Five-layer-coextrusion, high-thermal-insulation, antifogging and drip-free agricultural greenhouse plastic film

A fog-free, drip-free, agricultural greenhouse technology, which can be used in layered products, greenhouse cultivation, synthetic resin layered products, etc. Advanced problems, to achieve longevity and good transparency, improve yield and quality, and be beneficial to growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

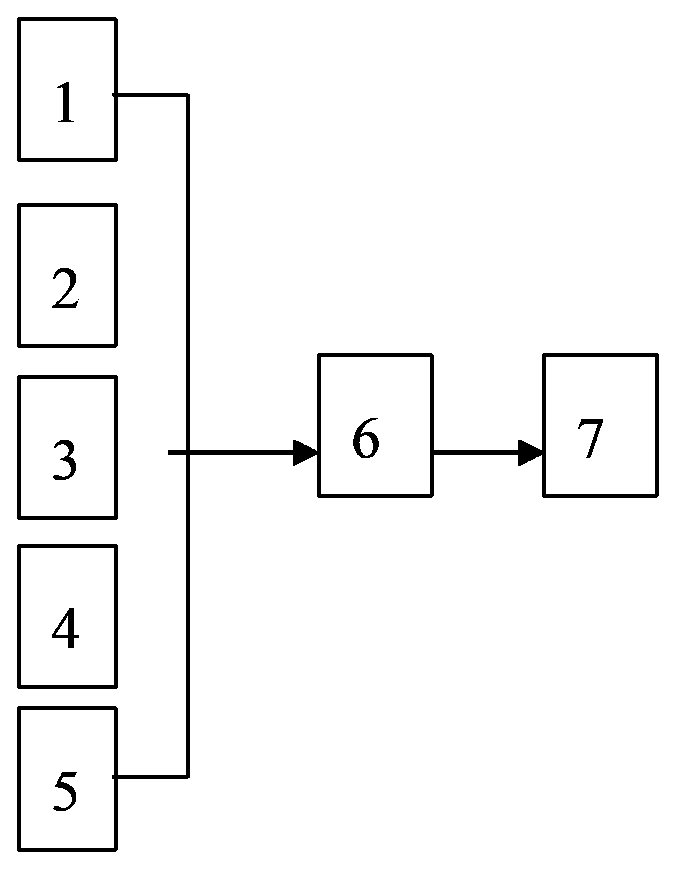

[0010] The names and weight percentages of the raw materials of each layer of the five-layer co-extruded high thermal insulation non-drip and anti-fog agricultural greenhouse plastic film are detailed in the following Tables 1, 2, 3, 4, 5 and 6 for details and data.

[0011] Table 1 The weight percentage of each layer of raw materials in the total film

[0012] level

inner layer

inner second floor

middle layer

outer second floor

outer layer

Weight percentage (%)

15-30

15-30

15-25

15-20

15-20

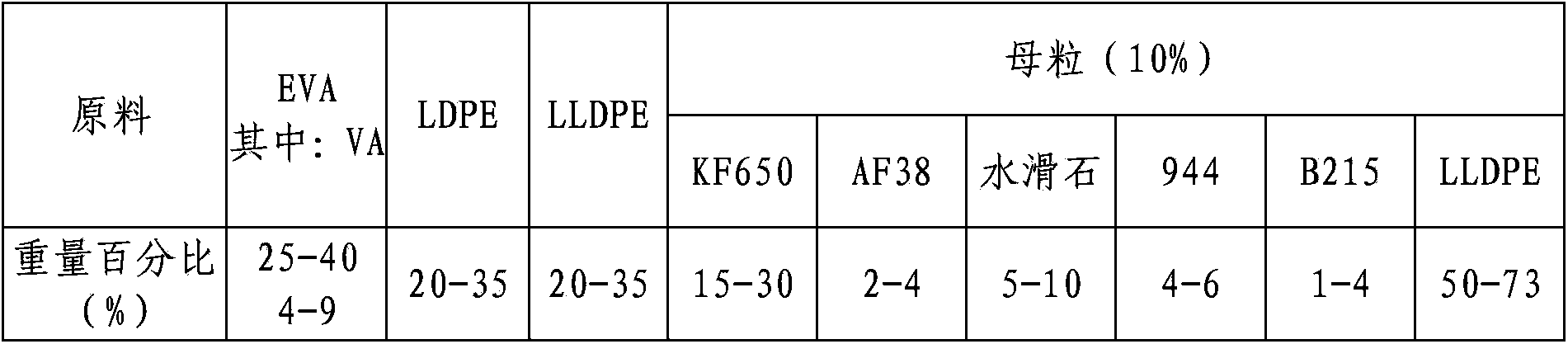

[0013] The raw materials and their weight percentages in the inner layer of table 2

[0014]

[0015] The function of this layer is mainly to solve the problems of eliminating fog and dripping and anti-aging during use.

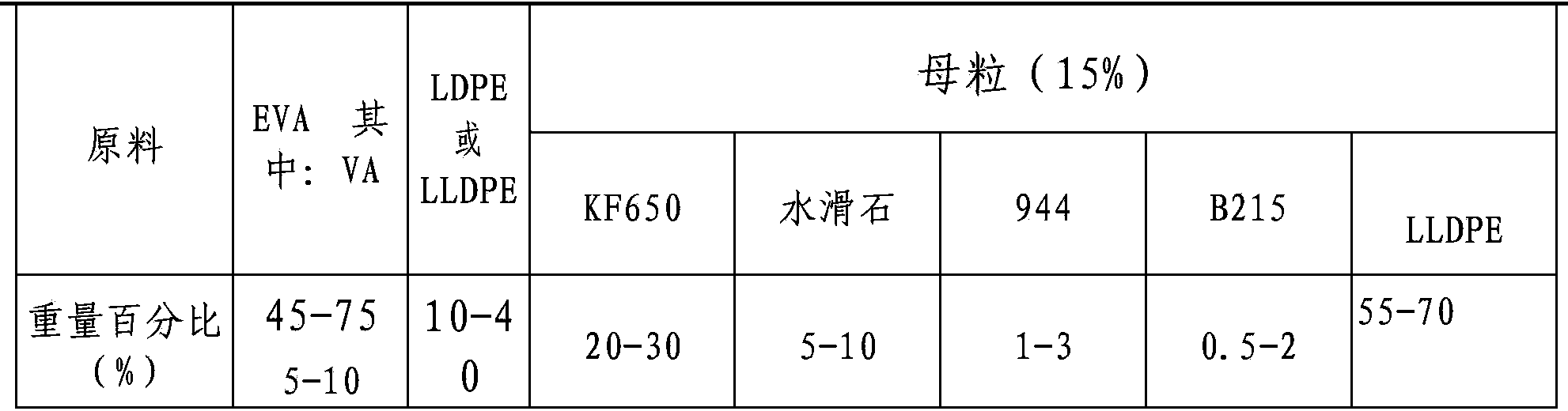

[0016] The raw materials of the inner two layers in table 3 and their weight percentages

[0017]

[0018] The function of this layer is mainly to solve the problem of drip extension and aging in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com