / L, Color Fixing Base TC 5g / L, Leveling Agent 0.1g / L, uniformly mixed by peristaltic pump, spray volume to fiber weight ratio of 1.6:1, output at the outlet of dyeing equipment The dy...

Embodiment 3

[0046] Continuous dyeing of Tencel fibers. The specific steps are:

[0047] (1) Laying of Tencel fiber: put the original Tencel fiber into the cotton feeding machine part of the web laying equipment, pass through the double roller double licker-in roller wire drawing and laminating machine, comb and remove impurities, draw to form a mesh, and go out of the net The speed is 20m / min, and the cotton net weight is 400g / m 2 , The impurity removal rate is 96%.

[0048] (2) Dyeing: Adjust the speed of the fiber dyeing equipment to 15m / min, which is consistent with the speed of the previous net laying equipment. The fibers after exiting the net directly enter the dyeing equipment through the conveyor belt. The nozzles are 110-degree fan-shaped nozzles. The dye prescription is: Reactive Brilliant Blue 80g / L, Fixing Base TC 50g / L, Leveling Agent 20g / L, uniformly mixed by a peristaltic pump, the ratio of spray volume to fiber weight is 0.8:1, the dyeing output from the outlet of the dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com